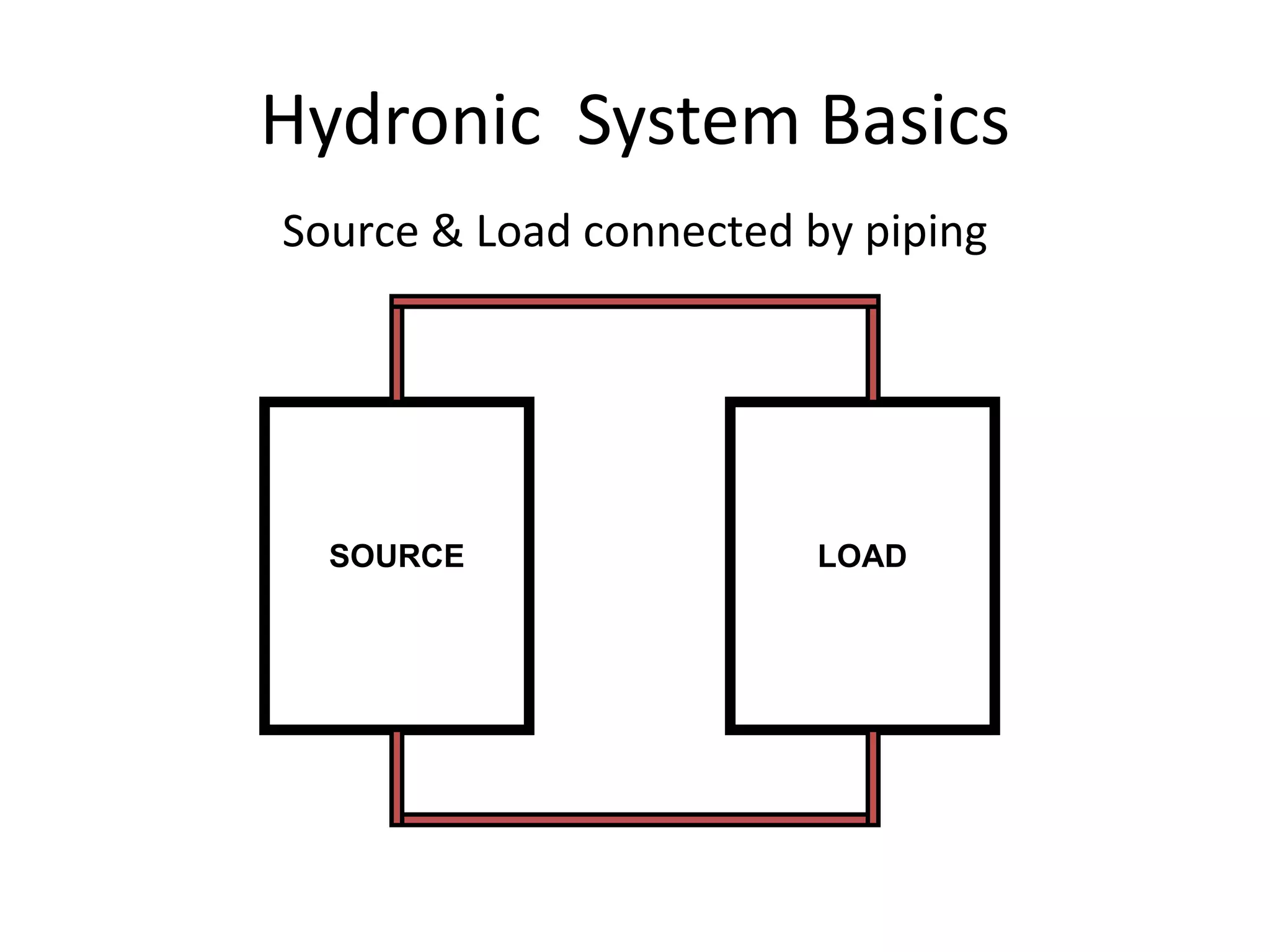

The document discusses various topics related to hydronic system design including:

