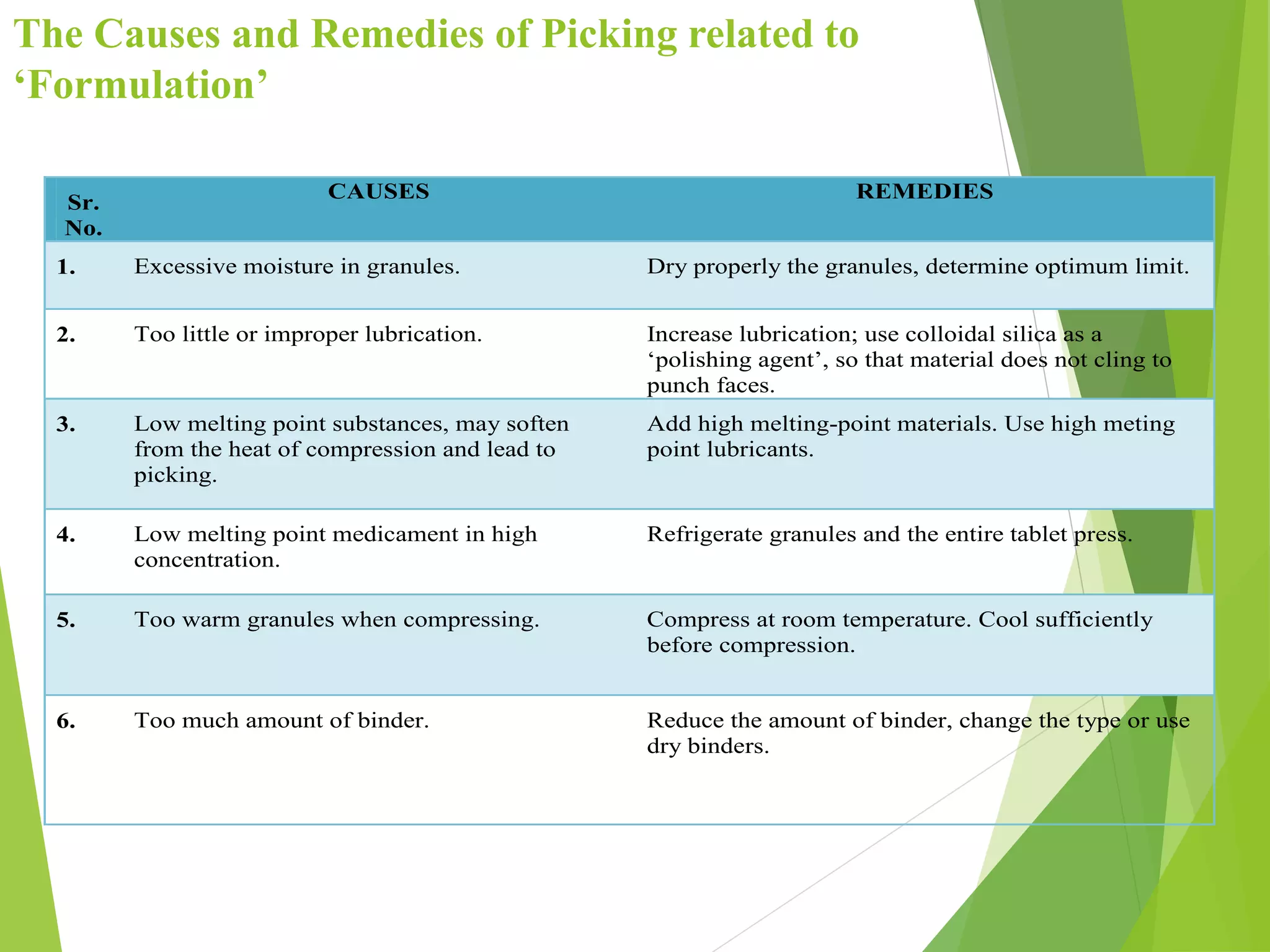

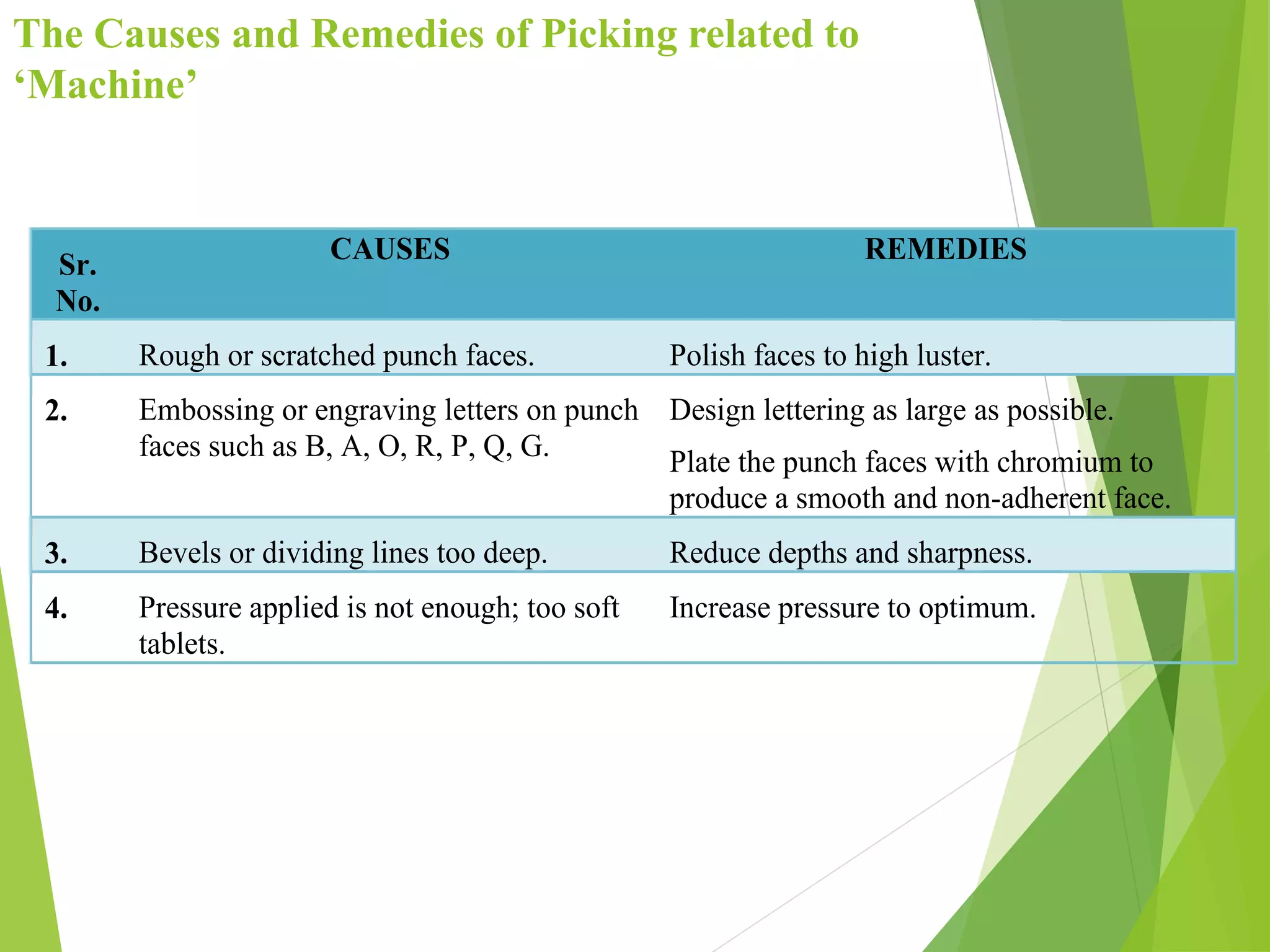

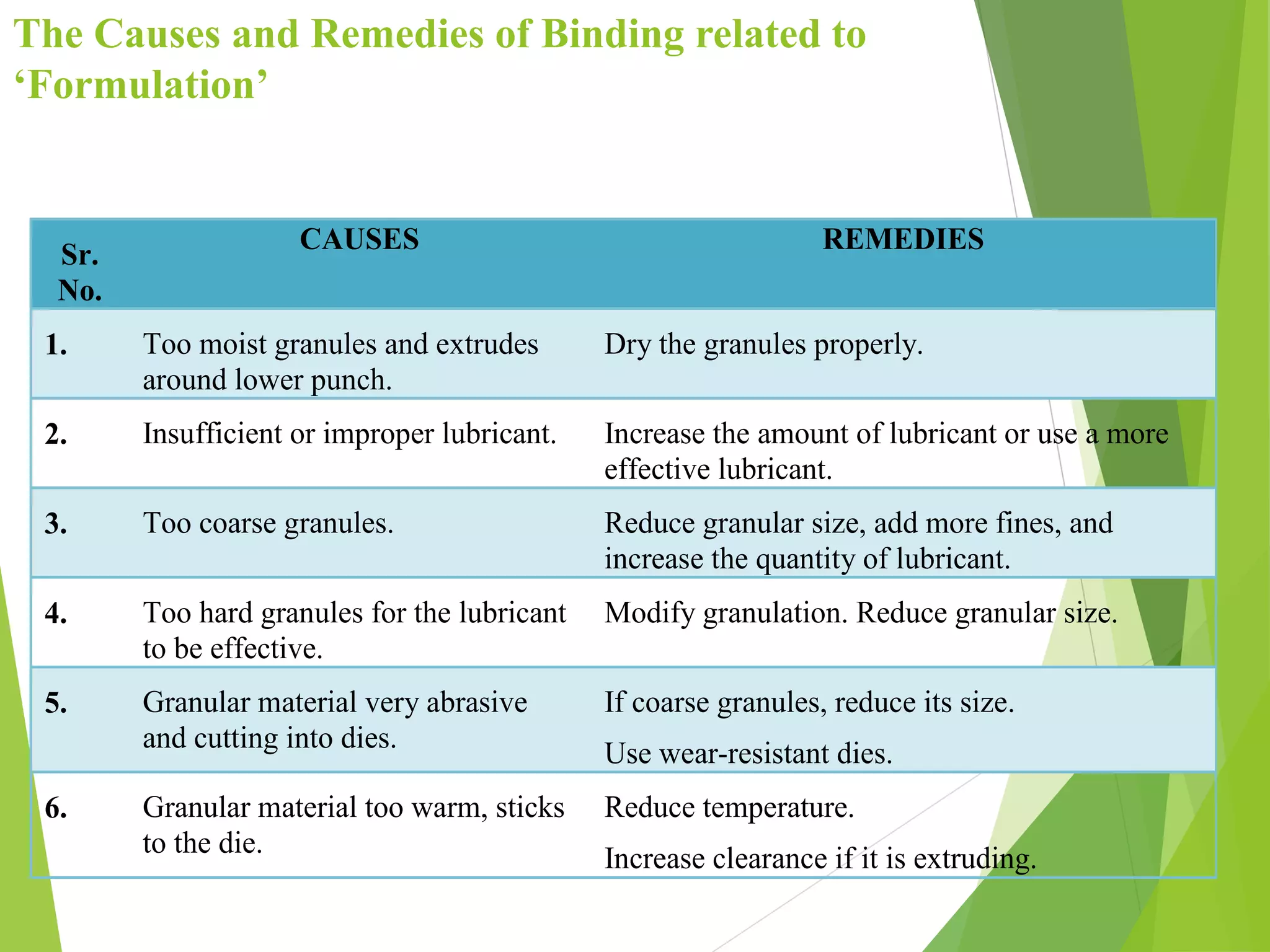

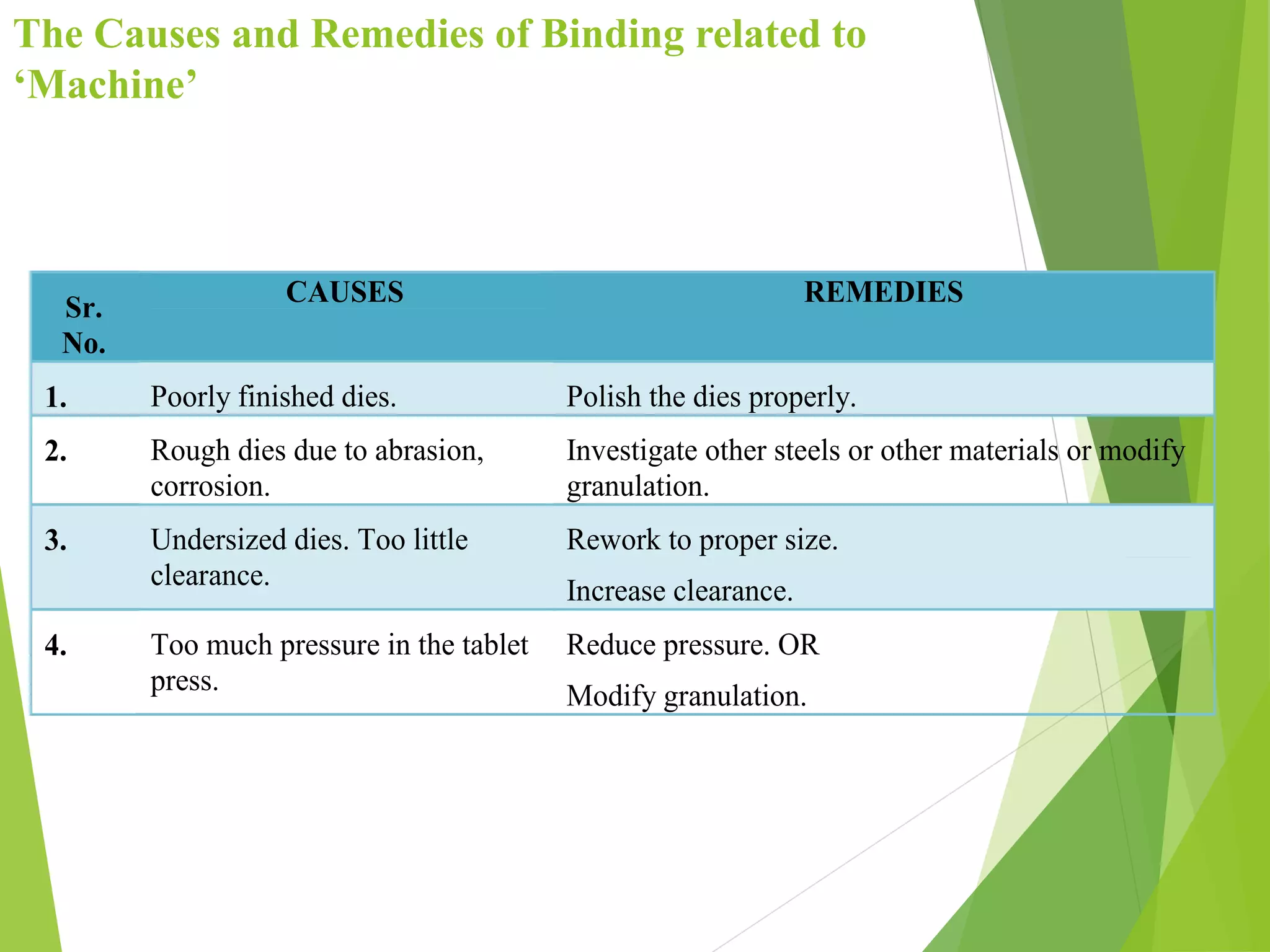

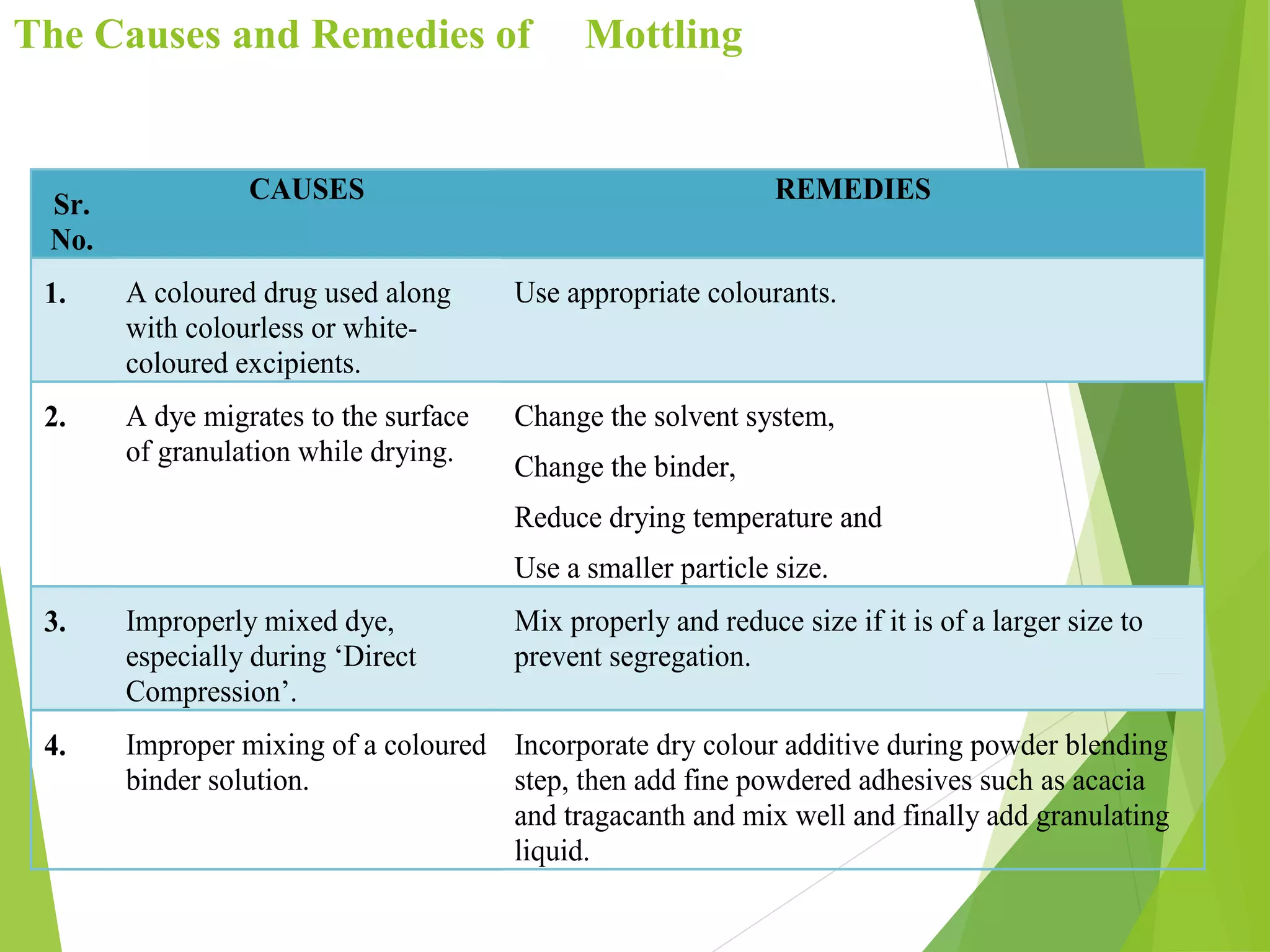

