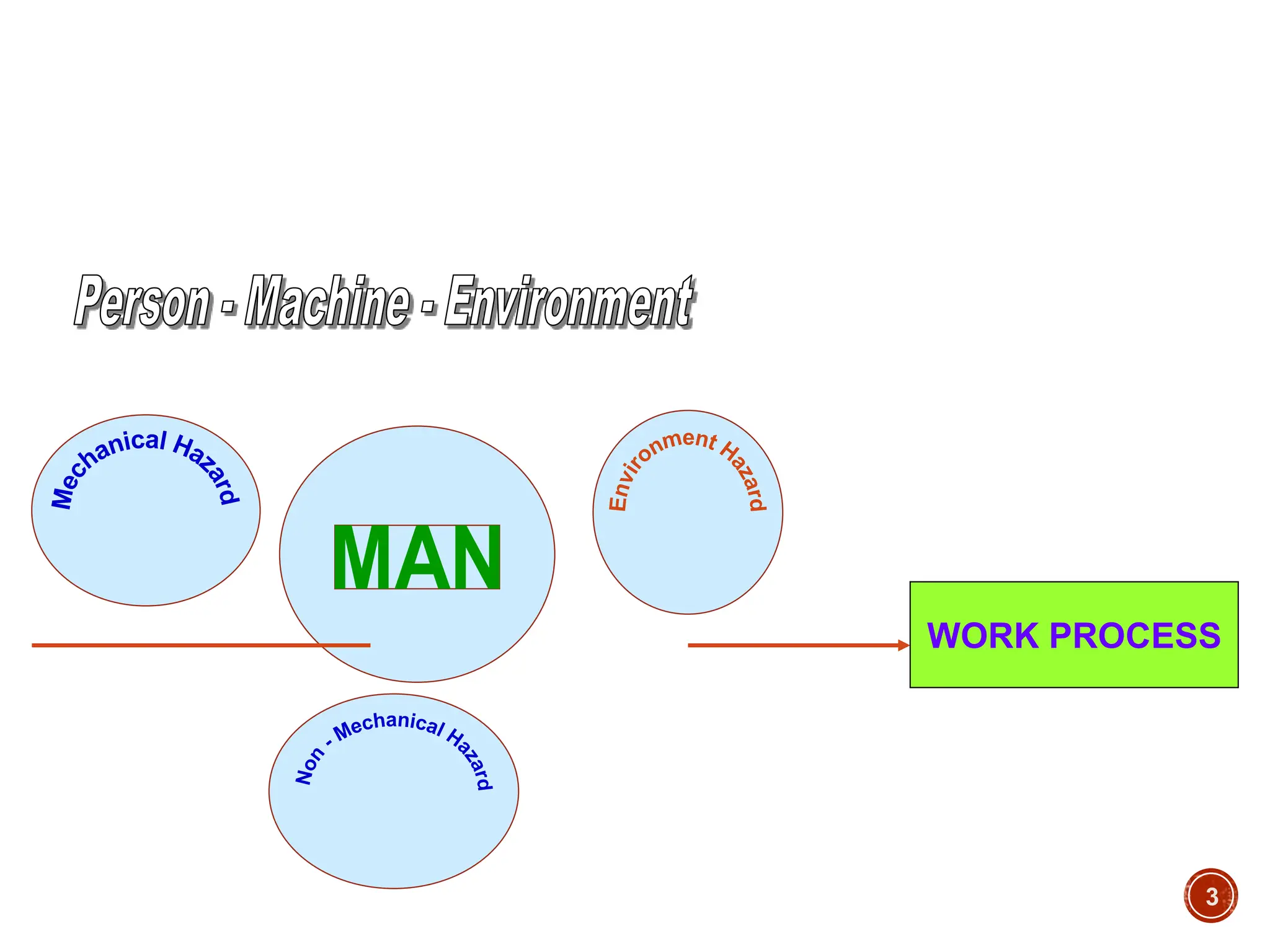

This document discusses machine safety and guarding. It outlines several benefits of machine safety like preventing accidents and environmental contamination. It then discusses various machine hazards like fumes, heat, noise and dust. It provides questions to help identify hazards related to people, procedures, machines and the environment. It discusses guarding requirements including the purpose of guards to prevent contact with dangerous moving parts. Finally, it outlines principles of machine guarding and different guarding methods like fixed, adjustable, interlocked and automatic guards.