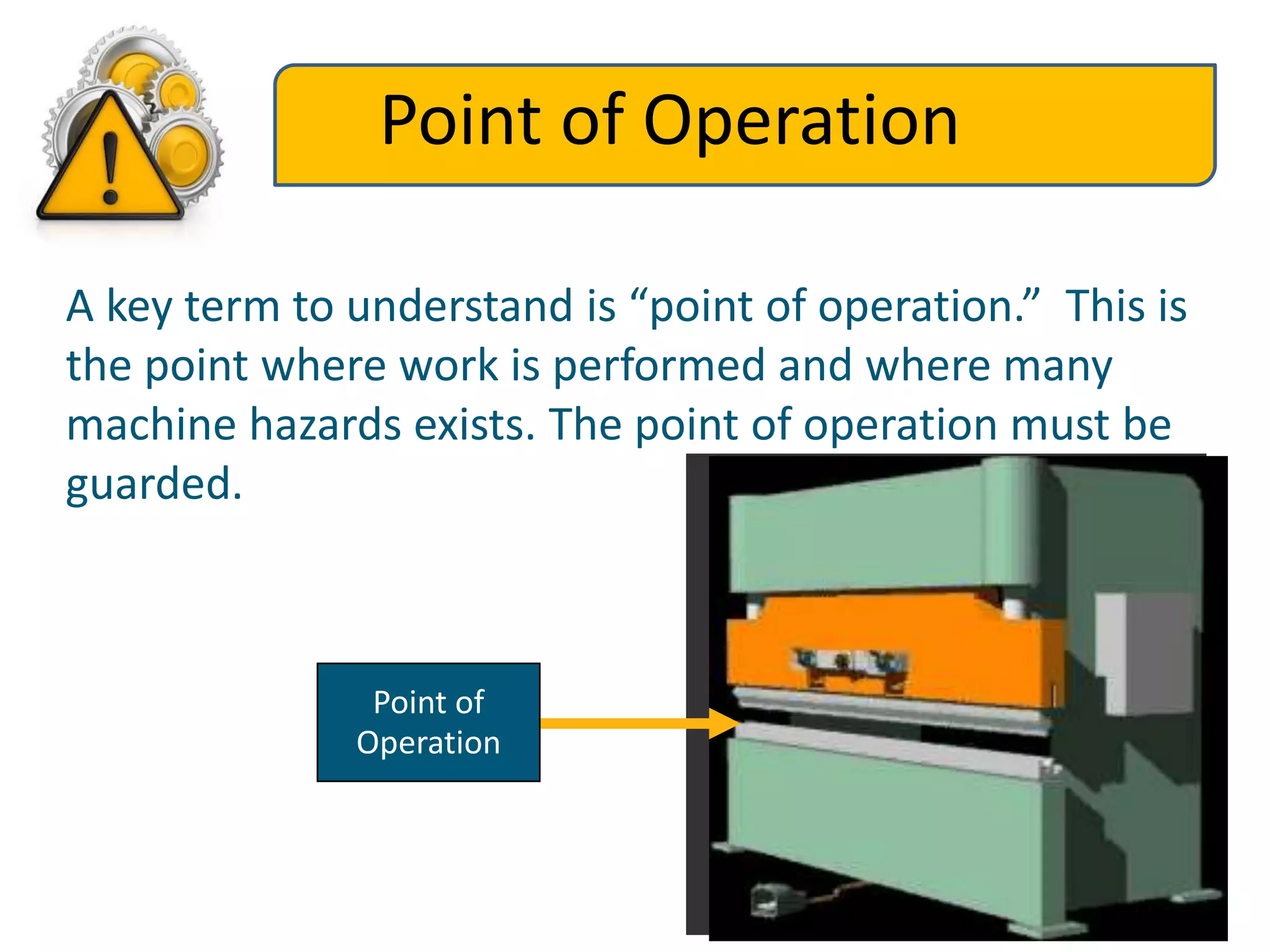

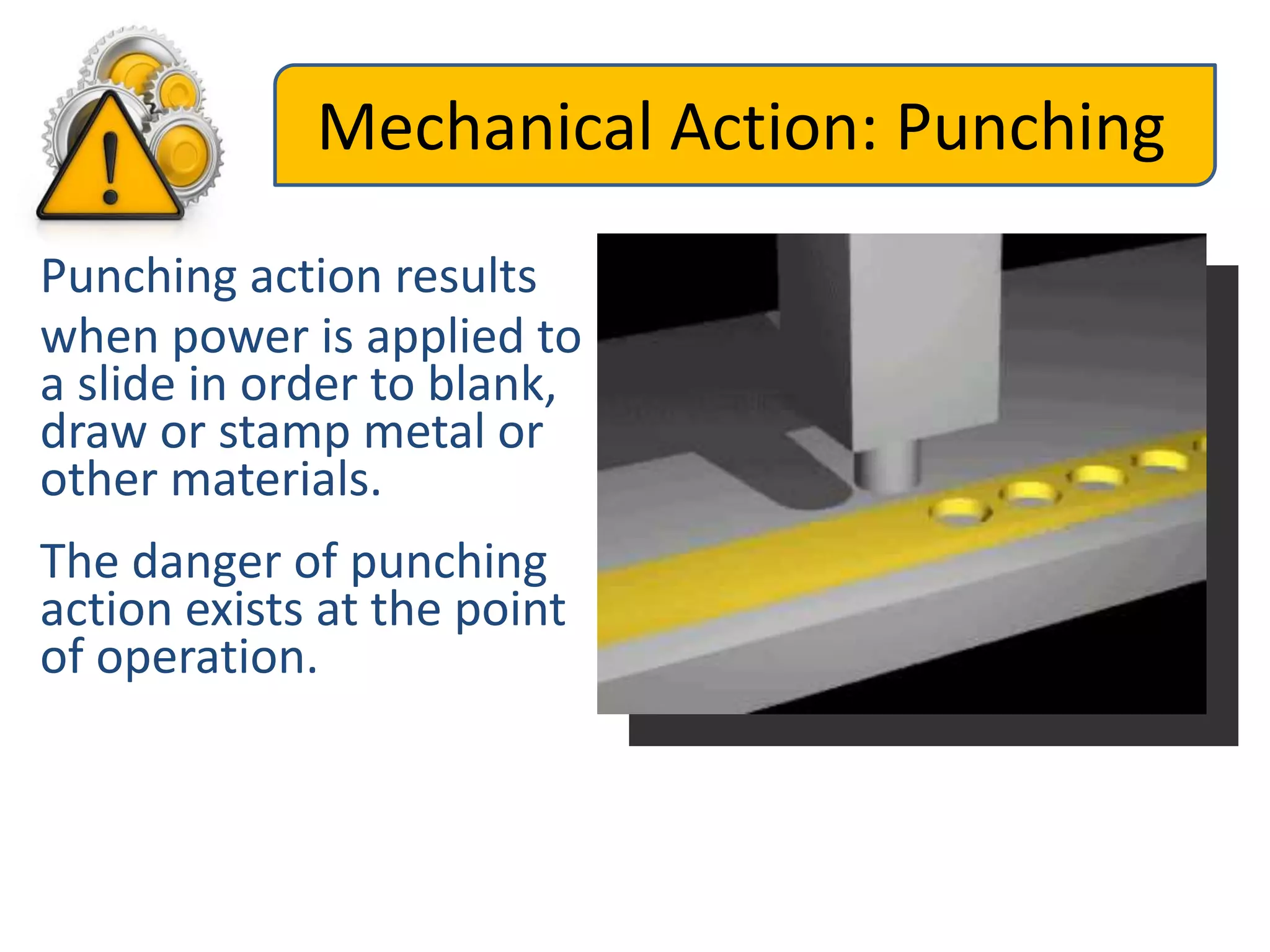

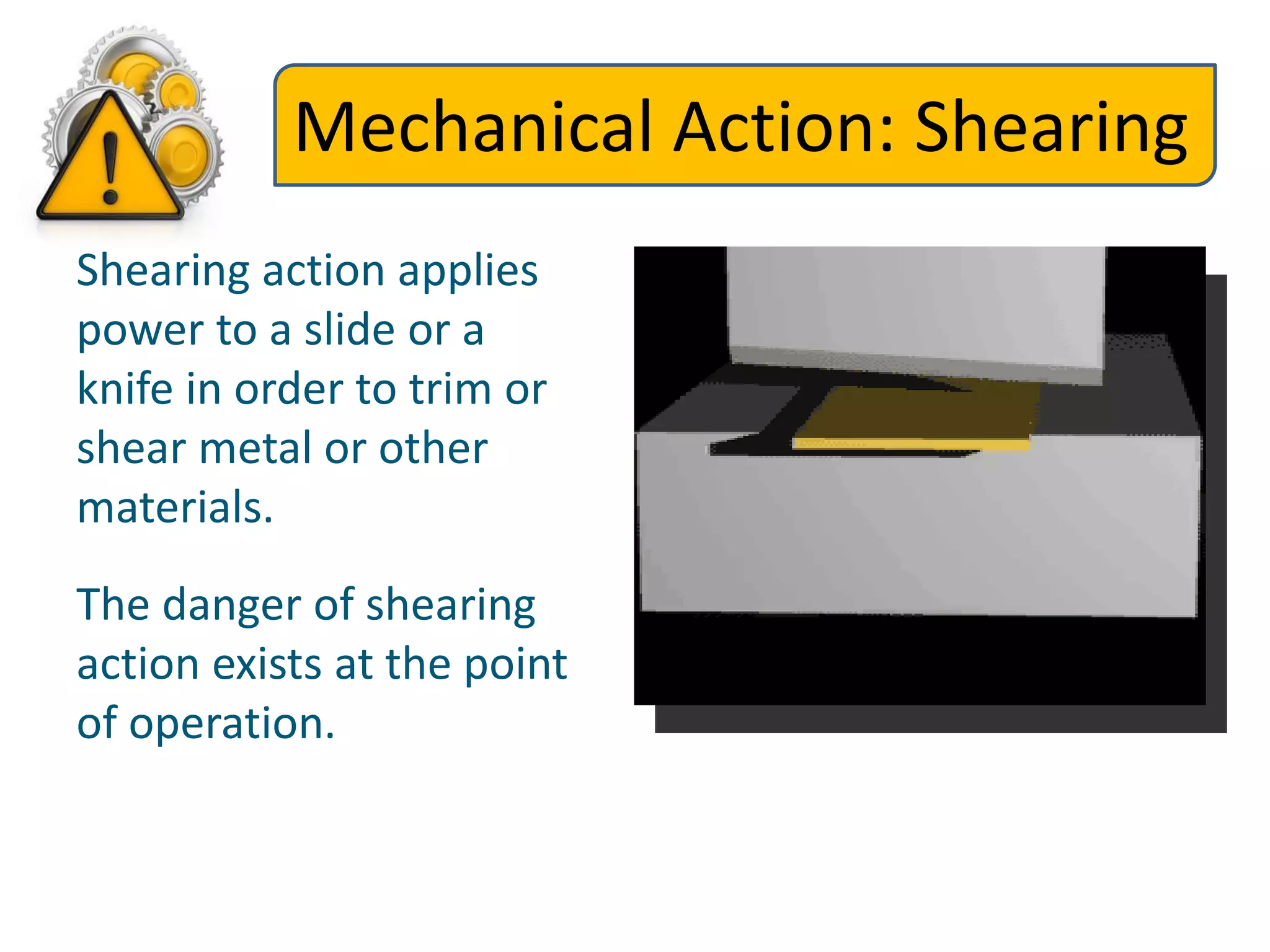

