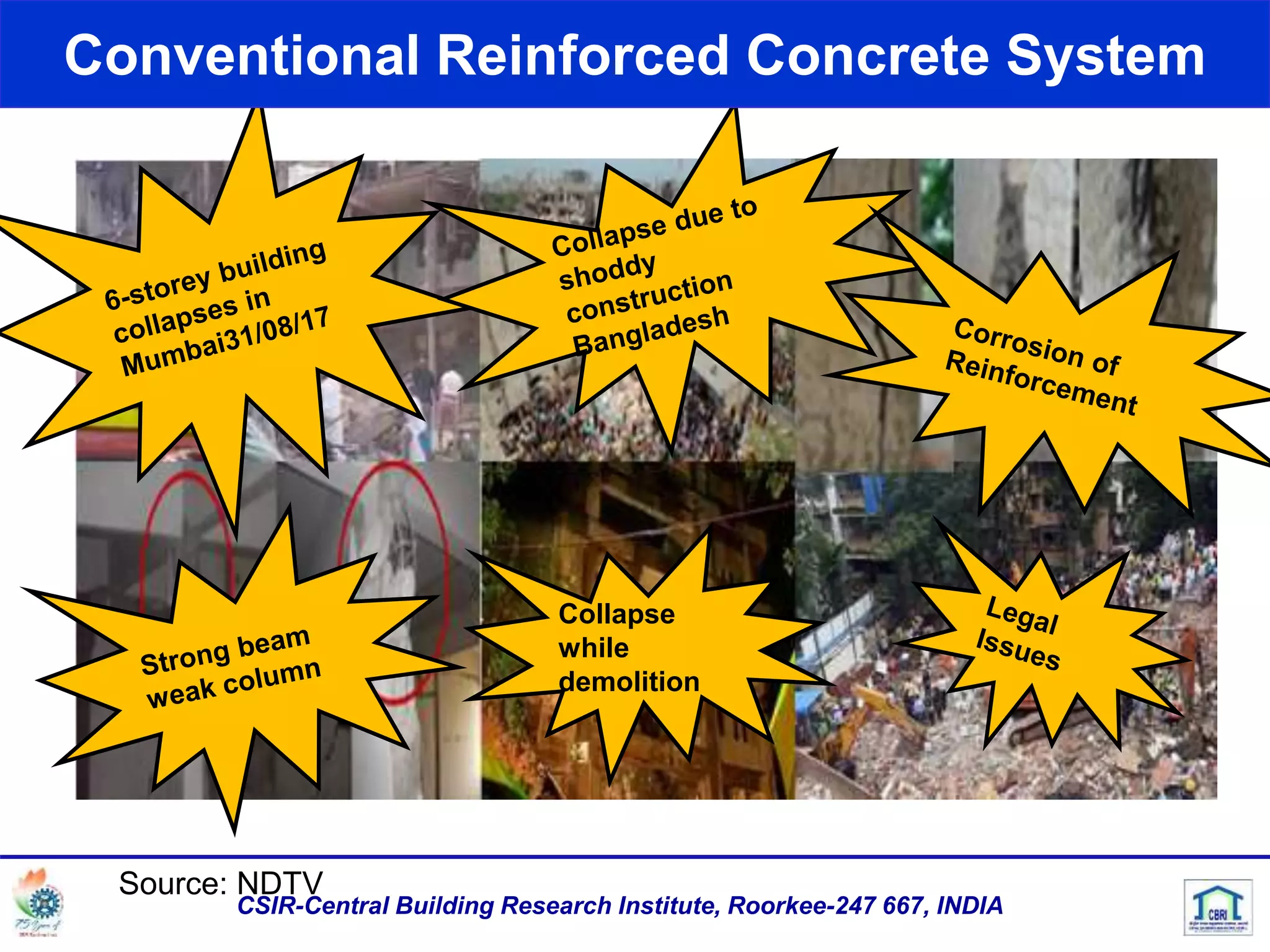

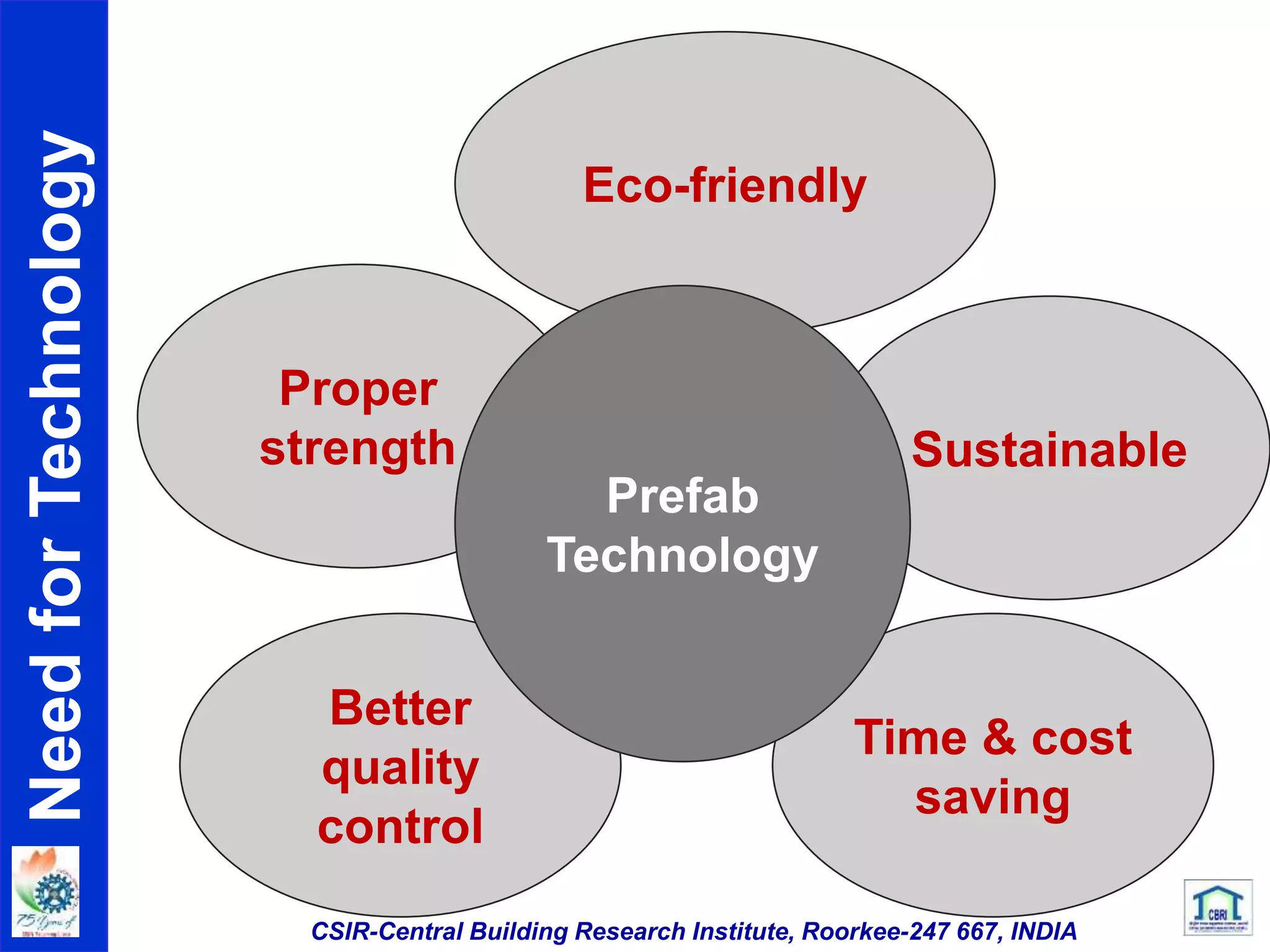

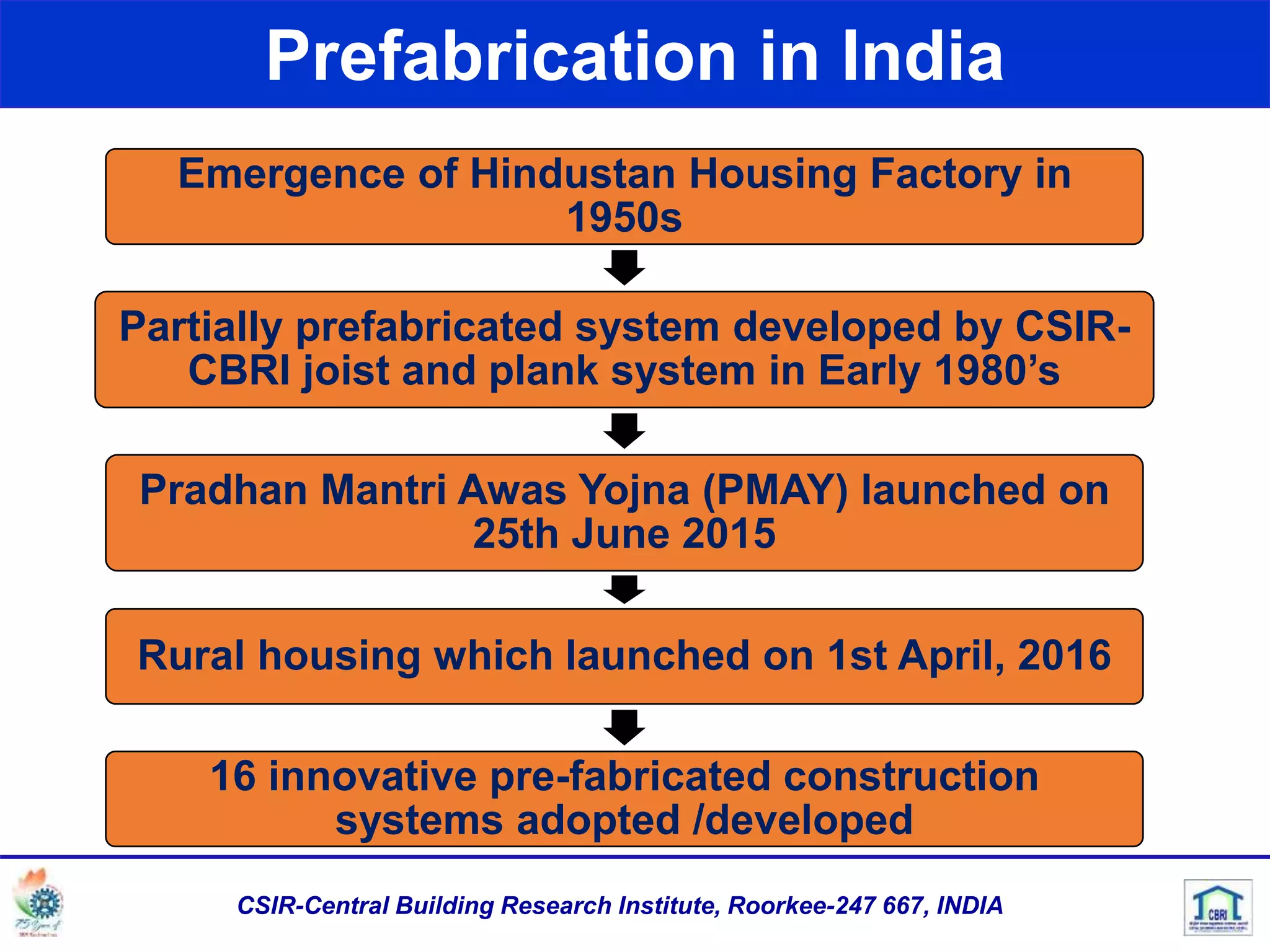

