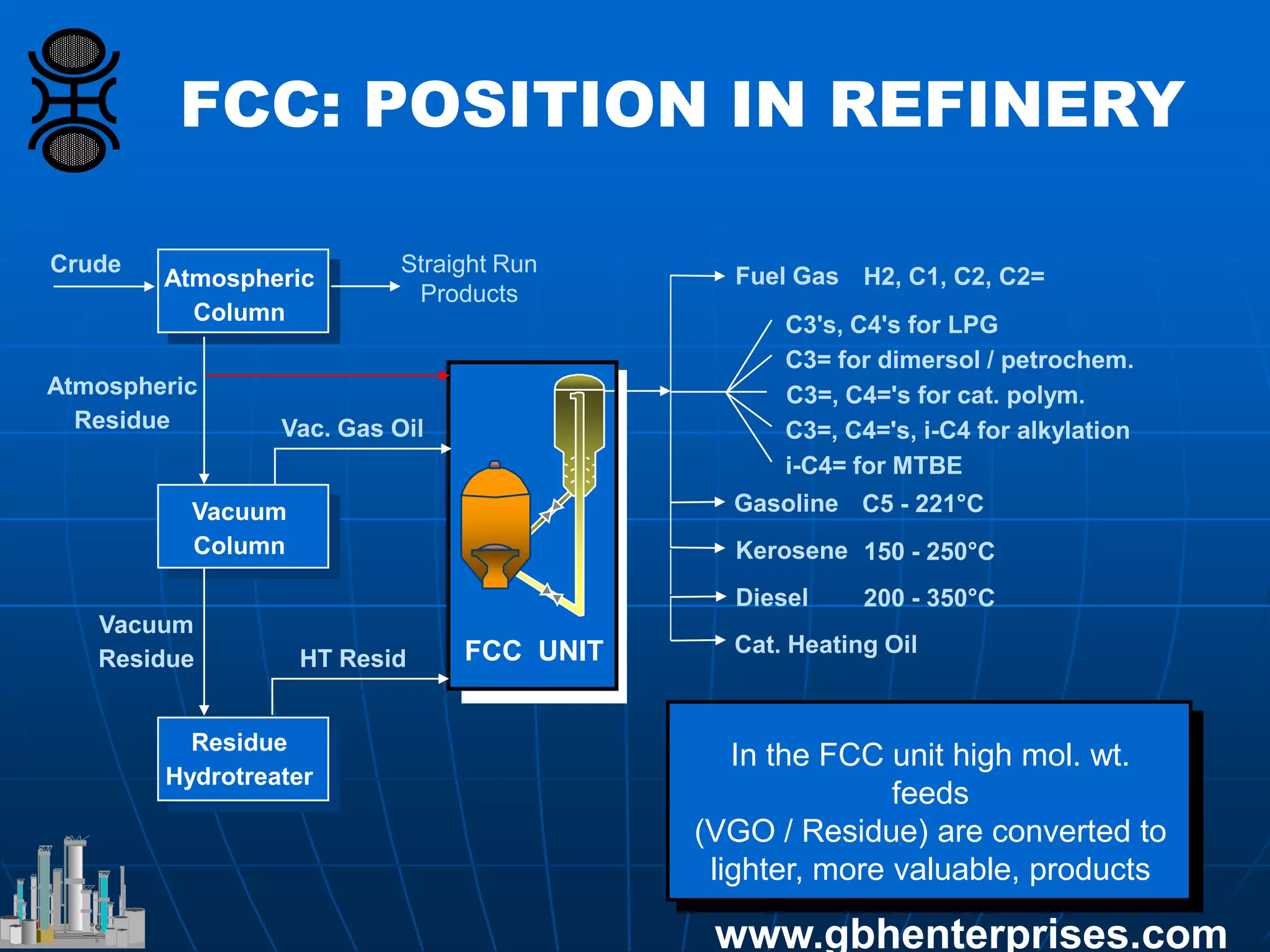

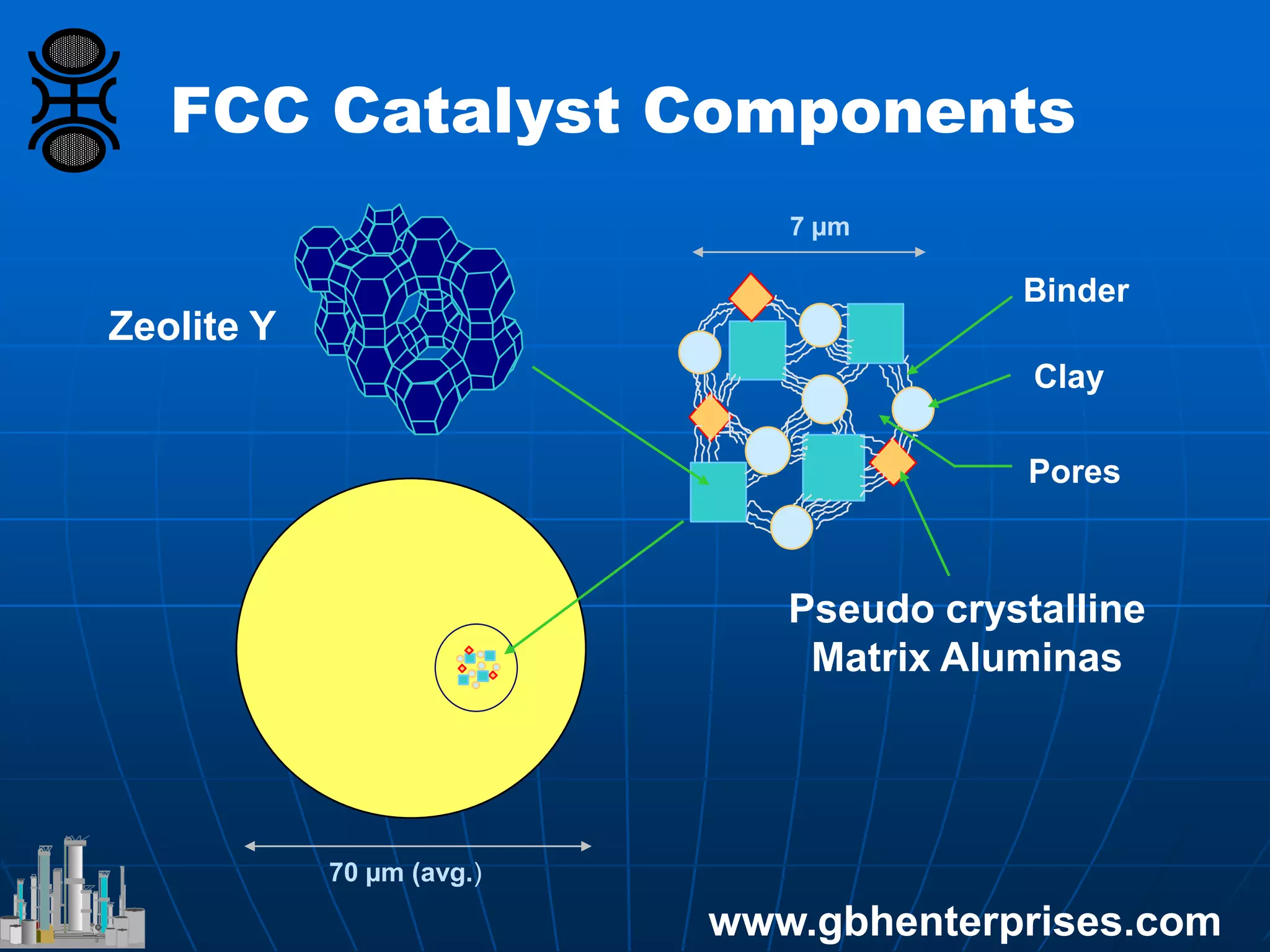

The document provides an in-depth overview of FCC catalyst design, including components such as zeolites and matrices, their manufacturing processes, and reaction chemistry involved in converting high molecular weight feeds into lighter hydrocarbons. It discusses the operational conditions of an FCC unit, the roles of various catalyst components, and the effects of zeolite properties on product selectivity and cracking activity. Additionally, the document covers the environmental implications of FCC processes, including sulfur management and NOx emissions reduction strategies.