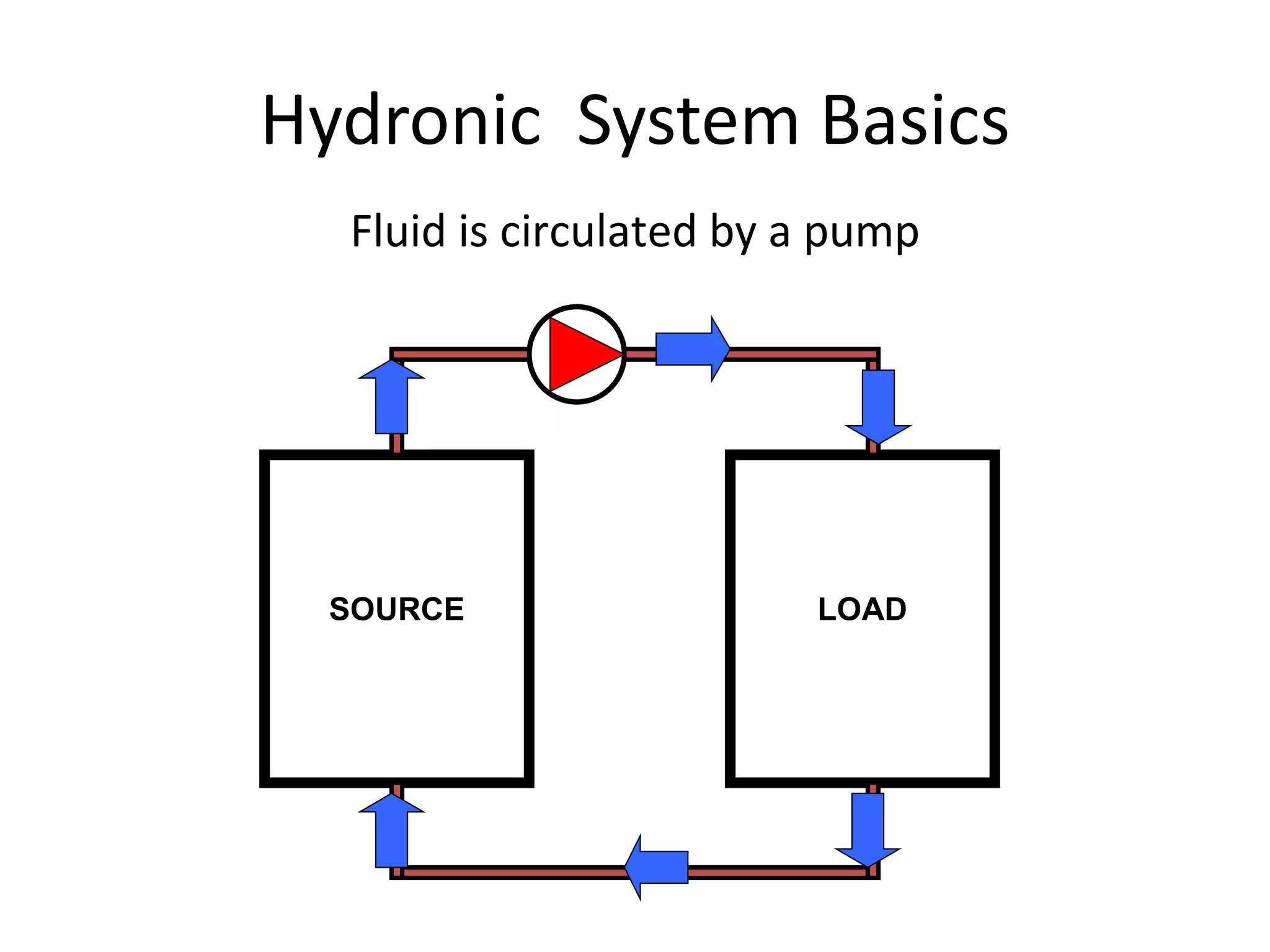

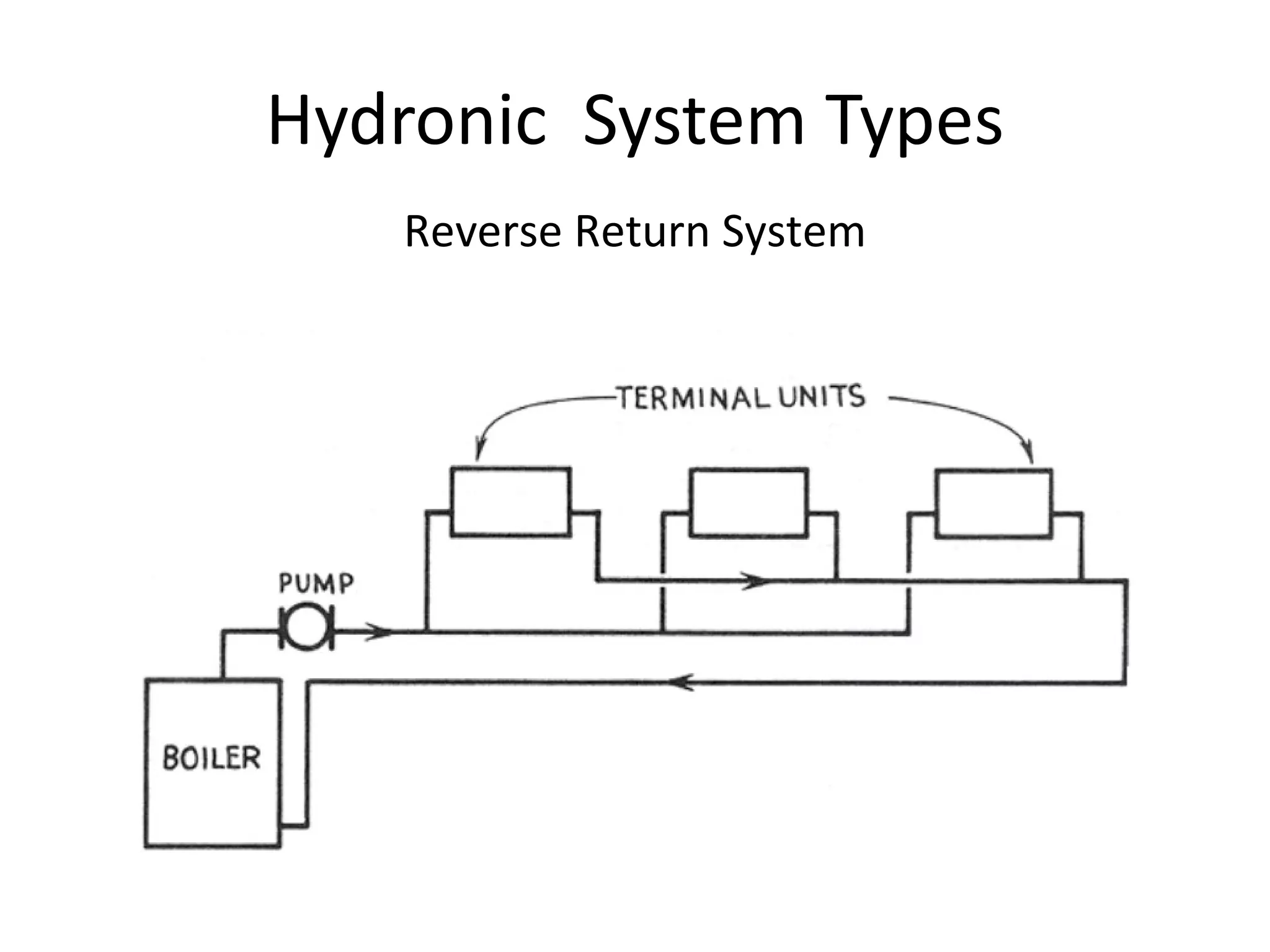

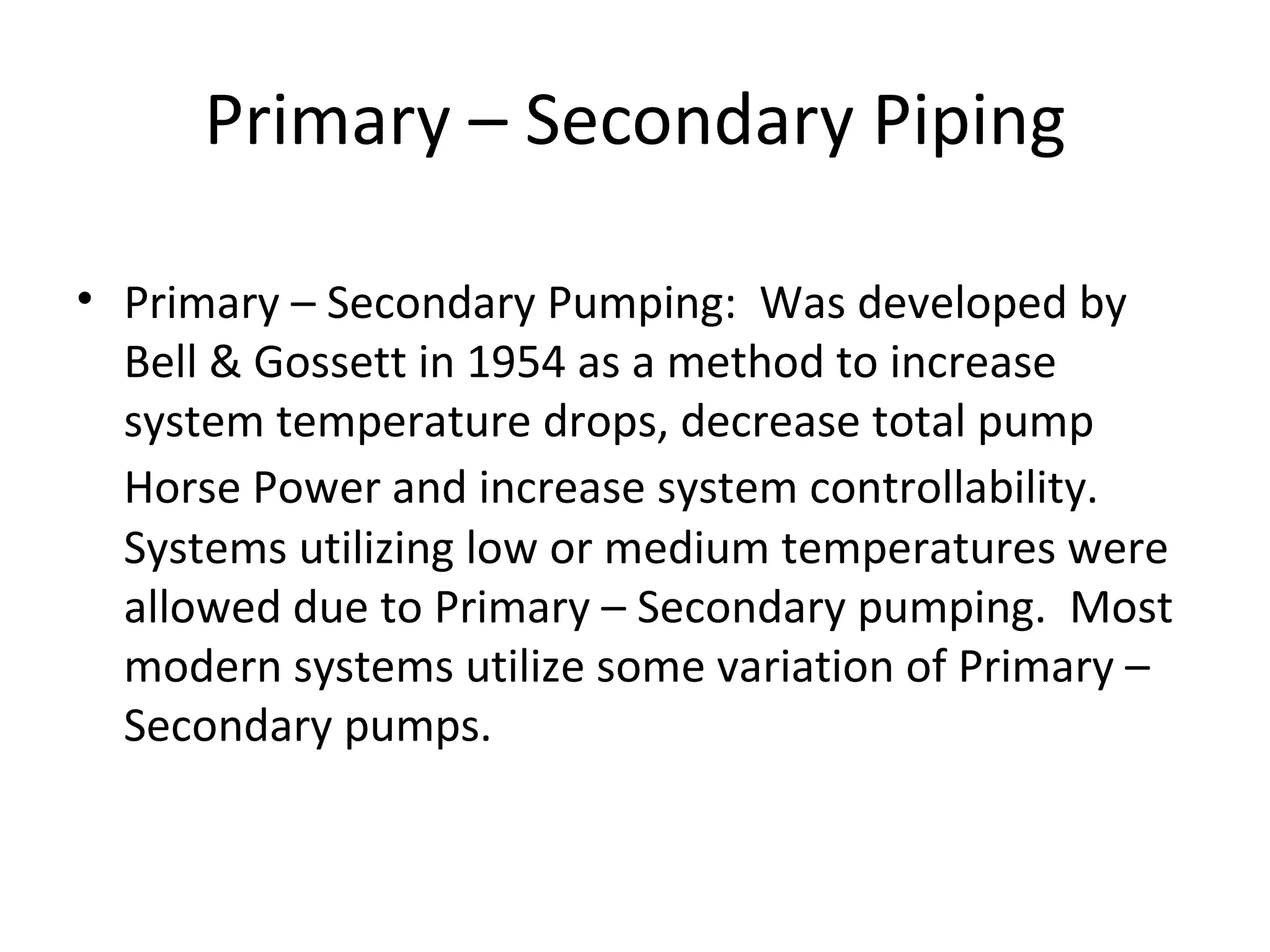

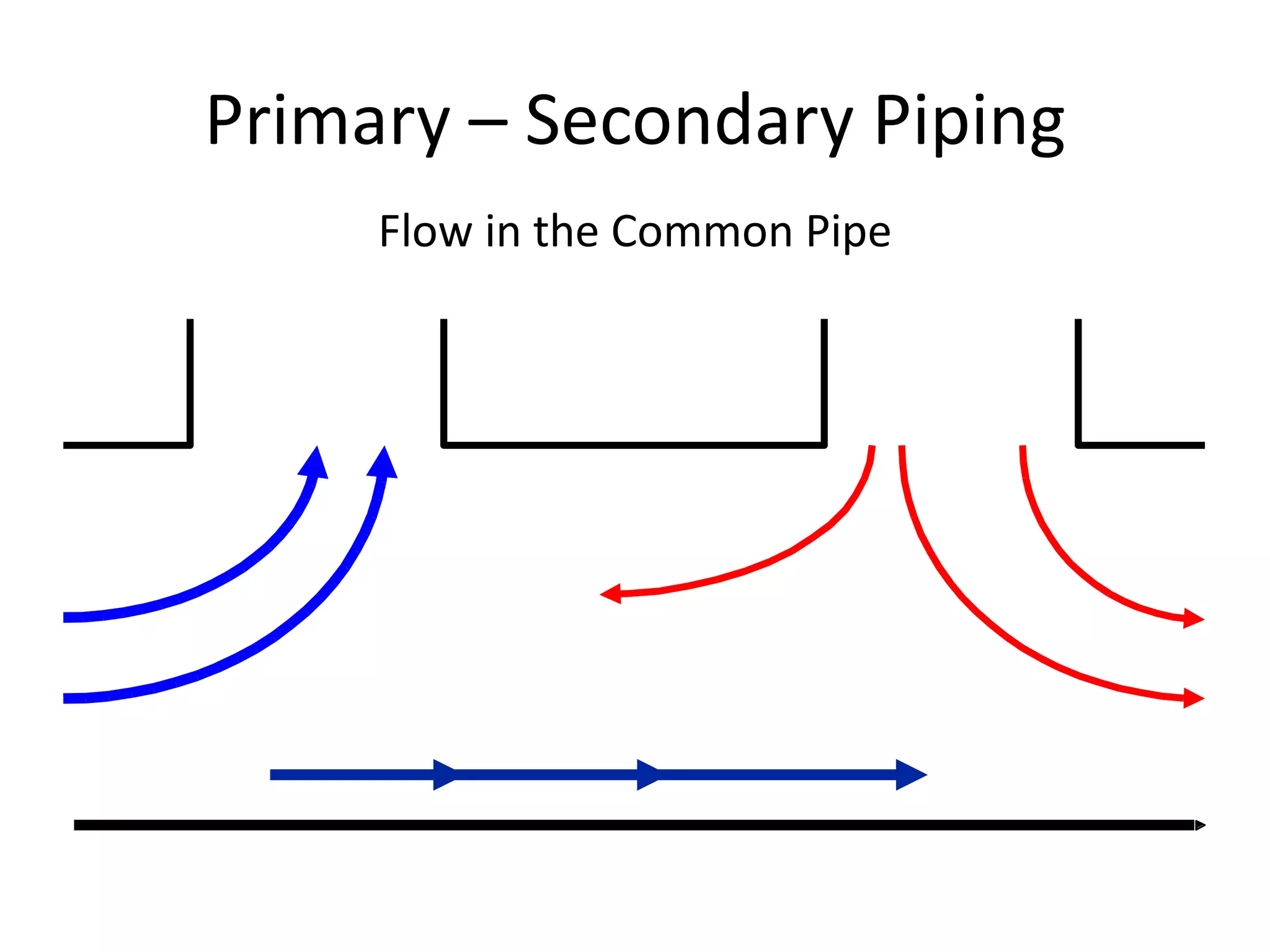

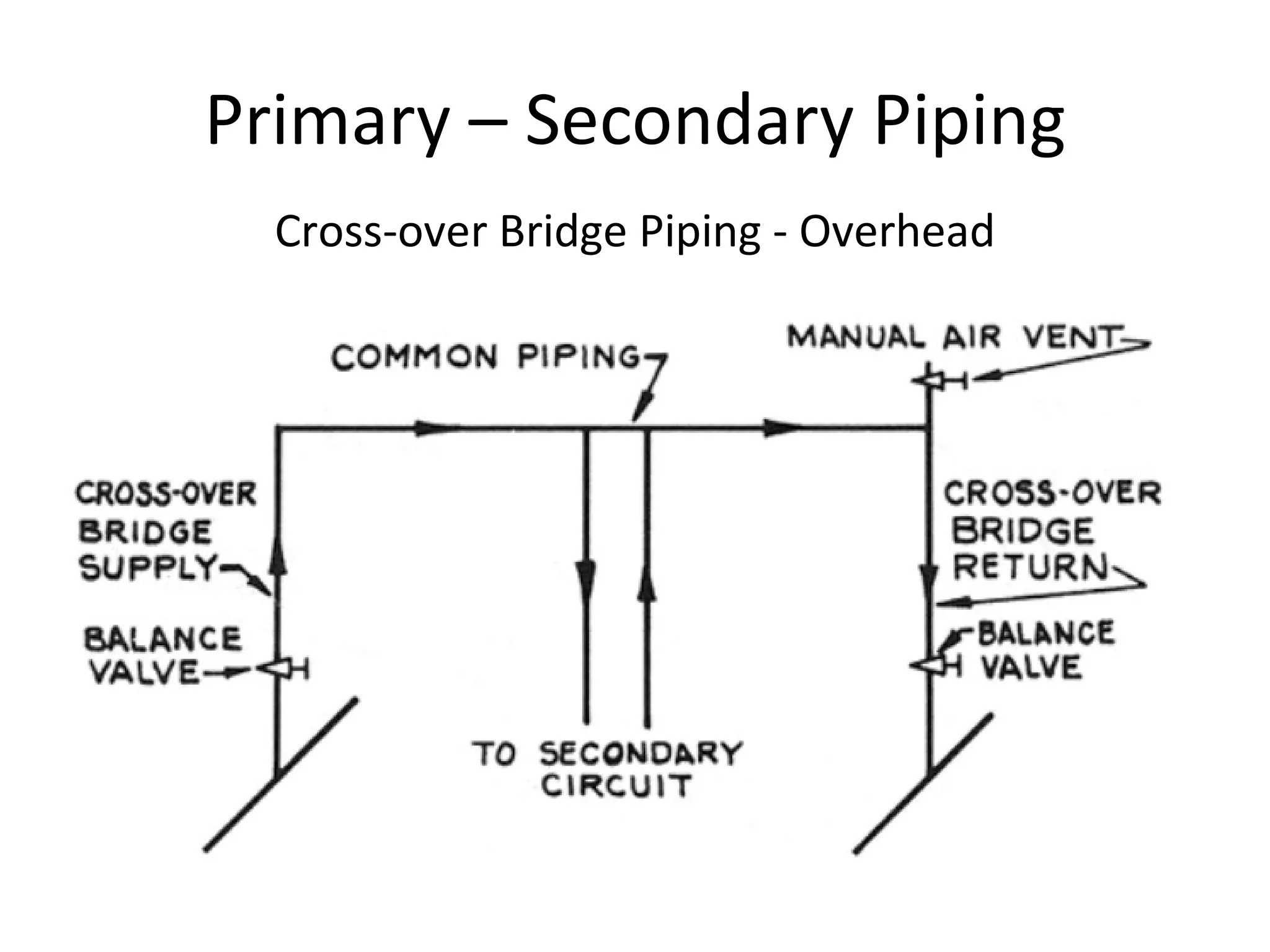

