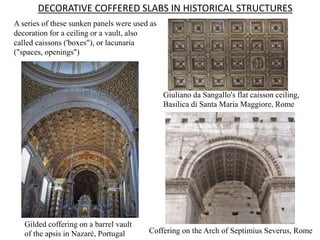

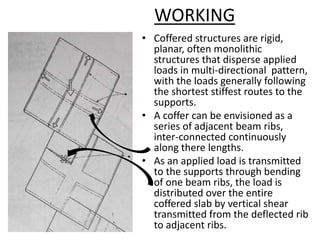

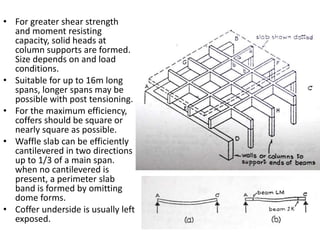

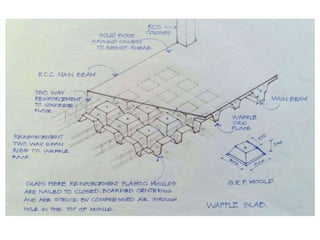

Coffered ceilings and slabs are rigid, planar structures that use a series of intersecting ribs to distribute loads across a space. The document discusses the history and architectural uses of coffered ceilings. It also describes different types of coffered slab structures like waffle slabs and drop slabs that are used for their load bearing capacities in long span structures like schools and hospitals. Various coffered slab construction techniques are outlined, including the use of precast elements and how services can be run through the coffered spaces.