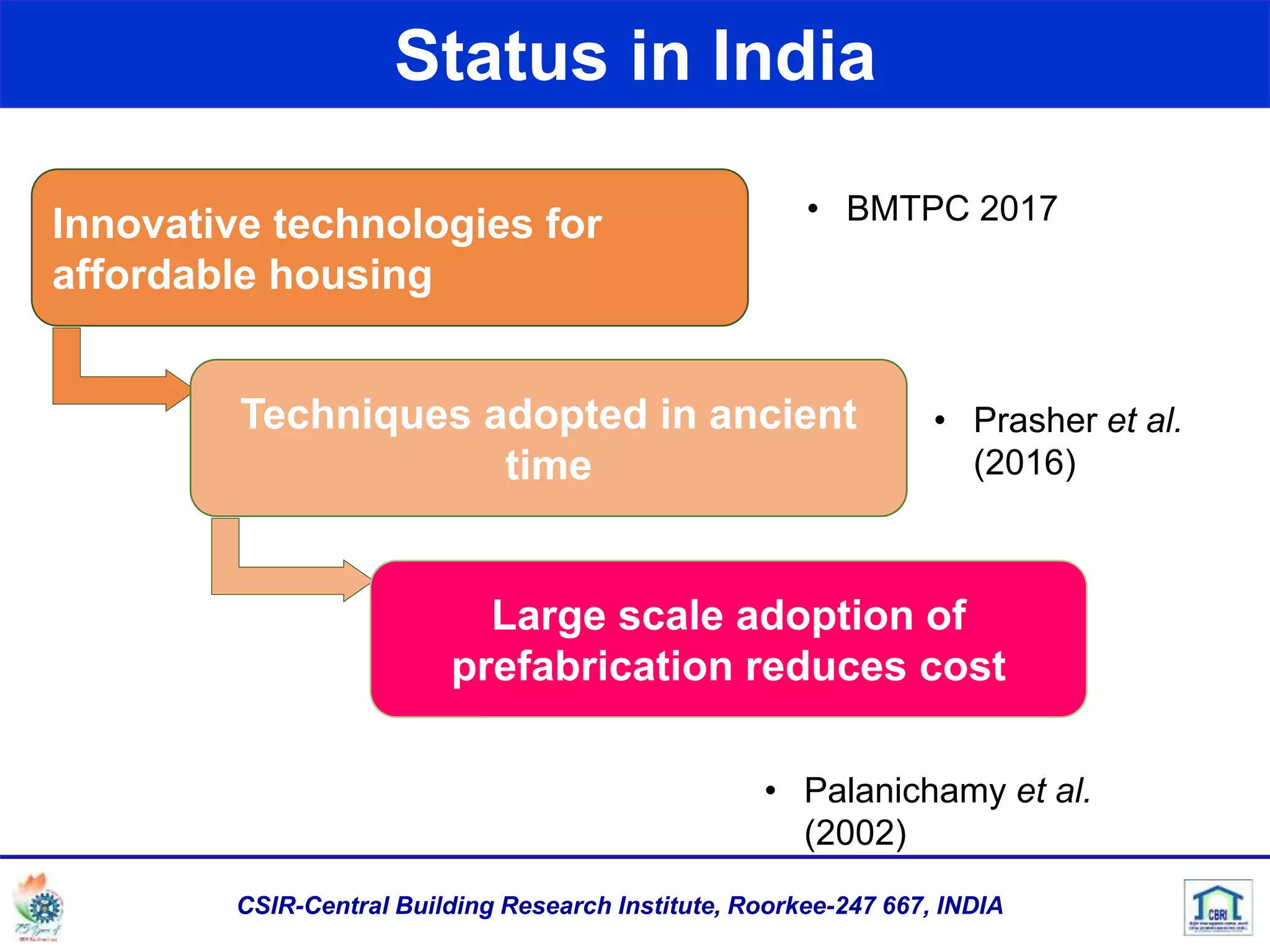

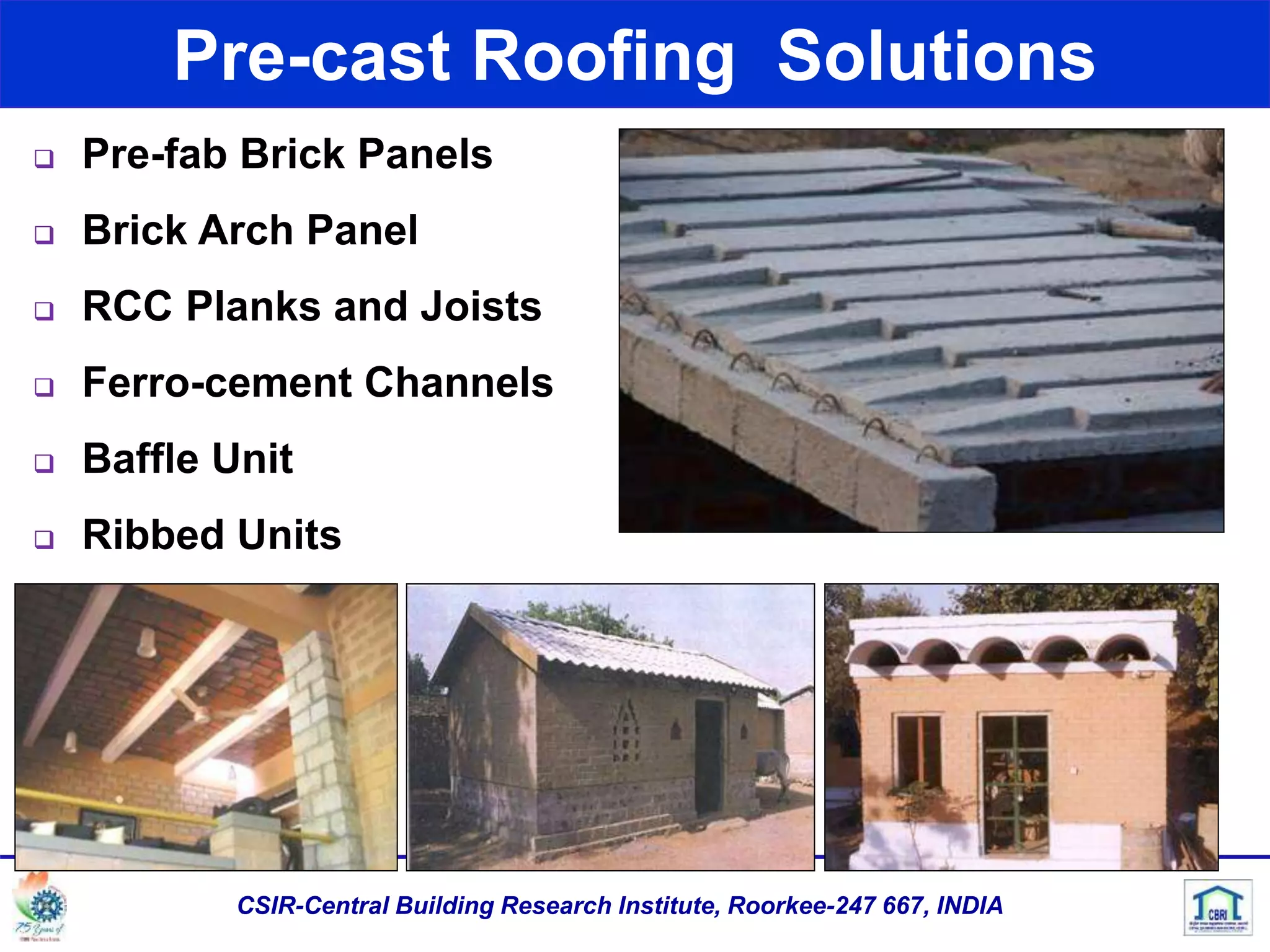

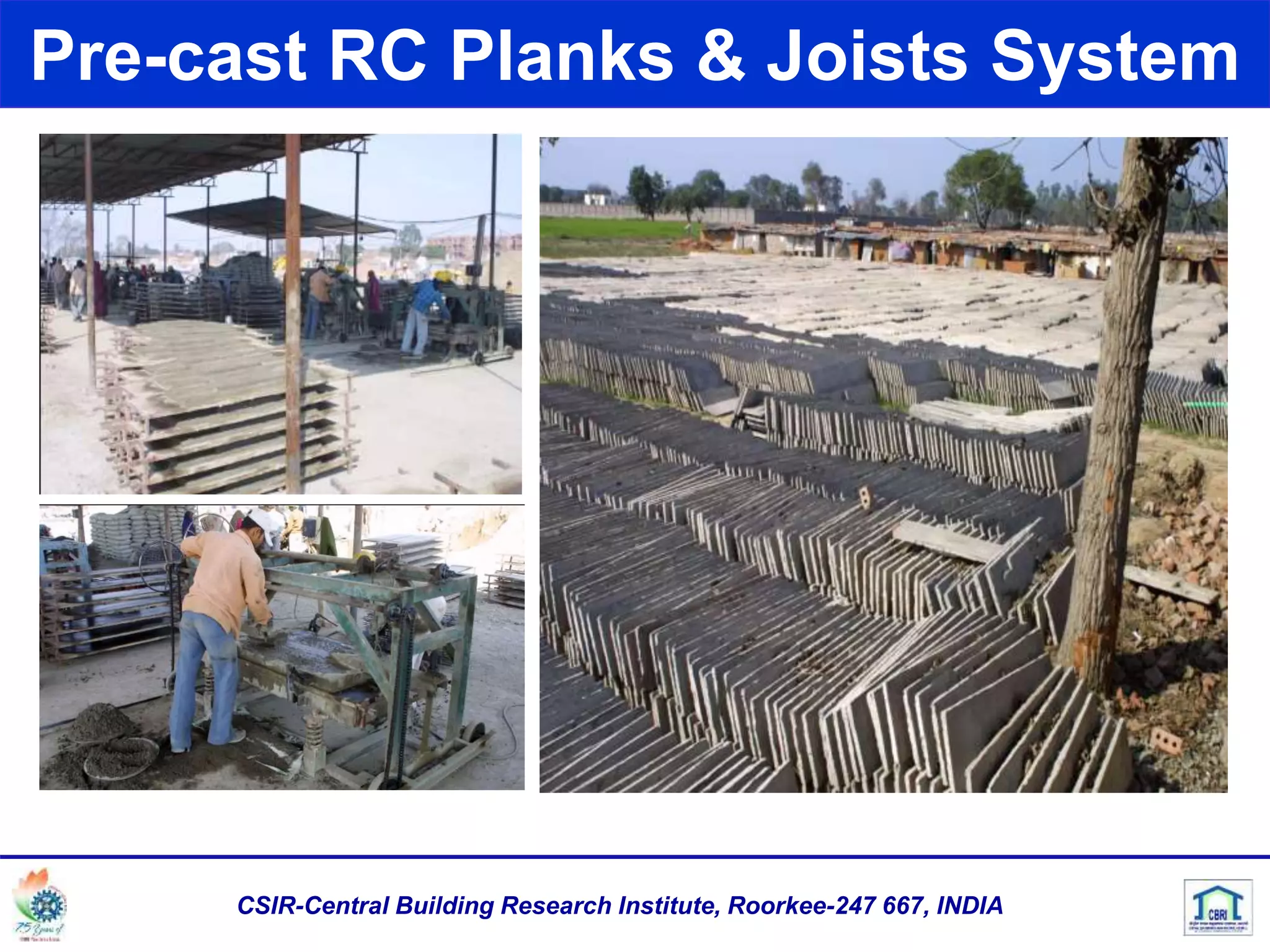

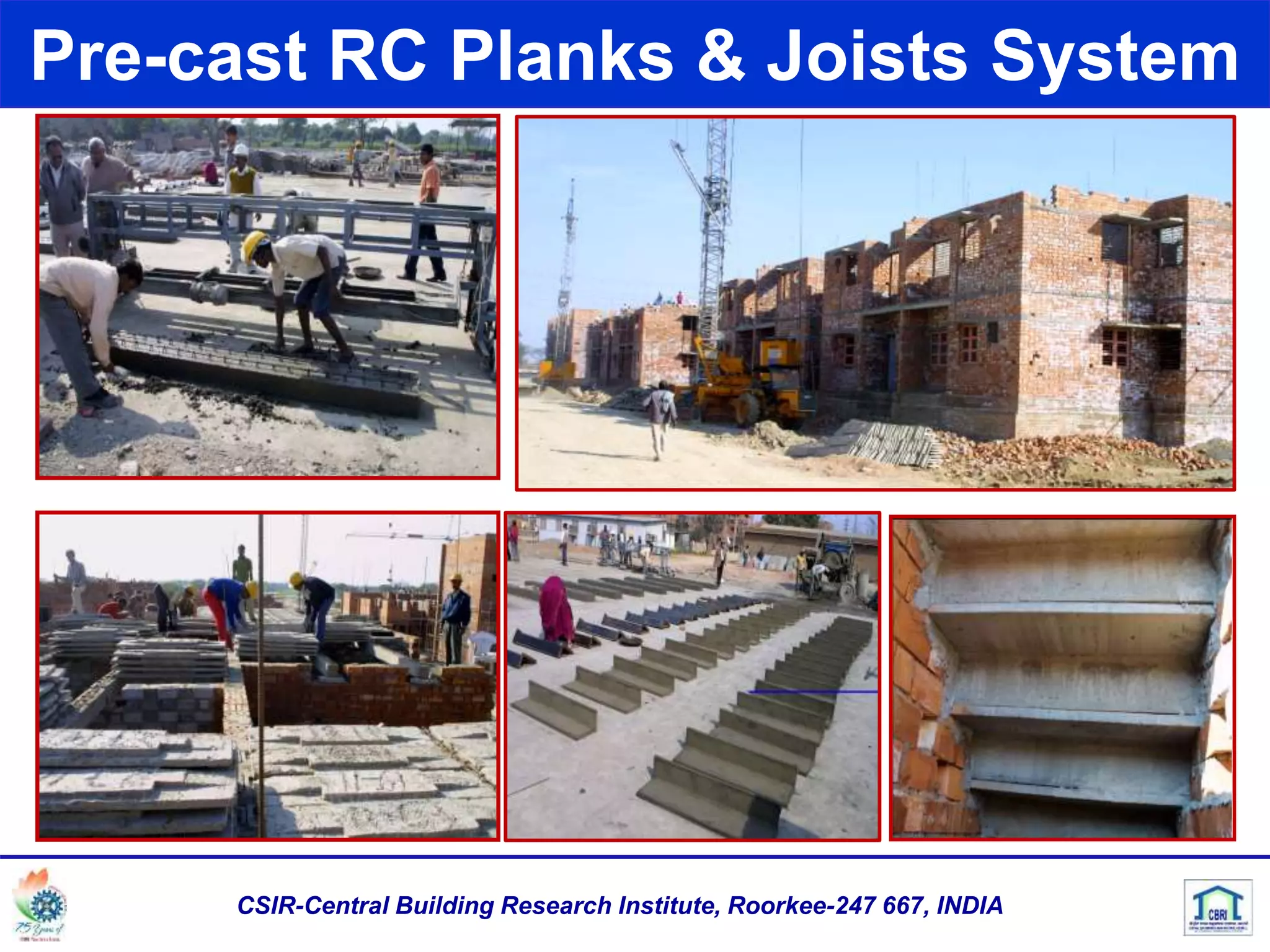