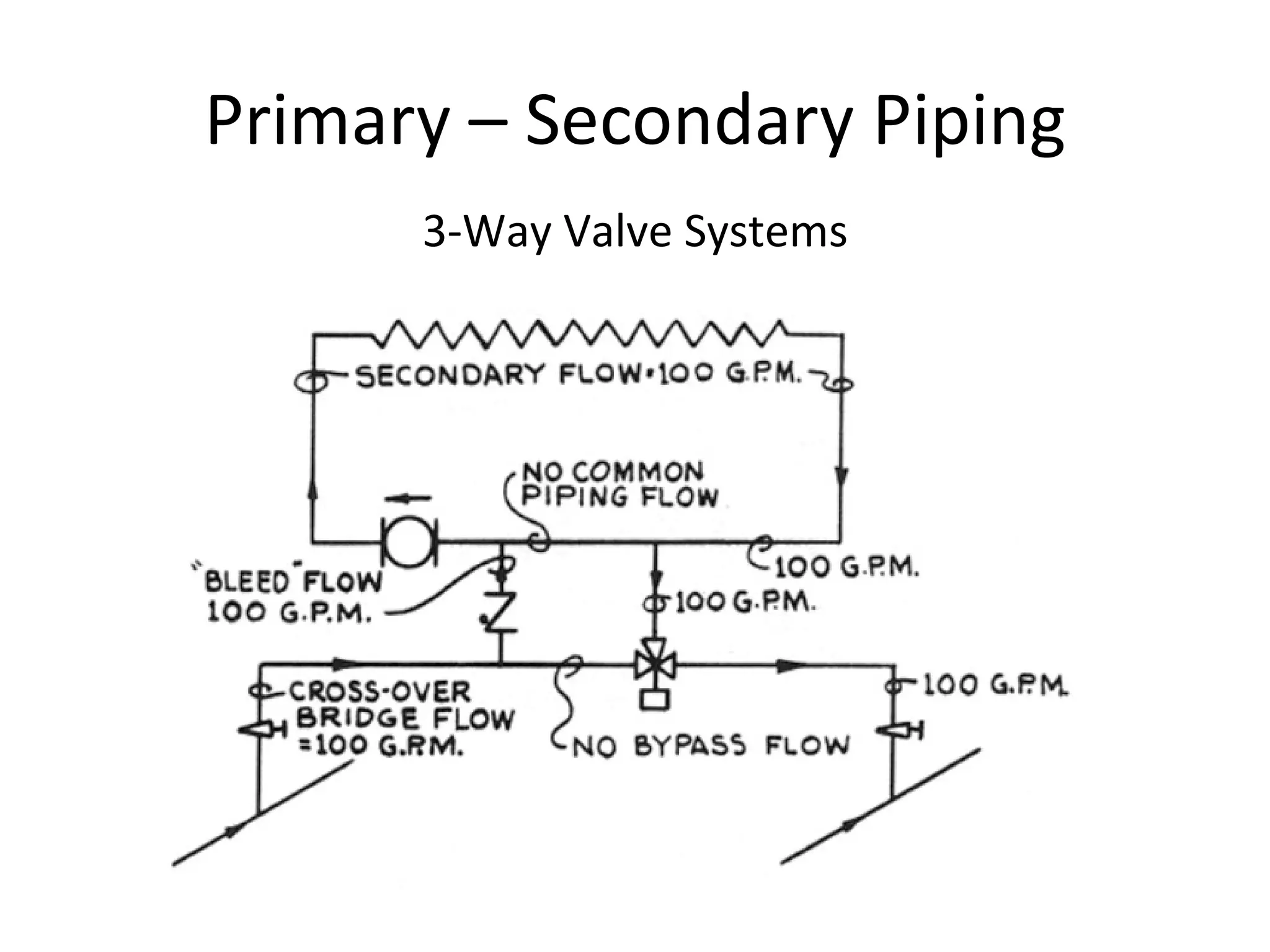

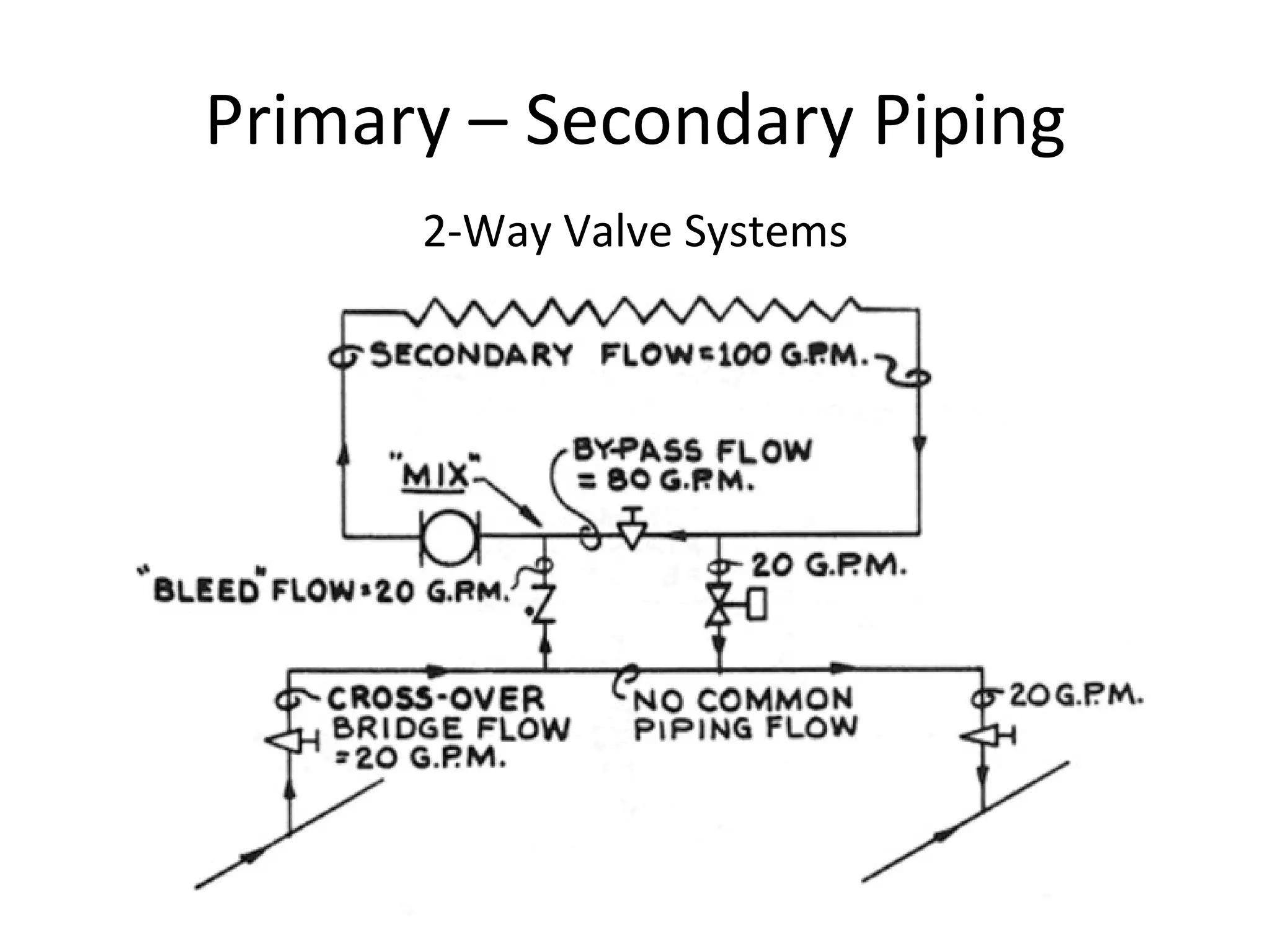

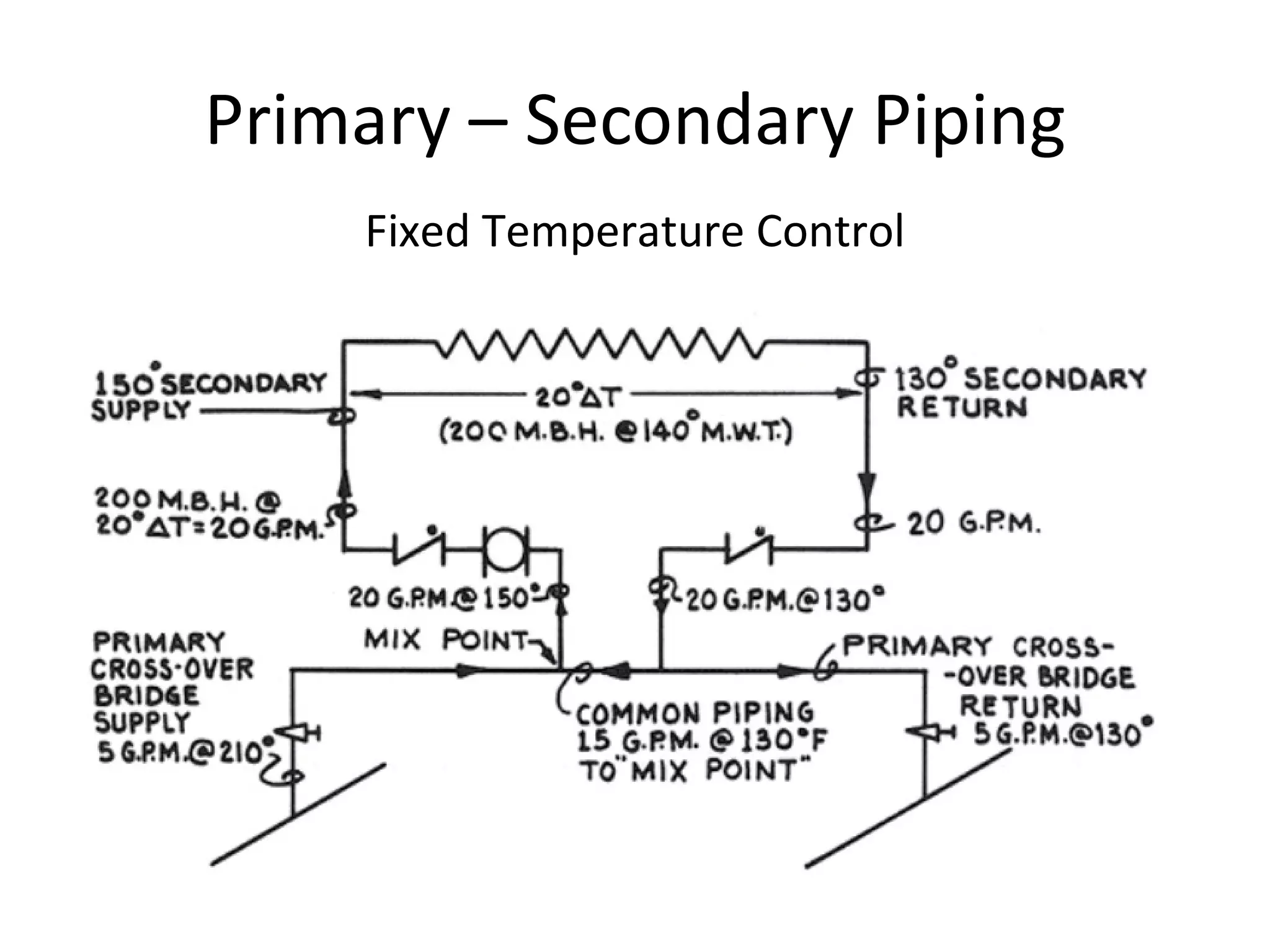

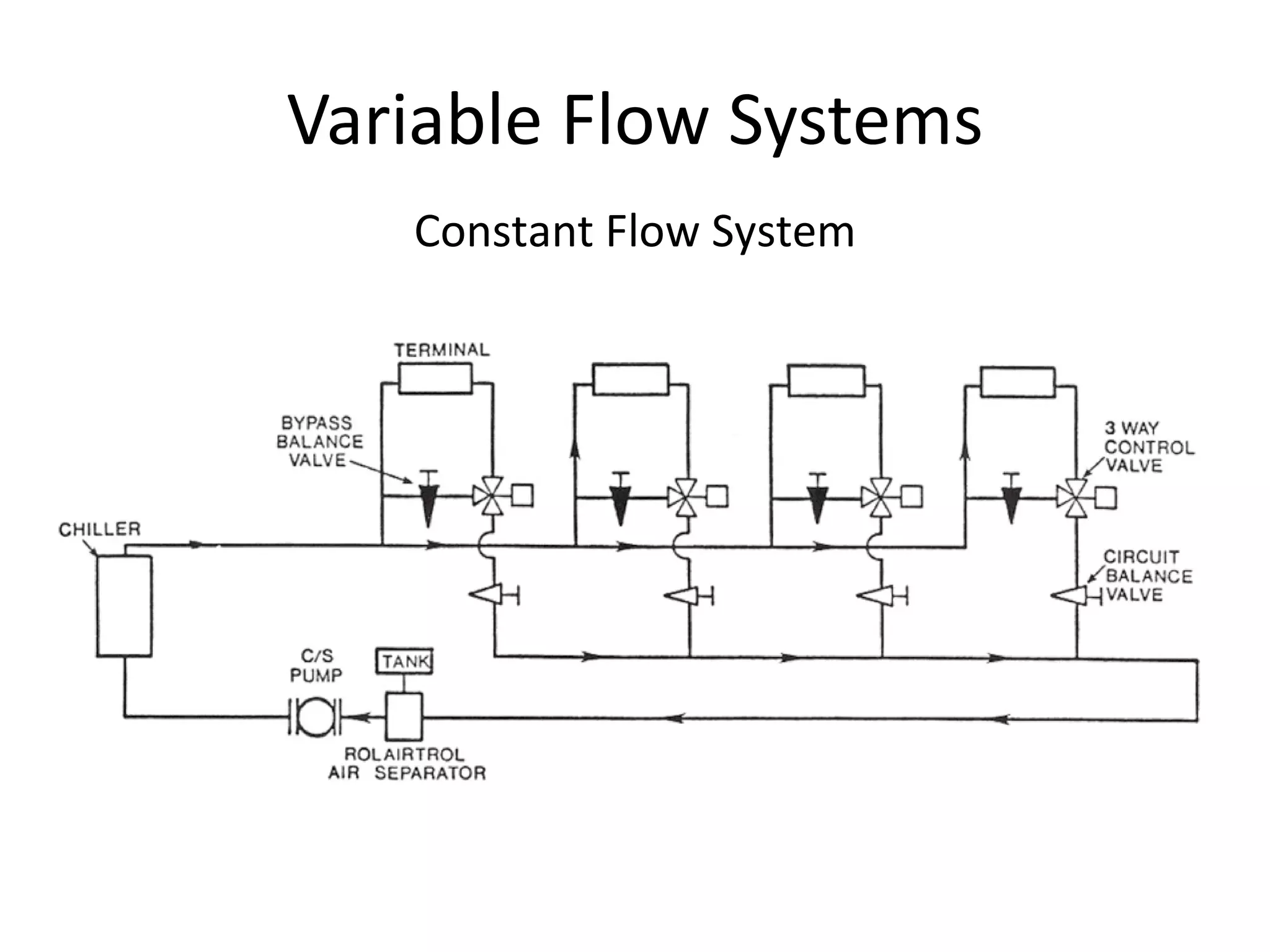

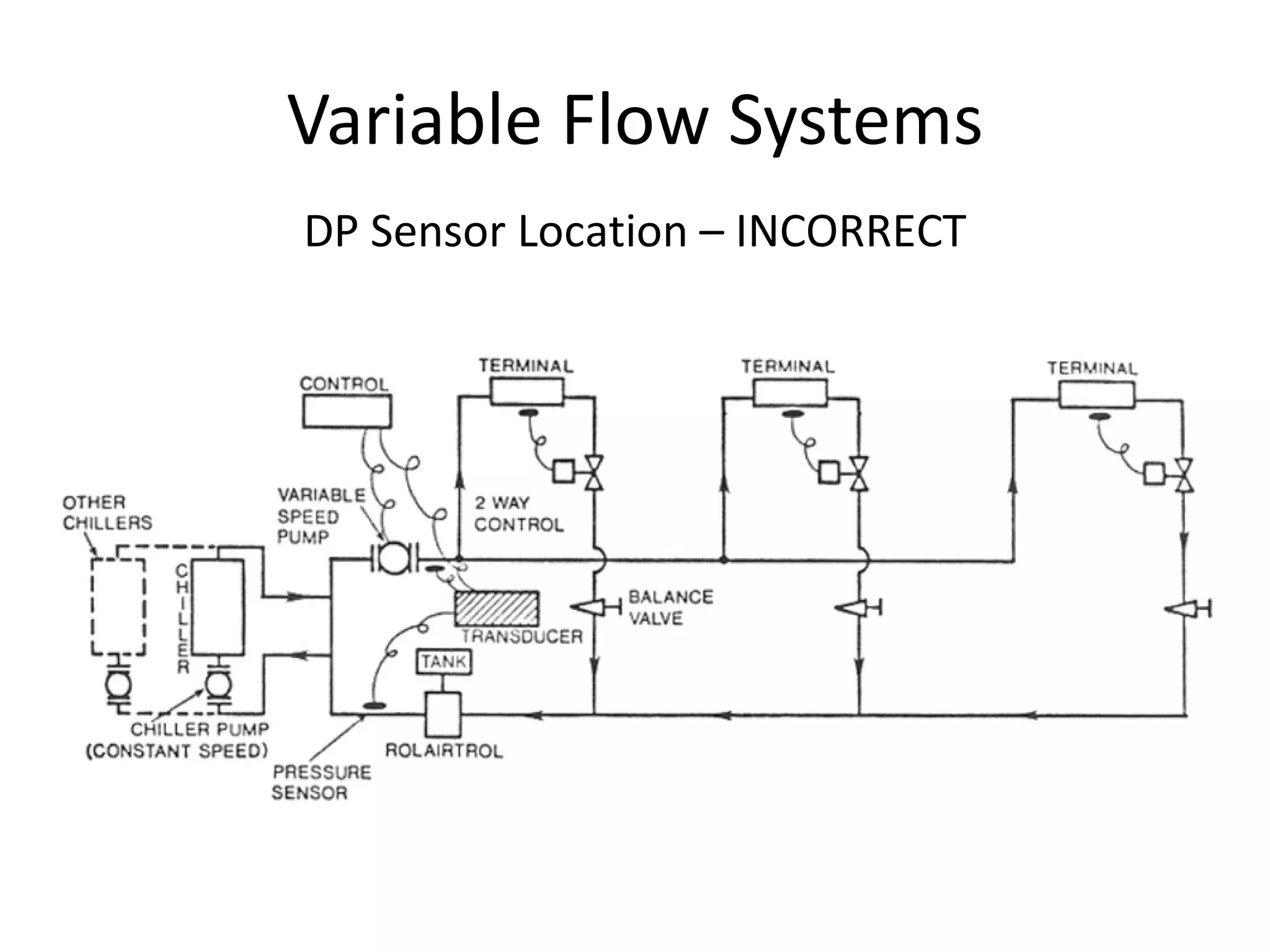

