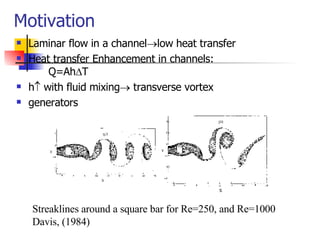

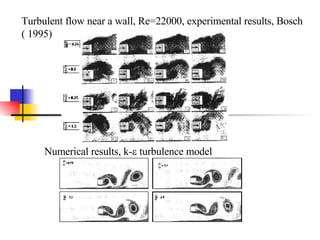

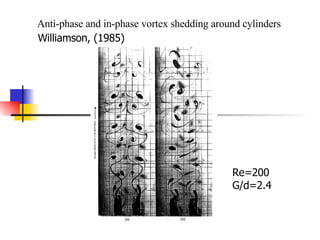

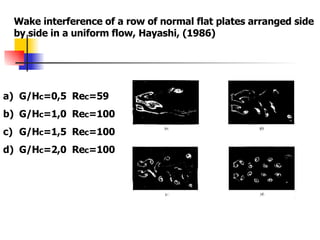

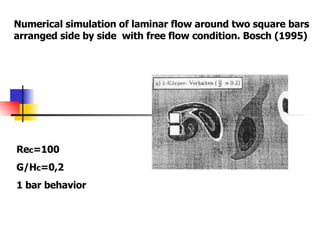

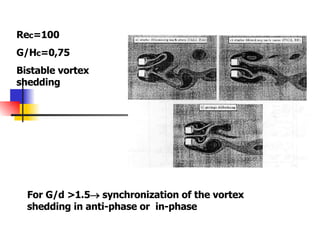

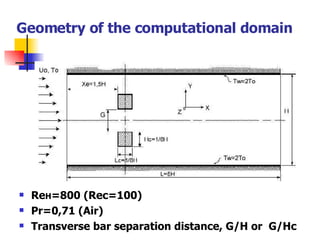

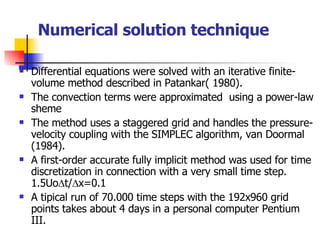

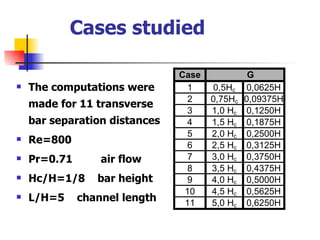

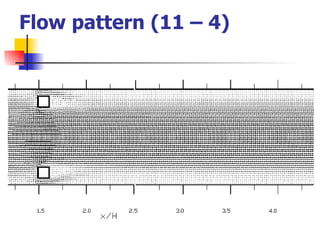

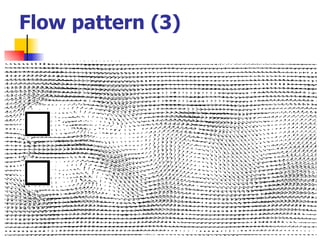

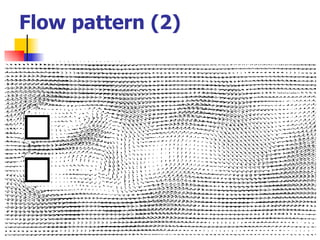

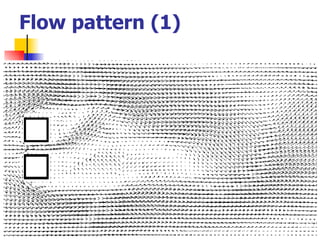

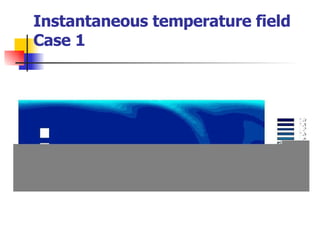

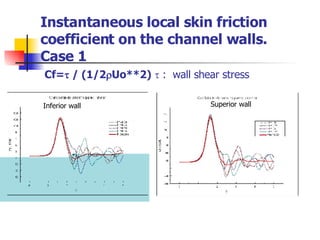

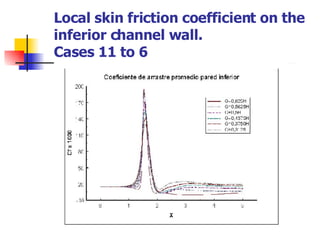

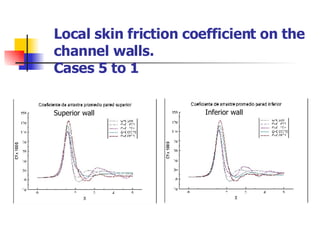

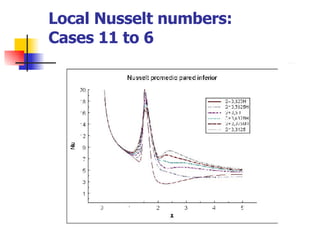

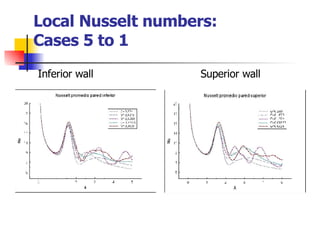

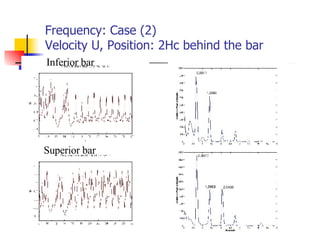

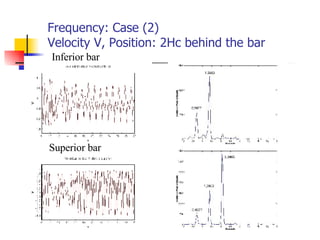

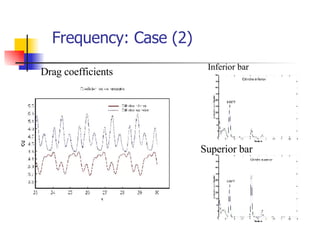

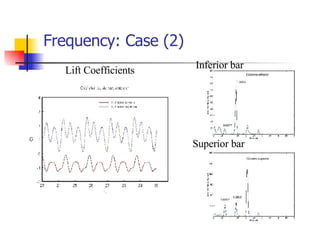

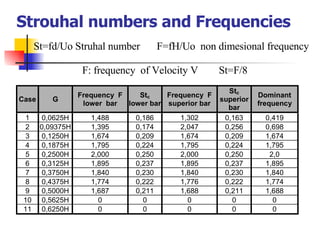

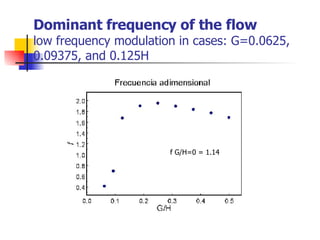

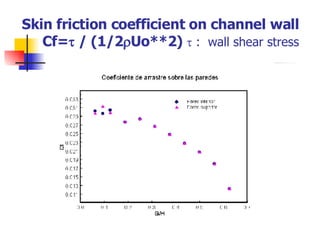

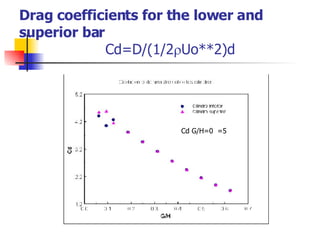

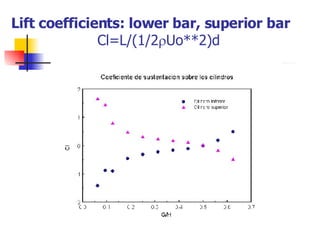

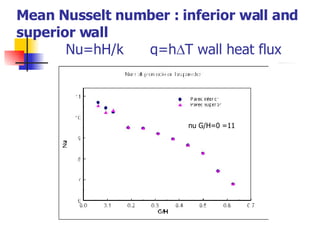

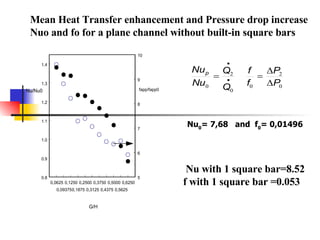

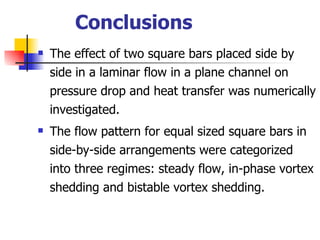

