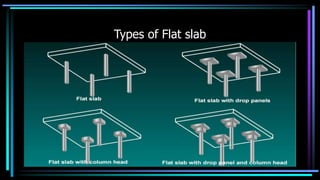

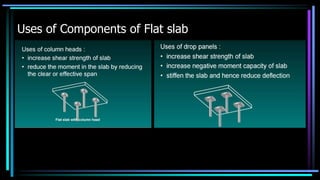

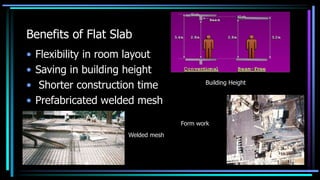

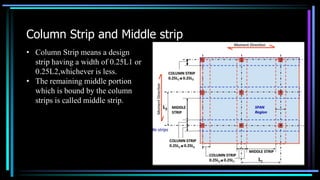

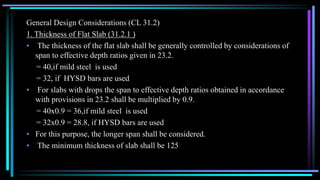

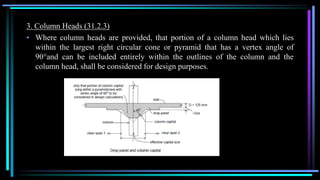

This document discusses the design of flat slab structures. It begins by defining a flat slab as a type of slab supported directly on columns without beams. It then provides details on the types of flat slabs, their common uses in buildings, and benefits such as flexibility in layout and reduced construction time. The document goes on to discuss key design considerations for flat slabs including thickness, drops, column heads, and methods of analysis. It focuses on the direct design method and provides limitations for its use.