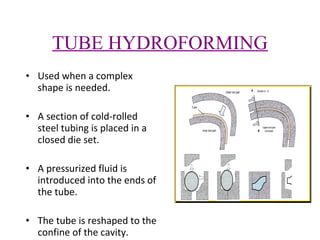

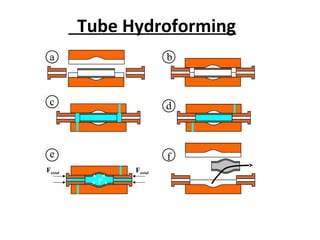

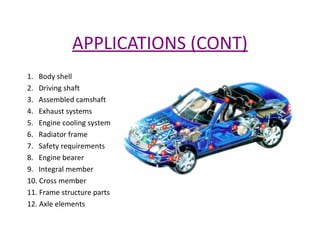

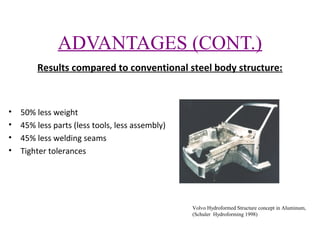

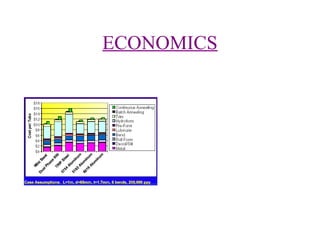

This seminar report discusses the hydroforming process. Hydroforming uses liquid pressure to form complex metal shapes. There are two types: tube hydroforming forms tubing, while sheet hydroforming forms sheet metal. Hydroforming offers advantages over conventional forming like reduced weight, fewer parts, and tighter tolerances. It is increasingly used in automotive and aerospace industries. The report provides details on the different hydroforming techniques, design considerations, materials used, and economics of hydroforming.