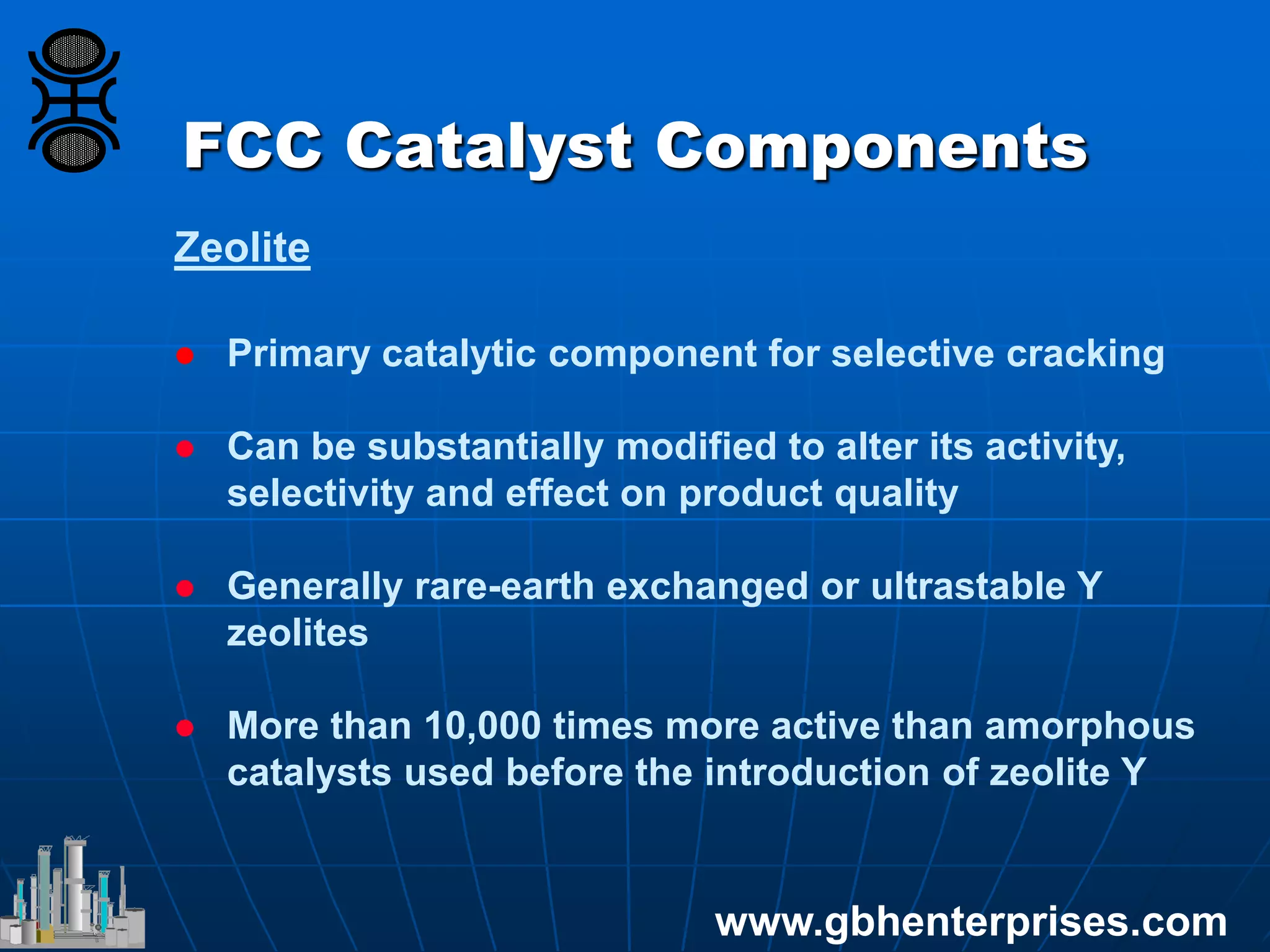

![Ion Exchange to Generate Acid

Sites (H+)

Na+-Z- + NH4

+ Na+ + NH4

+-Z-

NH4

+-Z- H+-Z- + NH3

↑

calcine

3Na+-Z- + RE(H2O)6

3+ 3Na+ + RE(H2O)6

3+-[Z]3

-

RE(H2O)6

3+-[Z]3

- RE(H2O)5(OH)2+ -H+-[Z]3

-

hydrolysis

Ammonium Exchange

Rare Earth Exchange

www.gbhenterprises.com](https://image.slidesharecdn.com/fcccatalystdesignmorphphysiooptimization-150107212315-conversion-gate01/75/FCC-Catalyst-Design-Morphology-Physiology-Reaction-Chemistry-and-Manufacturing-16-2048.jpg)

