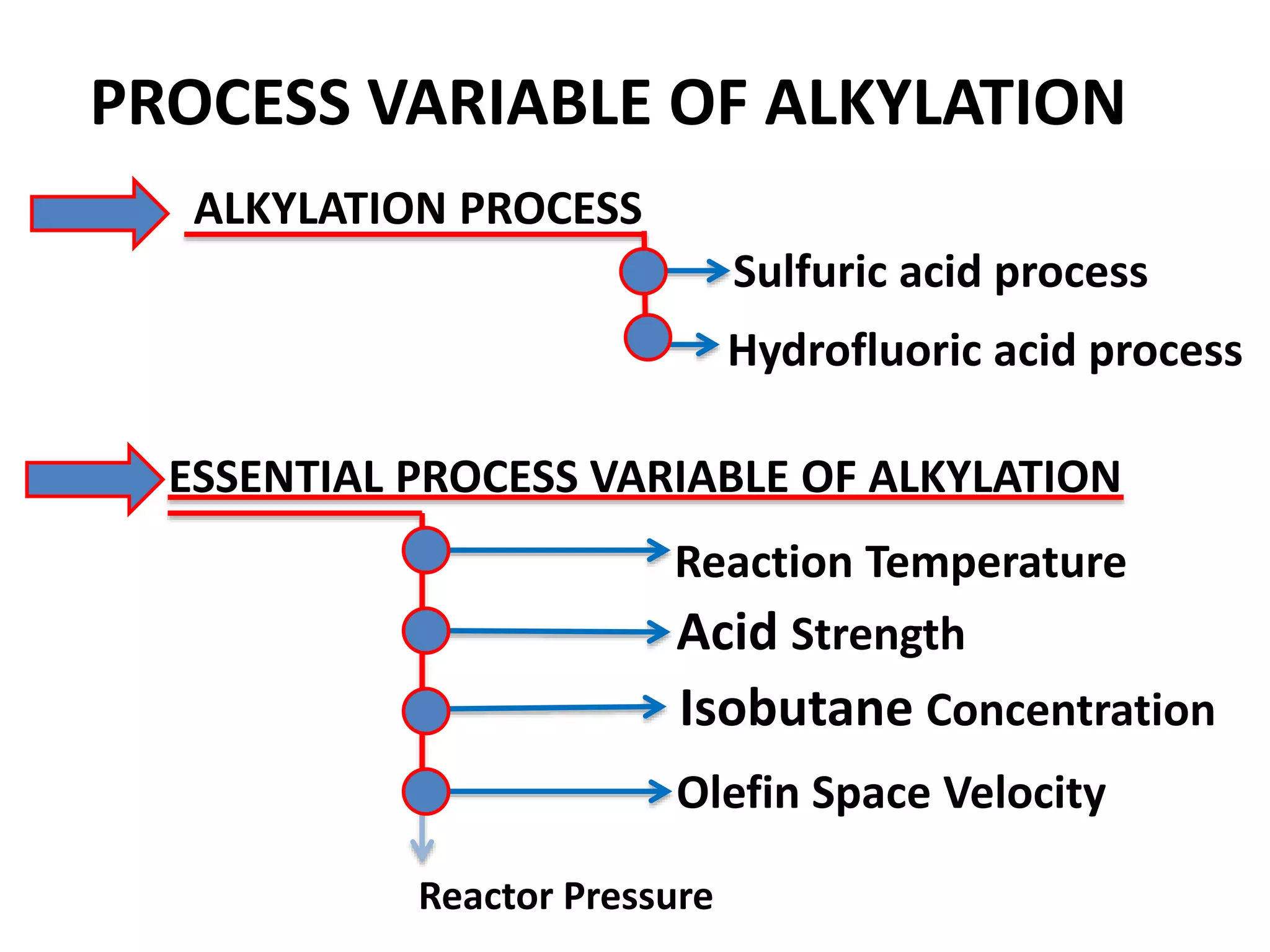

The key process variables in an alkylation unit are reaction temperature, acid strength, isobutane concentration, and olefin space velocity. Reaction temperature and acid strength affect product quality, with lower temperatures and appropriate acid strengths producing higher quality alkylate. Isobutane concentration is generally expressed as the isobutane to olefin ratio, with higher ratios increasing octane number and yield. Olefin space velocity also affects product quality, with lower velocities increasing octane number. Sulfuric acid and hydrofluoric acid are the primary catalysts used. Olefins and isobutane are the main feedstocks.

