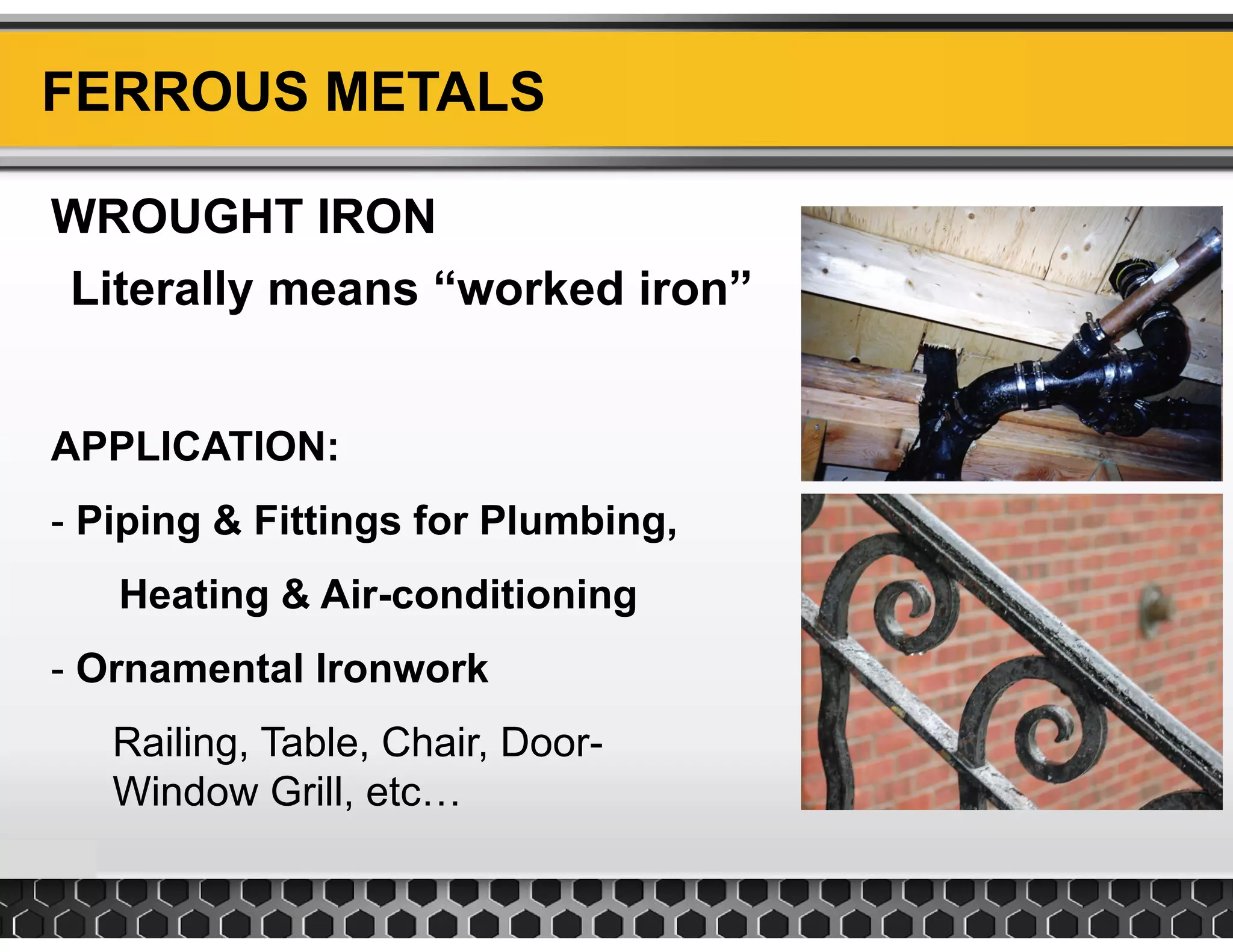

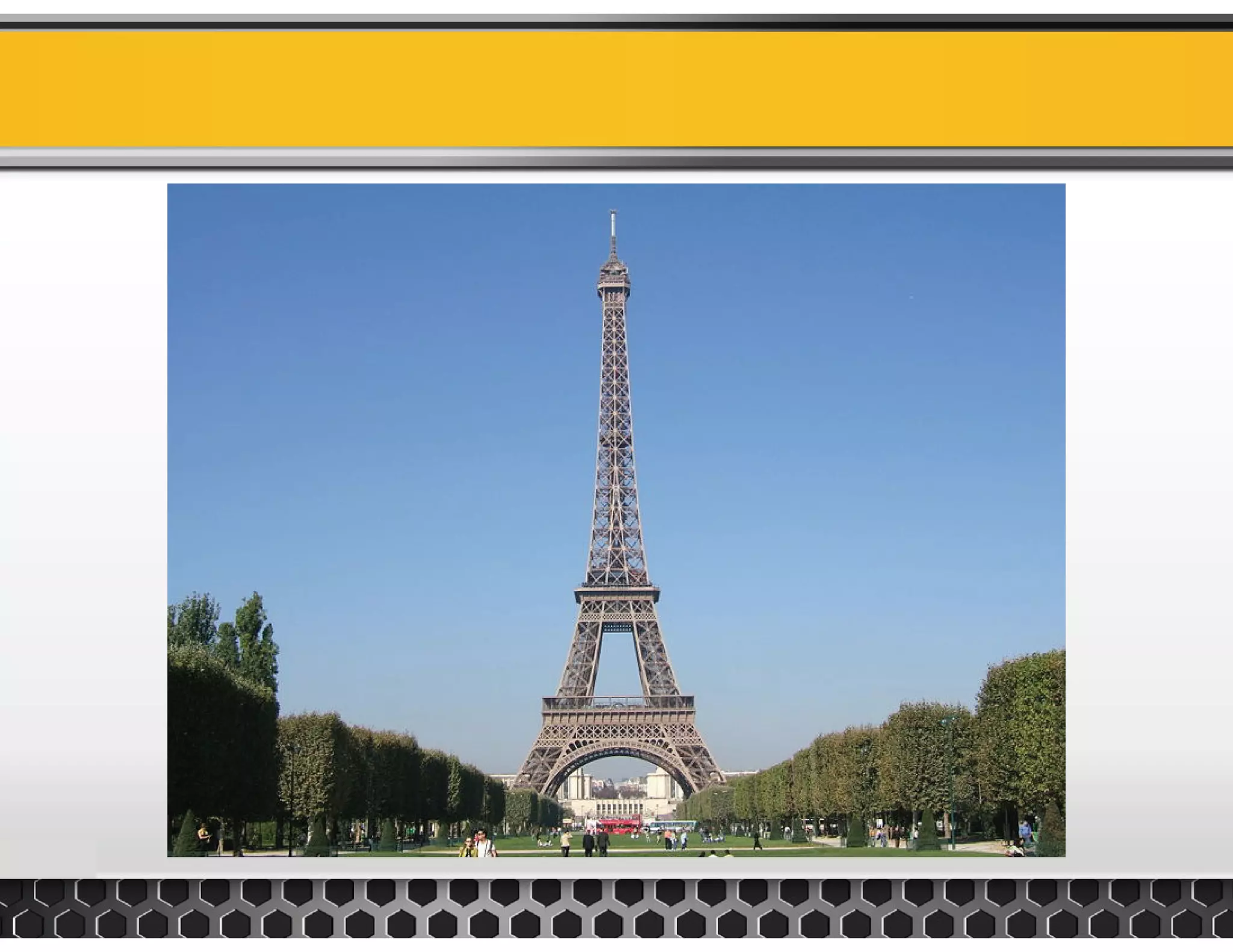

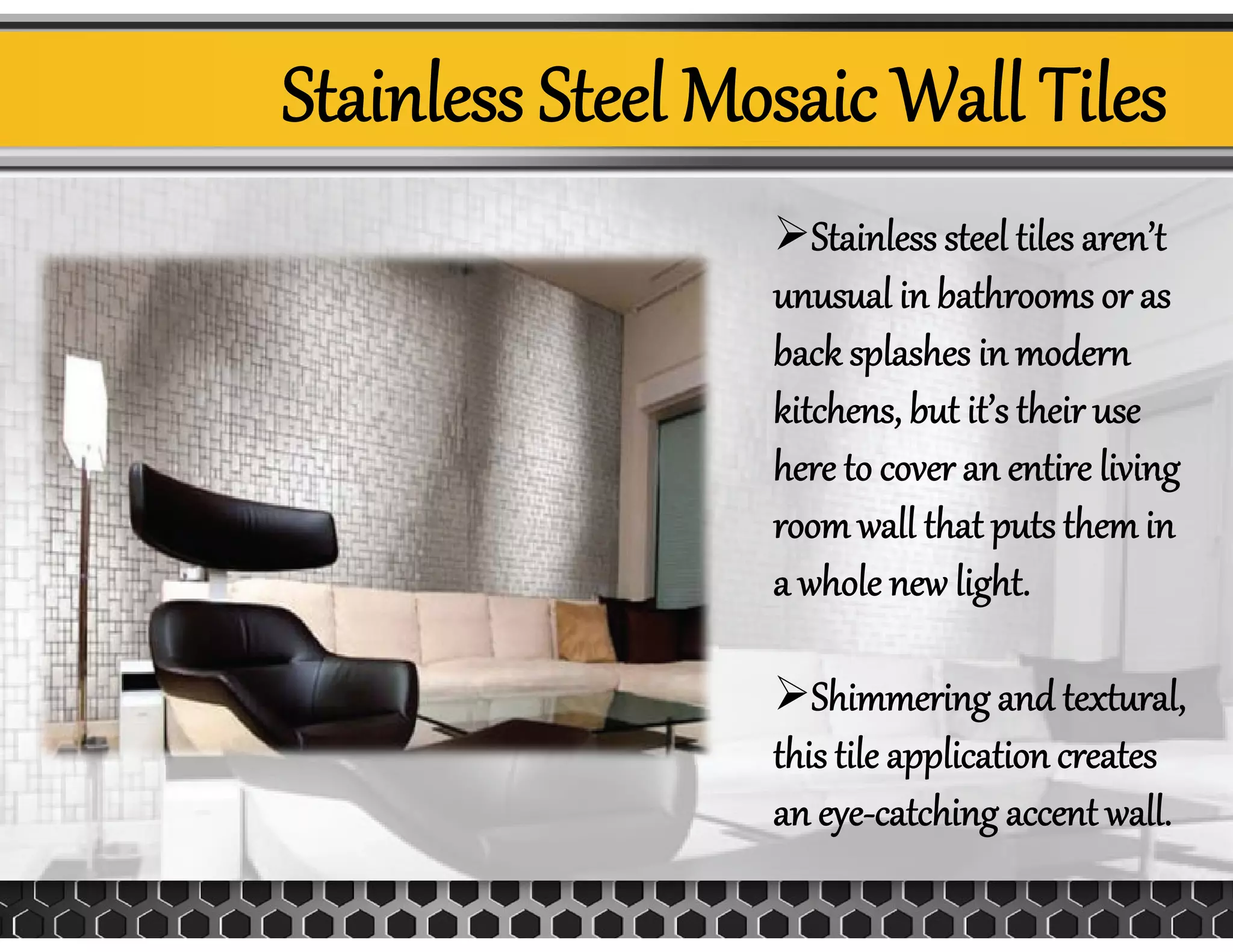

This document discusses various ferrous and non-ferrous metals used in construction. It describes steel as a primary structural building material that forms the skeleton of a building. Stainless steel is highlighted as an alloy of iron, carbon, chromium, nickel, and magnesium known for its corrosion resistance and attractive appearance due to chromium. The document also mentions aluminum, brass, copper, and lead as common non-ferrous metals used in secondary building elements and decorative applications.