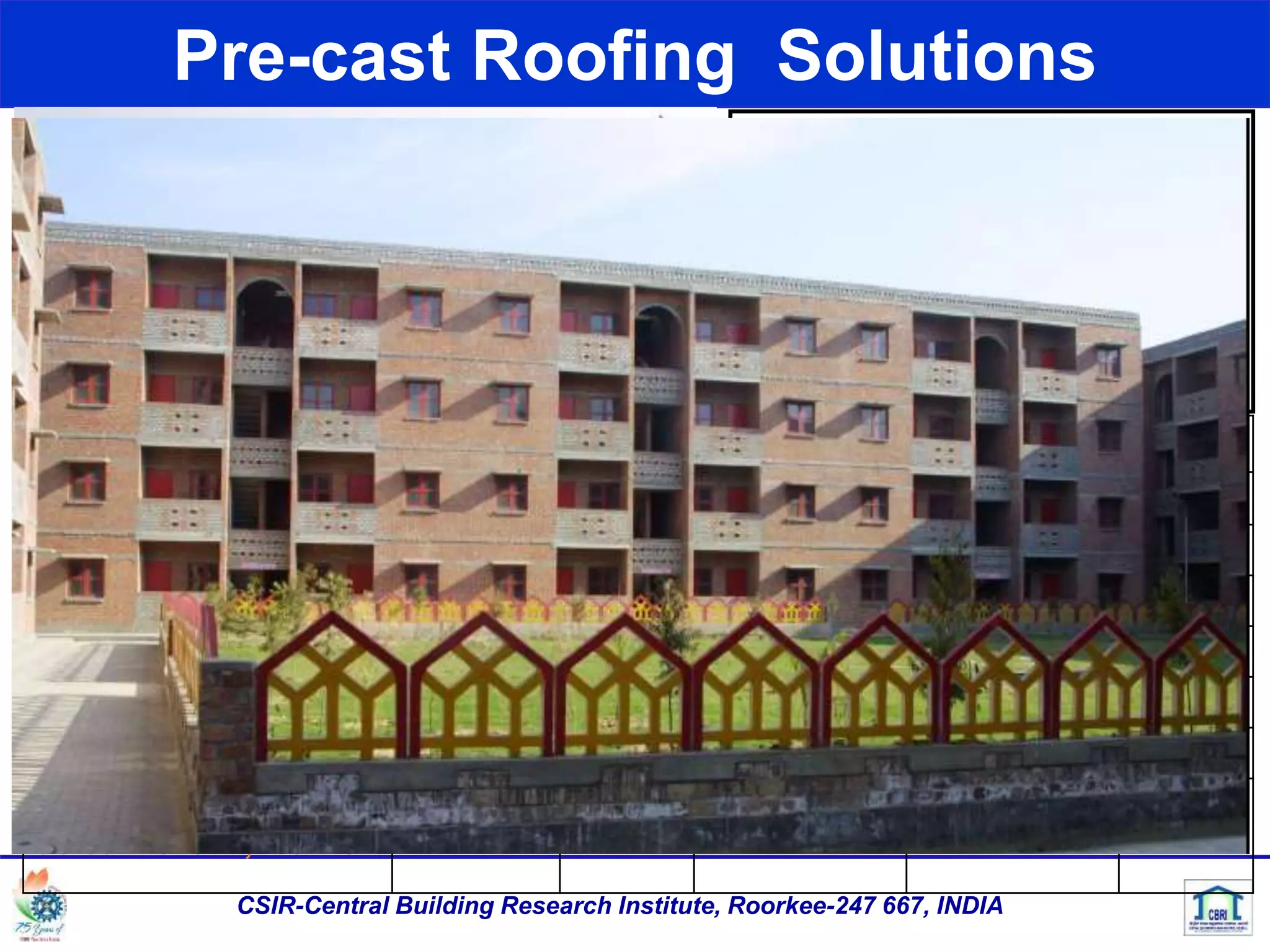

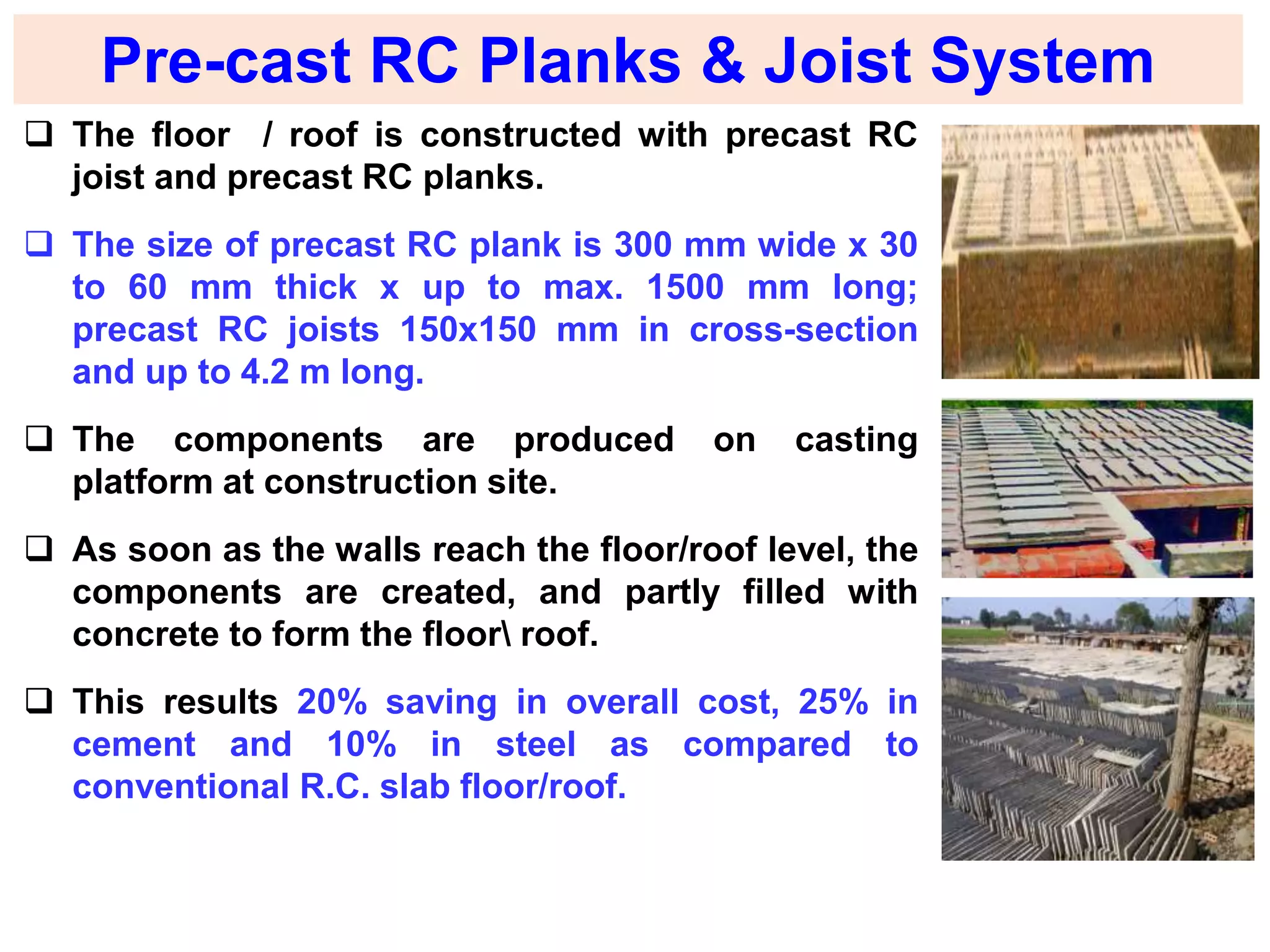

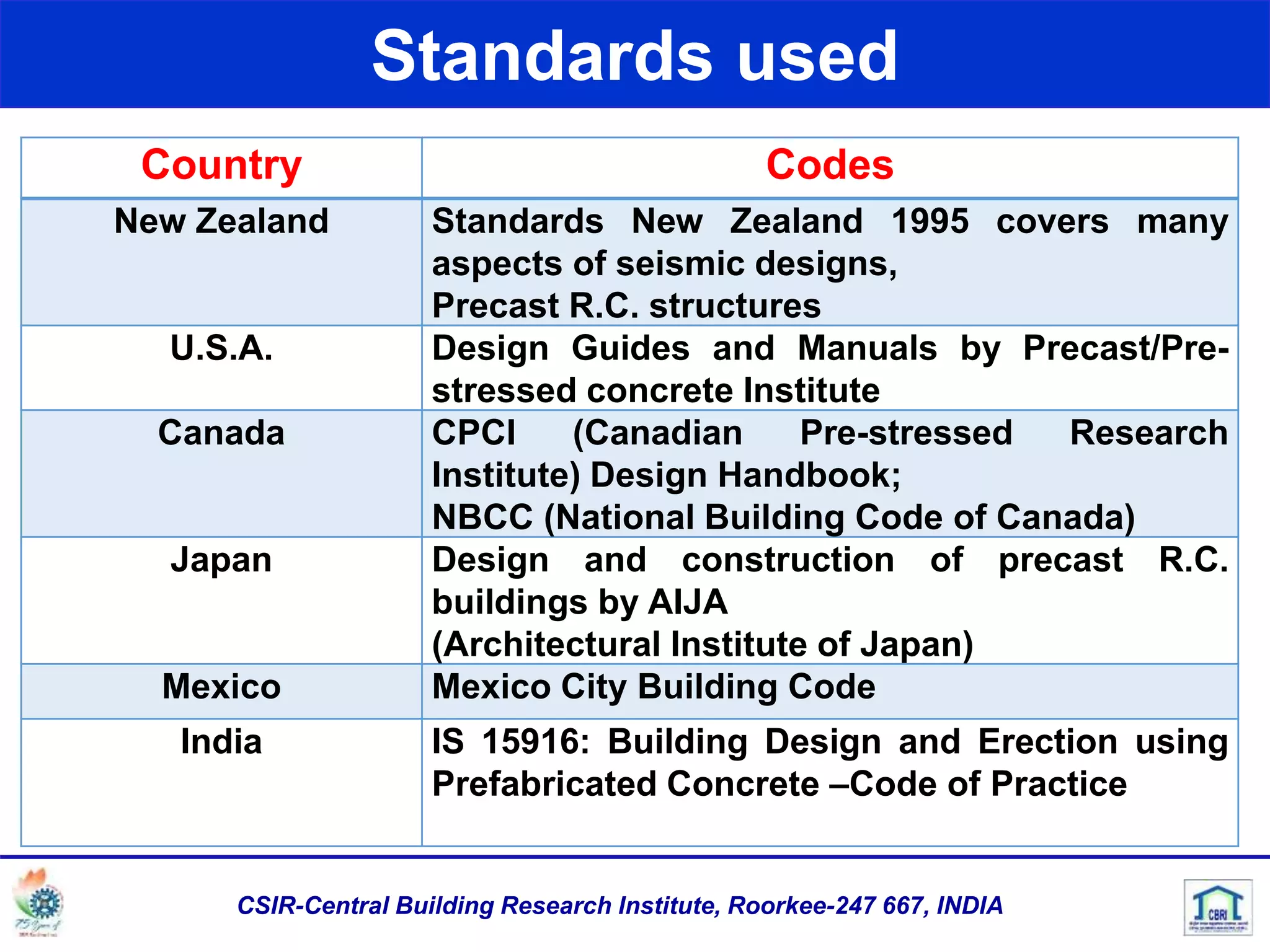