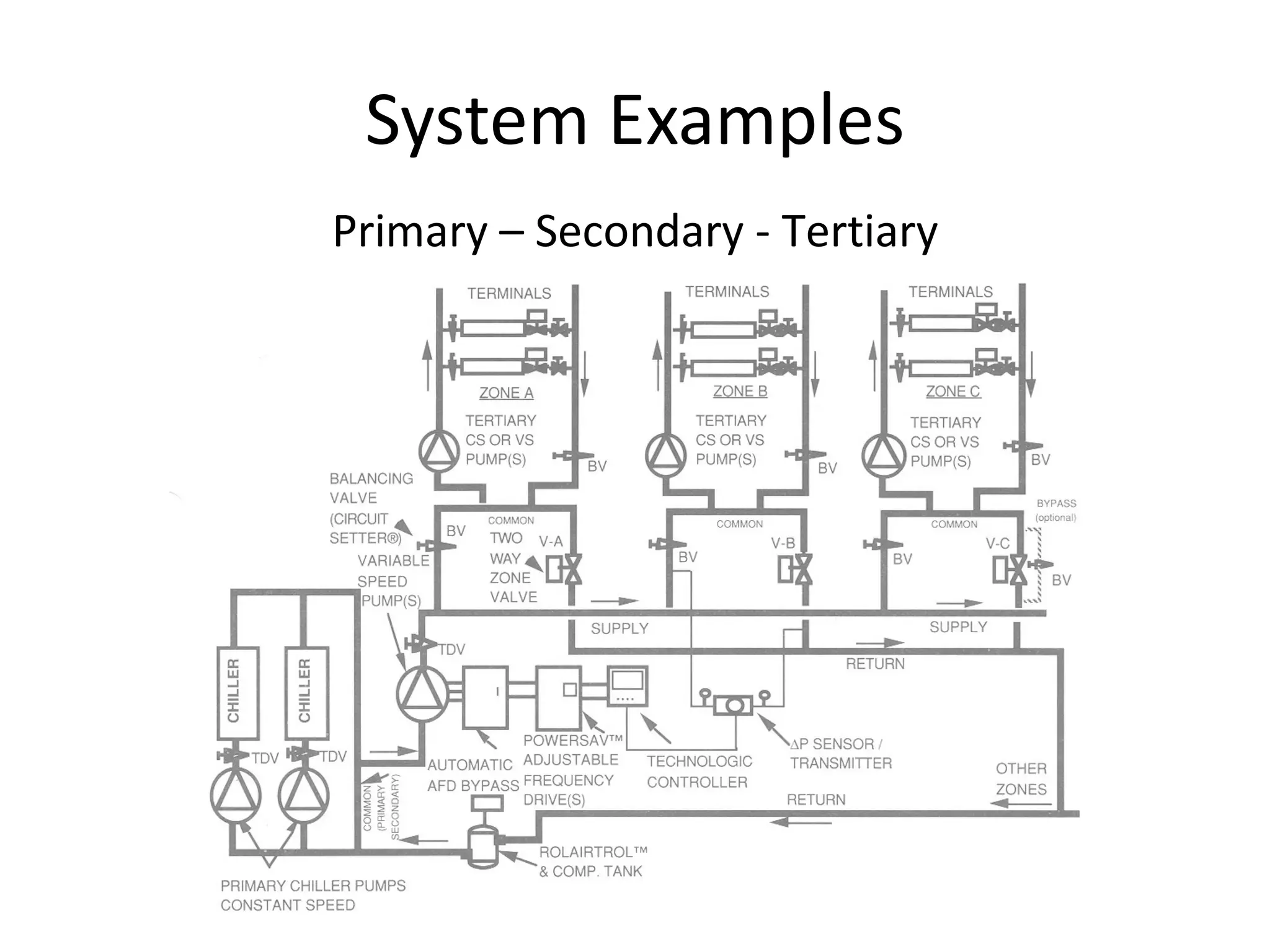

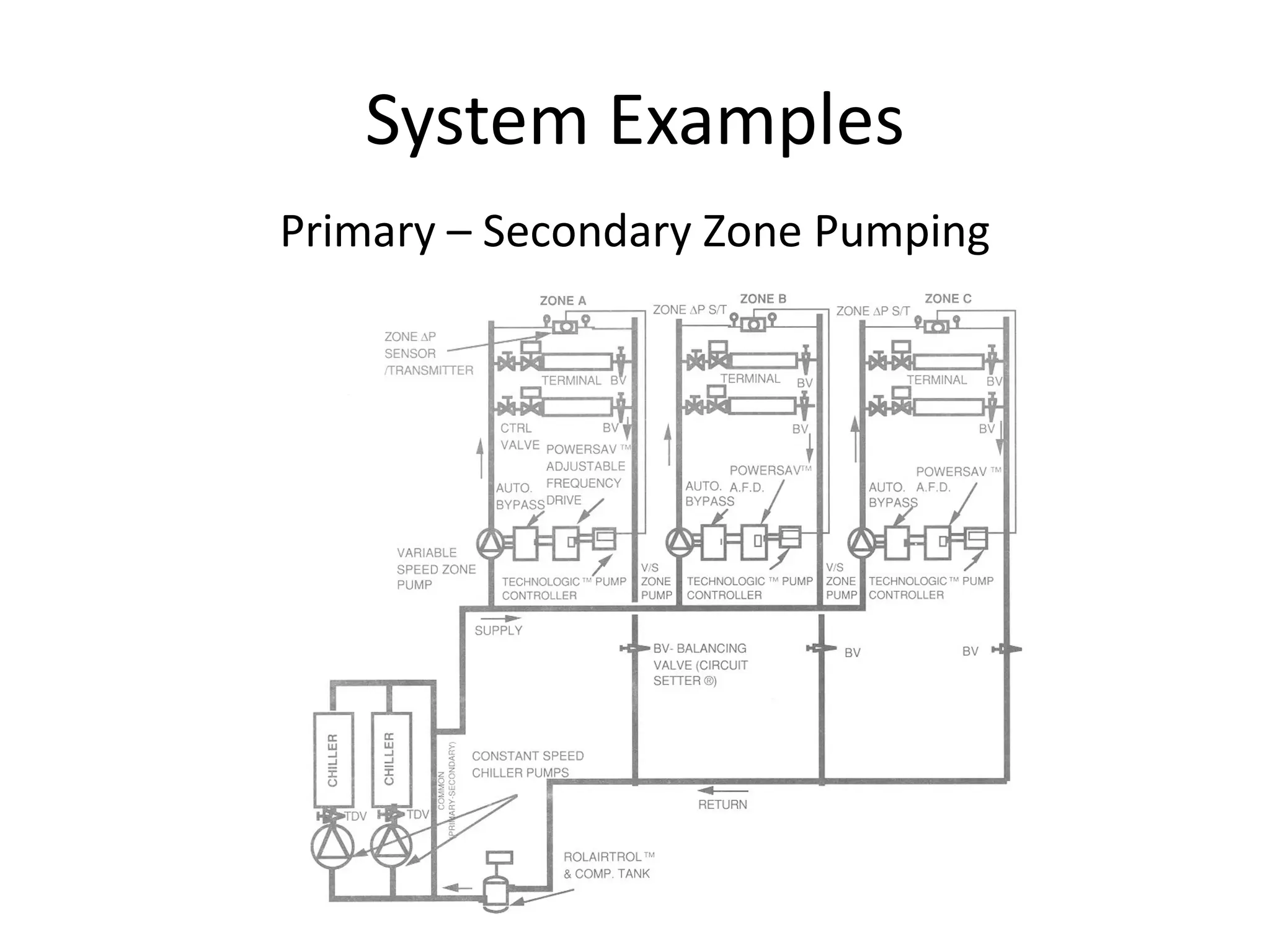

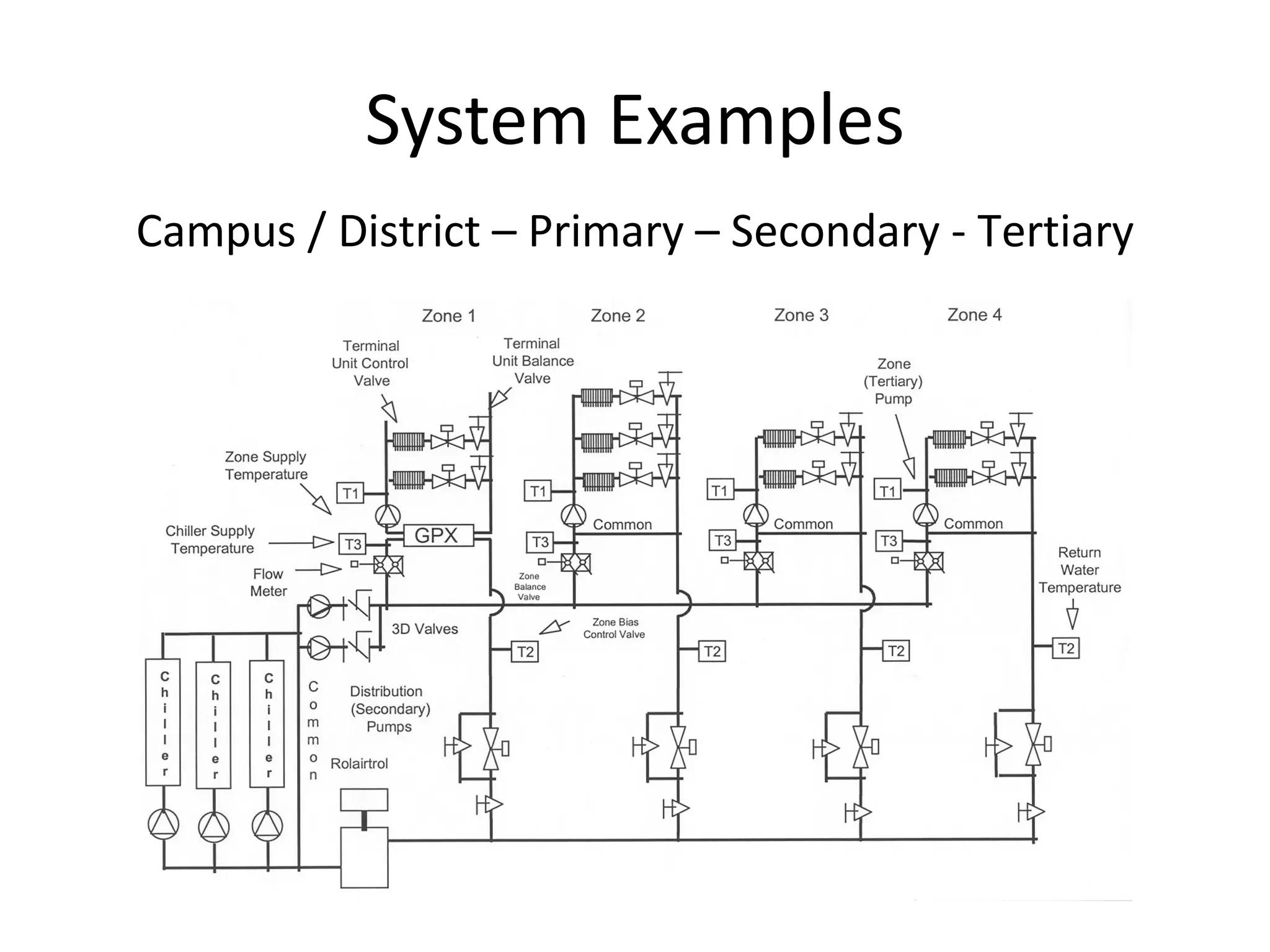

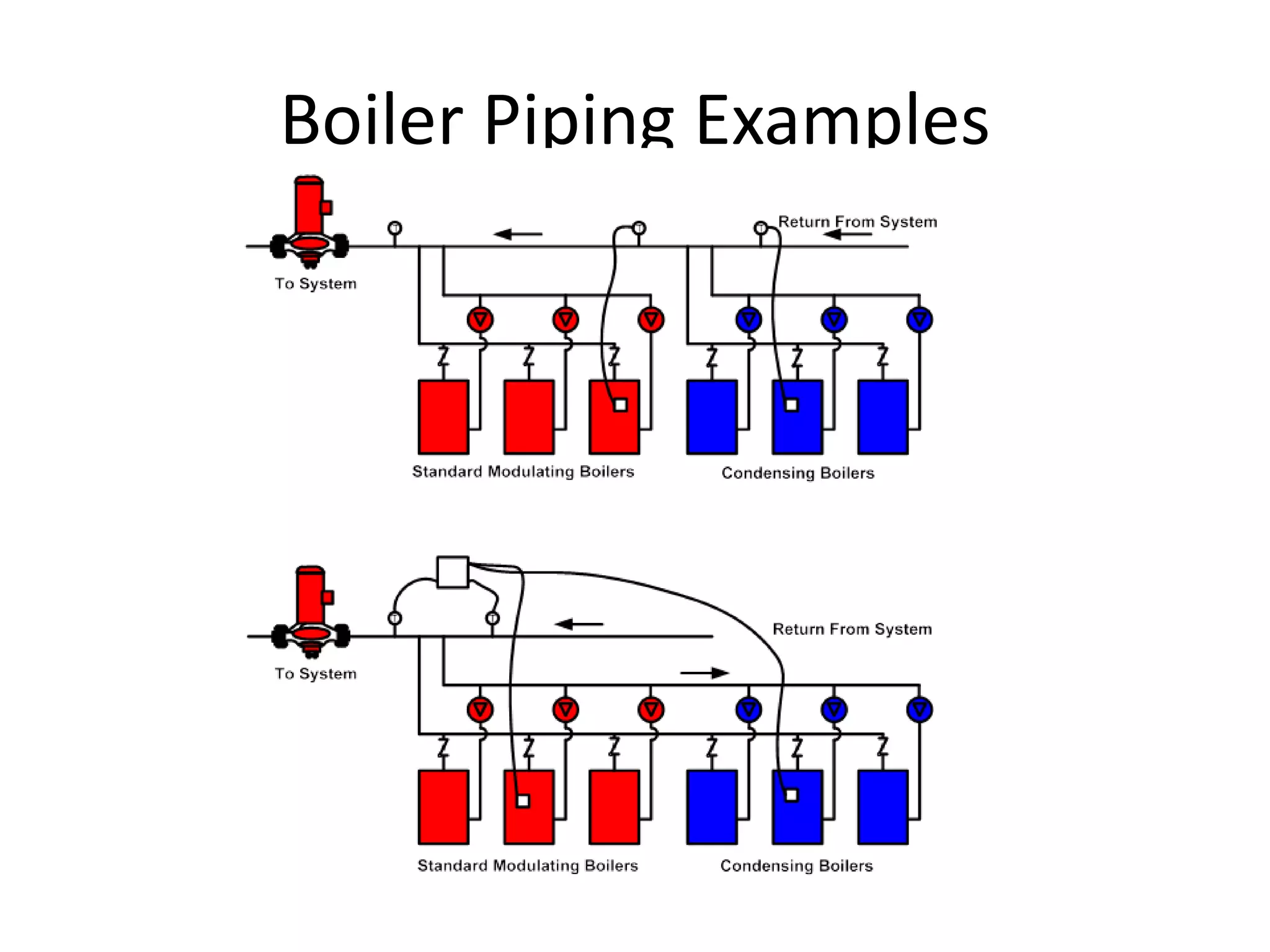

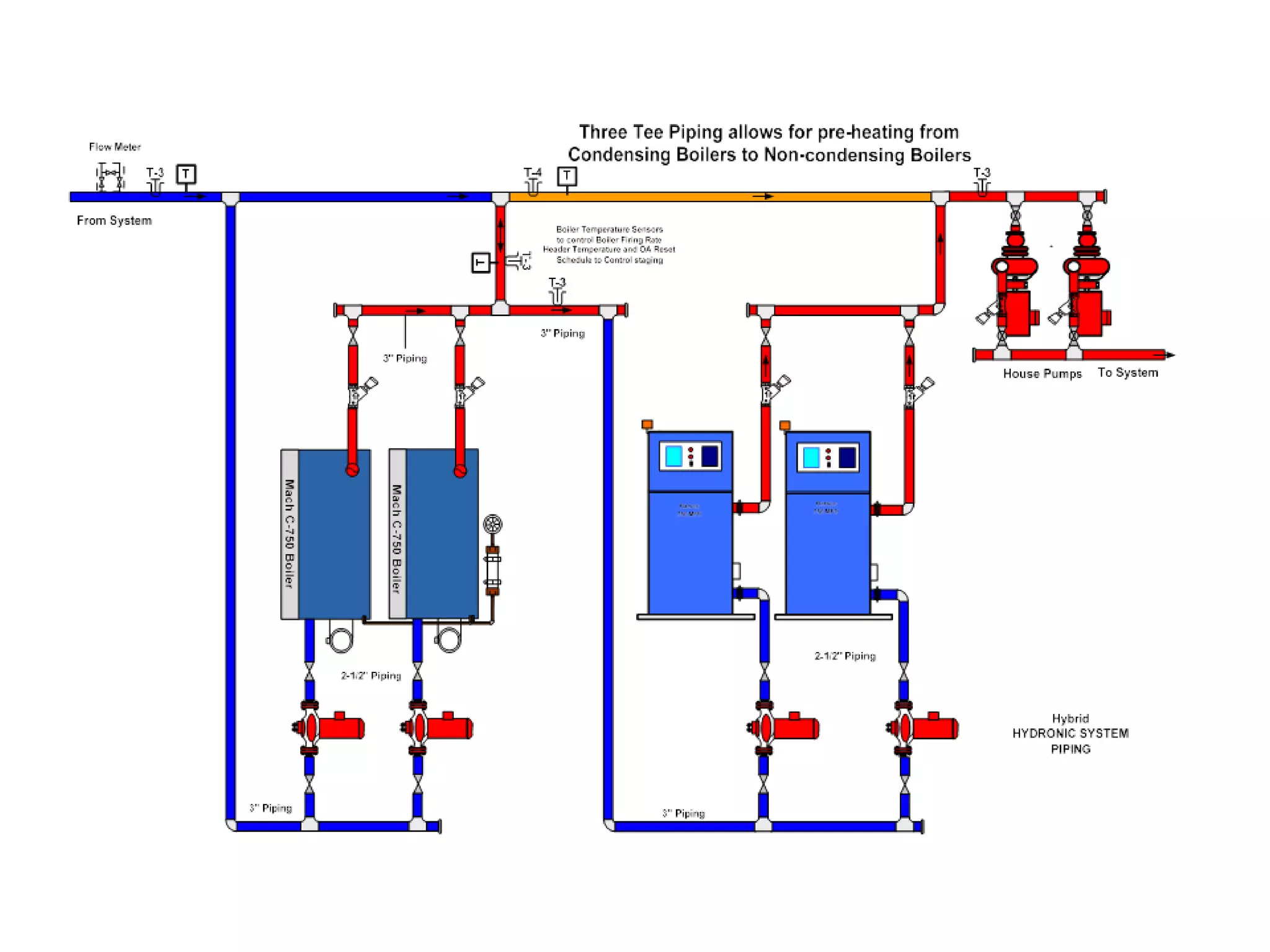

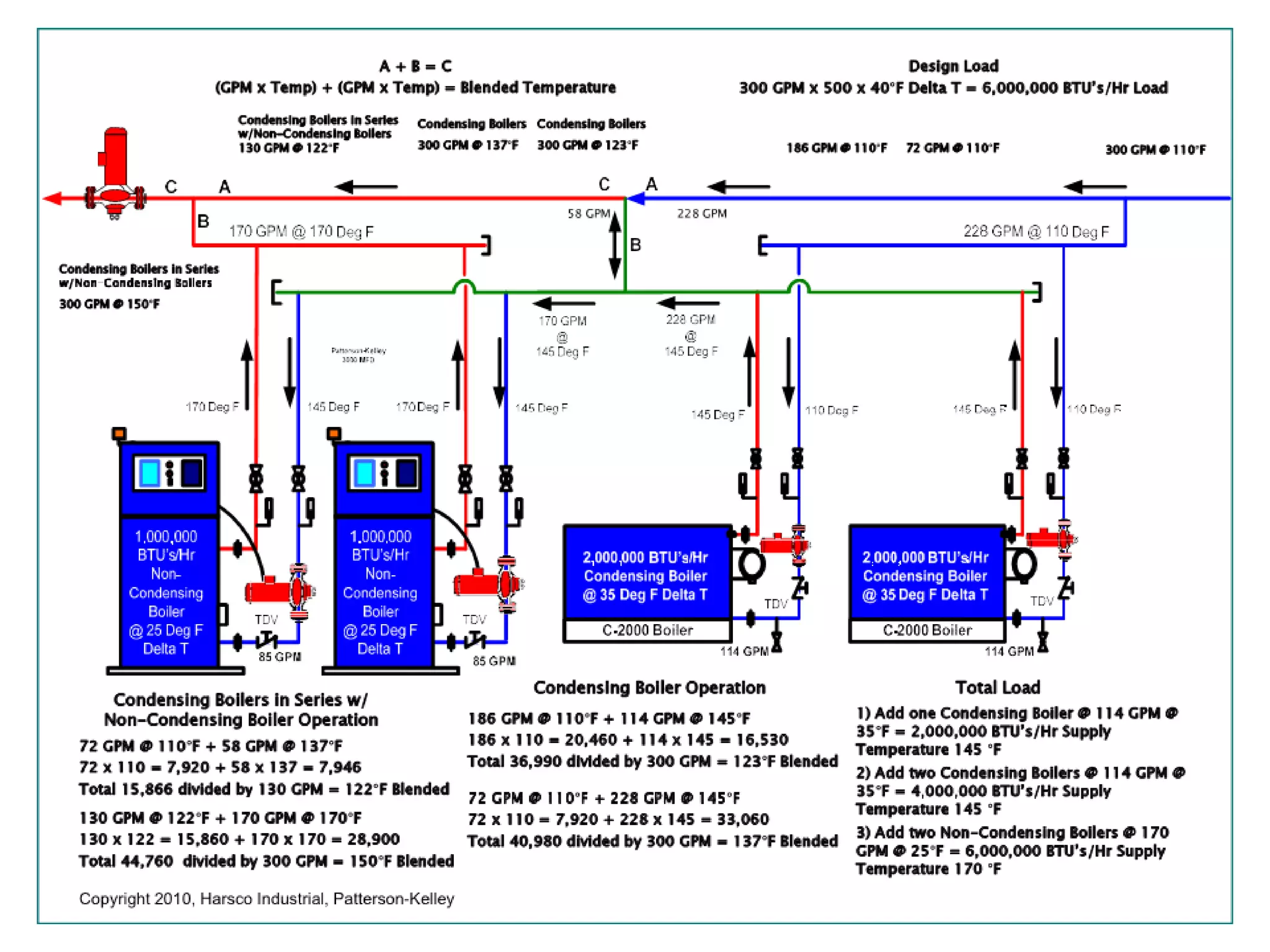