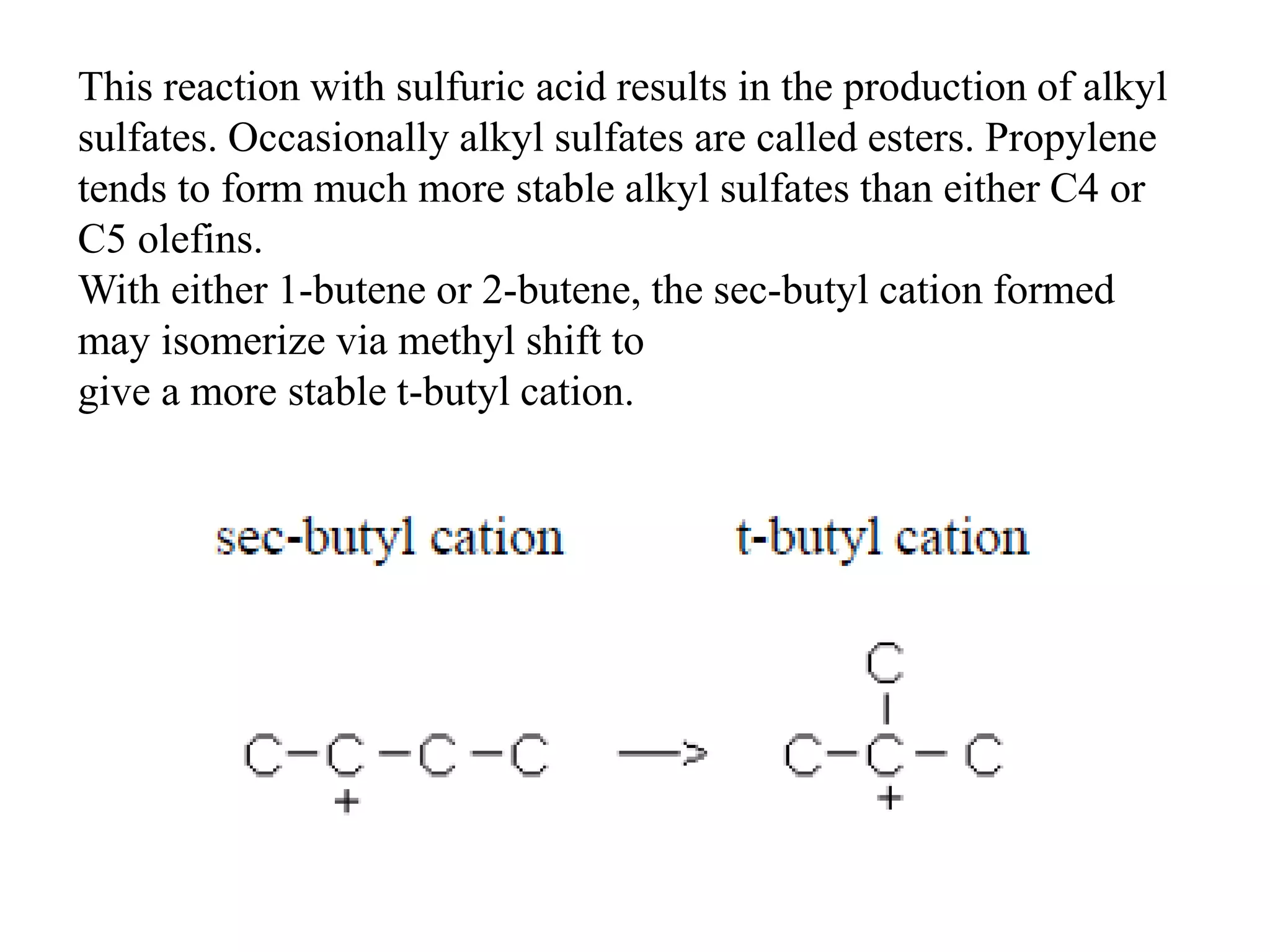

![PROCESS VARIABLES

The most important process variables are reaction temperature, acid strength,

isobutane concentration, and olefin space velocity. Changes in these variables

affect both product quality and yield.