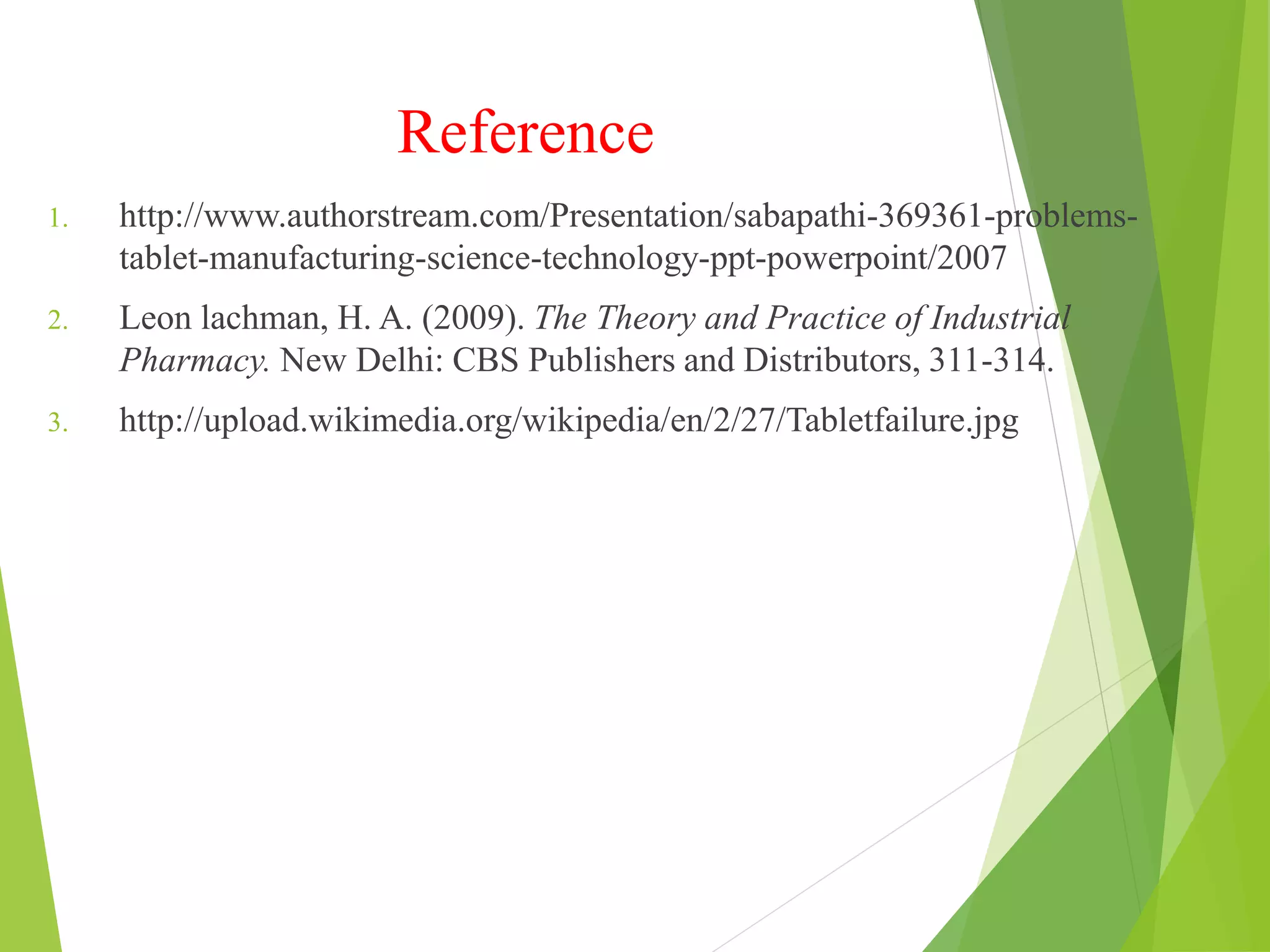

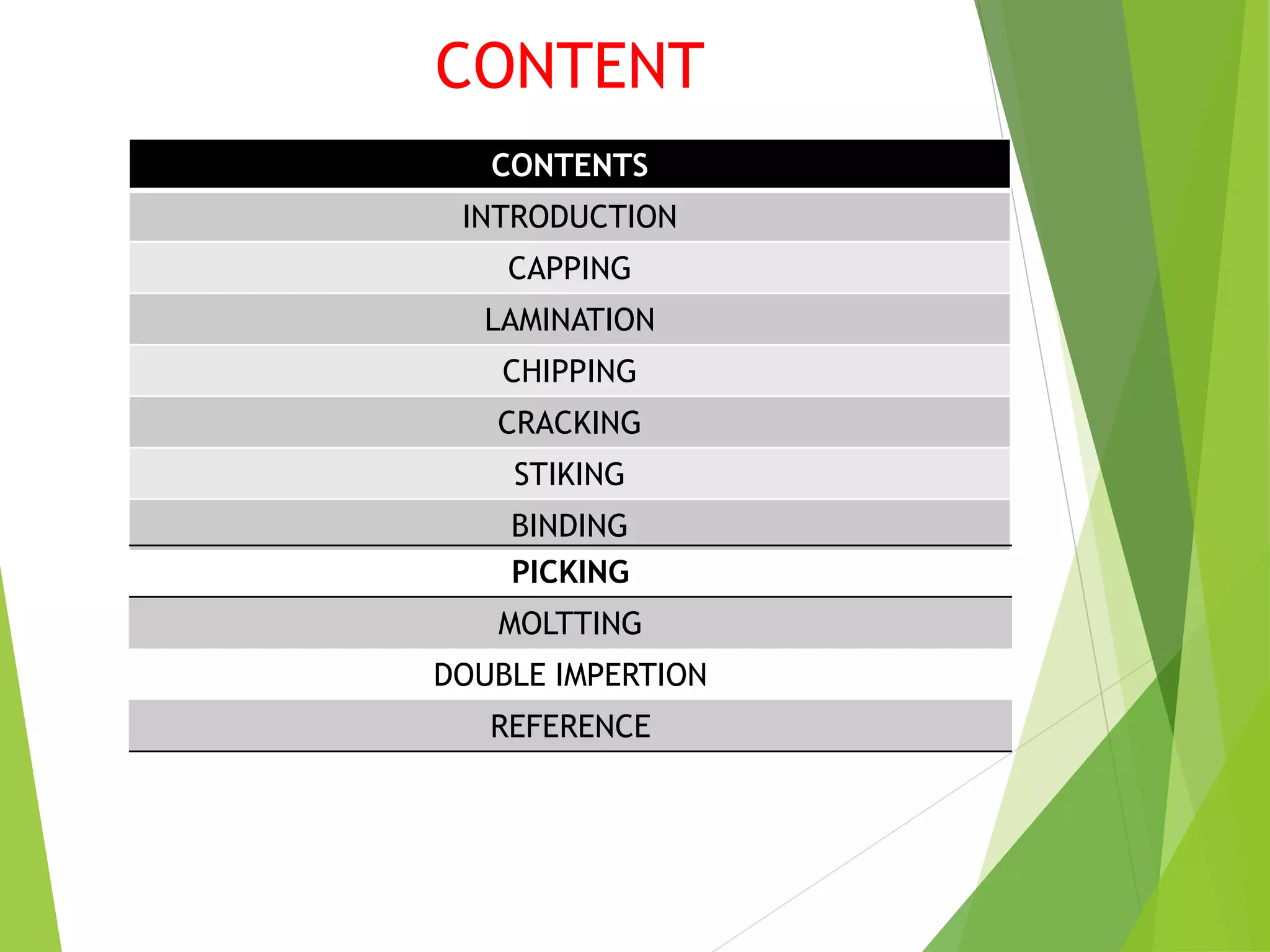

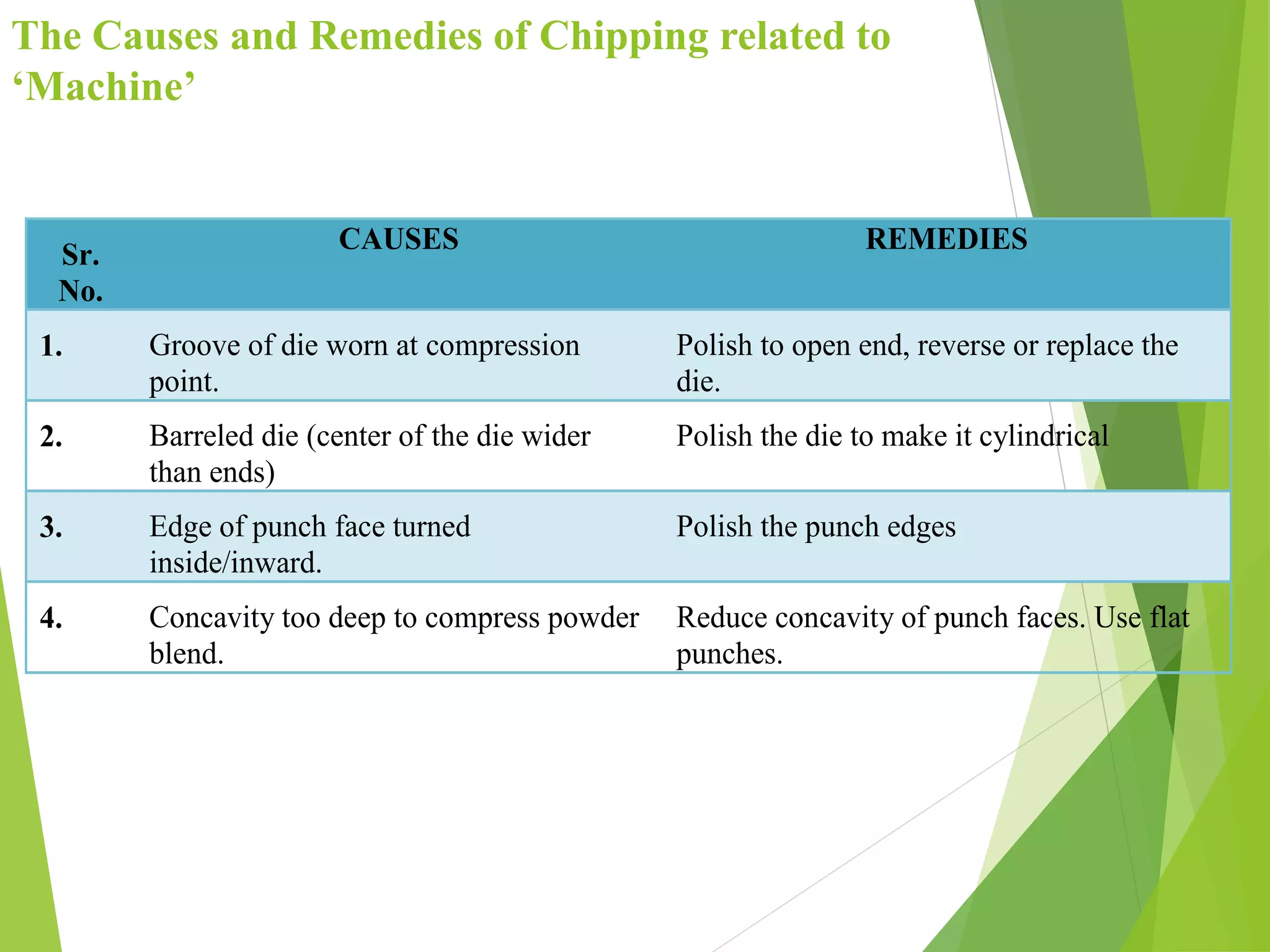

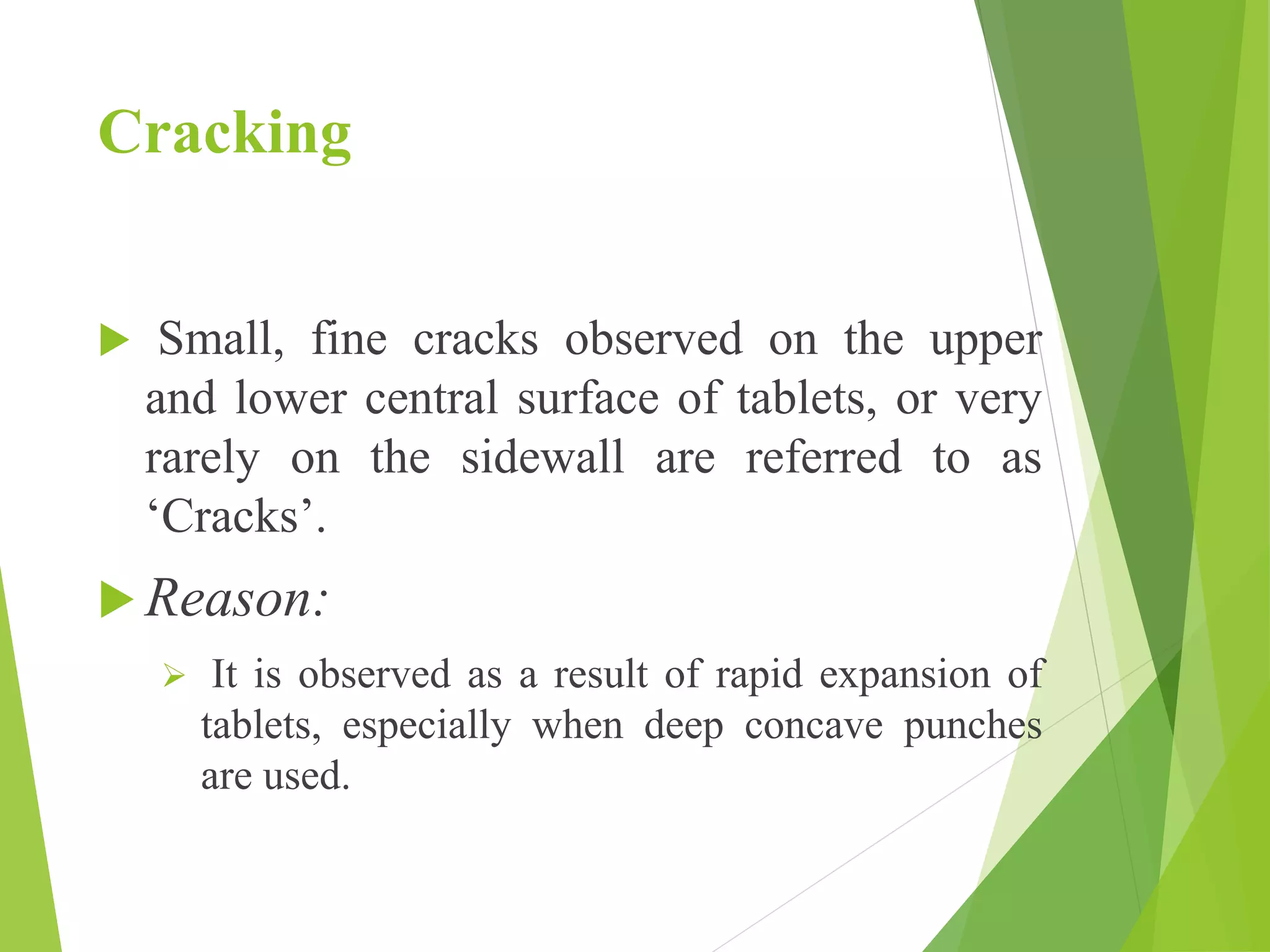

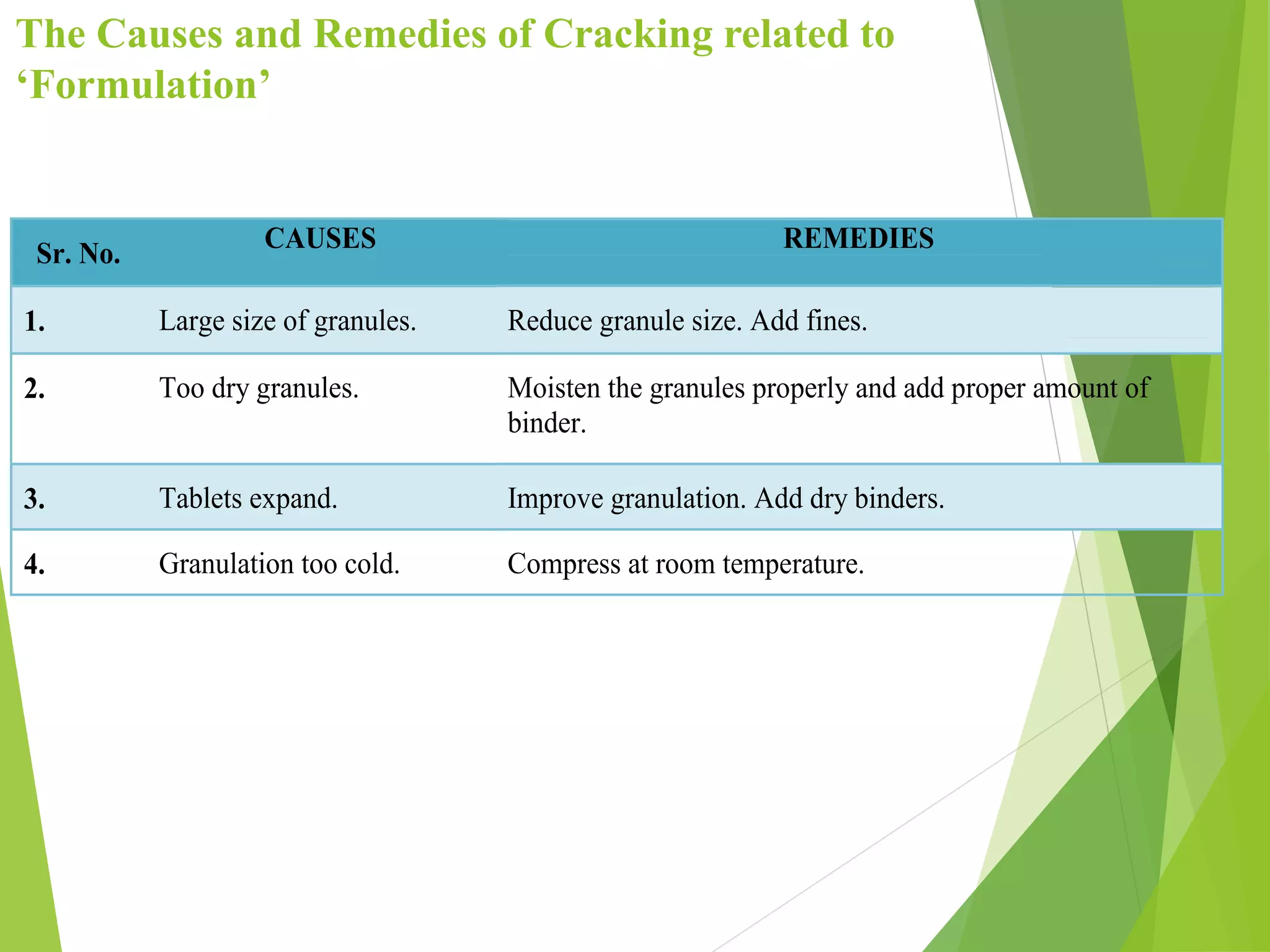