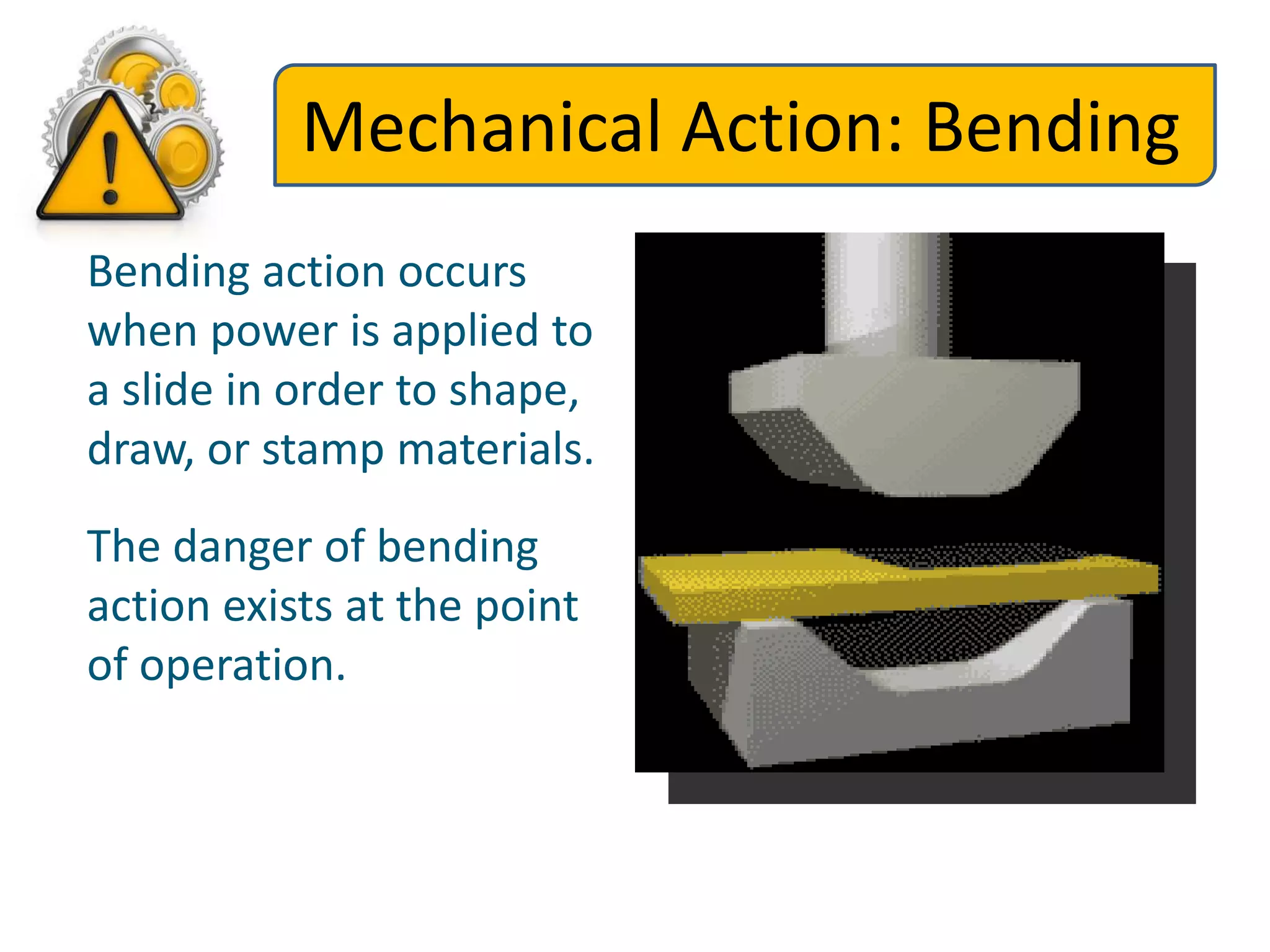

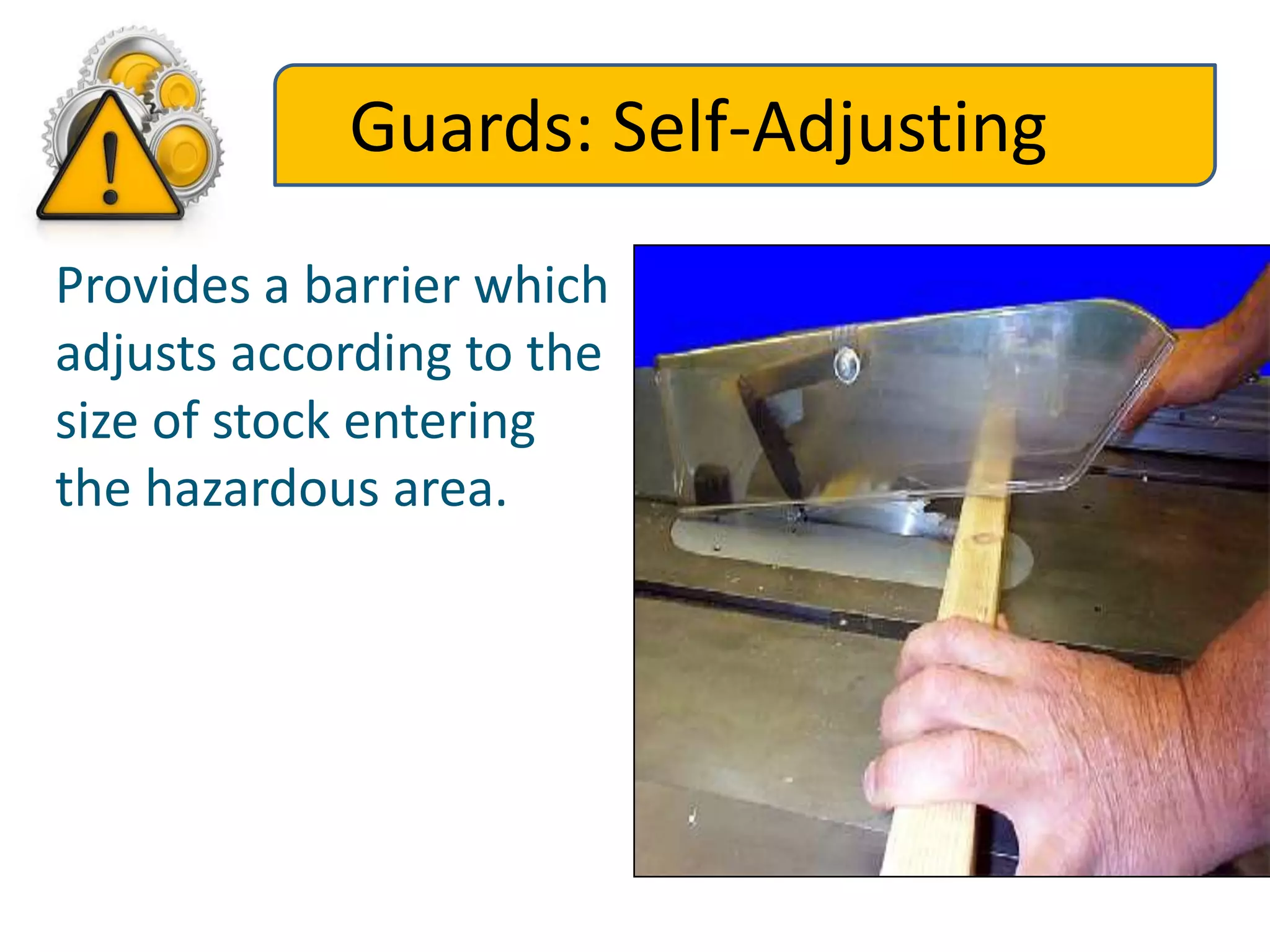

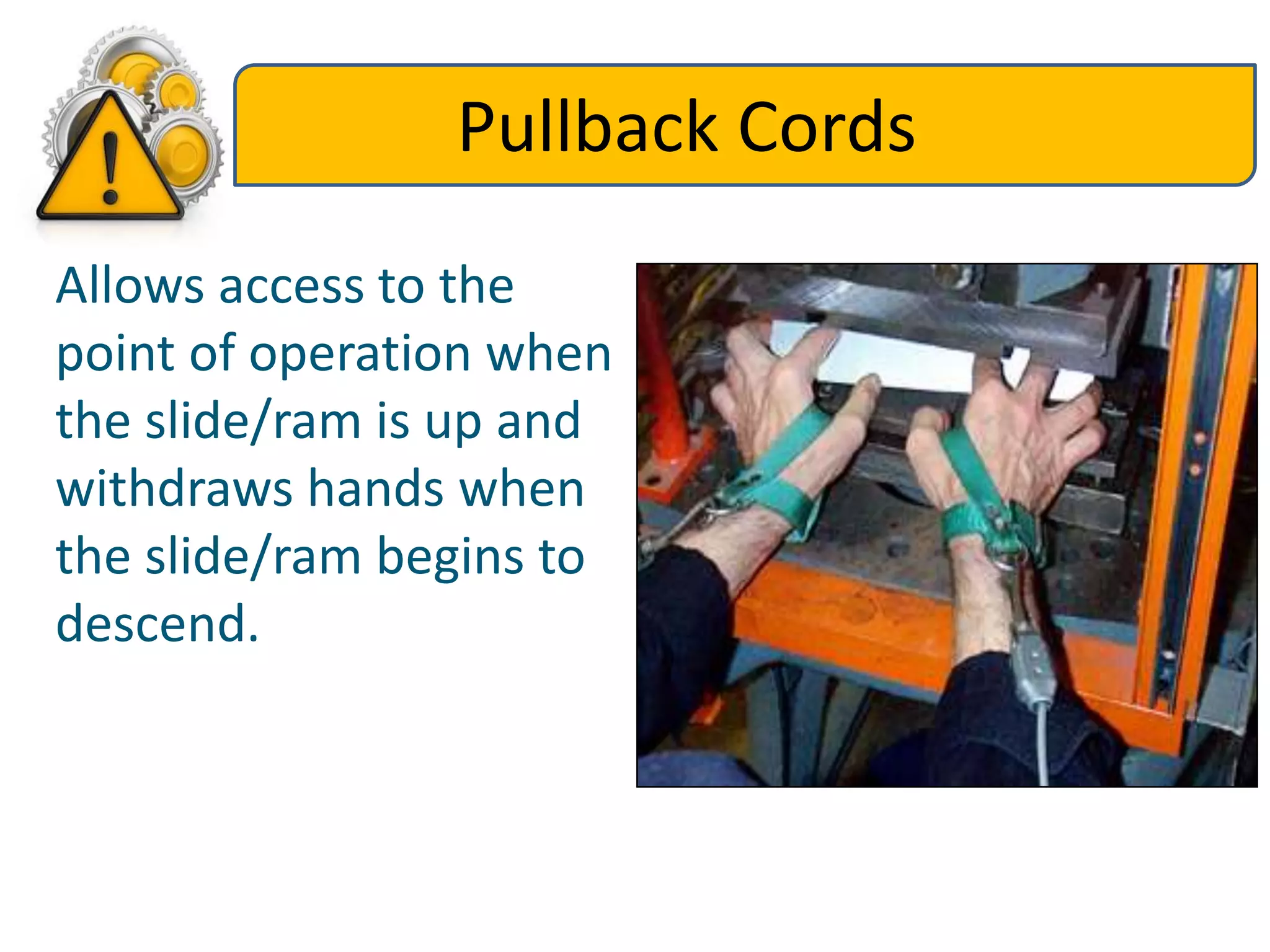

