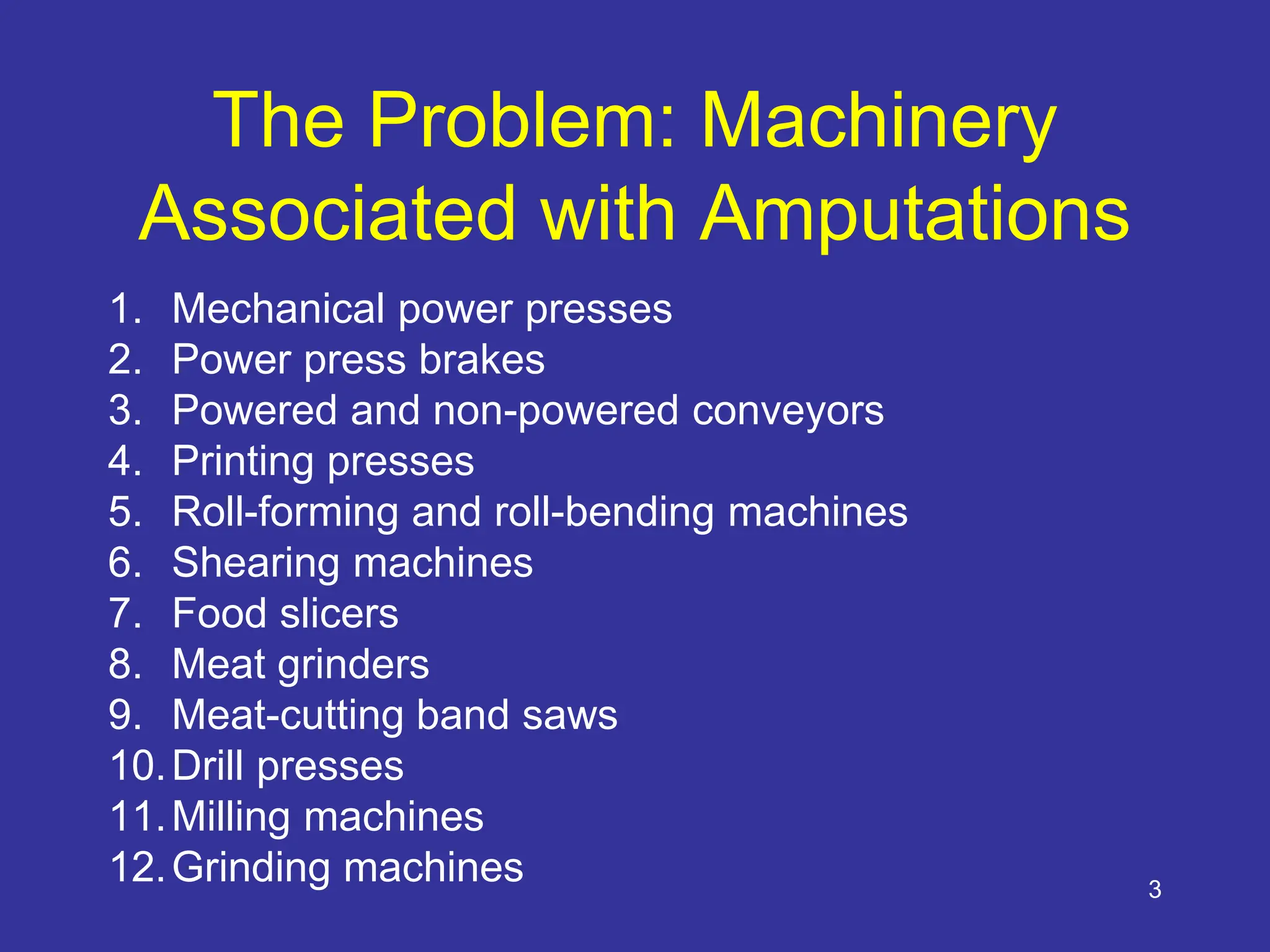

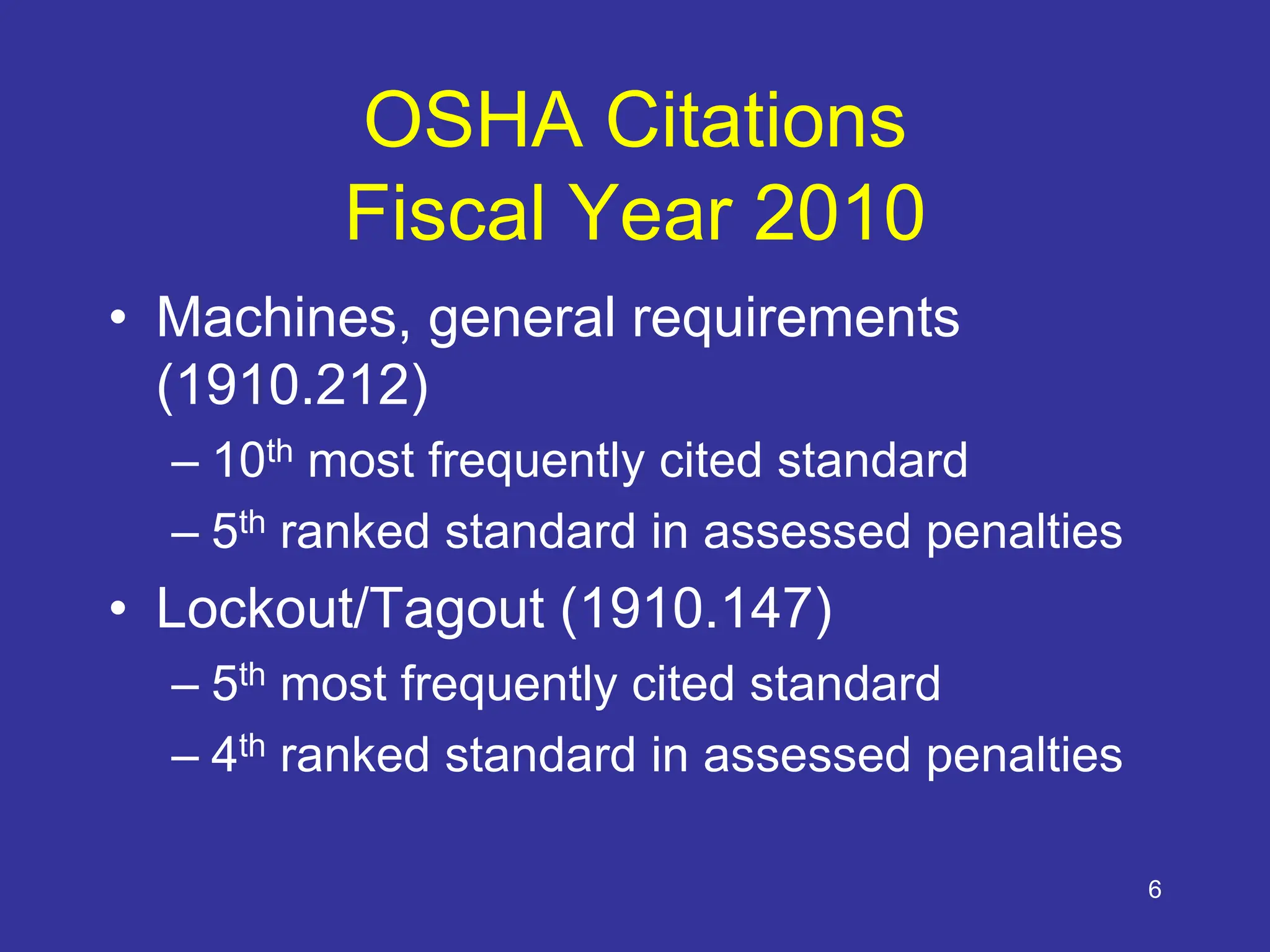

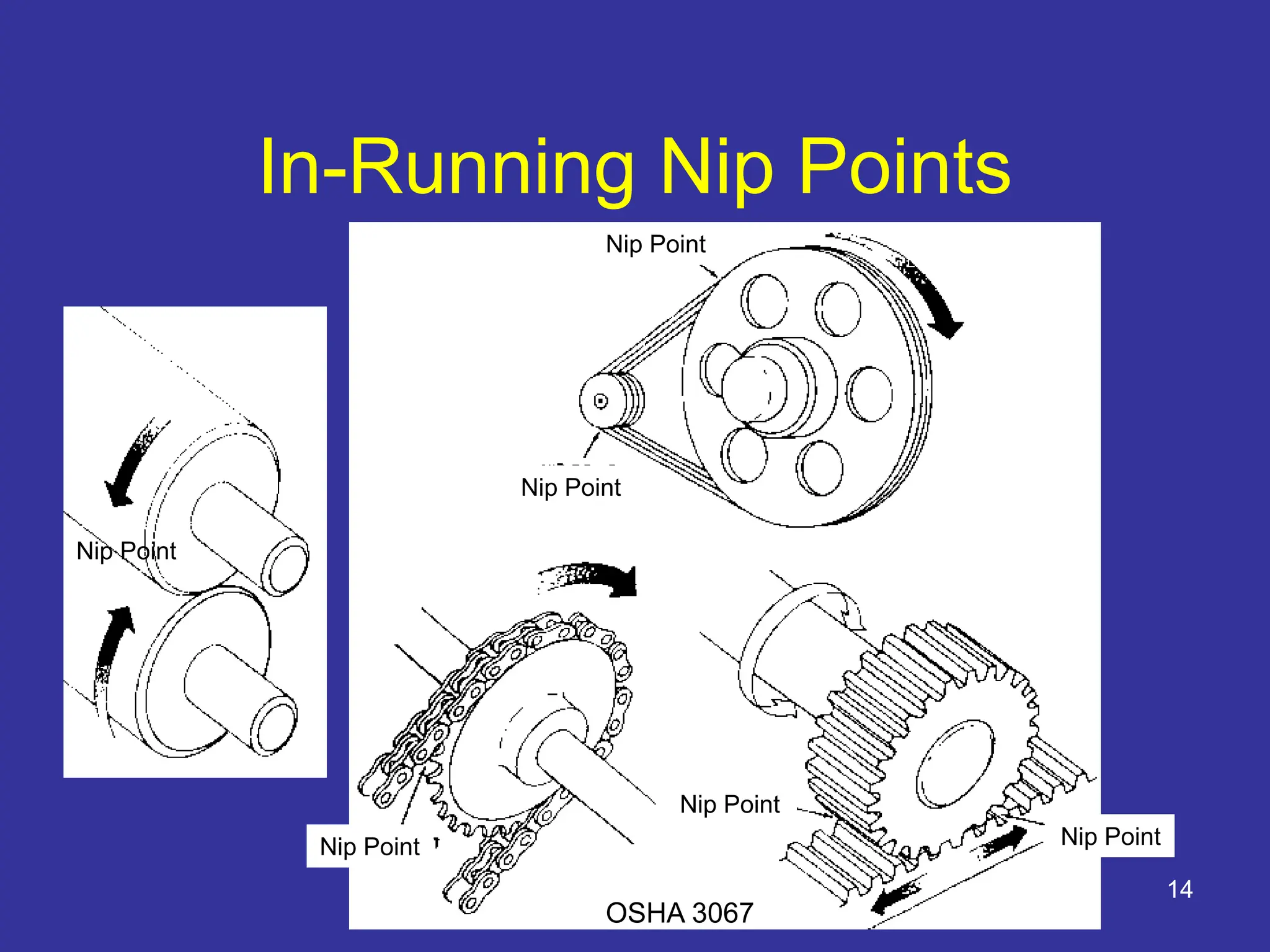

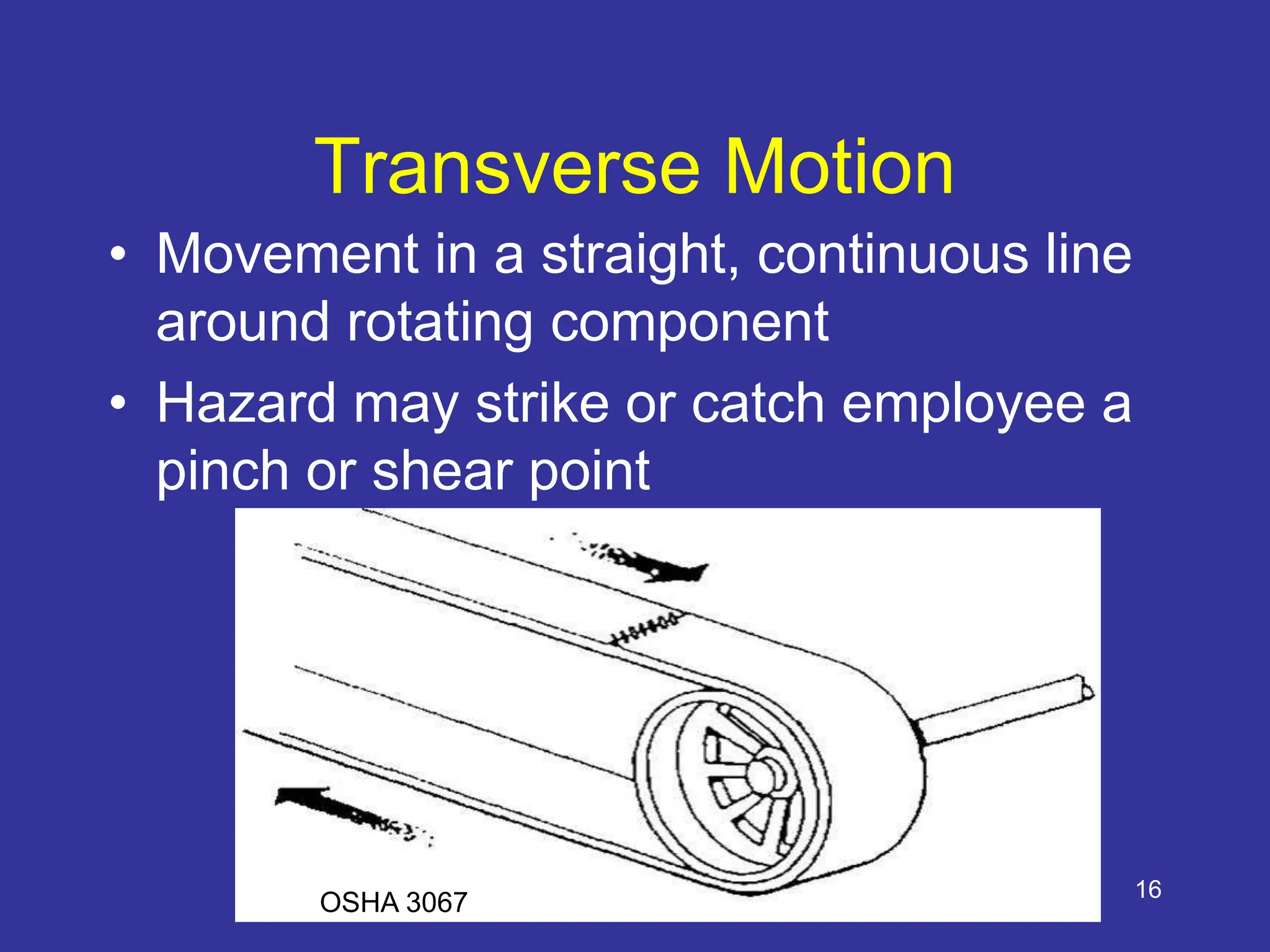

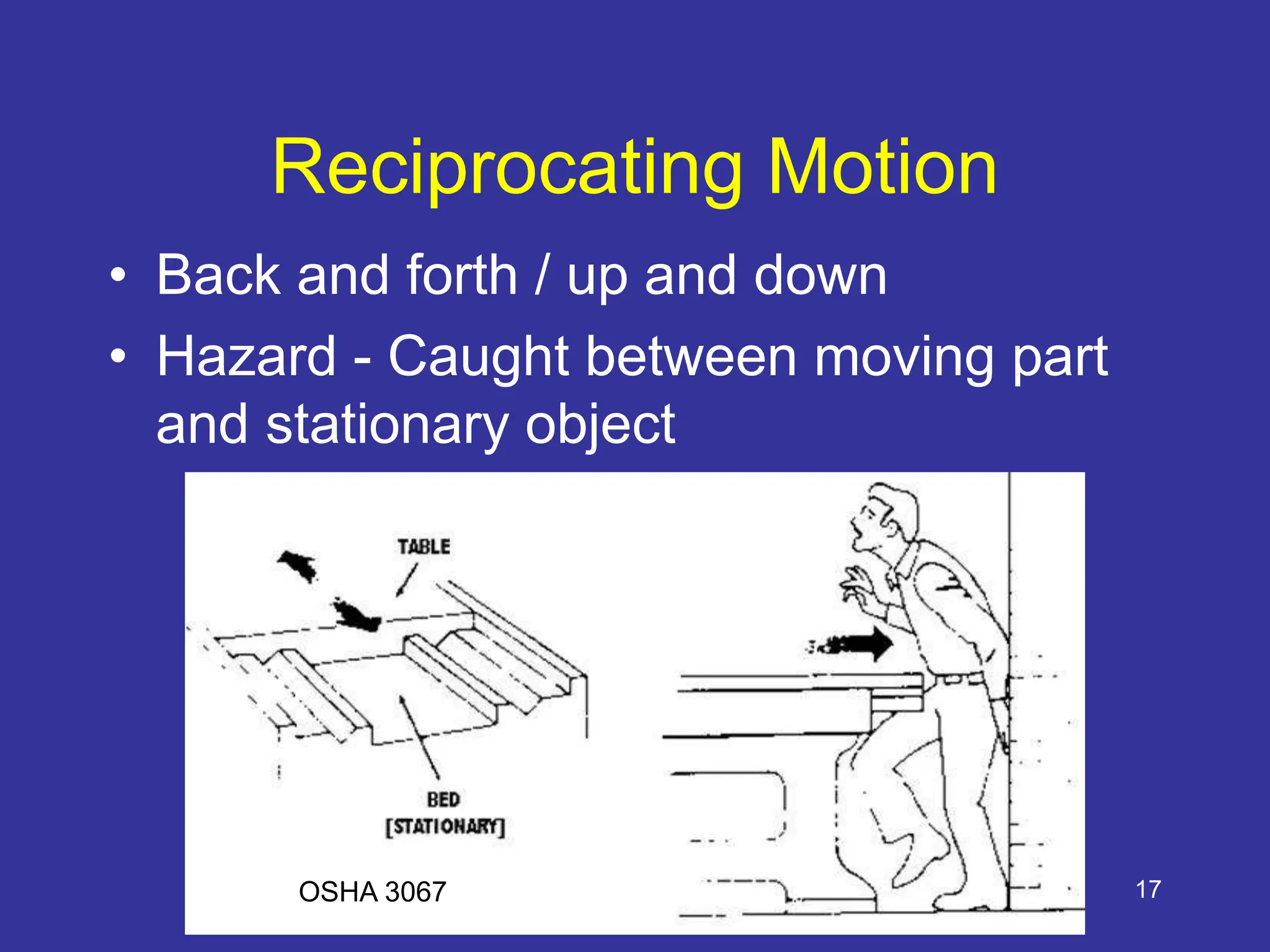

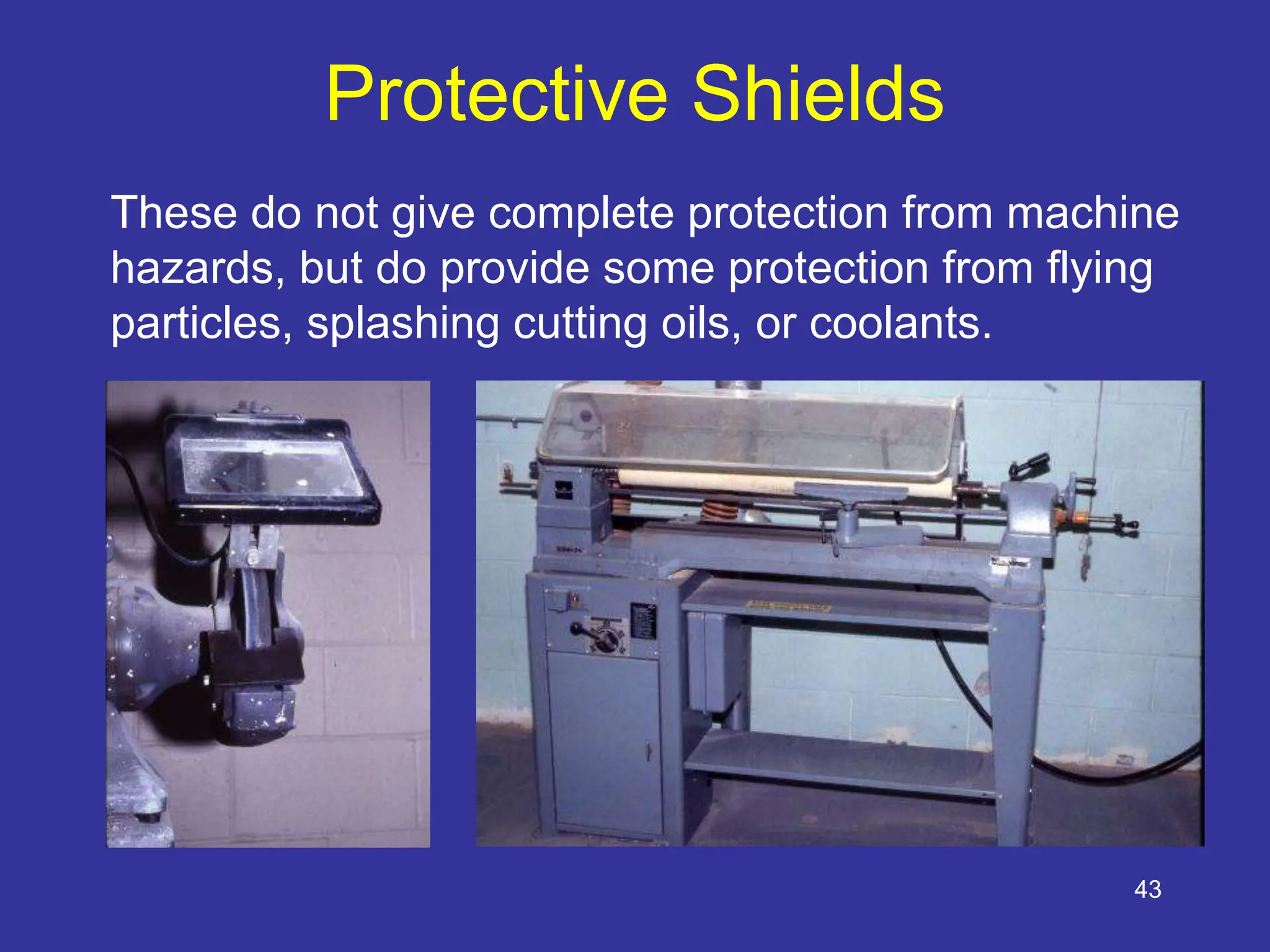

This document discusses machine guarding for warehouse and maintenance workers. It notes that around 18,000 workers suffer amputations, lacerations or other injuries from machinery each year, while 800 die. It then lists some of the most common types of machinery associated with amputations. The document outlines causes of machine incidents like reaching into equipment or lack of training. It stresses the importance of guarding points of operation, power transmission areas and other moving parts. Overall it provides guidance on machine safety requirements and responsibilities to help prevent injuries.

![Machinery

Safety

Machine Guarding for Warehouse and

Maintenance Workers

What is wrong with this picture?

This material was produced and revised

(using information from OSHA’s website, publications and CDC website) under grant

[SH20856SH0] from the Occupational Safety and Health Administration, U.S. Department of

Labor. It does not necessarily reflect the views or policies of the U.S. Department of Labor, nor

does mention of trade names, commercial

products, or organizations imply endorsement by the U.S. Government](https://image.slidesharecdn.com/fy10sh-20856-10machineguarding1-231229004933-d96244d9/75/fy10_sh-20856-10_Machine_Guarding-1-ppt-1-2048.jpg)