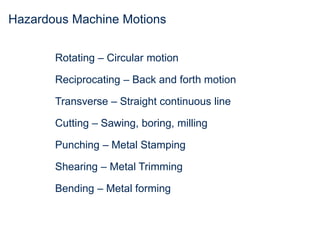

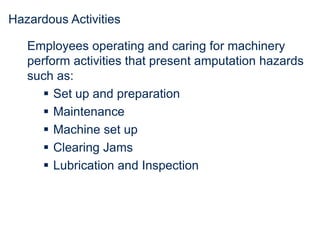

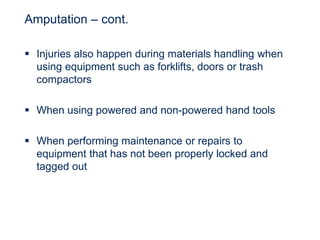

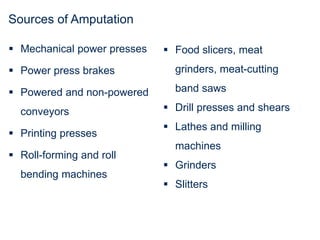

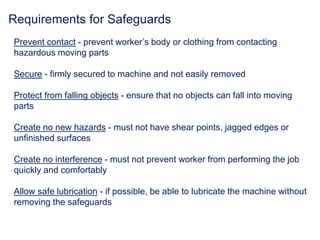

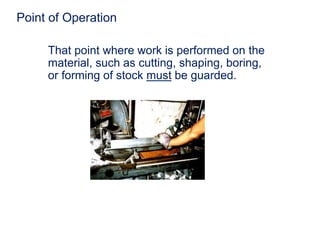

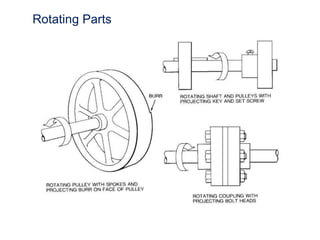

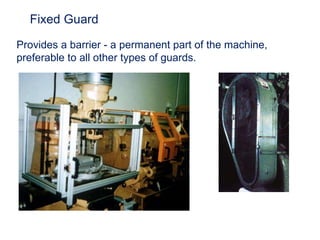

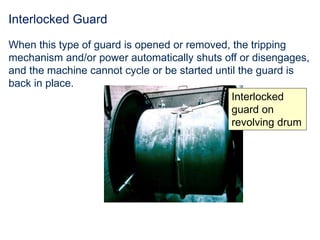

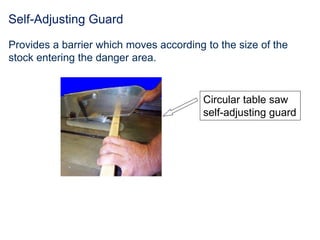

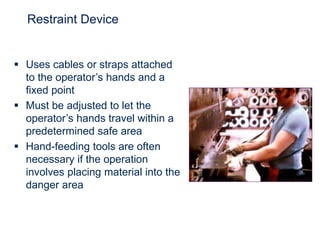

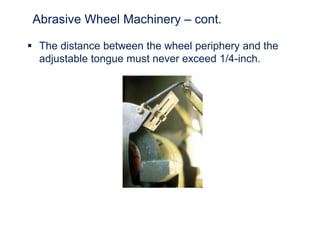

This document discusses machine guarding and amputation hazards. It notes that safeguards are essential to protect workers from preventable injuries from machinery. Any machine part or process that could cause injury must be safeguarded. Common causes of accidents include reaching into machinery and not using proper lockout/tagout procedures during maintenance. Proper guards and safety devices can control amputation hazards by preventing contact with hazardous moving parts. Employers must ensure machinery is properly guarded and trained, and employees must not operate unsafe equipment.