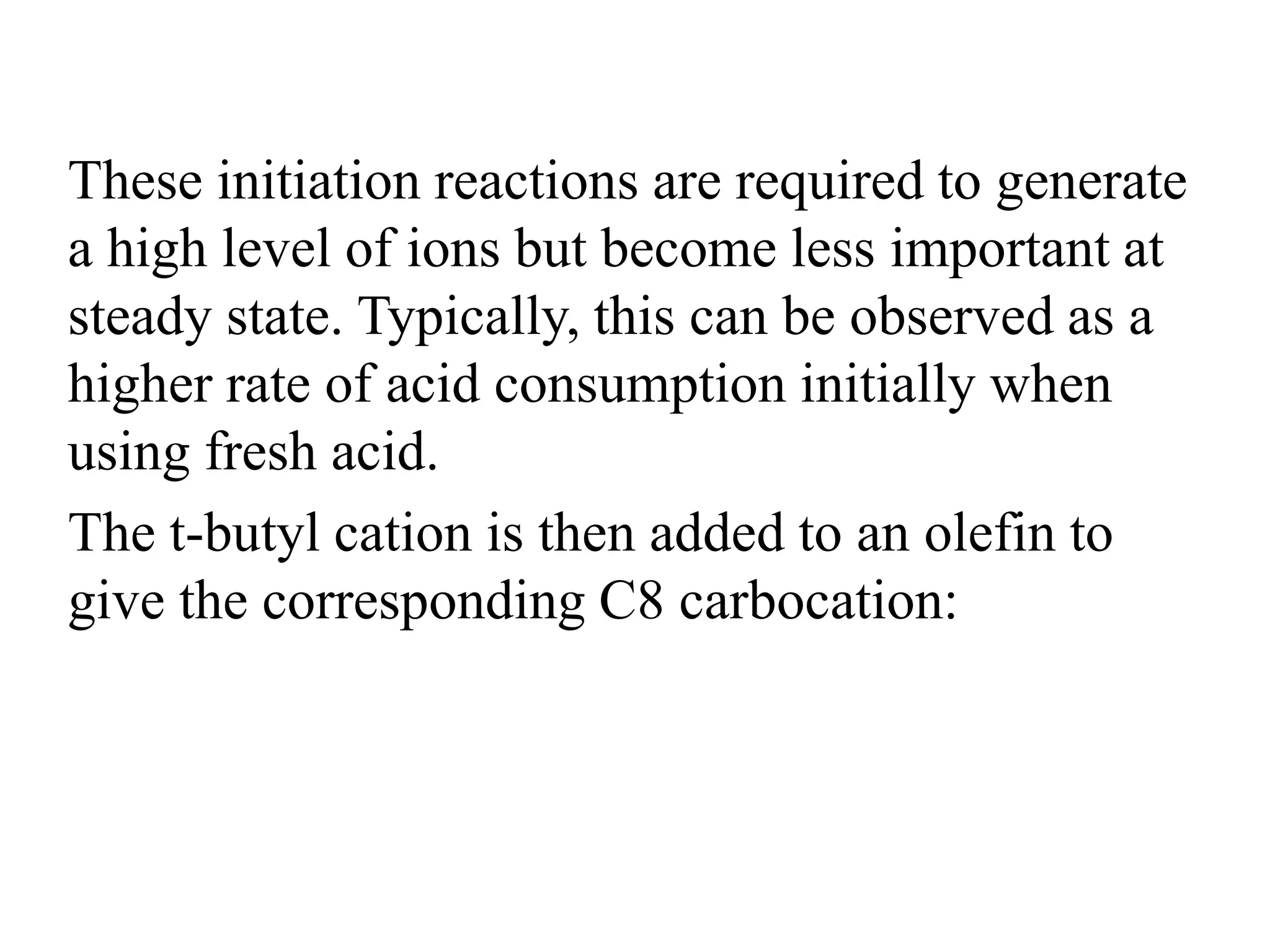

Reaction temperature has a greater effect in sulfuric acid processes than in those using

hydrofluoric acid. Low temperatures mean higher quality and the effect of changing sulfuric

