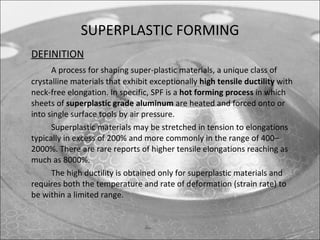

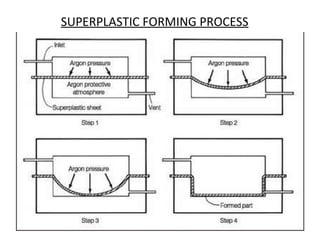

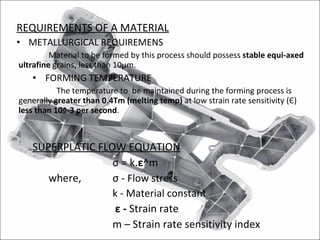

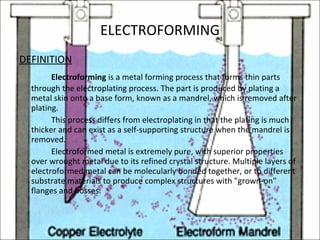

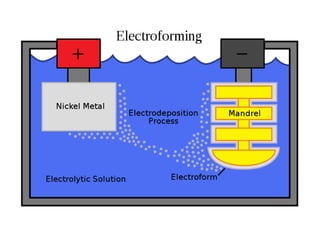

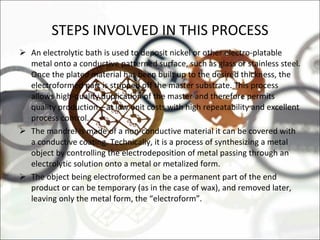

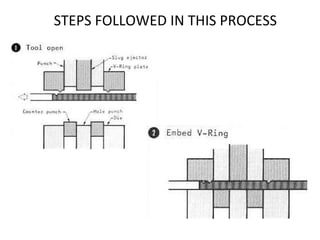

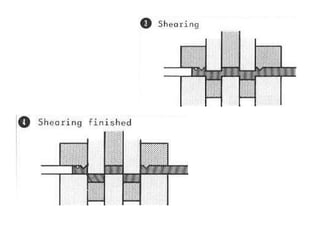

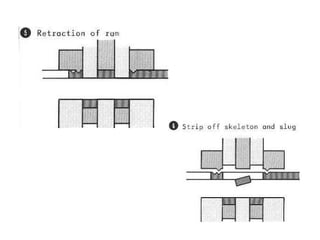

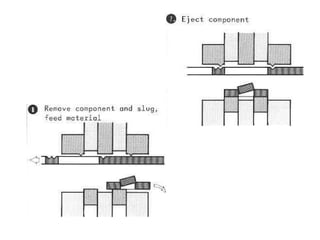

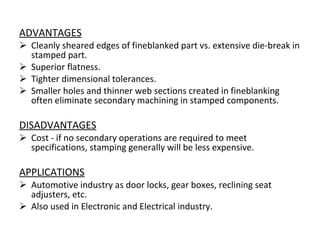

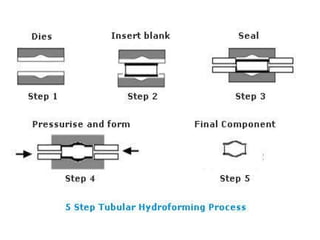

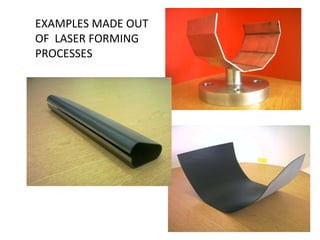

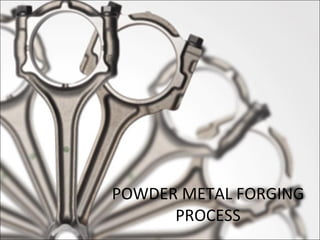

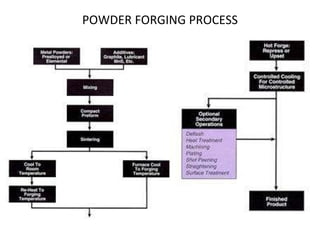

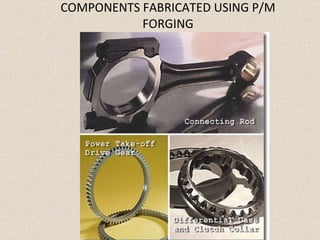

The document discusses several metal forming processes including superplastic forming, electroforming, fine blanking, hydroforming, laser forming, and powder metal forging. Superplastic forming uses air pressure to form superplastic materials like aluminum alloys into complex shapes at high temperatures. Electroforming produces thin metal parts by electroplating a metal skin onto a mandrel that is later removed. Fine blanking produces finished parts in a single press stroke with cleanly sheared edges. Hydroforming uses high-pressure fluid to form materials like steel into dies while laser forming thermally shapes sheet metal into 3D parts without contact. Powder metal forging fully densifies metal powders in a die to create precise net-shape components.