Professor Alvaro Valencia from the University of Chile studied laminar unsteady flow and heat transfer in a confined channel with square bars arranged side by side through numerical simulation. The study categorized flow patterns into three regimes based on the bar separation distance and examined the effects on pressure drop, heat transfer, and vortex shedding frequency. Results showed that local and overall heat transfer on channel walls increased significantly due to unsteady vortex shedding induced by the bars.

![References [1] H. Suzuki, Y. Inoue, T. Nishimura, K. Fukutani, k. Suzuki, Unsteady flow in a channel obstructed by a square rod (crisscross motion of vortex). International Journal of Heat and Fluid Flow 14 (1993) 2-9. [2] A. K. Saha, K. Muralidhar, G. Biswas, Transition and chaos in two-dimensional flow past a square cylinder, Journal of Engineering Mechanics, 126, (2000), 523-532. [3] M. Breuer, J. Bernsdorf, T. Zeiser, F. Durst, Accurate computations of the laminar flow past a square cylinder based on two different methods: lattice-Boltzmann and finite-volume, International Journal of Heat and Fluid Flow, 21, (2000), 186-196. [4] J. L Rosales, A. Ortega, J.A.C. Humphrey, A numerical simulation of the convective heat transfer in confined channel flow past square cylinders: comparison of inline and offset tandem pairs, International Journal of Heat and Mass Transfer, 44, (2001), 587-603. [5] K. Tatsutani, R. Devarakonda, J.A.C. Humphrey, Unsteady flow and heat transfer for cylinder pairs in a channel, International Journal of Heat and Mass Transfer, 36, (1993), 3311-3328. [6] A. Valencia, Numerical study of self-sustained oscillatory flows