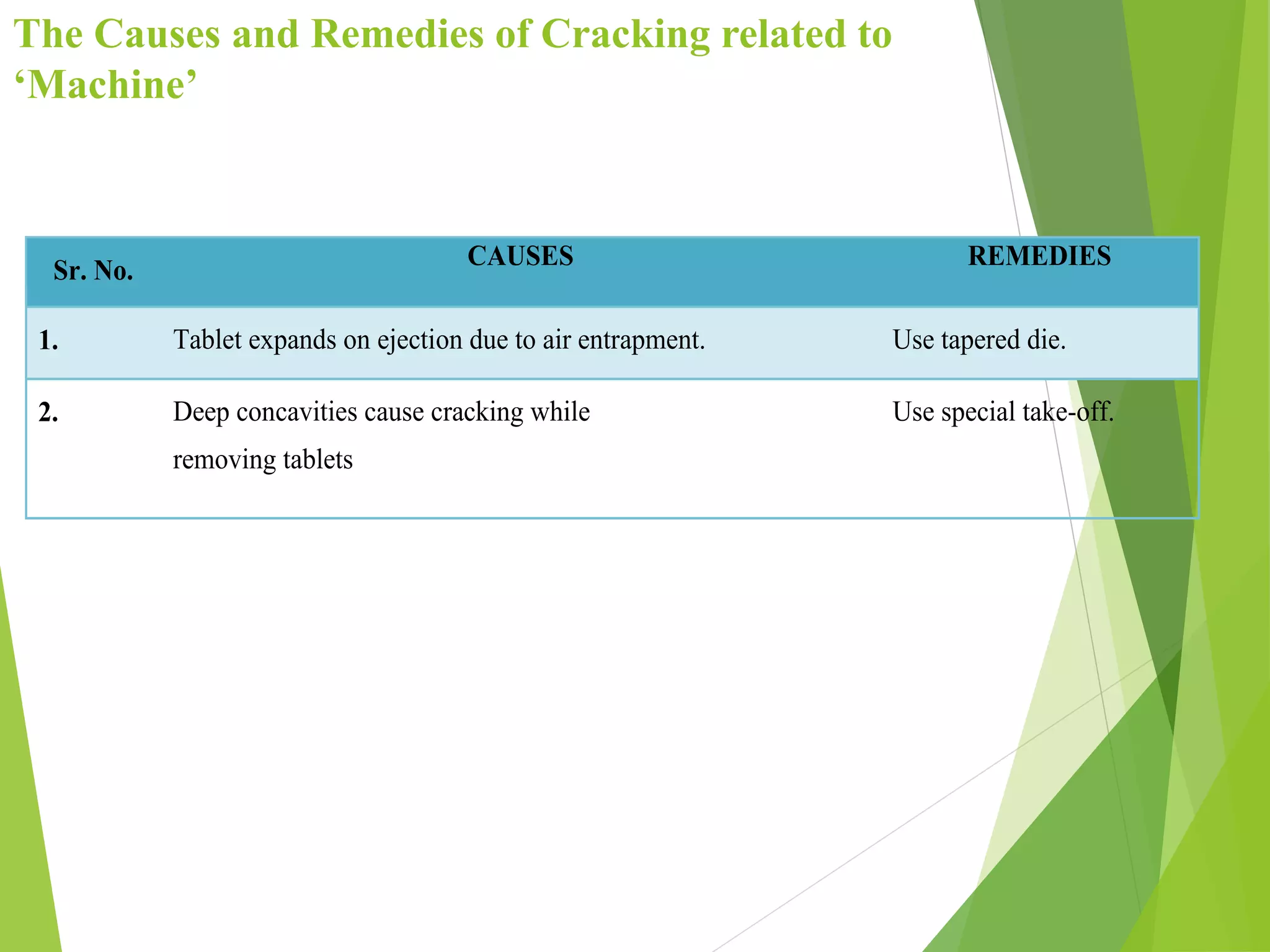

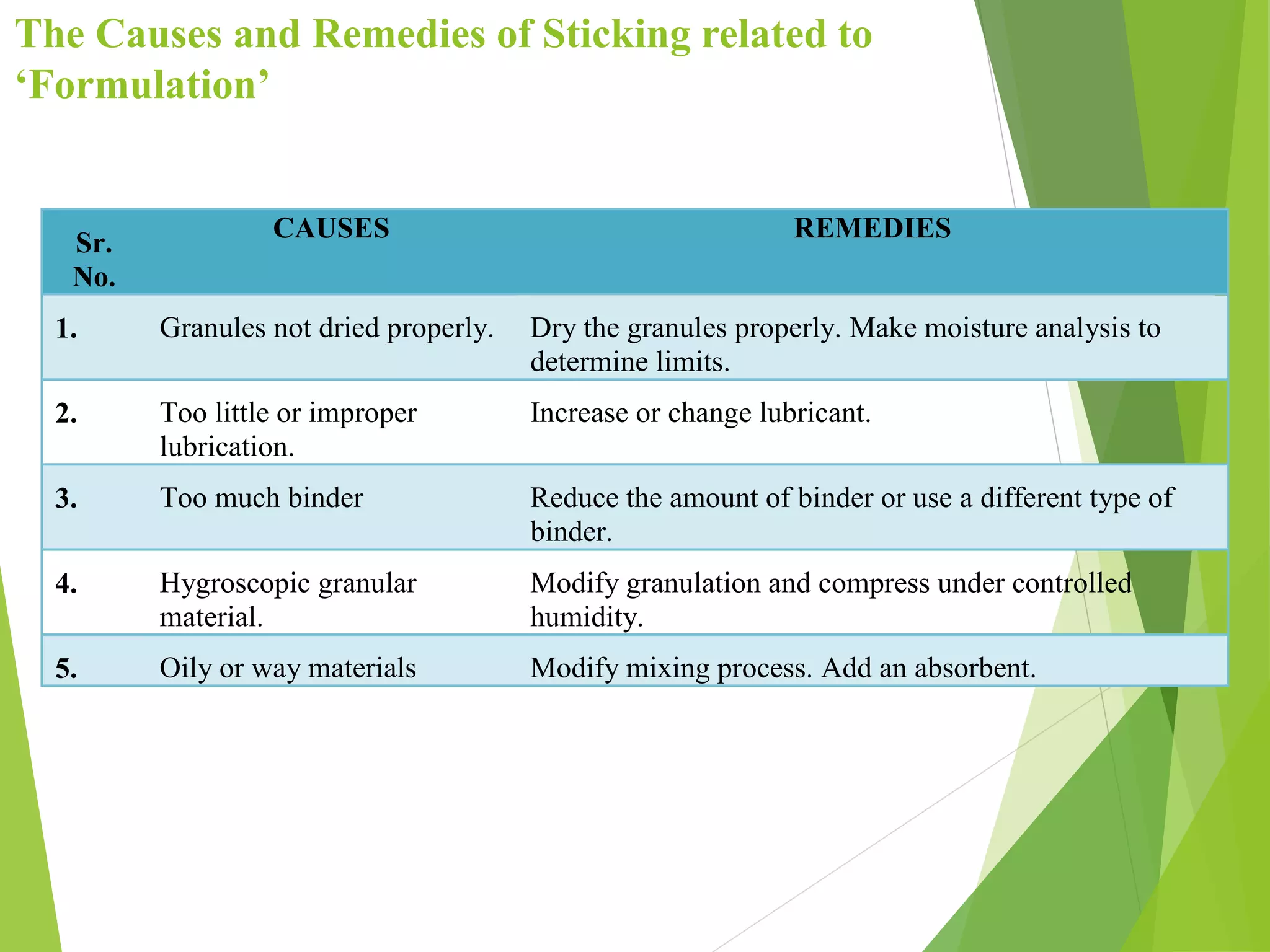

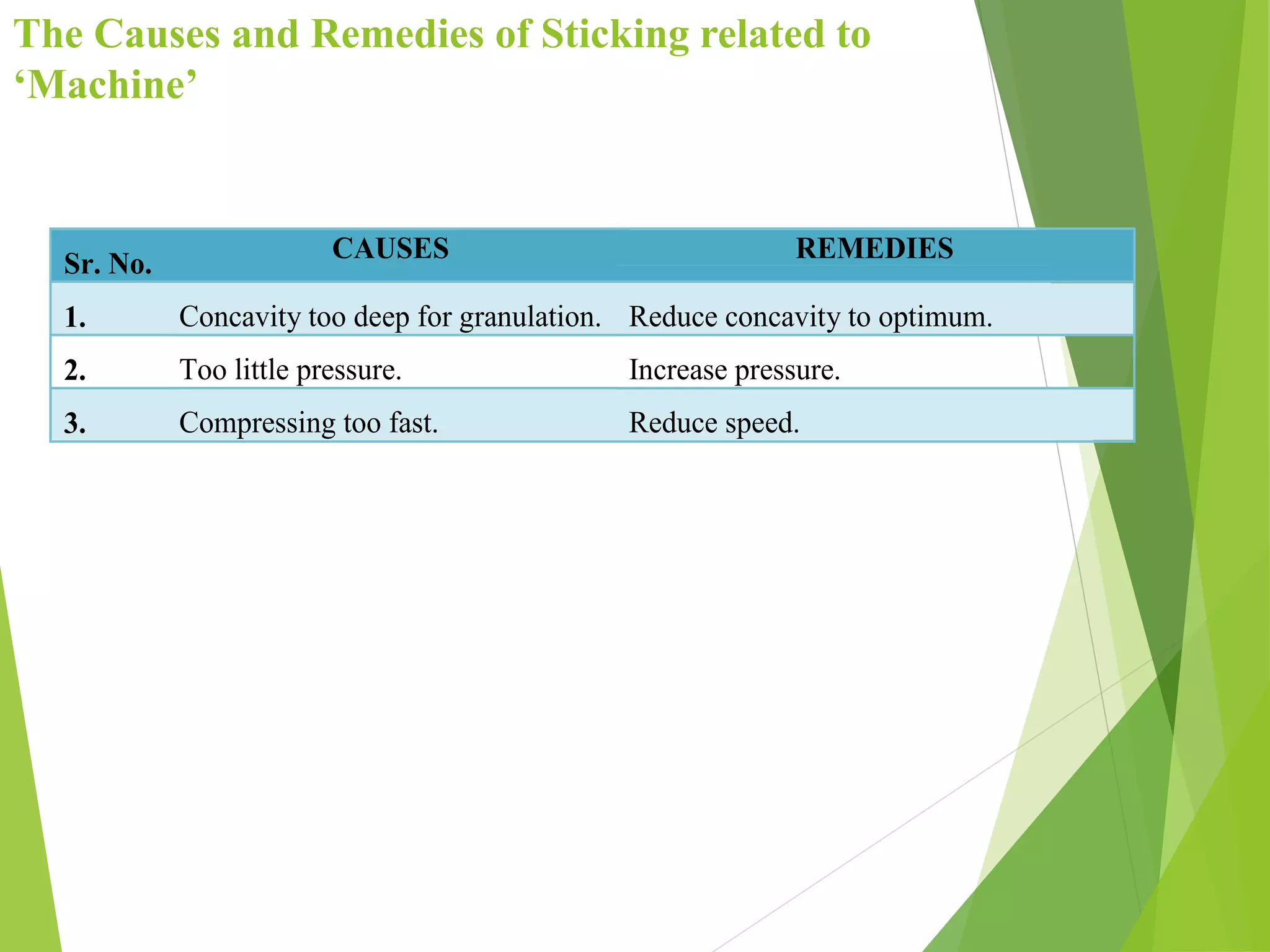

This document discusses various visual defects that can occur during tablet processing, including capping, lamination, chipping, cracking, sticking, picking, binding, and double impression. For each defect, the document describes the causes related to formulation, processing, and machine settings, and provides potential remedies. Some common causes mentioned are insufficient or improper binders/lubricants, too dry or moist granules, deep die concavities, worn dies, and improper machine settings. Suggested remedies include modifying the formulation, drying the granules, increasing binder/lubricant amounts, adjusting machine settings, and replacing worn parts.