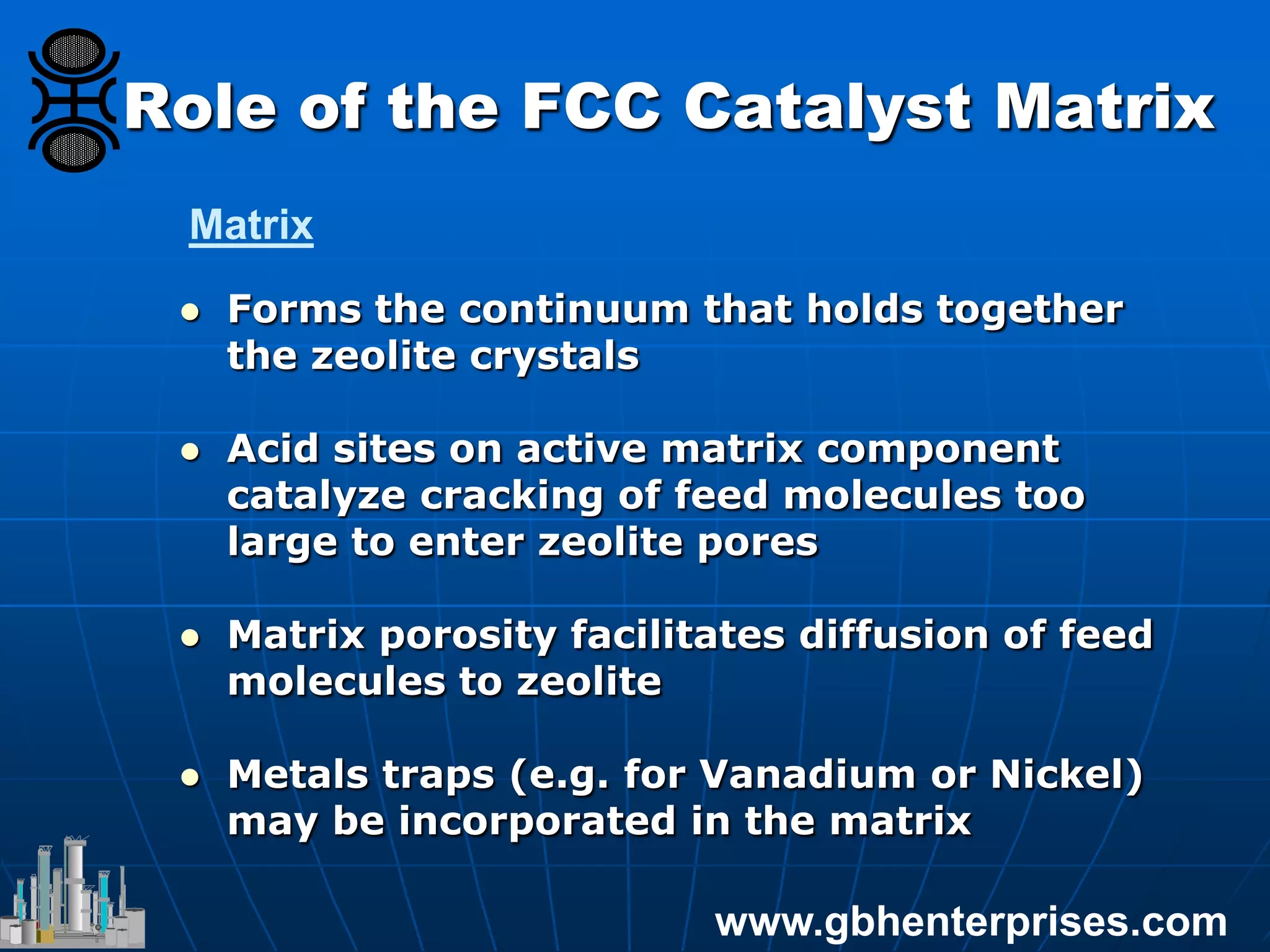

![Unit-Cell Size and Si/Al ratio

Numerous relationships given in the literature

Breck and Flanigen relationship widely used

NAl / ucs = 115.2 [ ao - 24.191 ]

and: NSi / ucs = 192 - NAl / ucs

thus: Si / Alframework = NSi / NAl

www.gbhenterprises.com](https://image.slidesharecdn.com/fcccatalystdesignmorphphysiooptimization-150107212315-conversion-gate01/75/FCC-Catalyst-Design-Morphology-Physiology-Reaction-Chemistry-and-Manufacturing-18-2048.jpg)