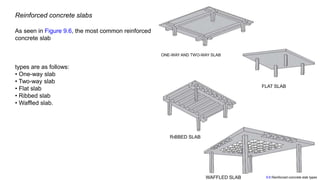

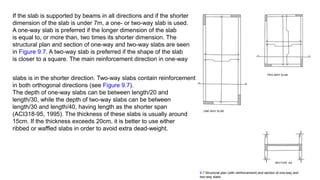

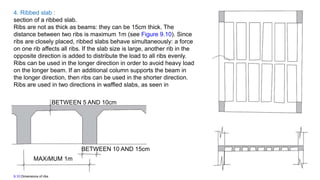

This document discusses different types of reinforced concrete slabs, including one-way slabs, two-way slabs, flat slabs, and ribbed slabs. One-way slabs are supported on two sides and bend in one direction, while two-way slabs are supported on all four sides and bend in both directions. Flat slabs do not have beams and loads are transferred directly to columns, providing a plain ceiling. Ribbed slabs contain reinforced concrete ribs spaced no more than 1 meter apart between which the slab spans.