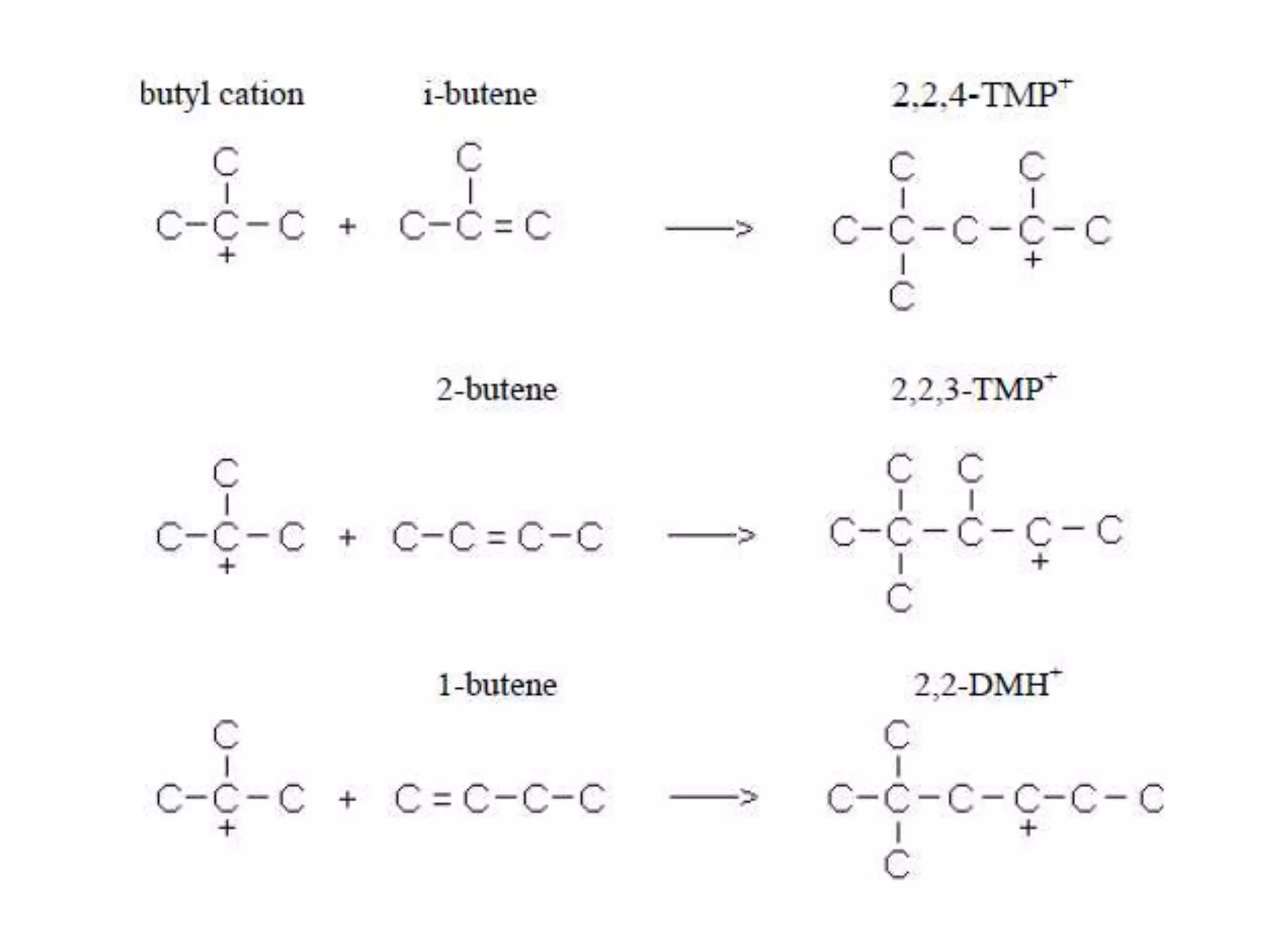

acid reactor temperature from 25 to 55°F (4 to 13°C) is to decrease product octane from one

to three numbers depending upon the efficiency of mixing in the reactor. In hydrofluoric acid

alkylation, increasing the reactor temperature from 60 to 125°F (16 to 52°C) degrades the

alkylate quality about three octane numbers [16]. In sulfuric acid alkylation, low

temperatures cause the acid viscosity to become so great that good mixing of the reactants

and subsequent separation of the emulsion is difficult. At temperatures above 70°F (21°C),

polymerization of the olefins becomes significant and yields are decreased. For these reasons

the normal sulfuric acid reactor temperature is from 40 to 50°F (5 to 10°C) with a maximum

of 70°F (21°C) and a minimum of 30°F (1°C).

For hydrofluoric acid alkylation, temperature is less significant and reactor

temperatures are usually in the range of 70 to 100°F (21 to 38°C).](https://image.slidesharecdn.com/441introduction9-140528122450-phpapp02/75/Alkylation-Unit-12-2048.jpg)

![At temperatures above 70°F (21°C), polymerization of the olefins becomes significant and

yields are decreased. For these reasons the normal sulfuric acid reactor temperature is from 40

to 50°F (5 to 10°C) with a maximum of 70°F (21°C) and a minimum of 30°F (1°C). For

hydrofluoric acid alkylation, temperature is less significant and reactor temperatures are

usually in the range of 70 to 100°F (21 to 38°C).