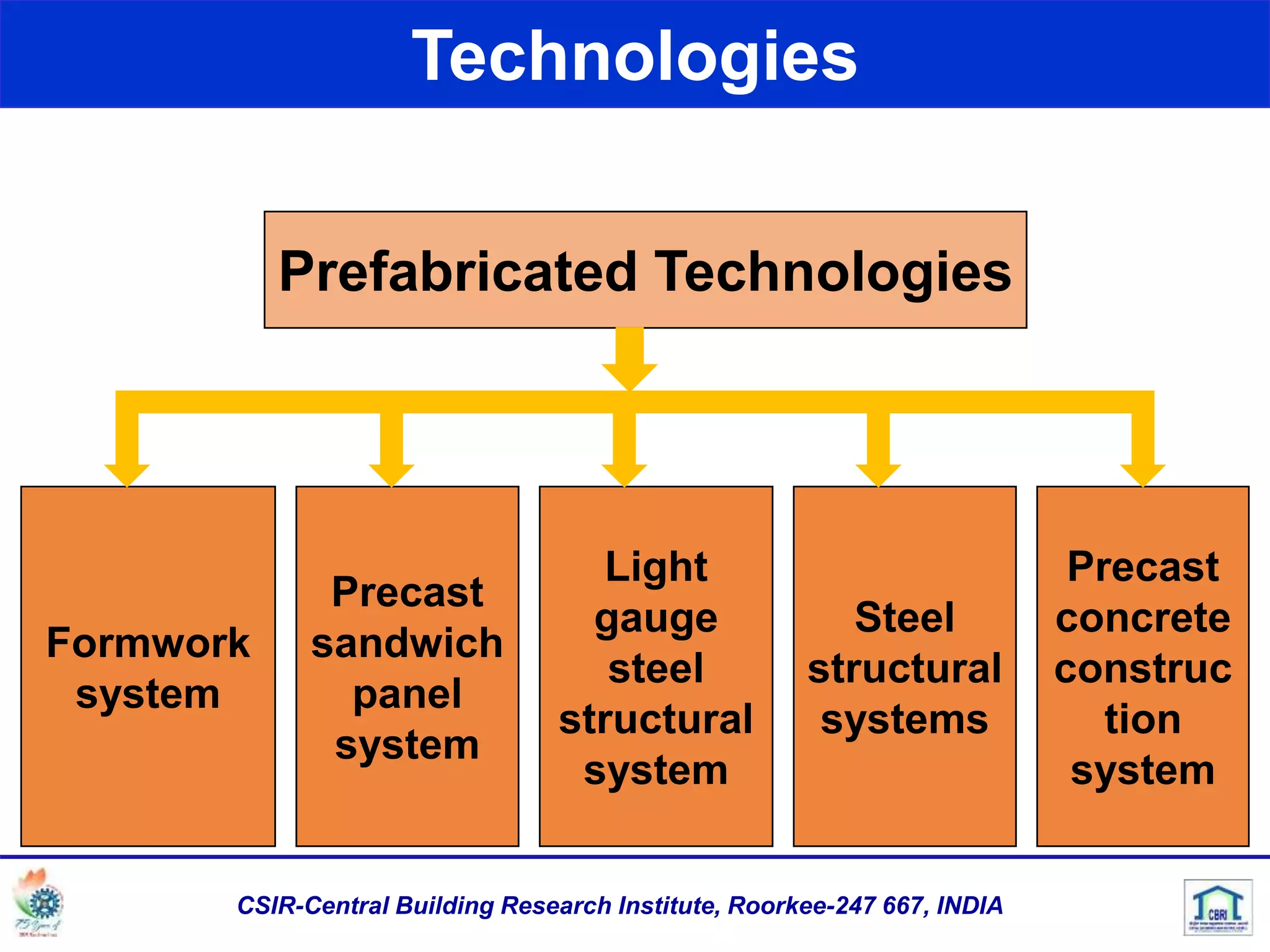

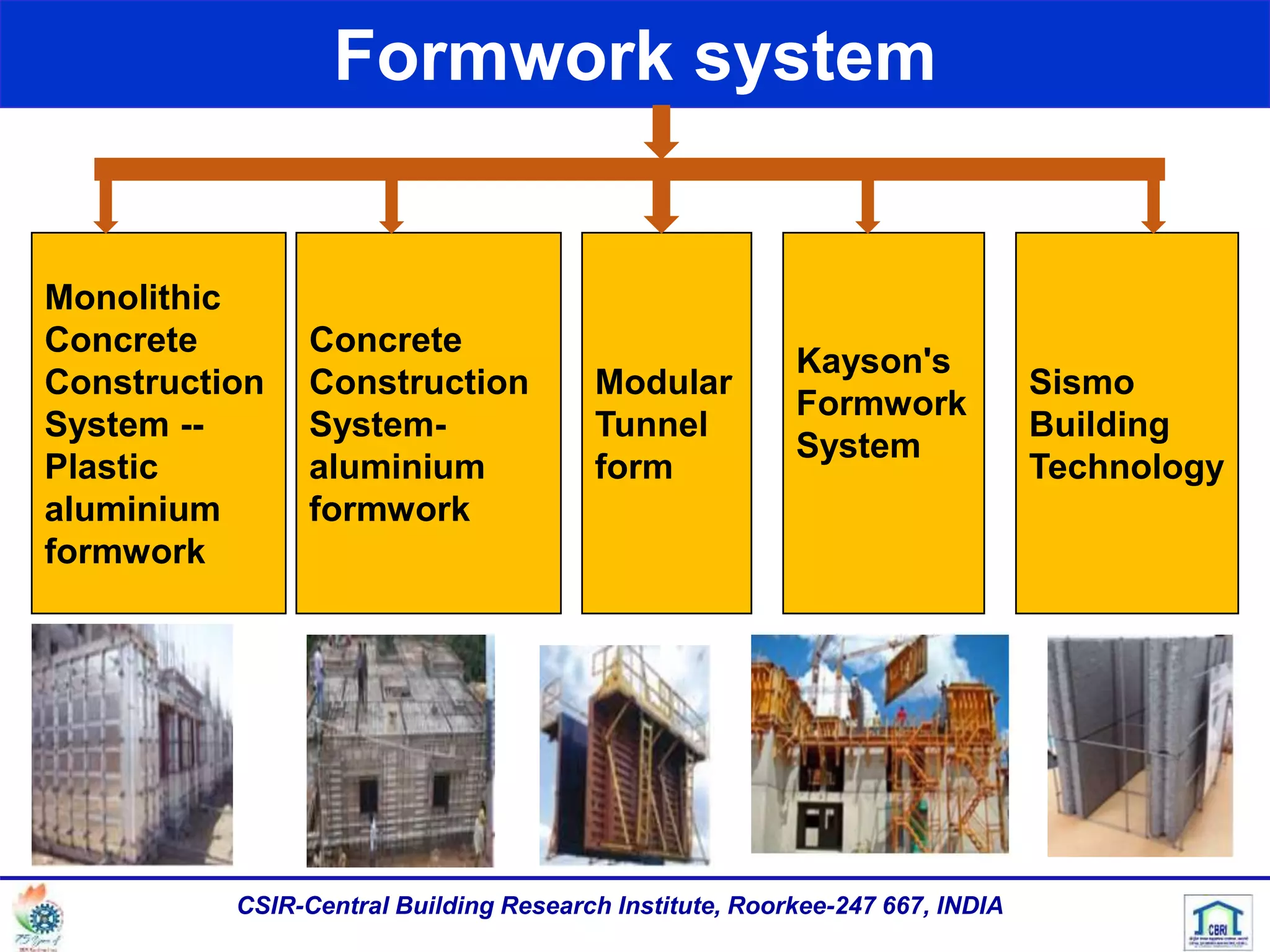

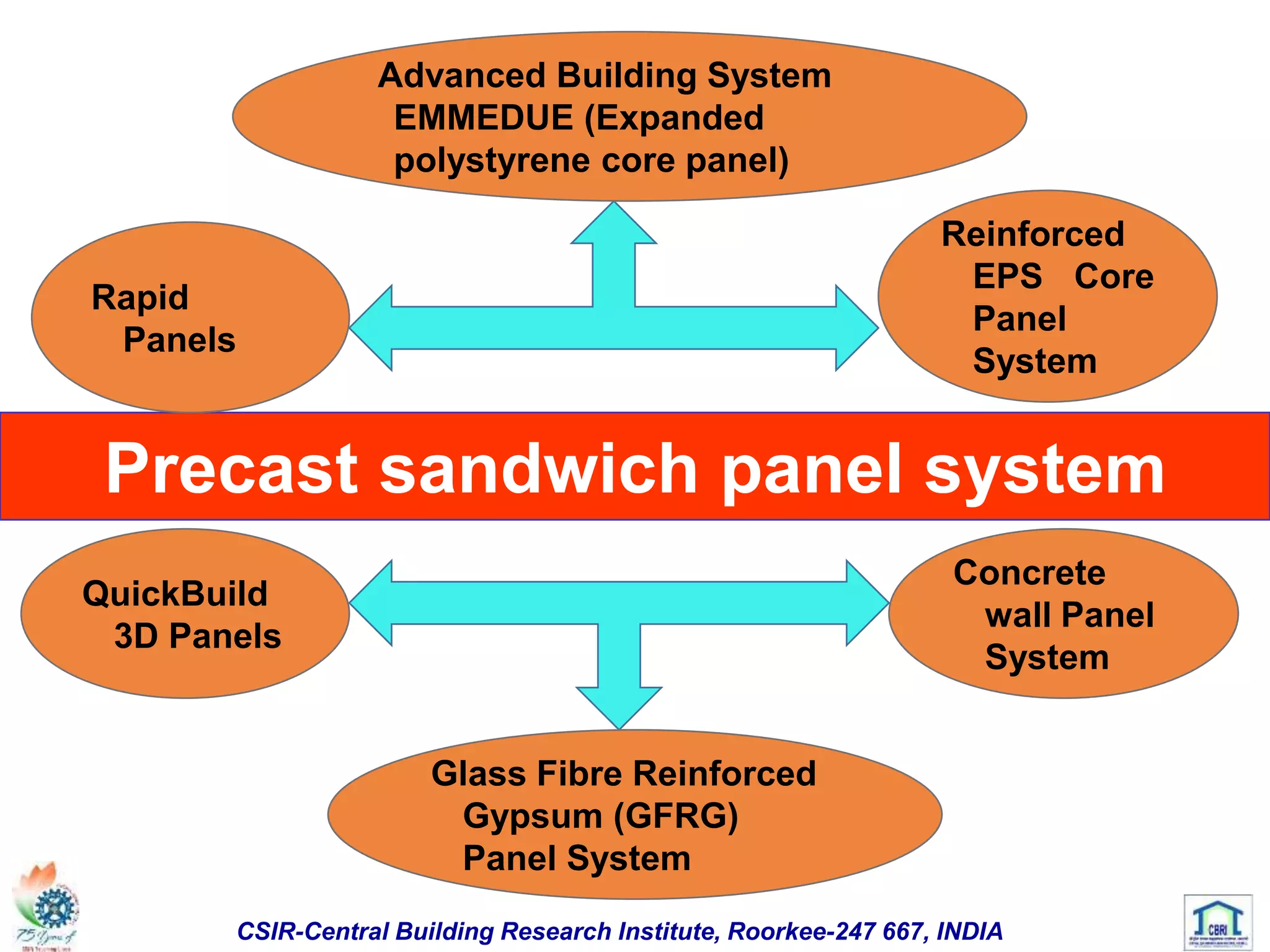