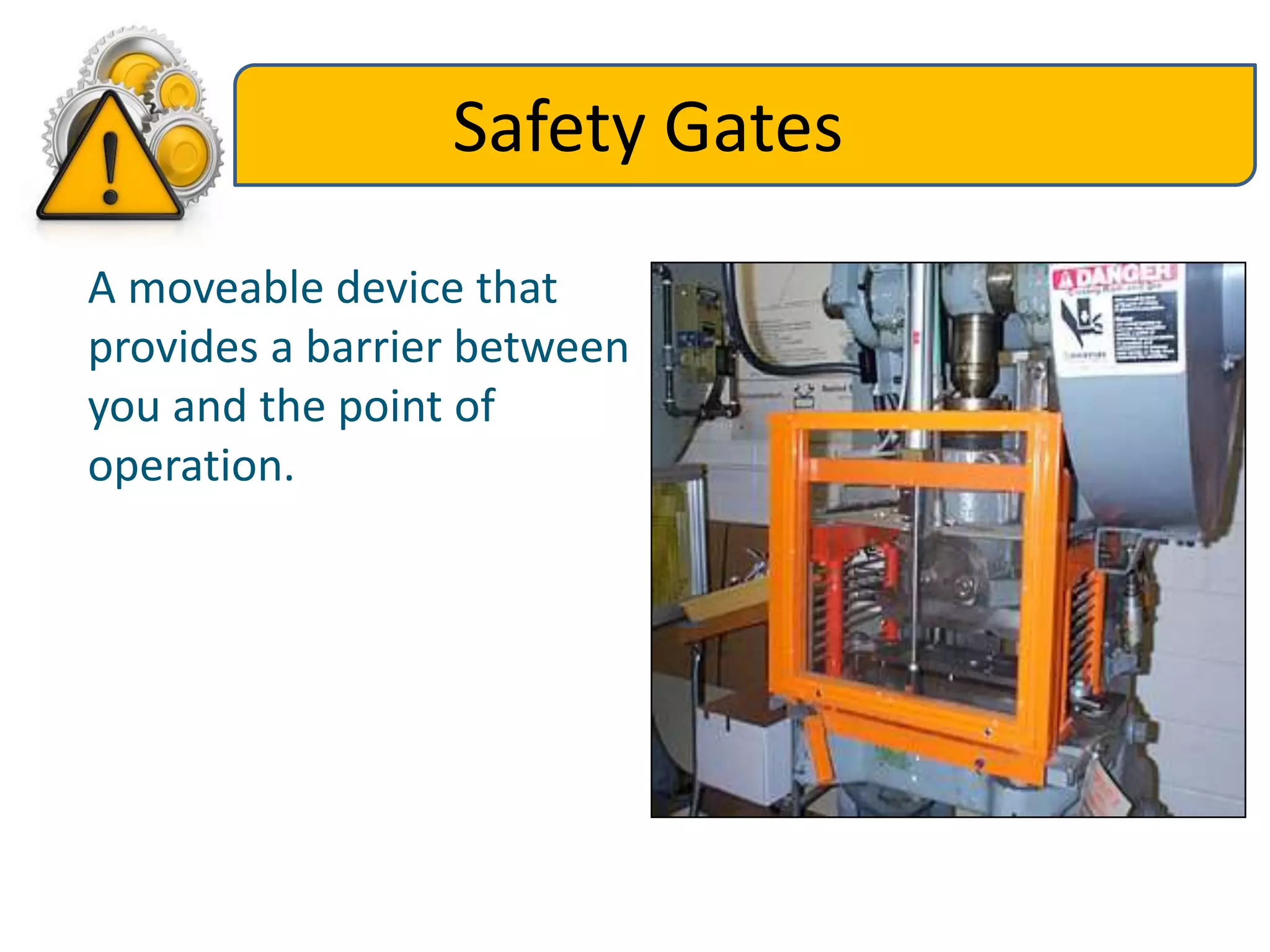

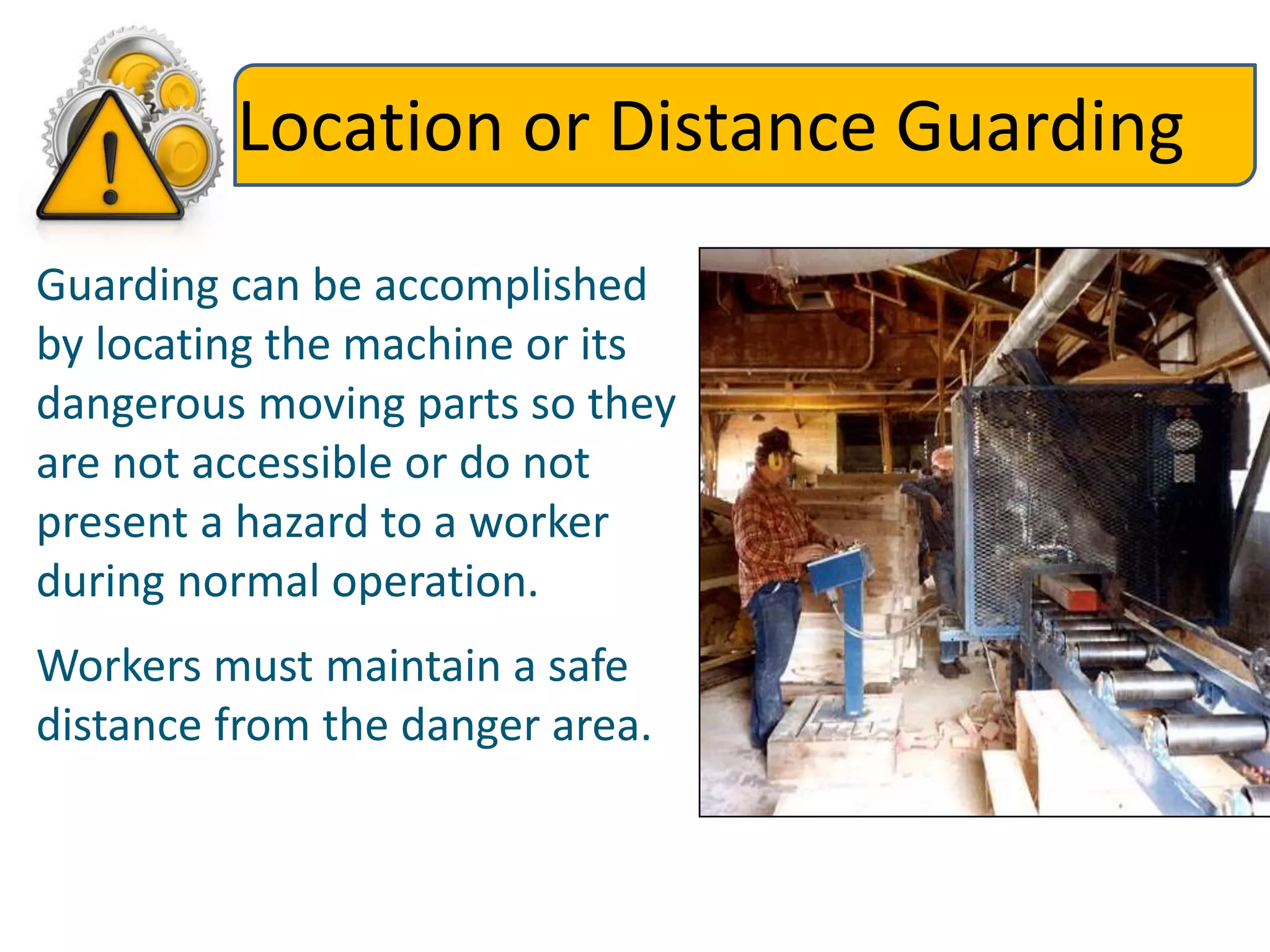