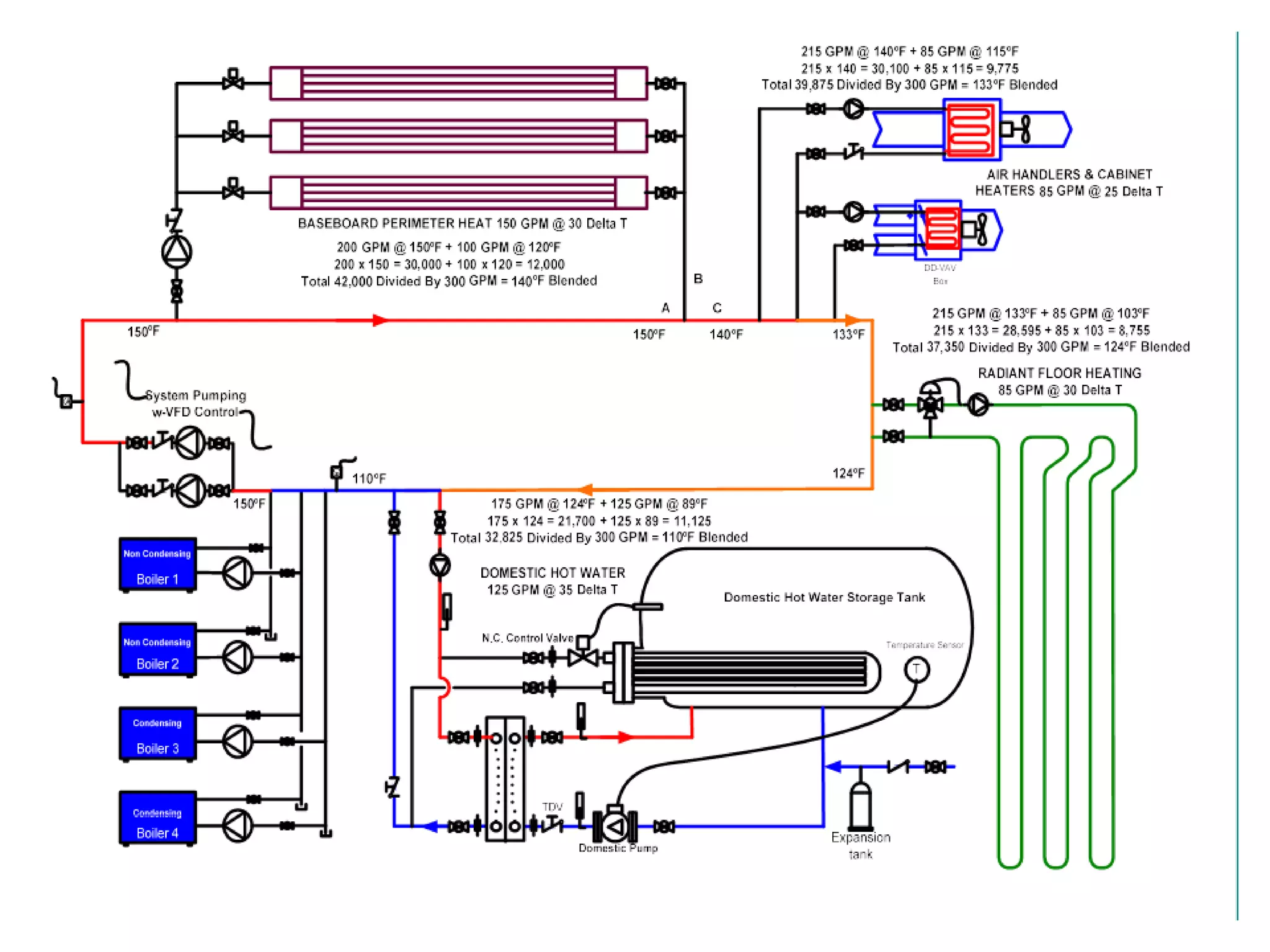

- Common hydronic system types like primary-secondary and variable flow systems

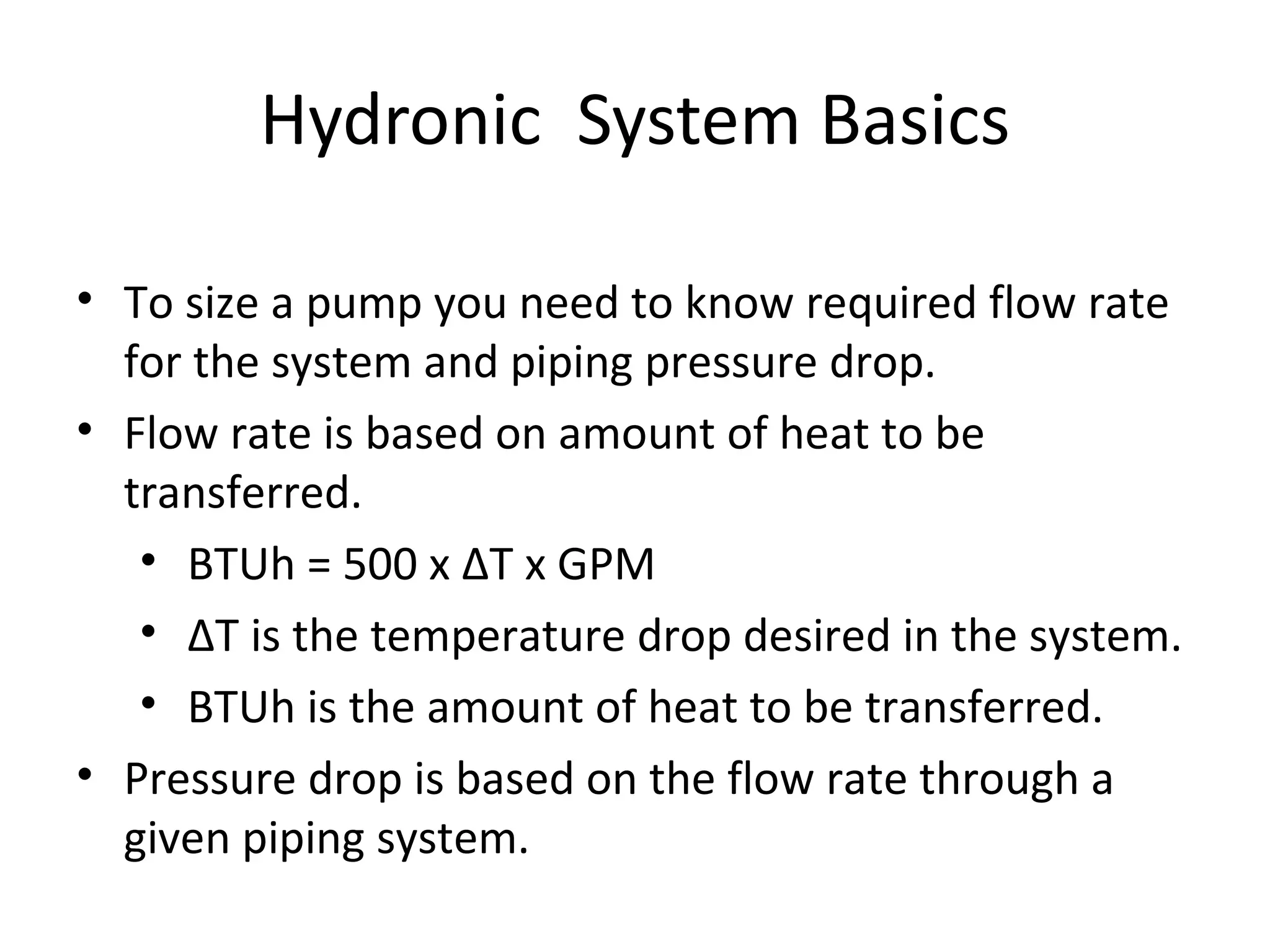

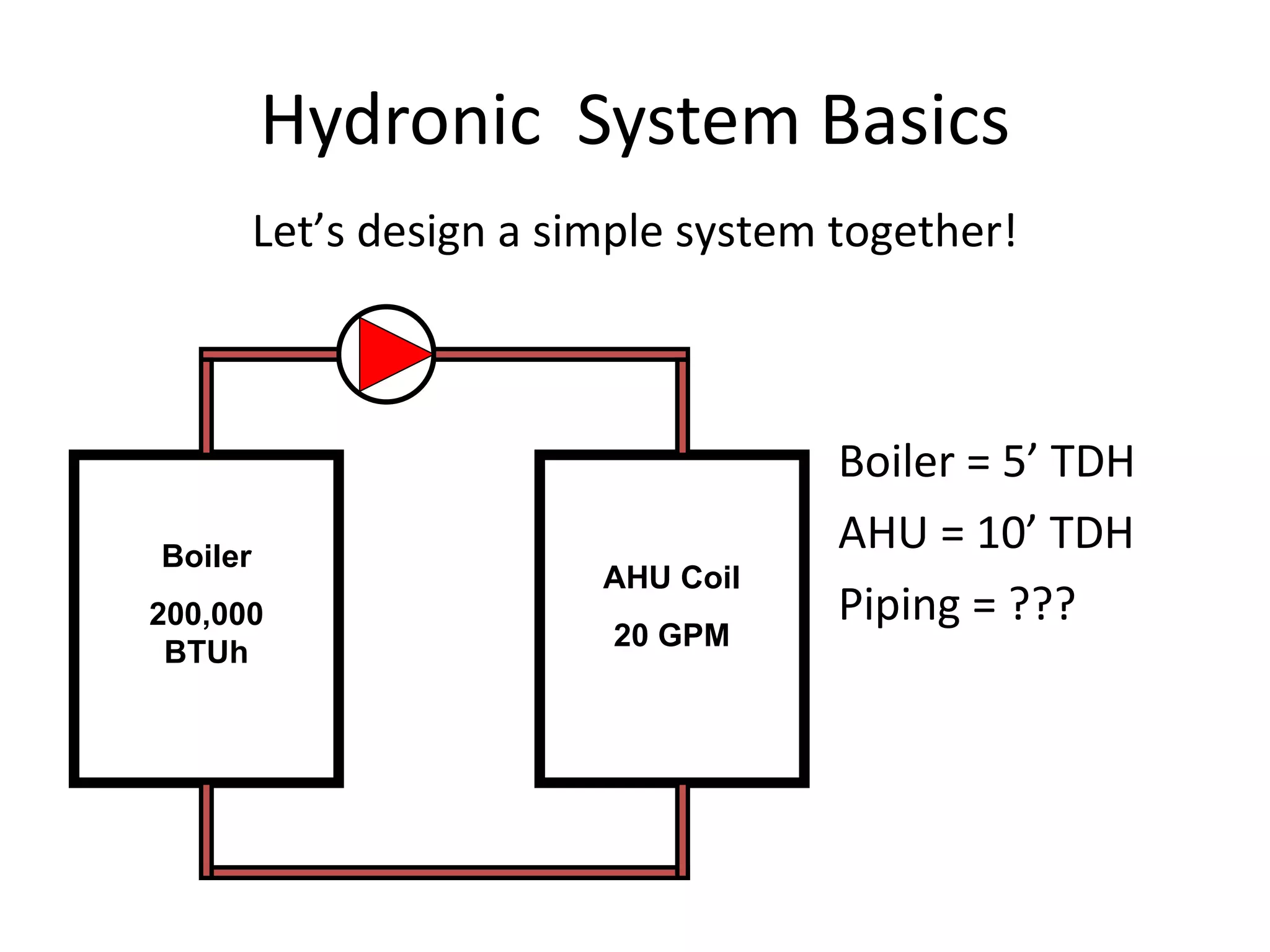