and heat transfer in channels with a tandem of transverse vortex generators, Heat and Mass Transfer, 33, (1998), 465-470. [7] D. Sumner, S.J. Price, M.P. Païdoussis, Flow-pattern identification for two staggered circular cylinders in cross-flow, Journal of Fluid Mechanics, 411, (2000), 263-303. [8] C.H.K. Williamson, Evolution of a single wake behind a pair of bluff bodies, Journal of Fluid Mechanics, 159, (1985), 1-18. [9] J.J. Miau, H.B. Wang, J.H. Chou, Flopping phenomenon of flow behind two plates placed side-by-side normal to the flow direction, Fluid Dynamics Research, 17, (1996), 311-328. [10] M. Hayashi, A. Sakurai, Wake interference of a row of normal flat plates arranged side by side in a uniform flow, Journal of Fluid Mechanics, 164, (1986), 1-25. [11] S.C. Luo, L.L. Li, D.A. Shah, Aerodynamic stability of the downstream of two tandem square-section cylinders, Journal of Wind Engineering and Industrial Aerodynamics, 79, (1999), 79-103. [12] G. Bosch, Experimentelle und theoretische Untersuchung der instationären Strömung um zylindrische Strukturen, Ph.D. Dissertation, Universität Fridericiana zu Karlsruhe, Germany, (1995). [13] S. Patankar, Numerical heat transfer and fluid flow, Hemisphere Publishing Co., New York, (1980). [14] J.P. van Doormaal, G.D. Raithby, Enhancements of the SIMPLE method for predicting incompressible fluid flows. Numerical Heat Transfer, 7, (1984), 147-163.](https://image.slidesharecdn.com/laminar-flow4648/85/Laminar-Flow-46-320.jpg)