Acid strength has varying effects on alkylate quality depending on the effectiveness of

reactor mixing and the water content of the acid. In sulfuric acid alkylation, the best quality

and highest yields are obtained with acid strengths of 93 to 95% by weight of acid, 1 to 2%

water, and the remainder hydrocarbon diluents. The water concentration in the acid lowers its

catalytic activity about 3 to 5 times as much as hydrocarbon diluents, thus an 88% acid

containing 5% water is a much less effective catalyst than the same strength acid containing

2% water. The poorer the mixing in a reactor, the higher the acid strength necessary to keep

acid dilution down [16]. Increasing acid strength from 89 to 93% by weight increases alkylate

quality by one to two octane numbers. In hydrofluoric acid alkylation the highest octane

number alkylate is attained in the 86 to 90% by weight acidity range. Commercial operations

usually have acid concentrations between 83 and 92% hydrofluoric acid and contain lessthan

1% water. increasing the reactor temperature from 60 to 125°F (16 to 52°C) degrades the

alkylate quality about three octane numbers [16].In sulfuric acid alkylation, low temperatures

cause the acid viscosity to become so great that good mixing of the reactants and subsequent

separation of the emulsion is difficult.](https://image.slidesharecdn.com/441introduction9-140528122450-phpapp02/75/Alkylation-Unit-13-2048.jpg)