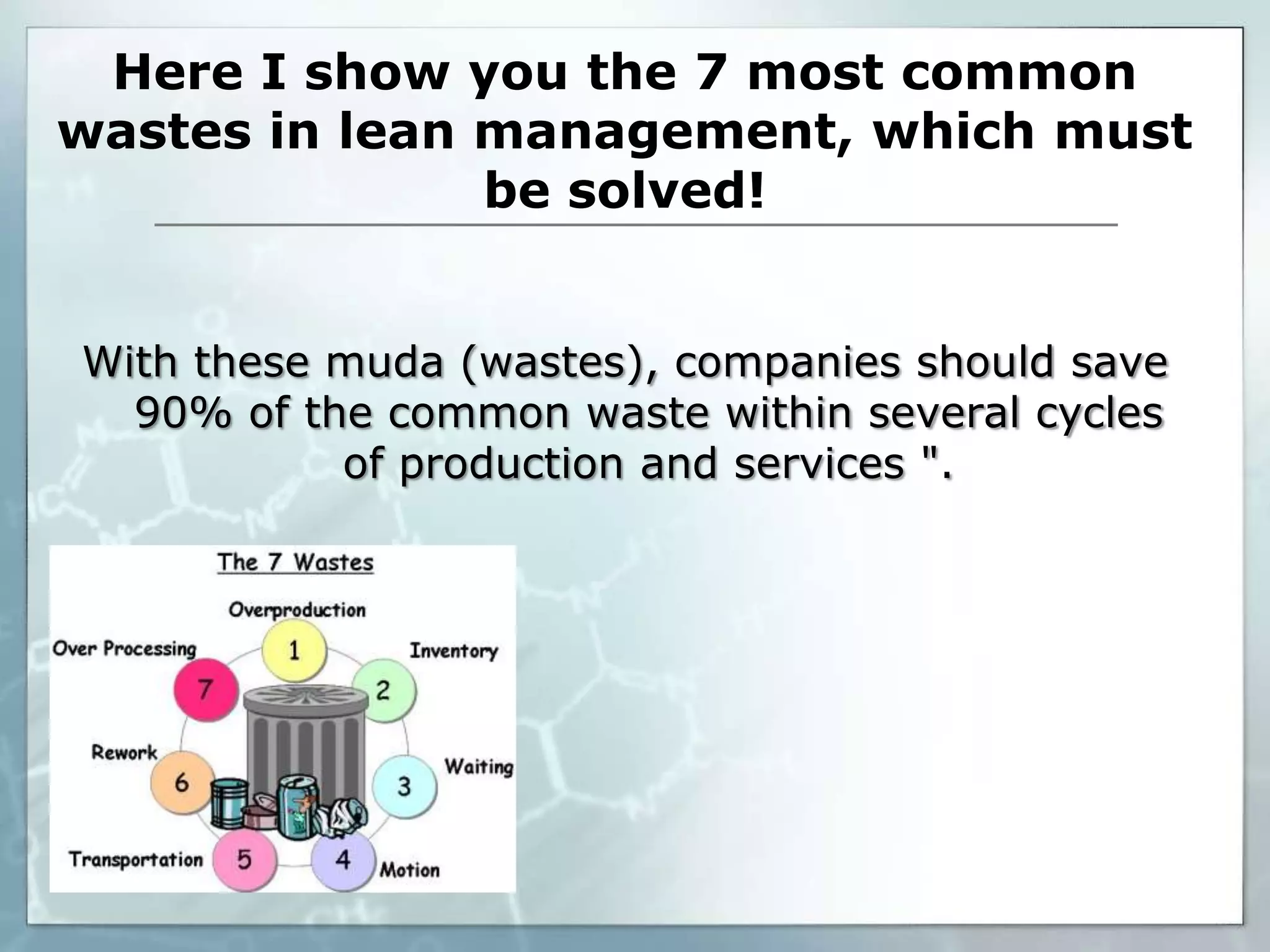

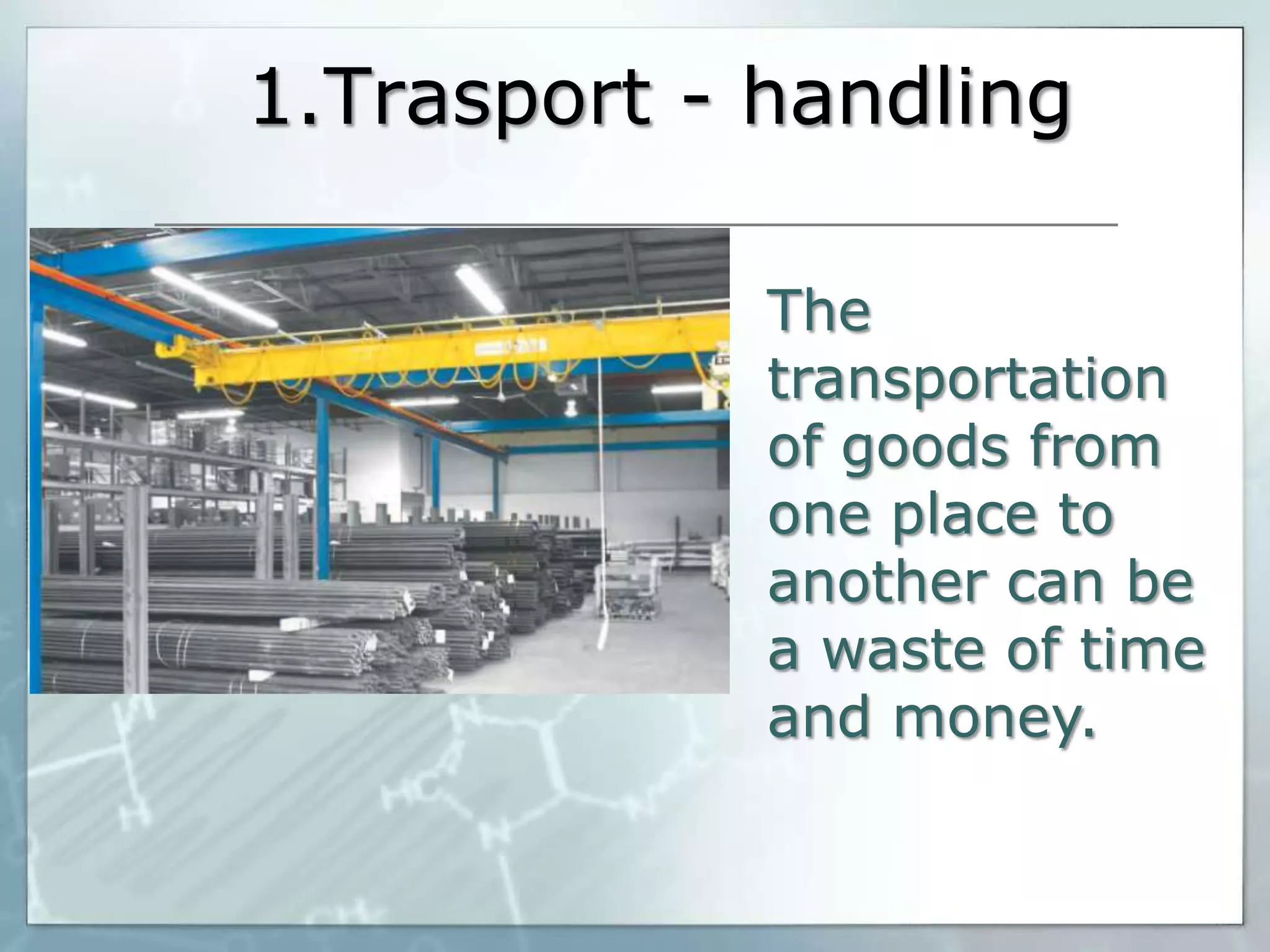

The document outlines the seven common wastes in lean management that companies need to address to improve efficiency and reduce costs. These wastes include transportation, unnecessary movement, waiting times, improper machine utilization, overproduction, and defects. Addressing these issues can lead to significant savings and improved productivity in production and services.