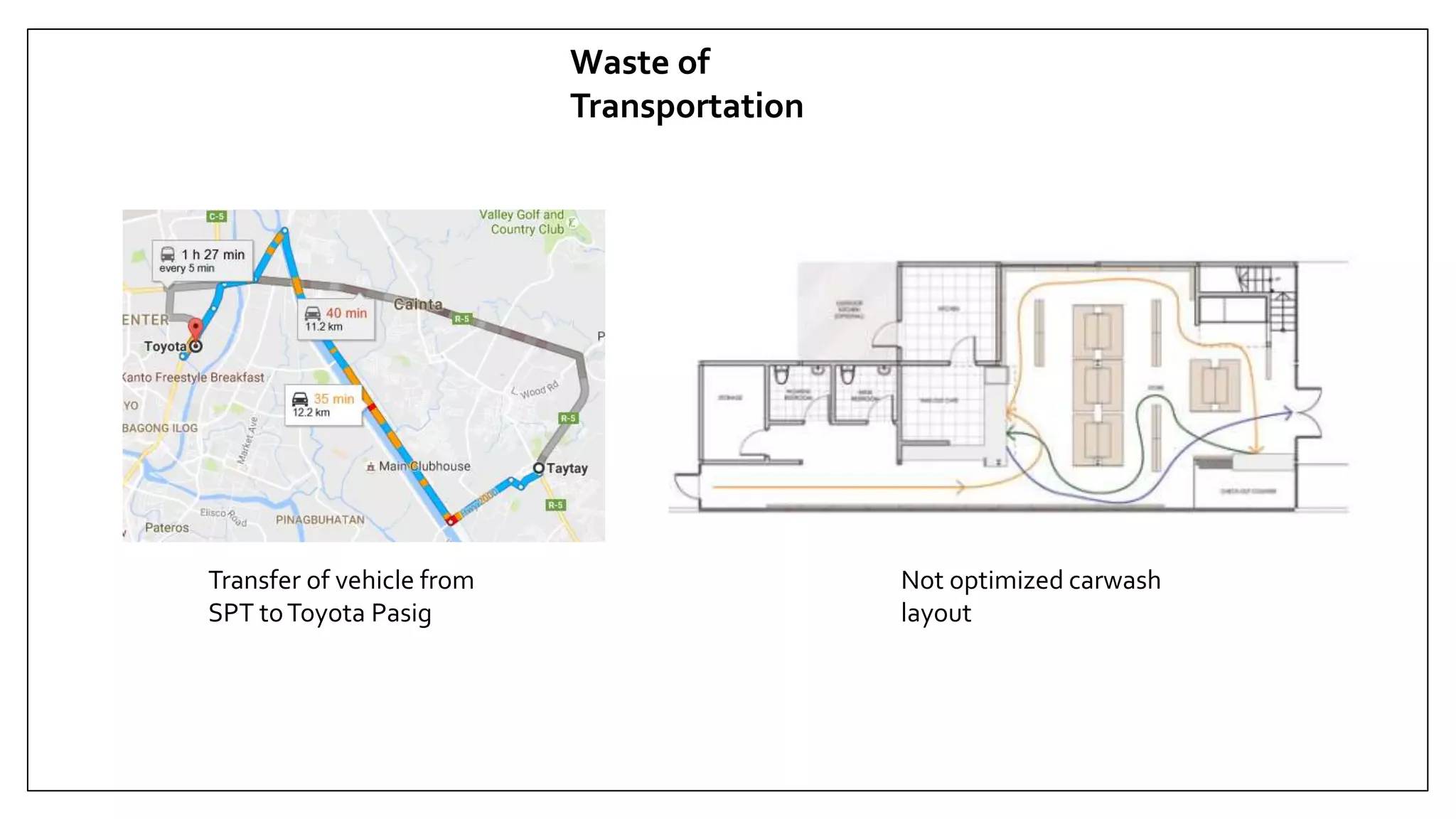

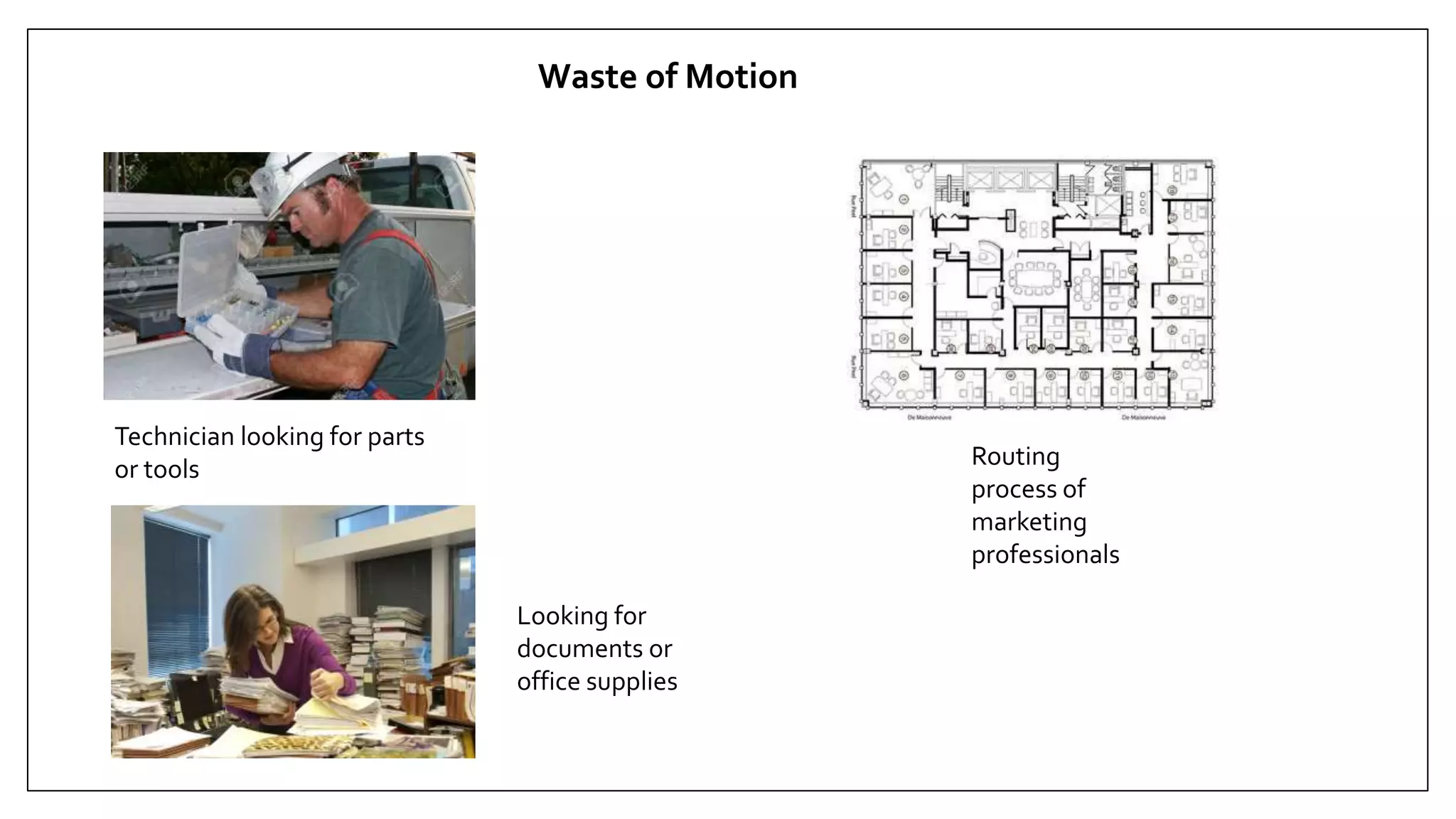

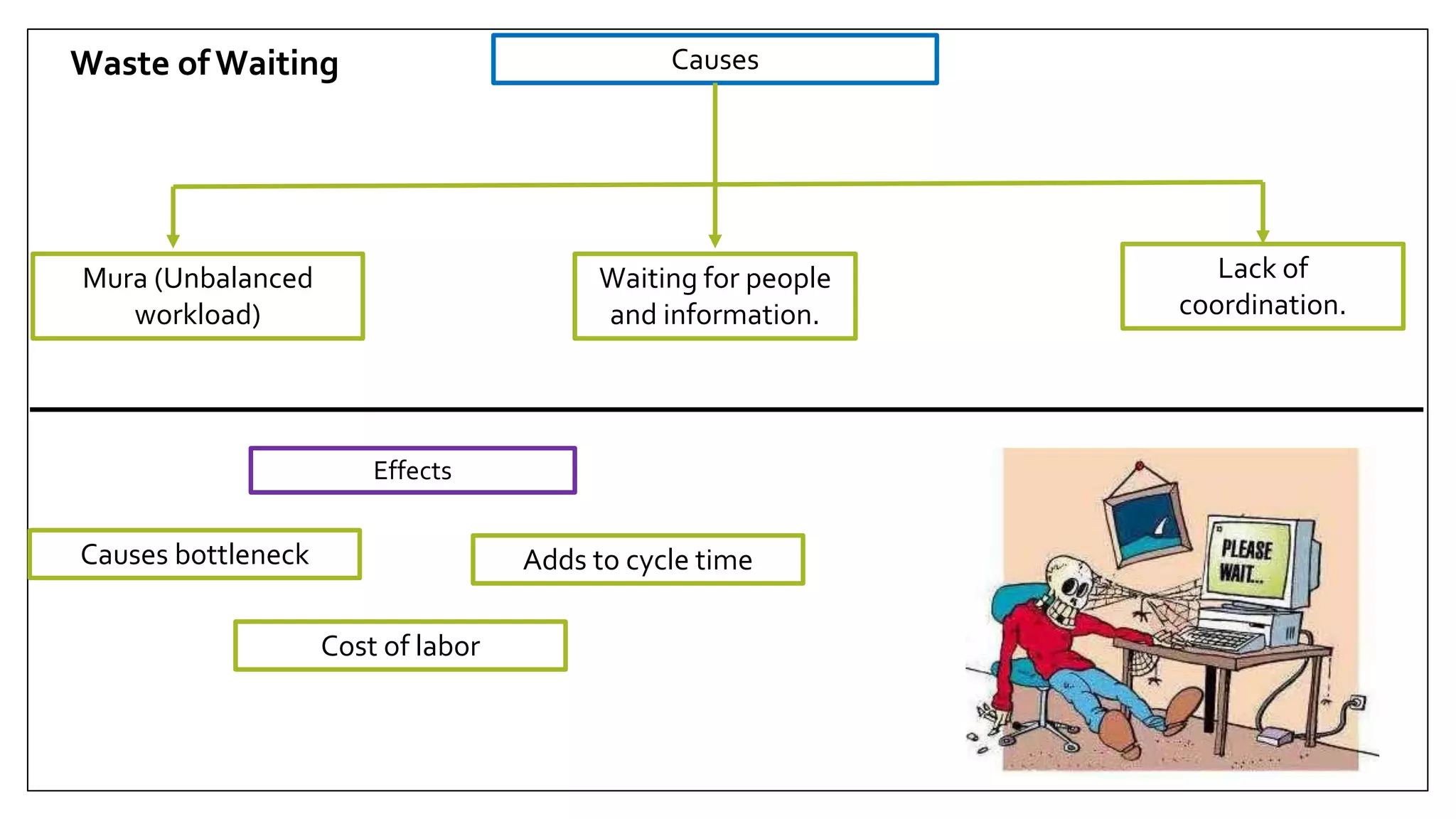

The document discusses the seven types of muda or waste in production processes - transportation, inventory, waiting, overproduction, overprocessing, motion, and defects. It defines each type of waste and provides examples. It also discusses causes and effects of each waste type. Lastly, it introduces the 5S methodology - sort, straighten, shine, standardize, and sustain - as a tool to combat the seven wastes in processes.