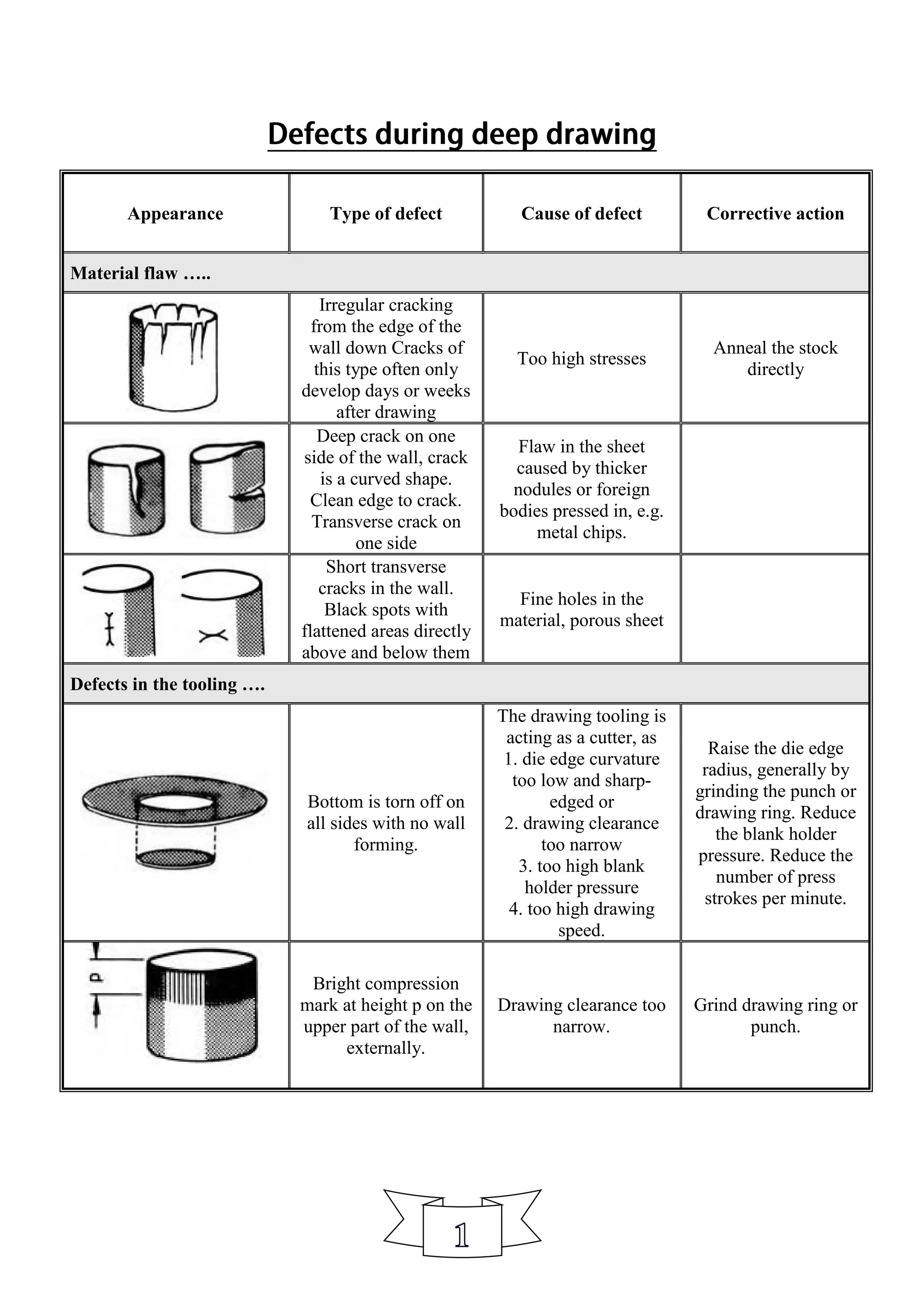

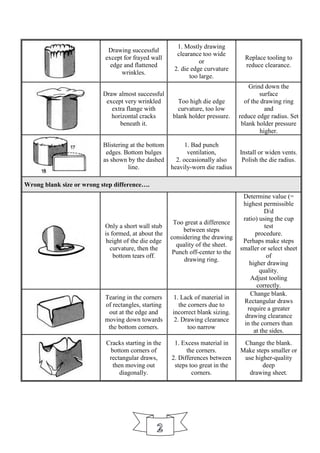

This document describes various defects that can occur during the metal deep drawing process, their causes, and recommended corrective actions. It lists different types of defects like cracking, tears, wrinkles, and earing. The causes of the defects include issues with tooling like incorrect die curvature, drawing clearance being too narrow/wide, and blank holder pressure being too high/low. It also lists causes related to the metal stock like flaws, holes, and incorrect blank sizing. The document provides solutions for correcting the defects such as annealing stock, grinding tooling, adjusting pressures and speeds, ensuring proper tool alignment, and selecting appropriate stock quality.