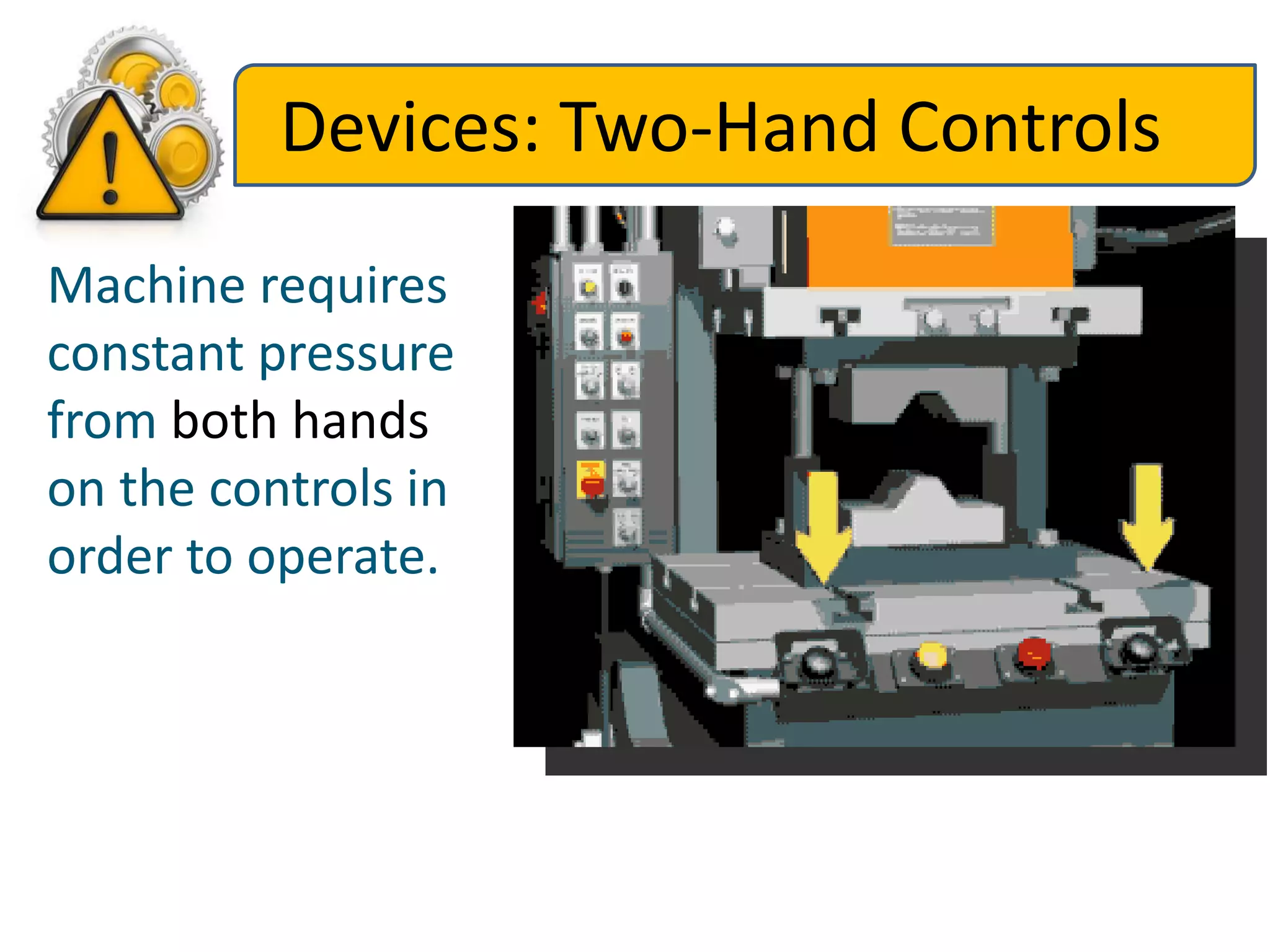

This document discusses machine guarding and how to safely operate machinery. It outlines various types of machine guards, including fixed, interlocking, adjustable, and self-adjusting guards. It also discusses safety devices like presence-sensing devices, restraints, pullback cords, two-hand controls, and safety gates. The document emphasizes the importance of training workers on all potential machine hazards and safe operating procedures to prevent injuries from rotating parts, nip points, cutting, shearing and other dangerous motions at the point of operation.