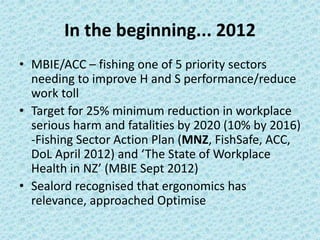

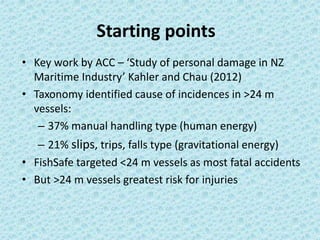

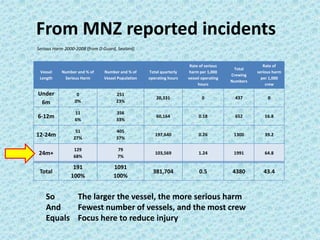

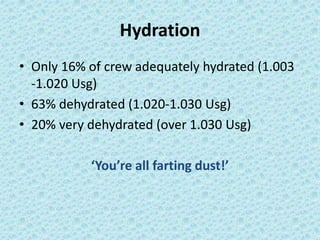

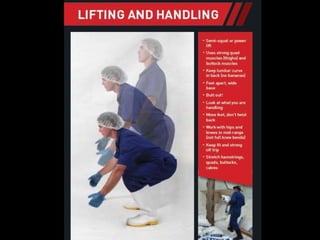

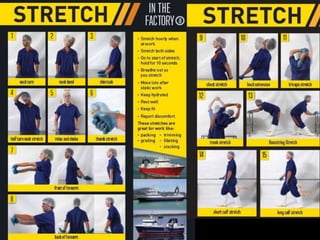

This document summarizes an assessment of musculoskeletal disorders on large fishing vessels in New Zealand. It finds that the risk of injury is highest on vessels over 24 meters due to more time spent at sea, more crew members, and more physically demanding tasks. The assessment identified manual handling and slips/trips/falls as the most common causes of injury. It observed many physically demanding tasks performed in difficult conditions and proposed that interventions focusing on ergonomic improvements, training, fitness and hydration could help reduce injuries in the fishing industry.