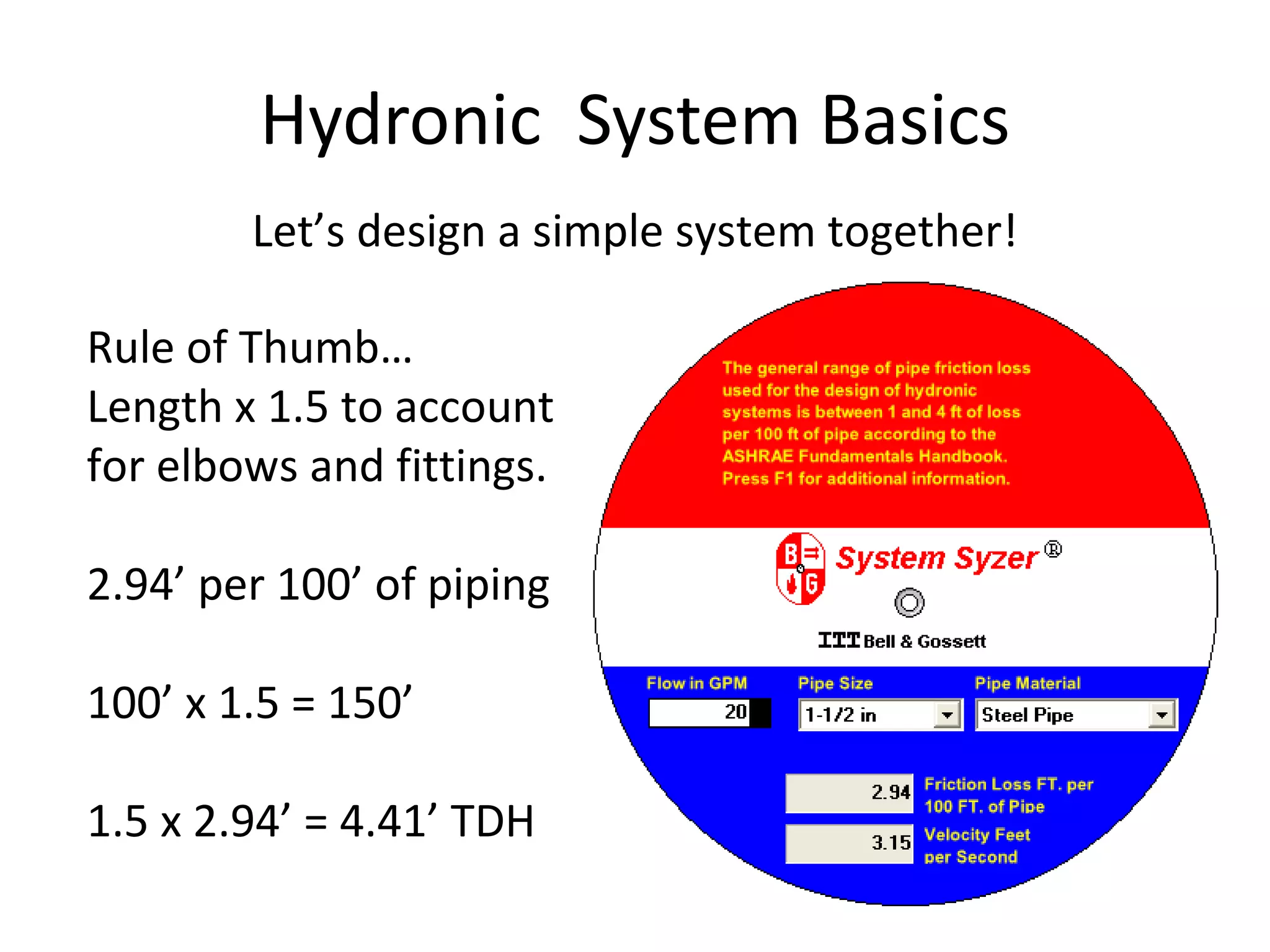

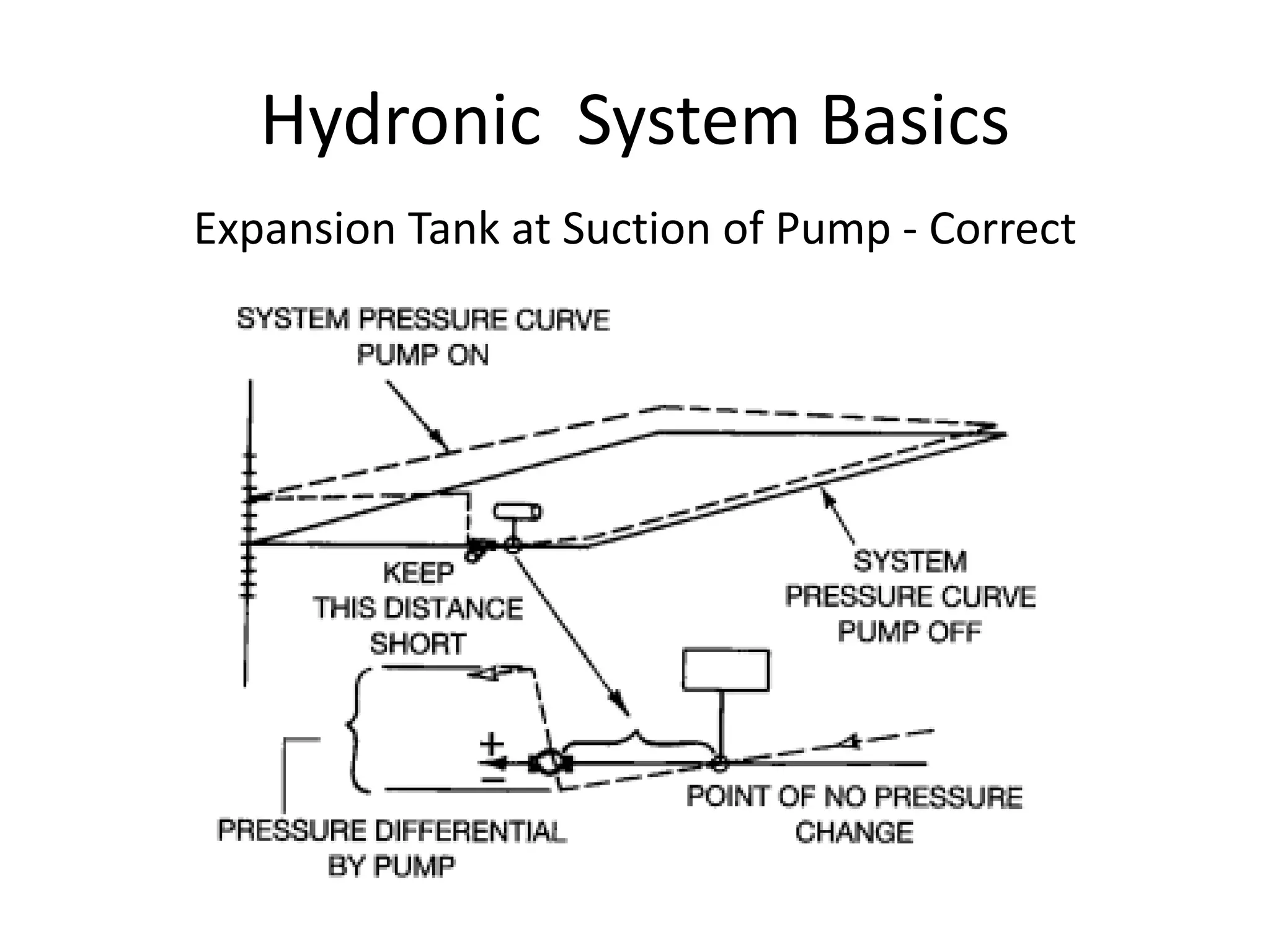

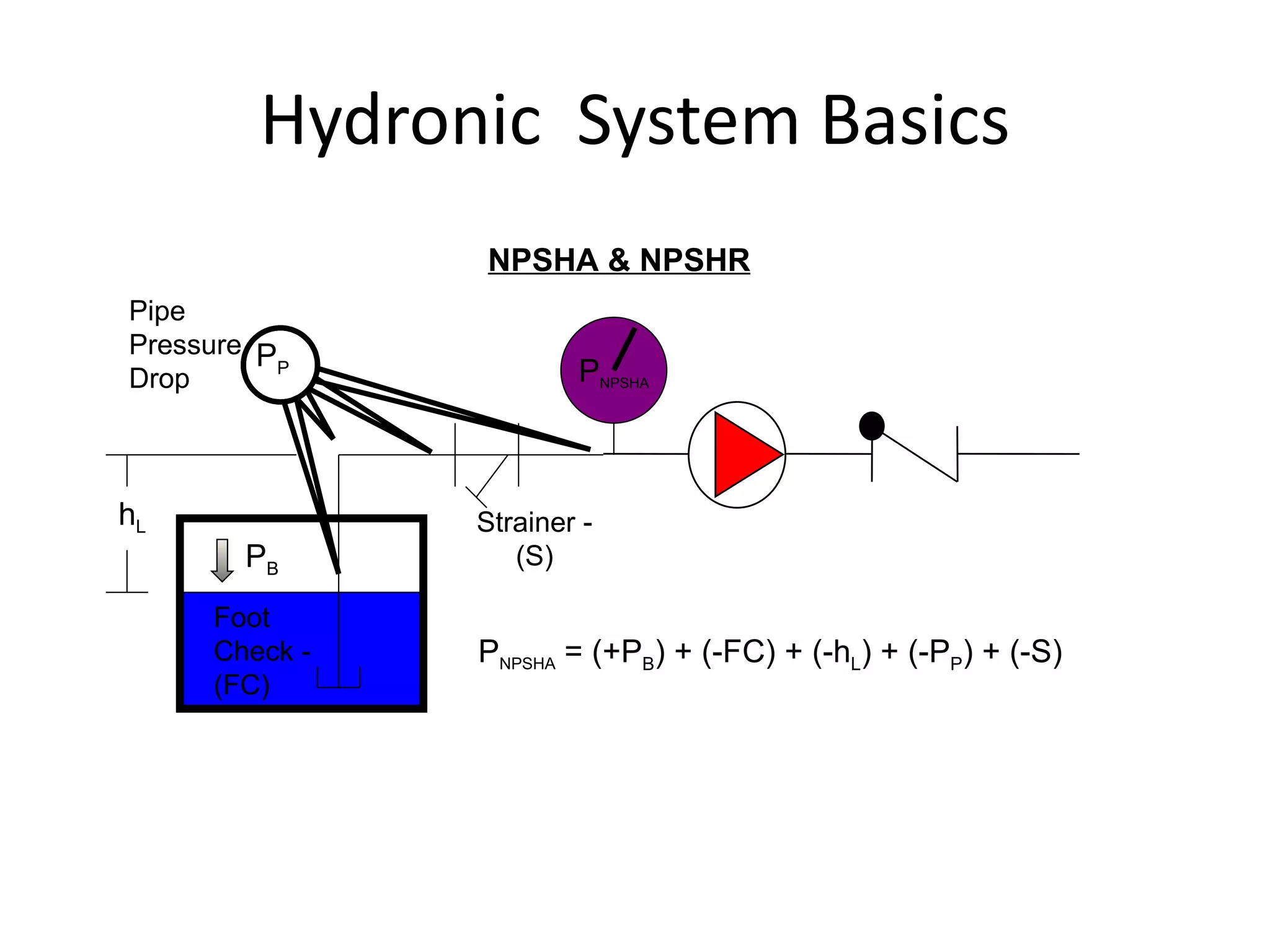

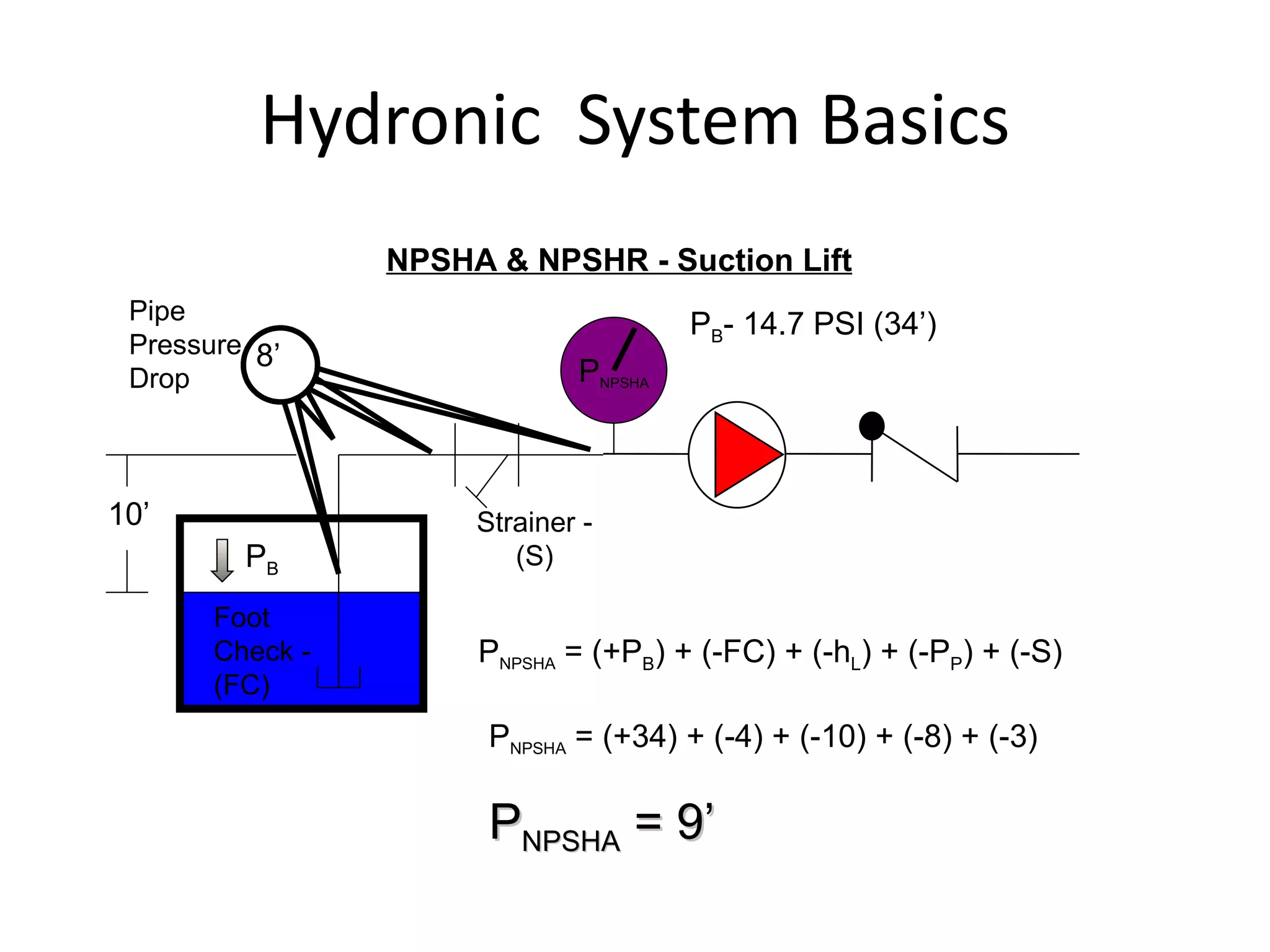

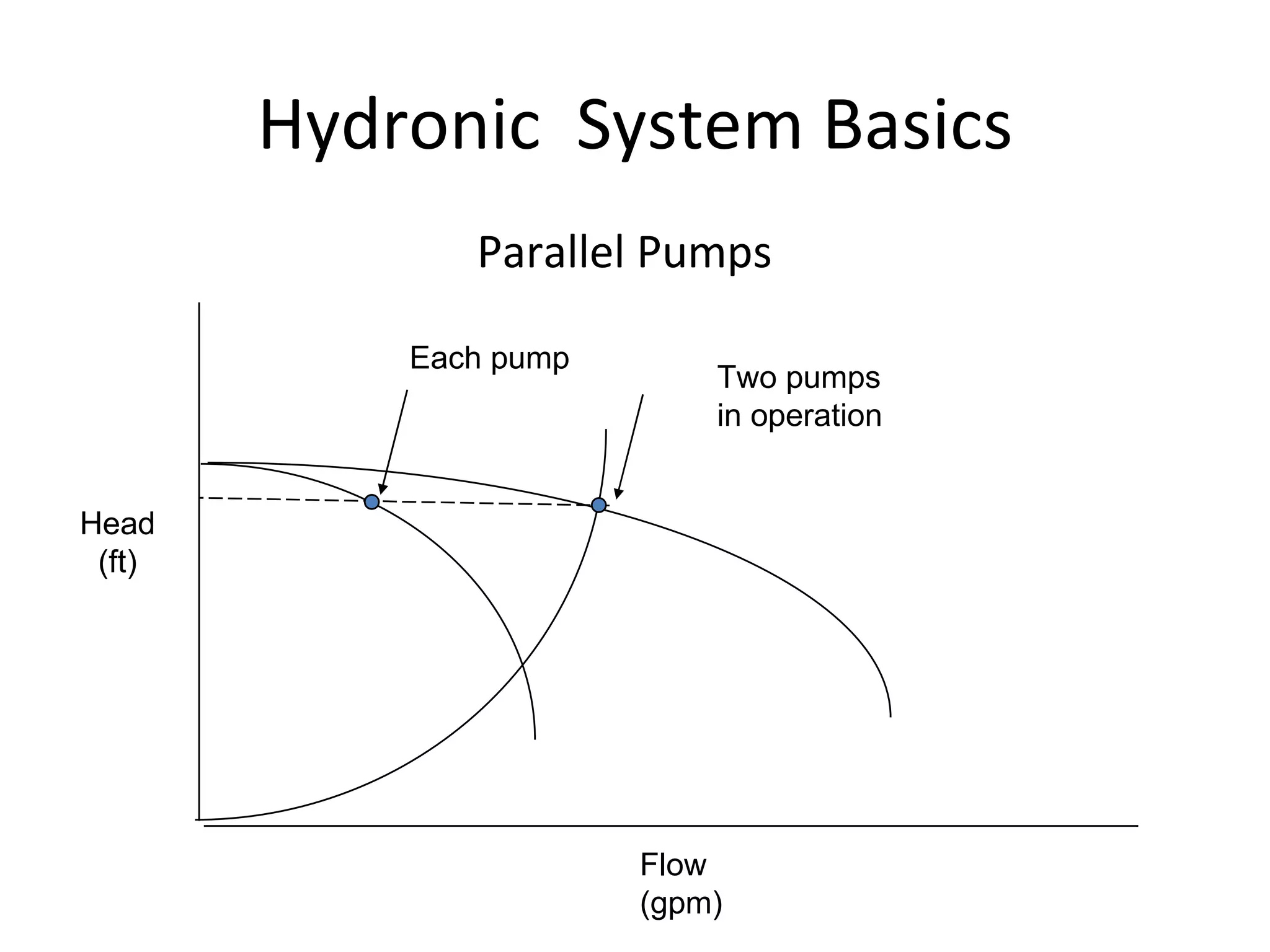