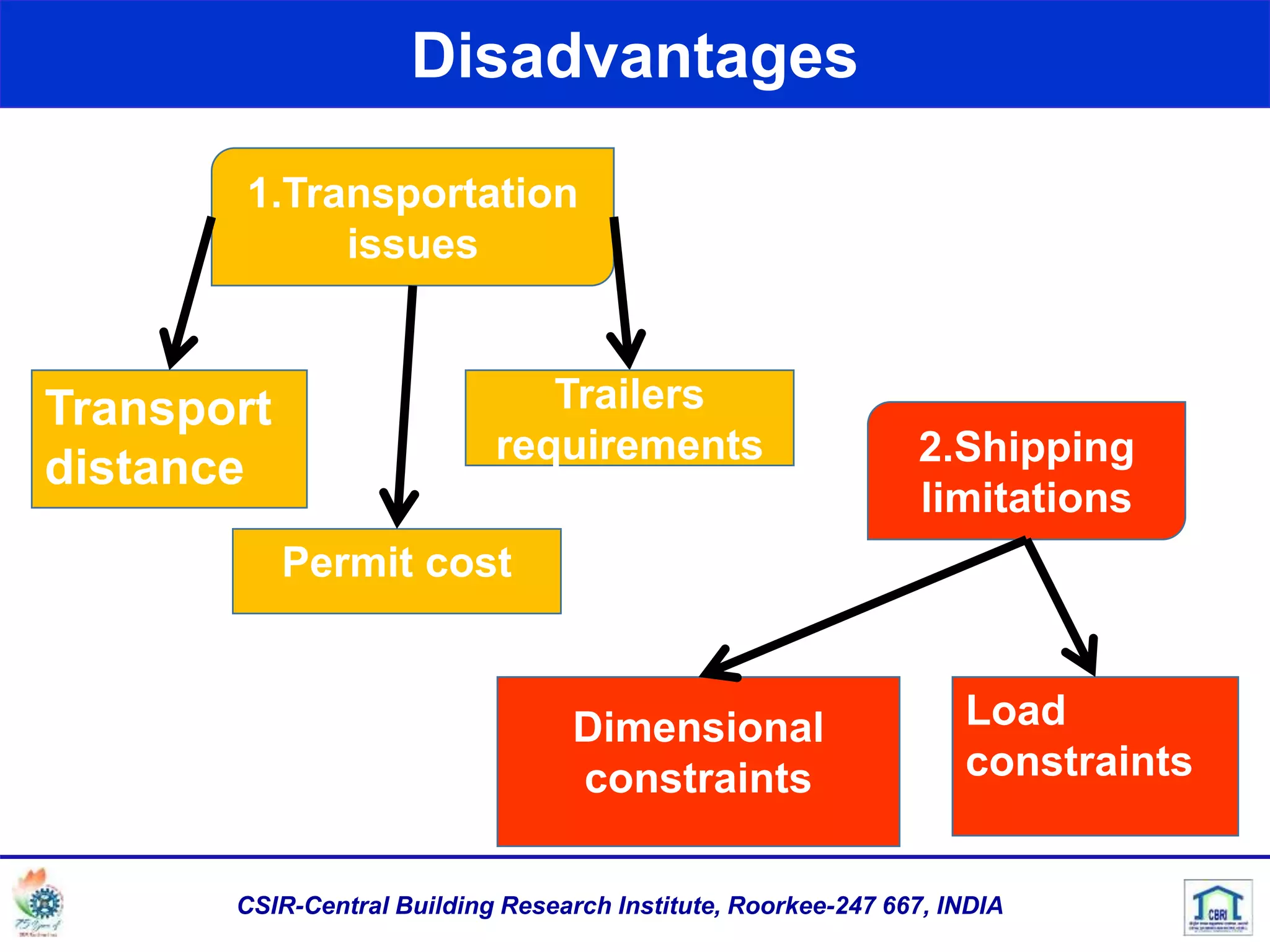

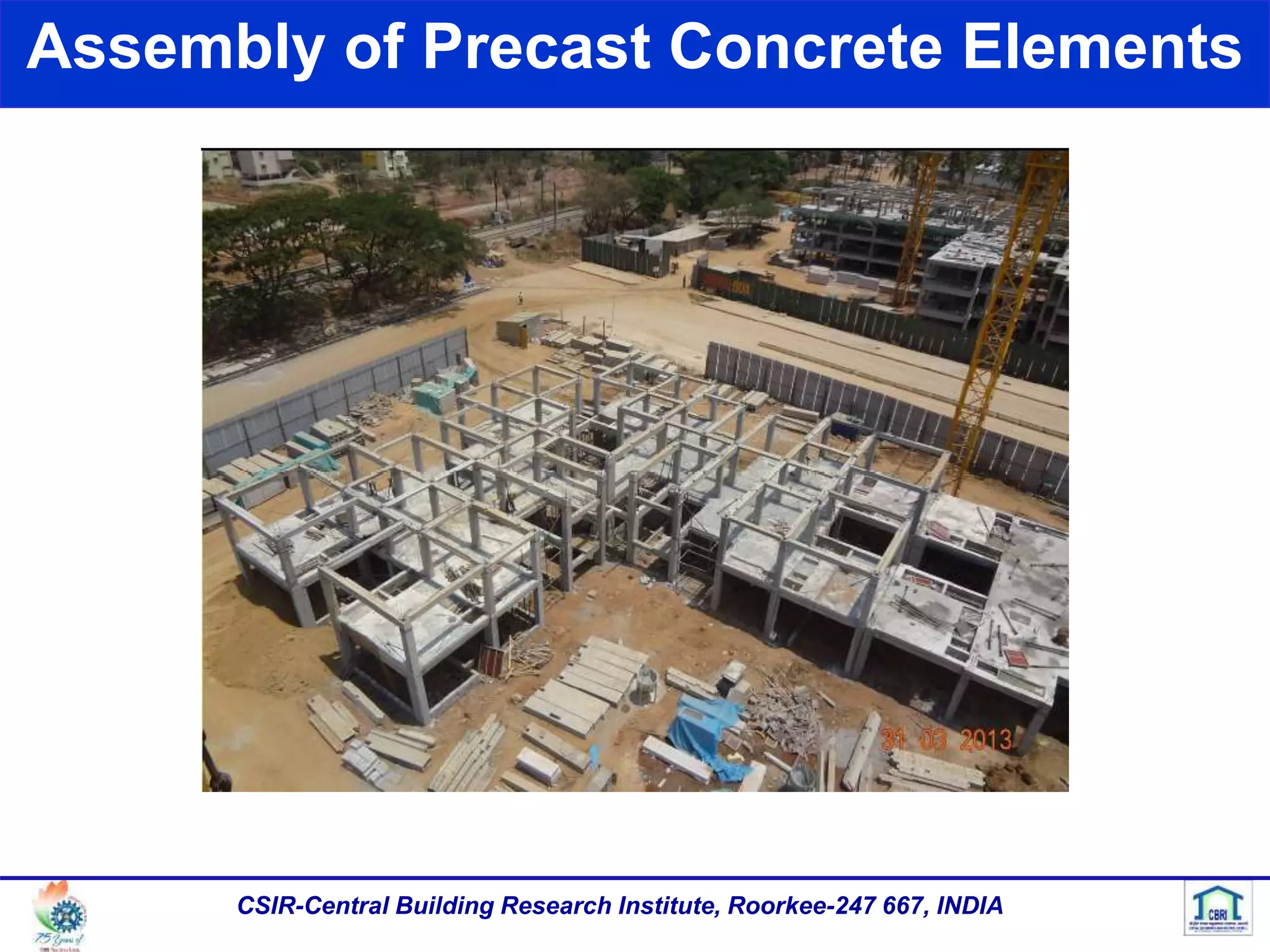

The document discusses the current status and challenges of prefabricated construction systems in India, particularly in the context of affordable housing. It highlights the benefits of prefabrication, such as cost and time savings, and the need for improved technology and guidelines to increase adoption. Additionally, it outlines various prefabricated technologies and emerging trends in the construction sector aimed at addressing housing shortages and sustainability issues.