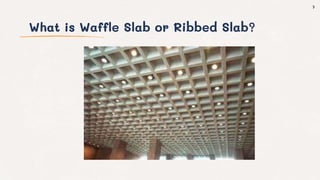

Waffle slab or ribbed slab is a structural component with a flat top surface and grid-like bottom surface containing perpendicular ribs. It has two-directional reinforcement and is used for large spans to avoid many interior columns. The waffle shape is formed by placing pods on the formwork before pouring concrete, leaving ribs containing reinforcement. Waffle slabs provide stiff, lightweight structures suitable for areas requiring low deflection and vibration control like airports and hospitals.