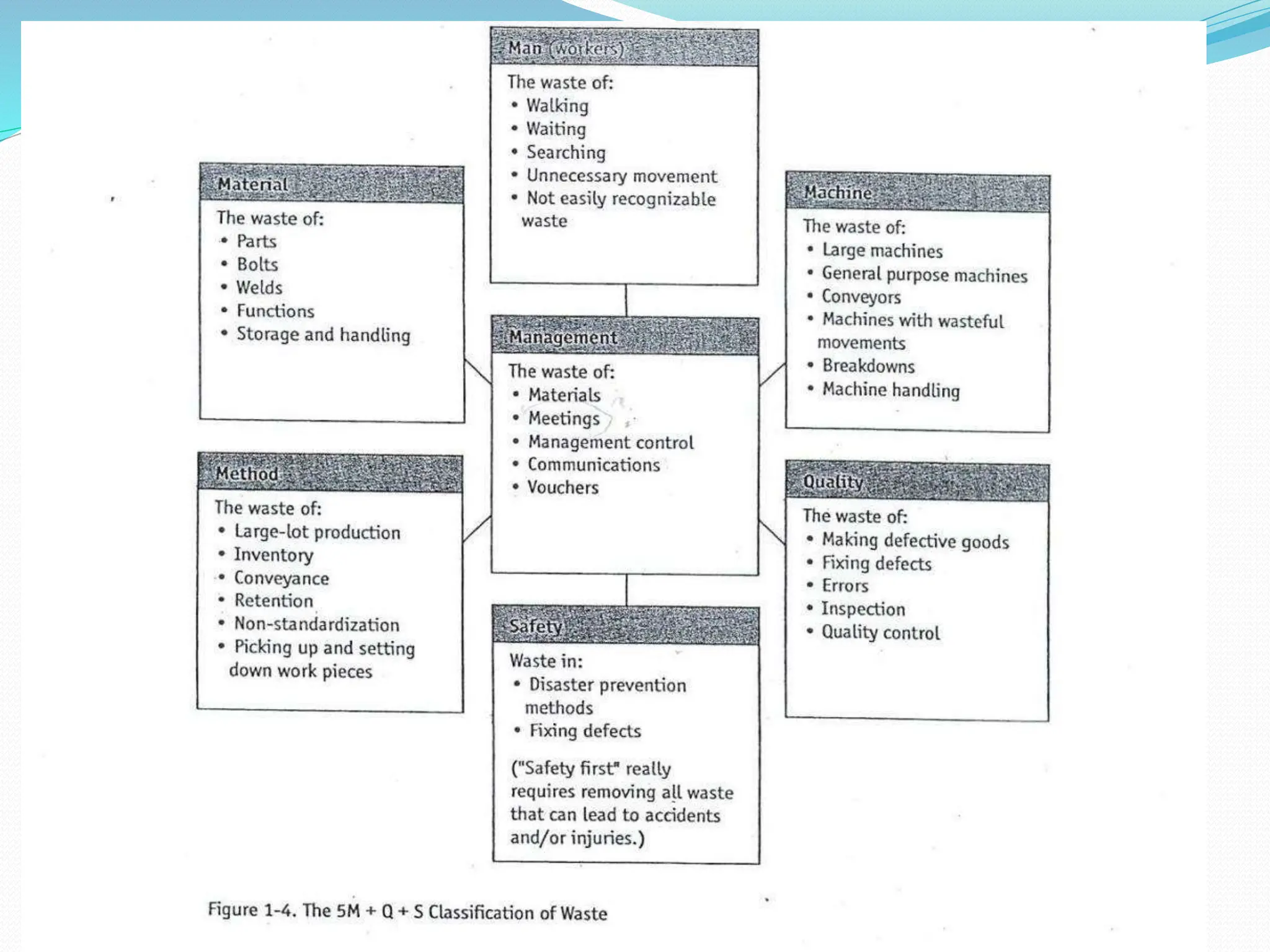

This document provides instruction on identifying and eliminating waste (muda) in the workplace. It discusses preparing a plan to identify muda and its causes and effects, such as overproduction leading to excess inventory. Tools and techniques are described for analyzing the current work situation, such as flow process charts. The seven main types of muda are identified as overproduction, inventory, motion, conveyance, waiting time, defects, and overprocessing. The document provides guidance on implementing lean principles to minimize waste.