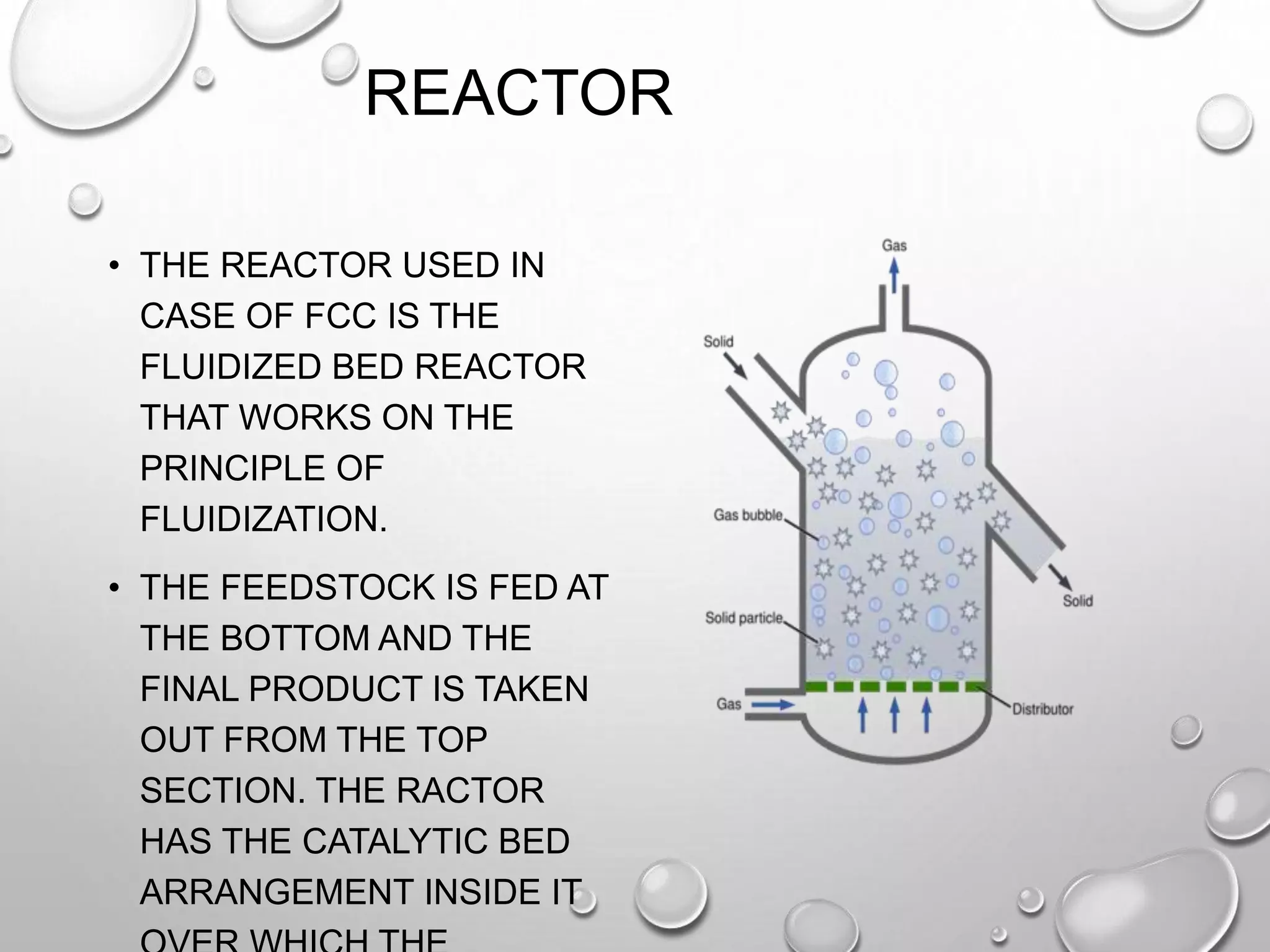

The document describes the process of fluidized catalytic cracking (FCC) used in petroleum refineries. It explains that FCC converts high-boiling petroleum fractions into high-value gasoline and heating oil using a zeolite catalyst. The key components of an FCC unit are the reactor, where the reaction occurs, and the regenerator, where the catalyst is regenerated by burning off coke deposits. It then provides details on the operation of each component and the flow of catalyst and feedstock through the system. It also discusses advantages and disadvantages of FCC and presents a case study analyzing catalyst selection for a refinery in Jiddah.