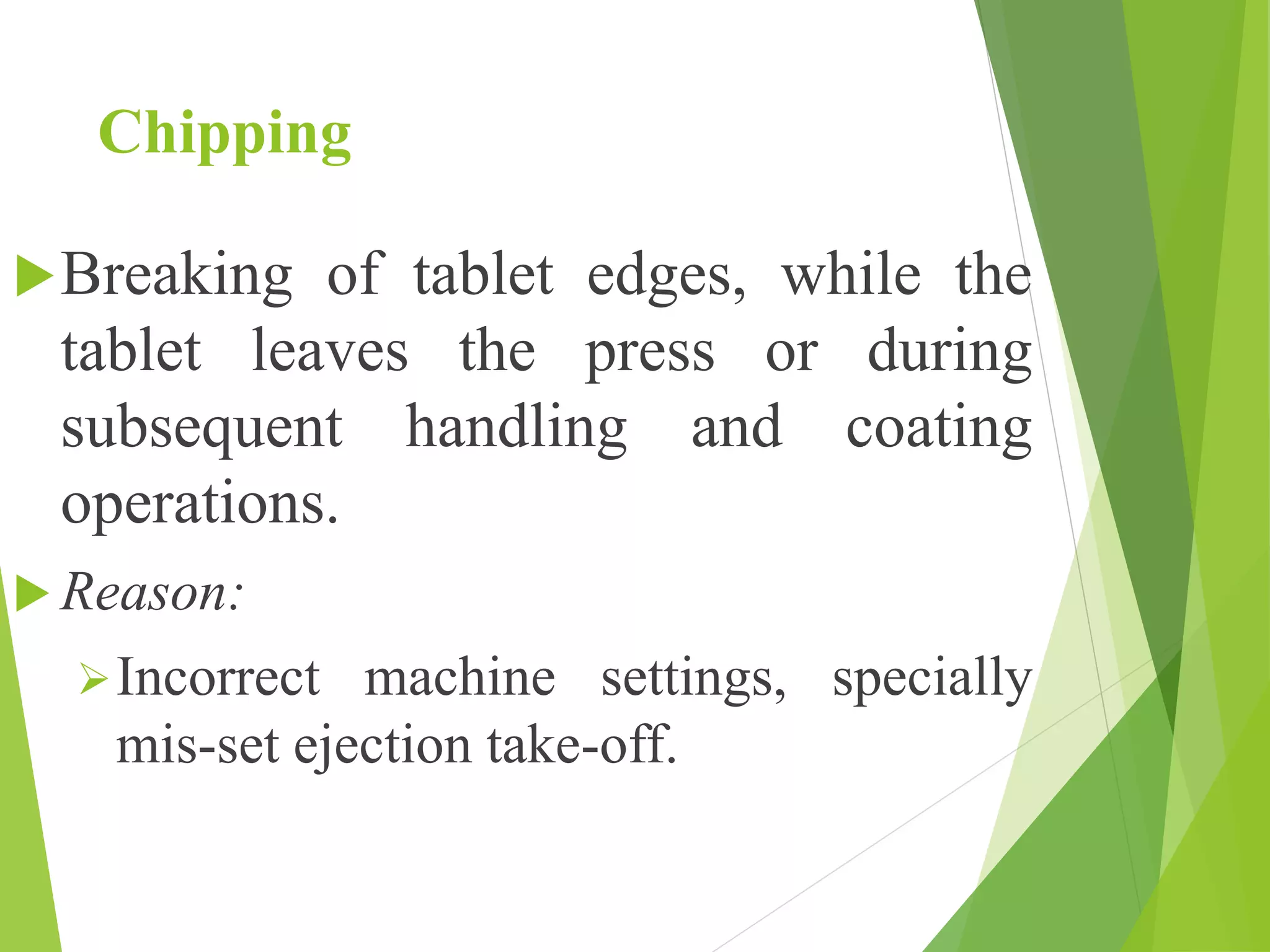

![ The Imperfections known as: ‘VISUAL

DEFECTS’ are either related to

Imperfections in any one or more of the

following factors[1]:

I. Formulation design

II. Tableting process

III. Machine](https://image.slidesharecdn.com/defectsintablet-150319035121-conversion-gate01/75/Defects-in-tablet-5-2048.jpg)

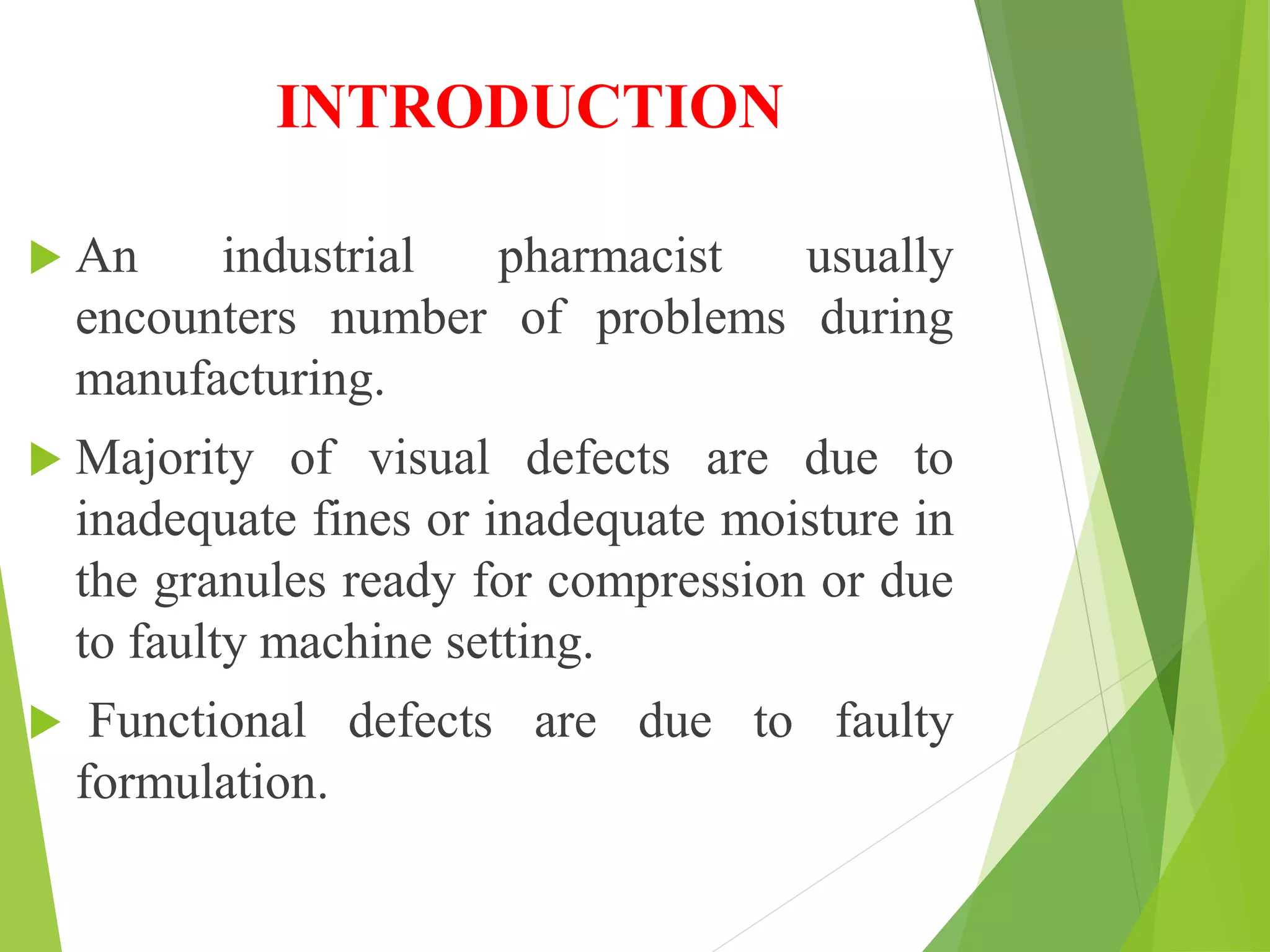

![Capping

The upper or lower segment of the tablet separates

horizontally, either partially or completely from the

main body and comes off as a cap, during ejection from

the tablet press, or during subsequent handling.

Reason:

Due to the air–entrapment in a compact during compression,

and subsequent expansion of tablet on ejection of a tablet

from a die.