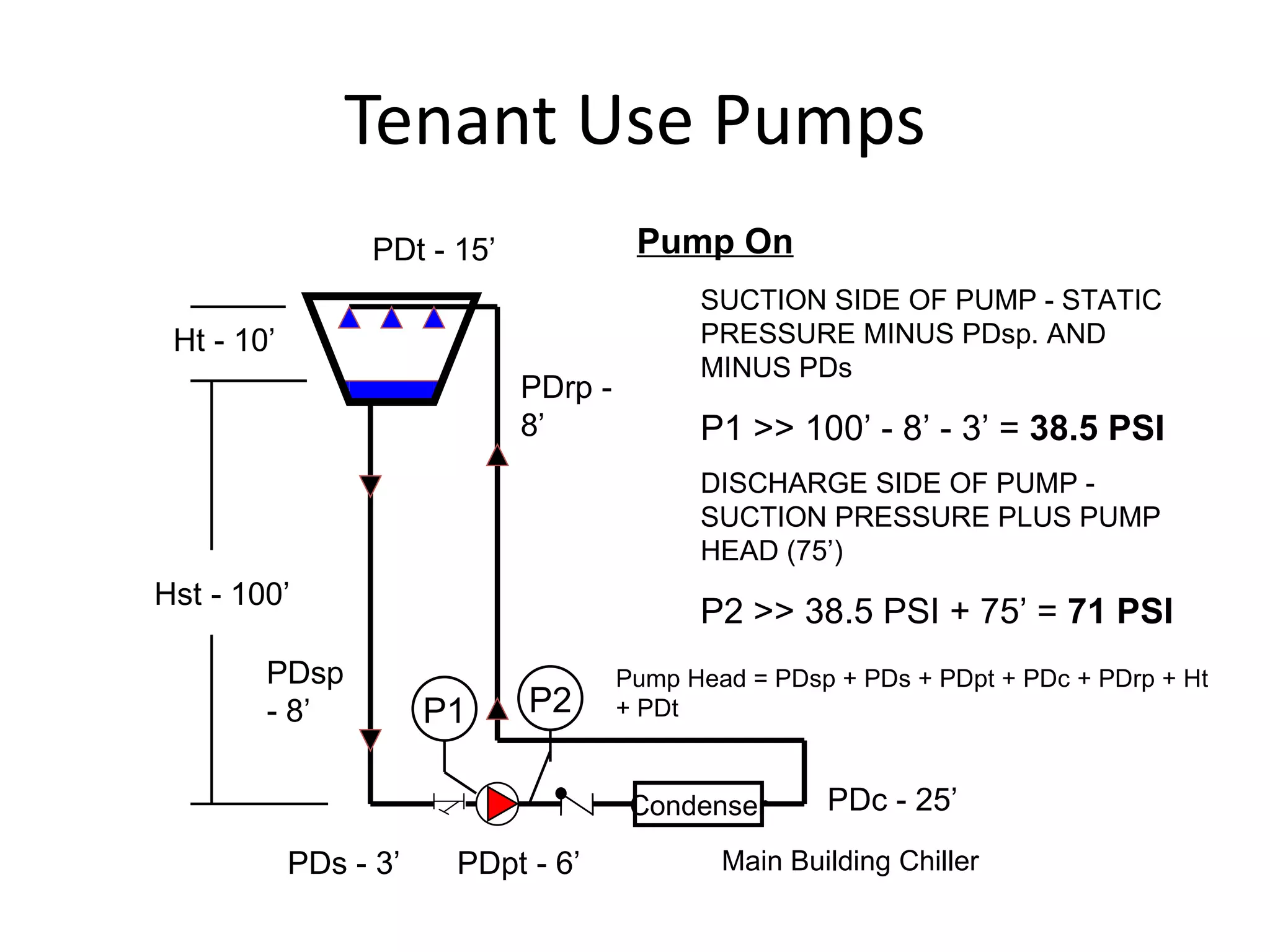

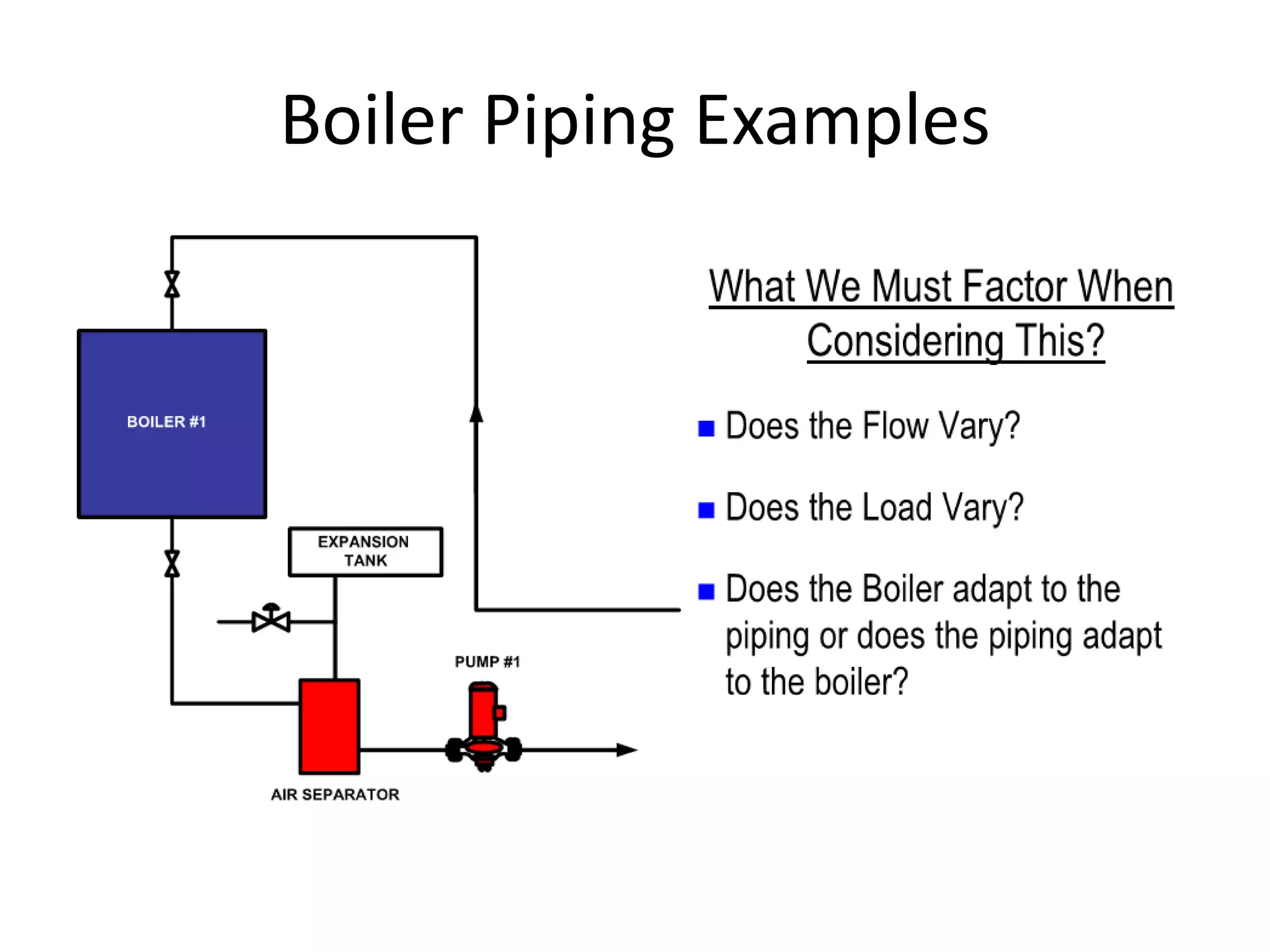

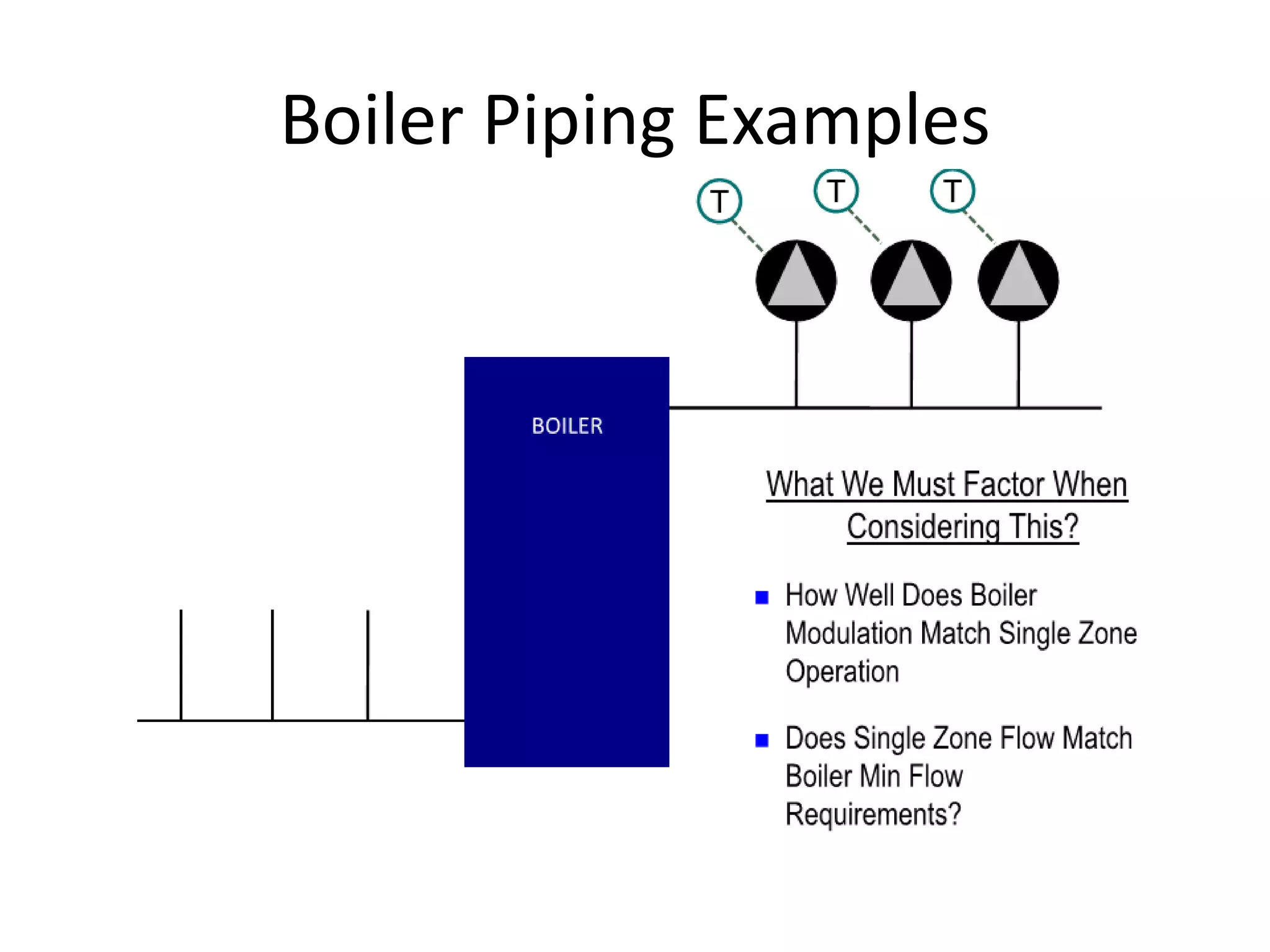

- Key considerations for piping design like pump sizing, pressure drops, and expansion tank placement

