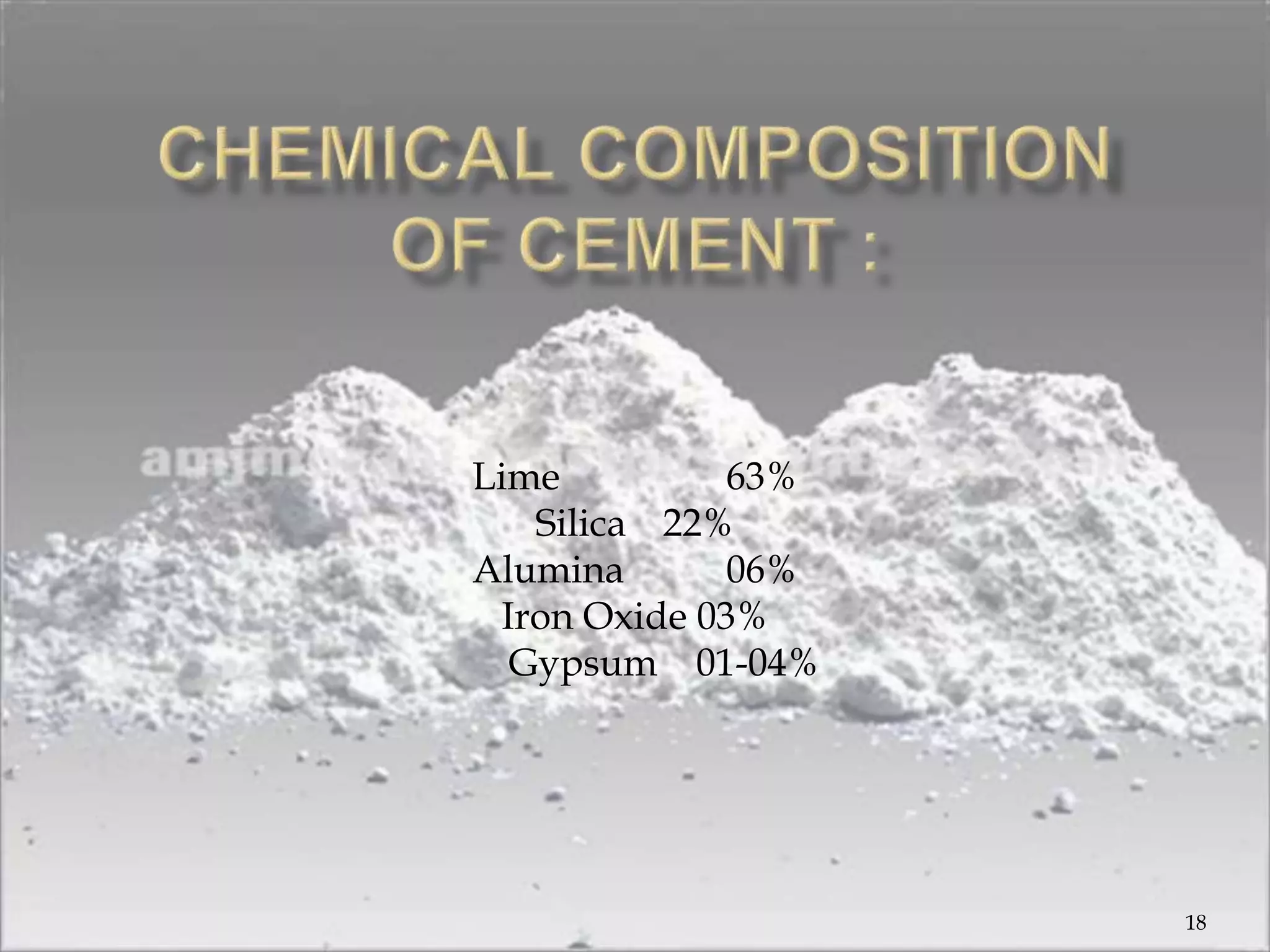

The document discusses the properties and production of concrete, highlighting the importance of water in mixing and its effects on compressive and tensile strength. It elaborates on reinforced concrete's advantages, the different types of cement and their compositions, and various concrete admixtures that enhance performance. Additionally, it covers the challenges of concrete, such as cracking and curing, alongside the increasing use of super plasticizers in modern construction.