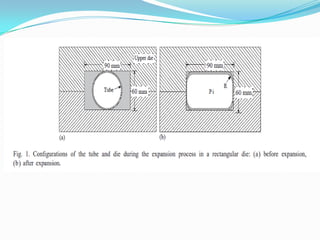

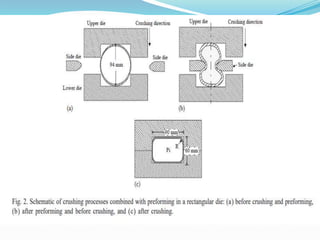

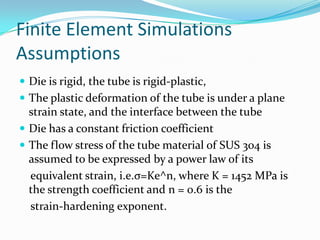

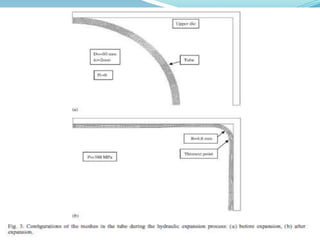

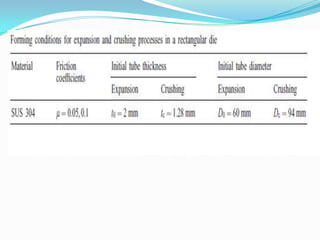

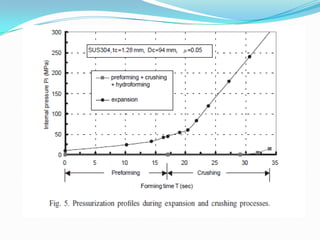

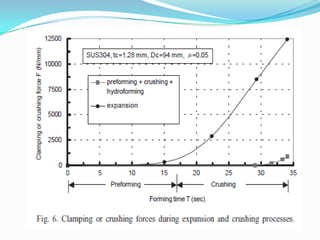

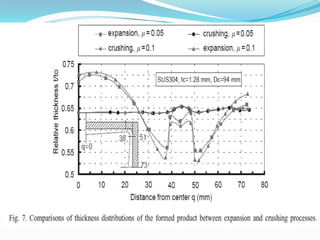

This document summarizes a student's presentation on using finite element modeling to simulate the plastic flow of circular tubes being hydraulically expanded or crushed into rectangular cross-sections. Key points include: using DEFORM software to model the tube expansion or crushing process under assumptions of plane strain and rigid tools; modeling the tube with 1000 elements over 6 thickness layers; and obtaining results on pressure requirements, thickness distributions, and conclusions that crushing requires less pressure and force than expansion while providing more uniform thickness.