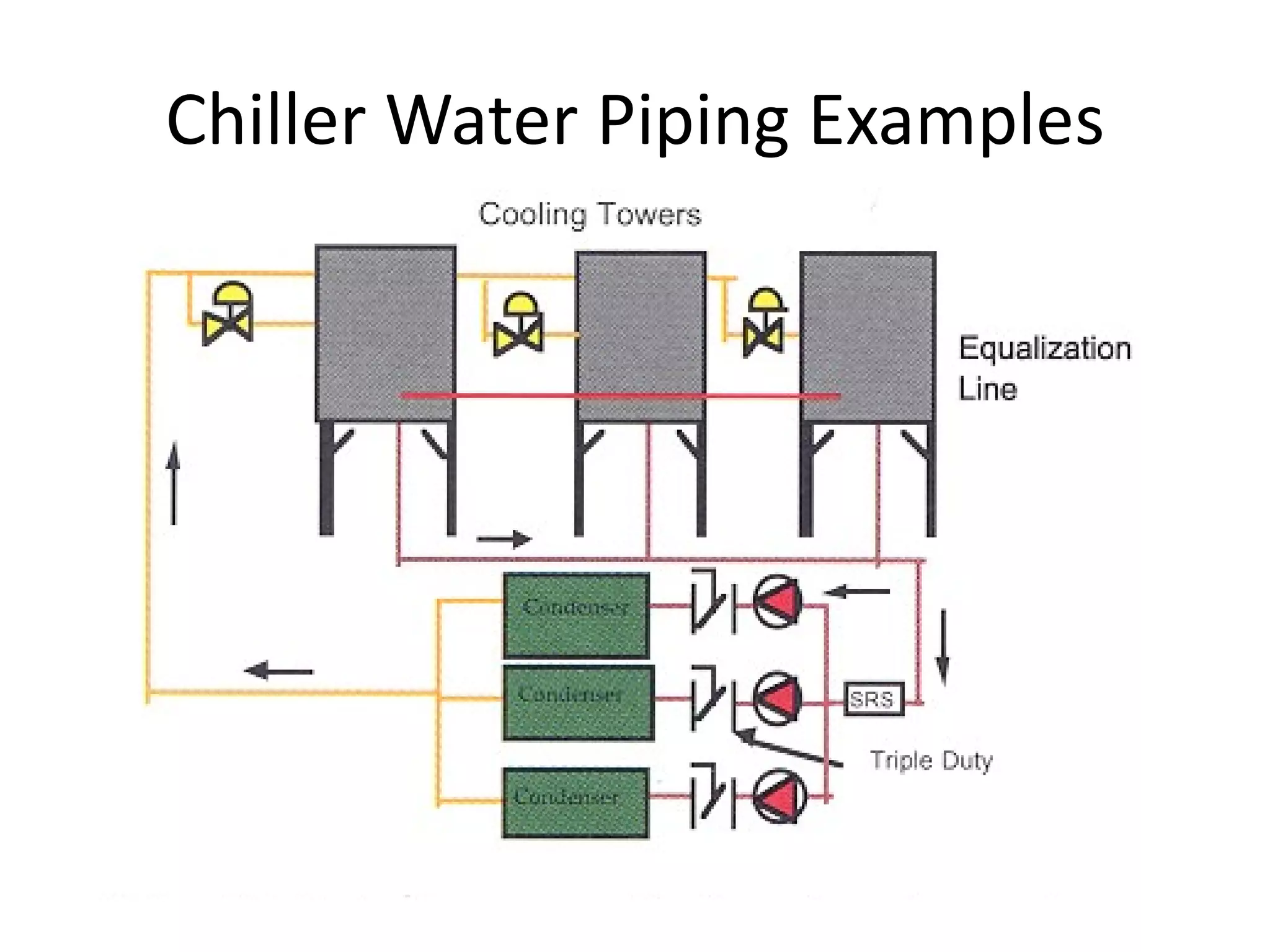

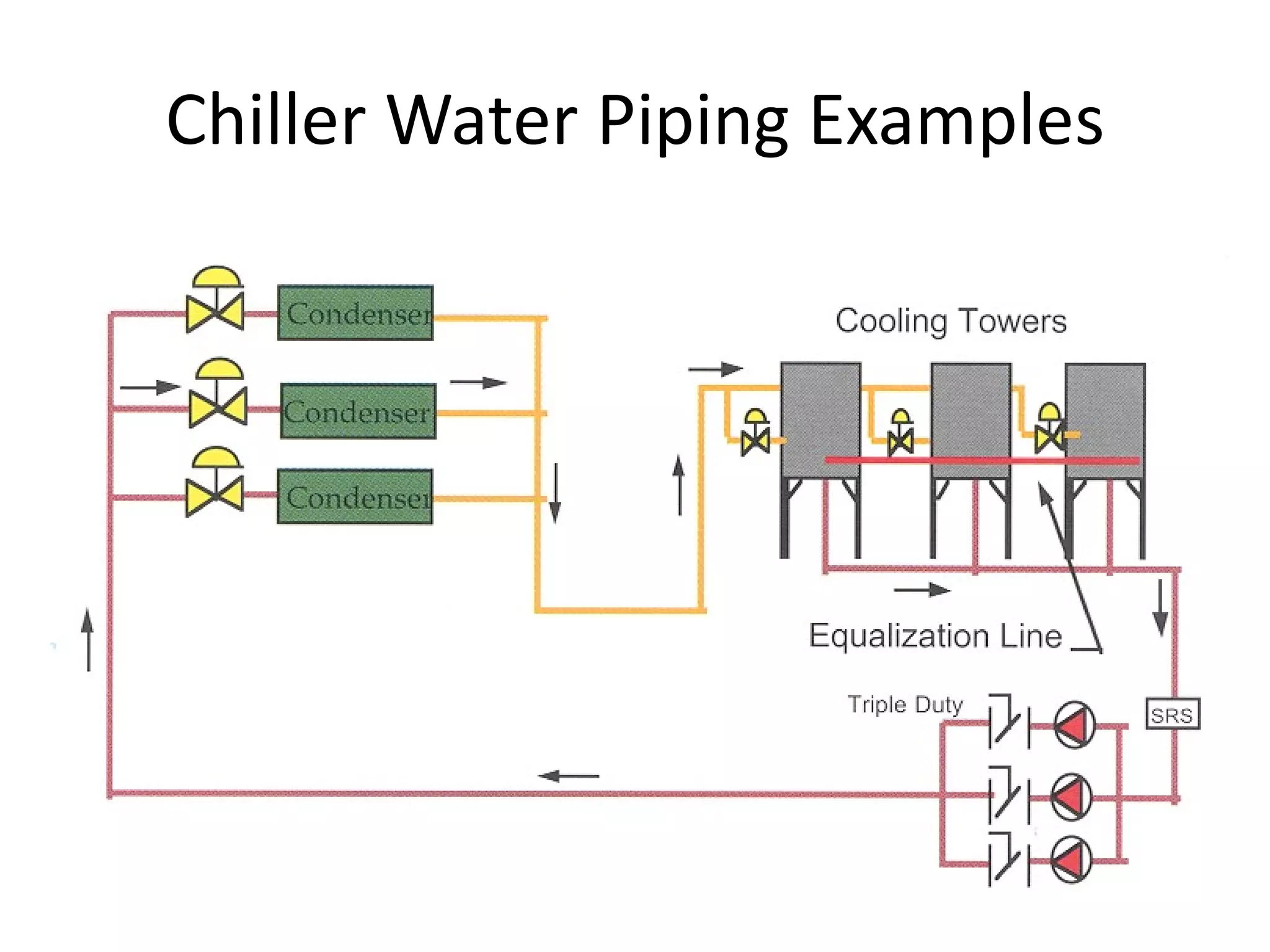

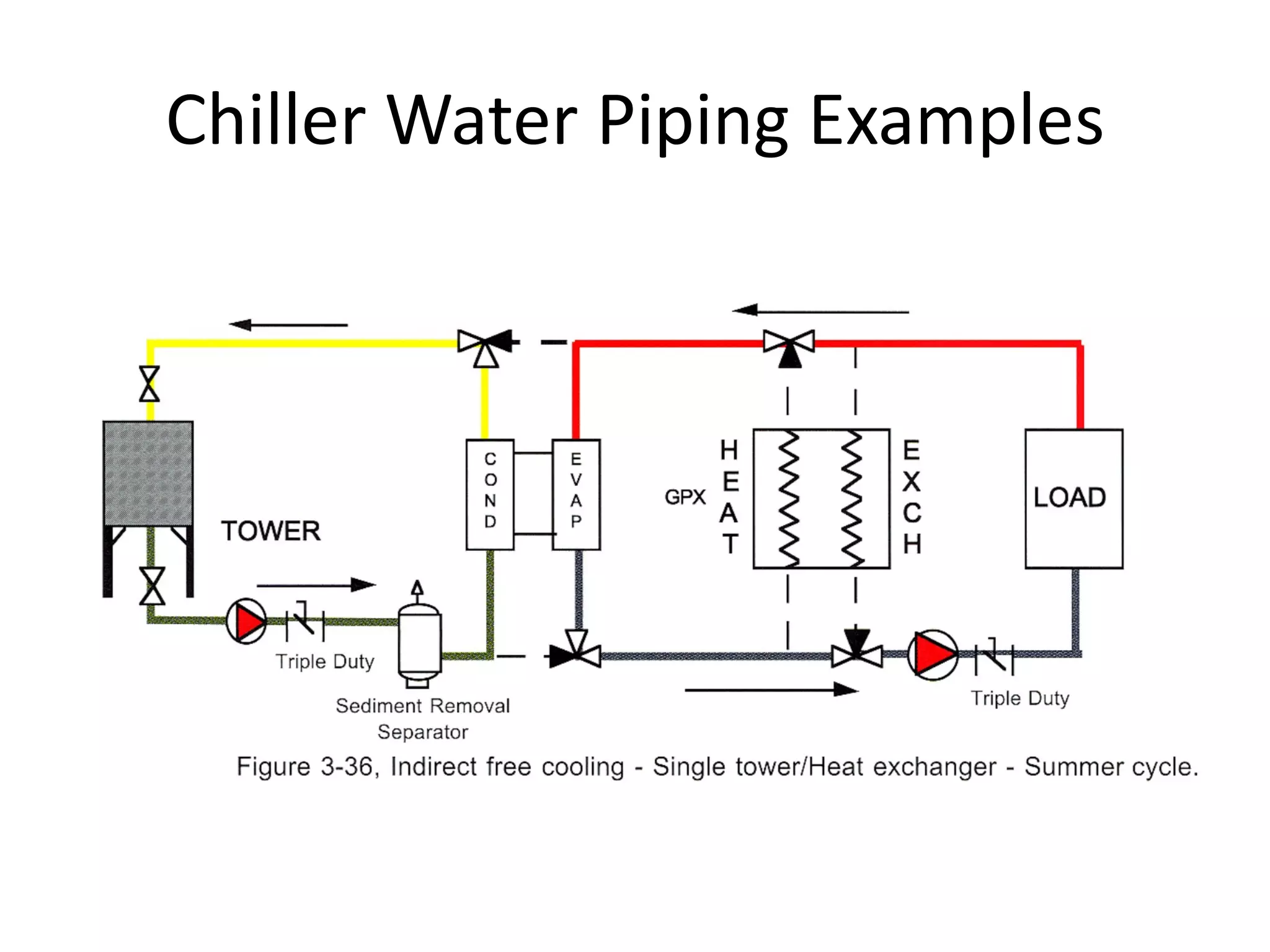

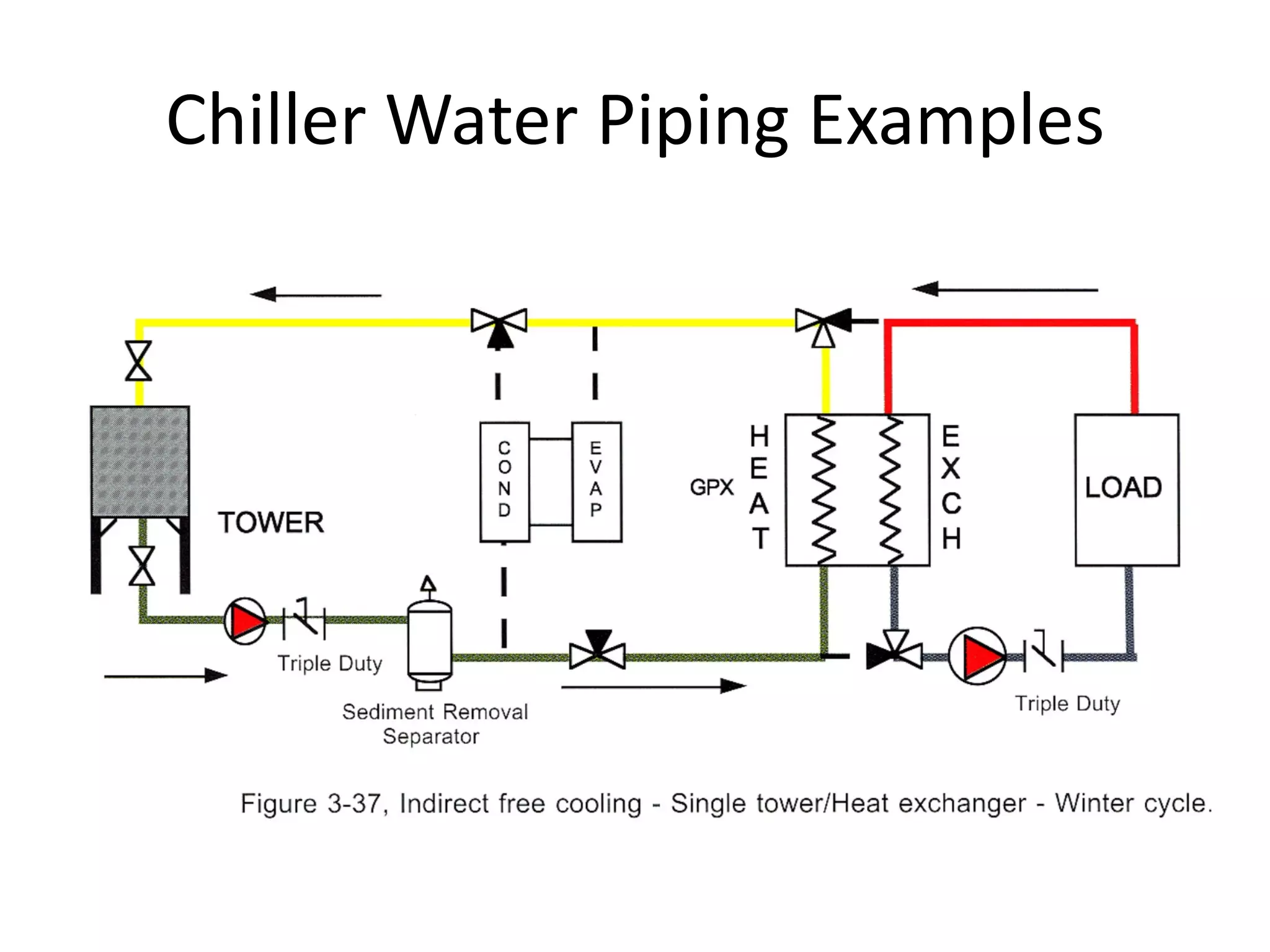

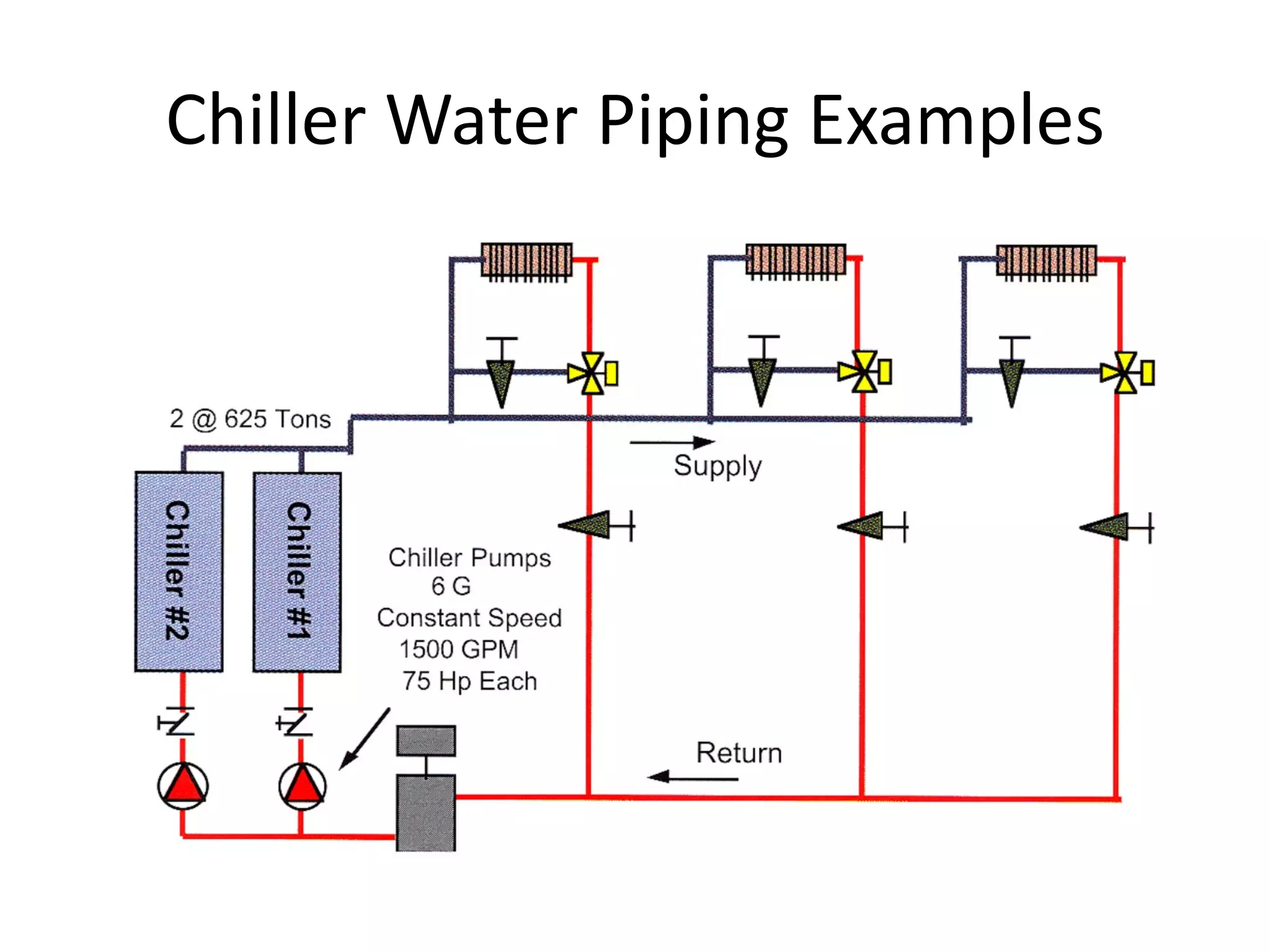

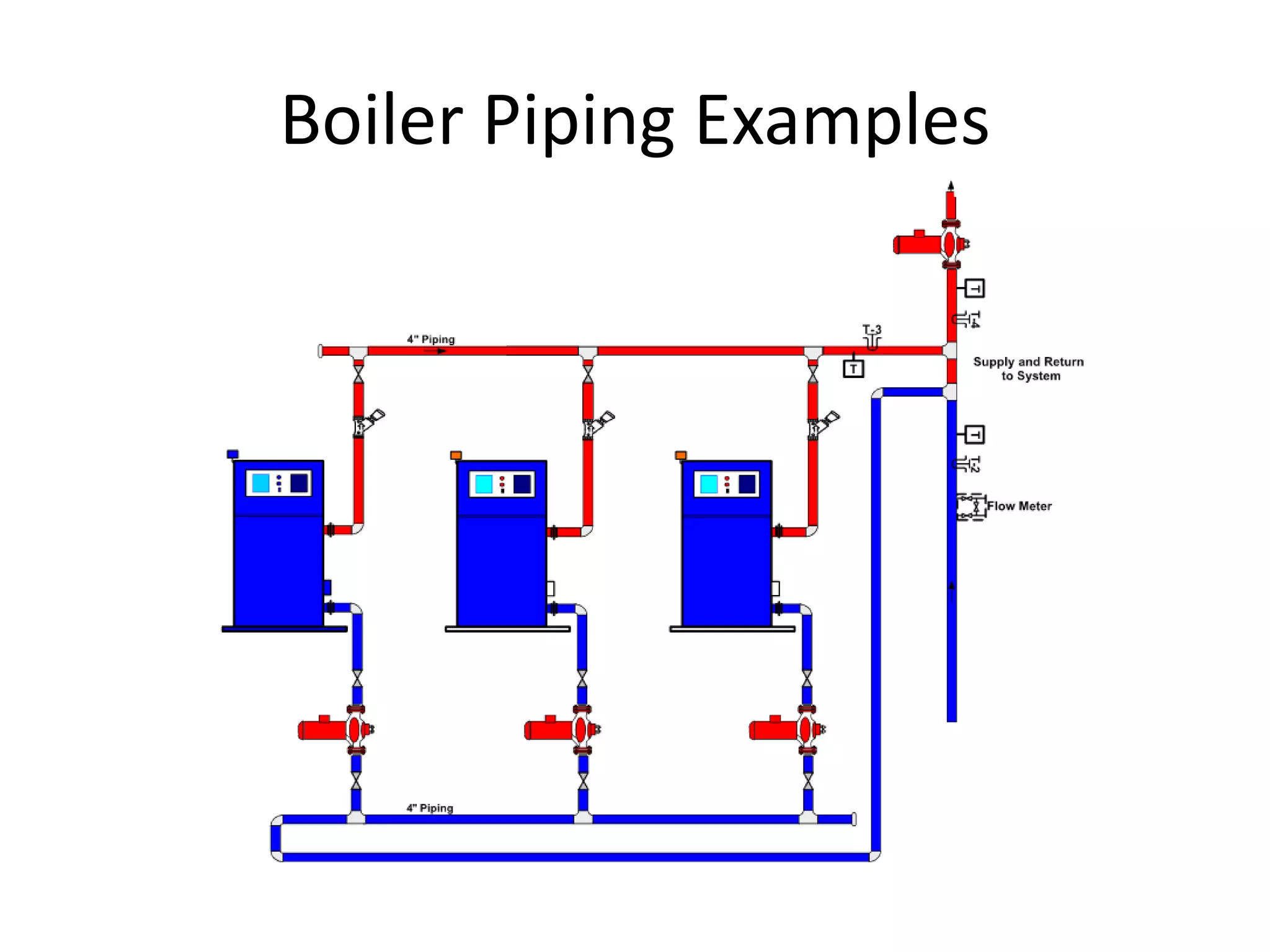

- Examples of specific system designs for chilled water, boiler water, and complex multi-building systems

- Benefits of variable speed pumps for energy efficiency and system controllability