Fig: Capping [1]](https://image.slidesharecdn.com/defectsintablet-150319035121-conversion-gate01/75/Defects-in-tablet-7-2048.jpg)

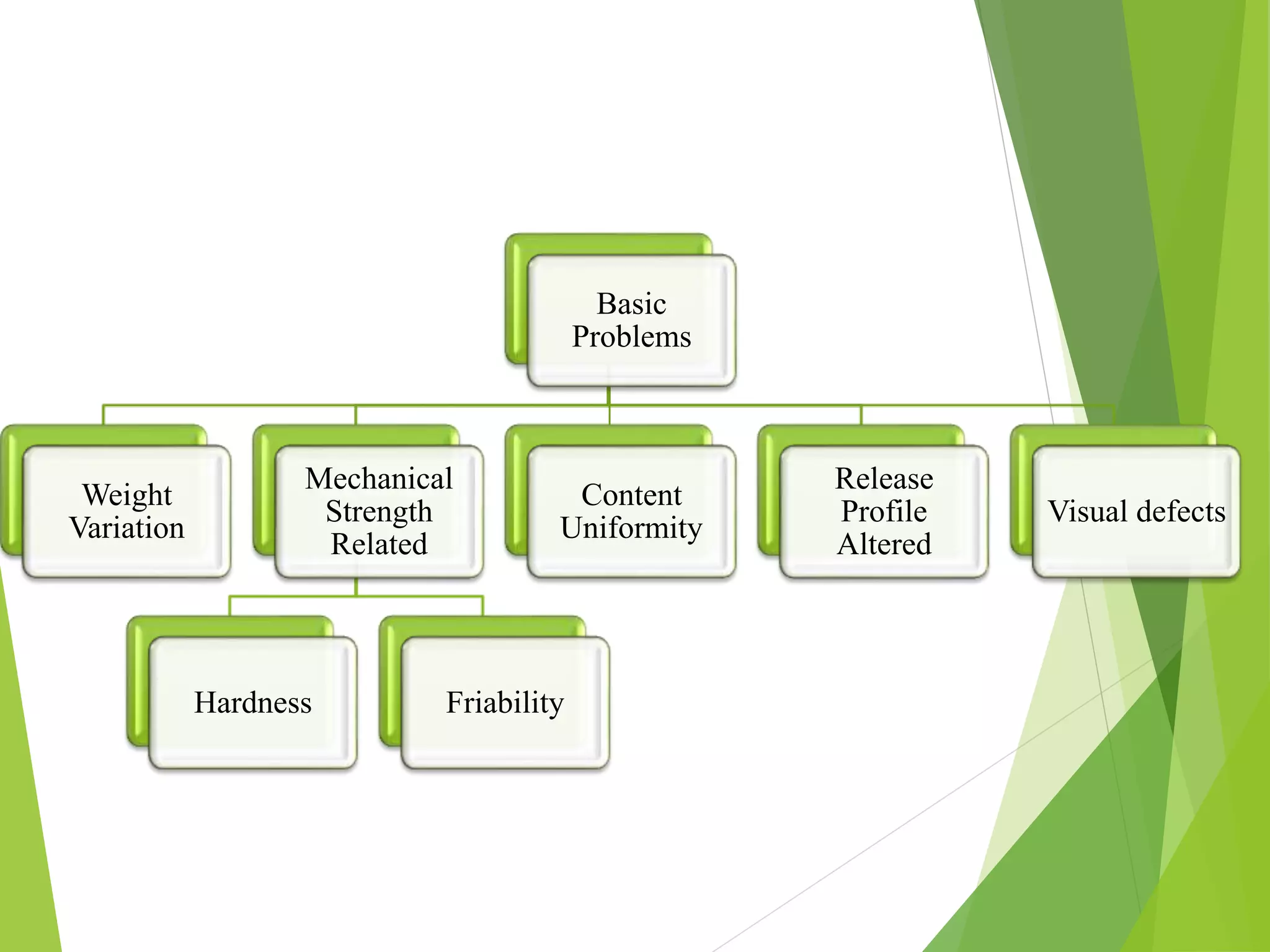

![Lamination

Separation of a tablet into two or more distinct

horizontal layers.

Reason:

Air–entrapment during compression and

subsequent release on ejection.

The condition is exaggerated by higher speed of

turret.

Fig: Lamination[1]](https://image.slidesharecdn.com/defectsintablet-150319035121-conversion-gate01/75/Defects-in-tablet-10-2048.jpg)

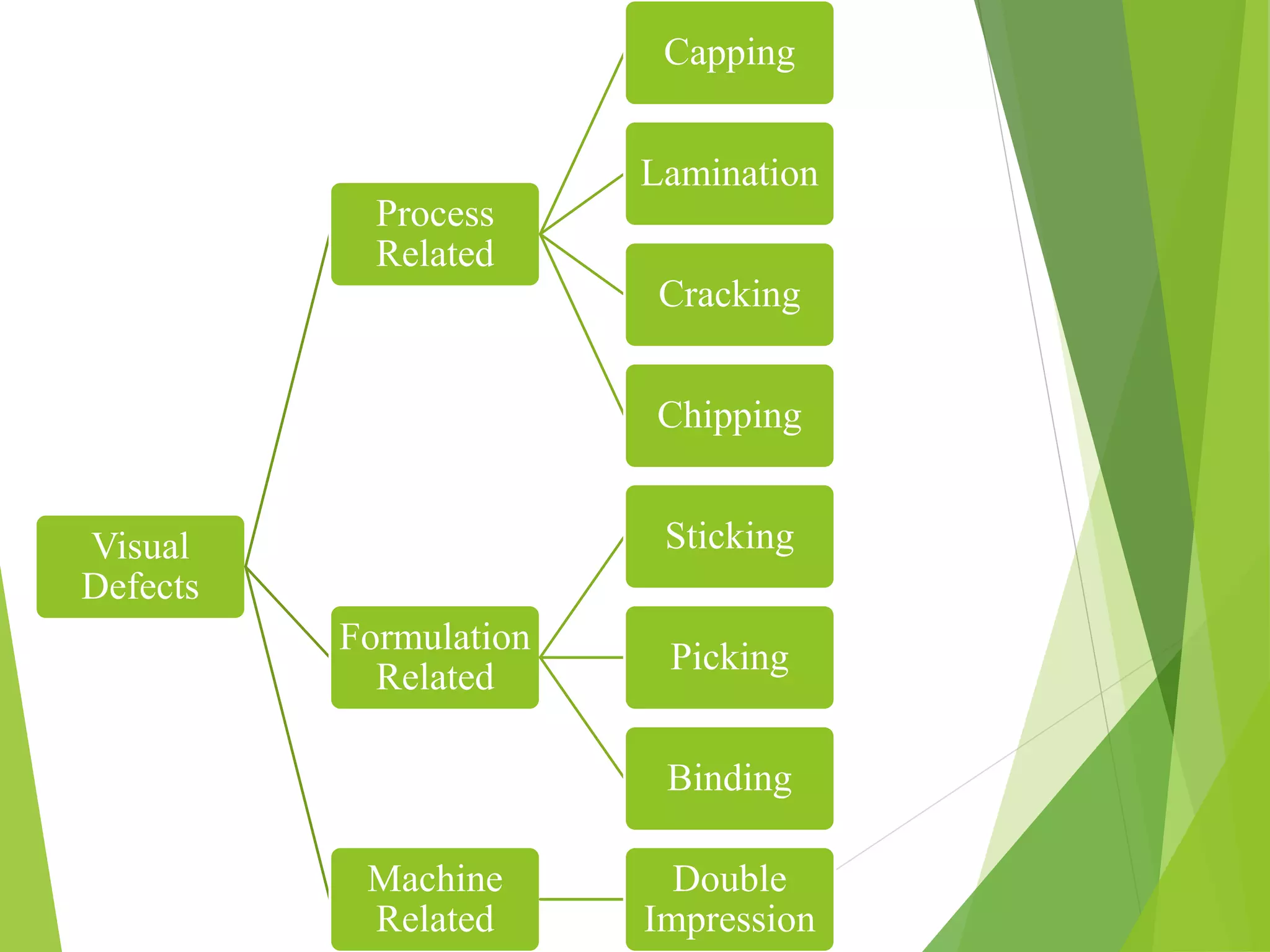

![Sticking

Tablet material adhering to the die wall.

Filming is a slow form of sticking and is

largely due to excess moisture in the

granulation.

Reason:

Improperly dried or improperly lubricated

granules.

Fig: Sticking on punch face[6]](https://image.slidesharecdn.com/defectsintablet-150319035121-conversion-gate01/75/Defects-in-tablet-19-2048.jpg)

![Picking

Small amount of material from a tablet is sticking to and

being removed off from the tablet-surface by a punch

face.

The problem is more prevalent on the upper punch faces

than on the lower ones.

Fig: Picking[1]](https://image.slidesharecdn.com/defectsintablet-150319035121-conversion-gate01/75/Defects-in-tablet-22-2048.jpg)