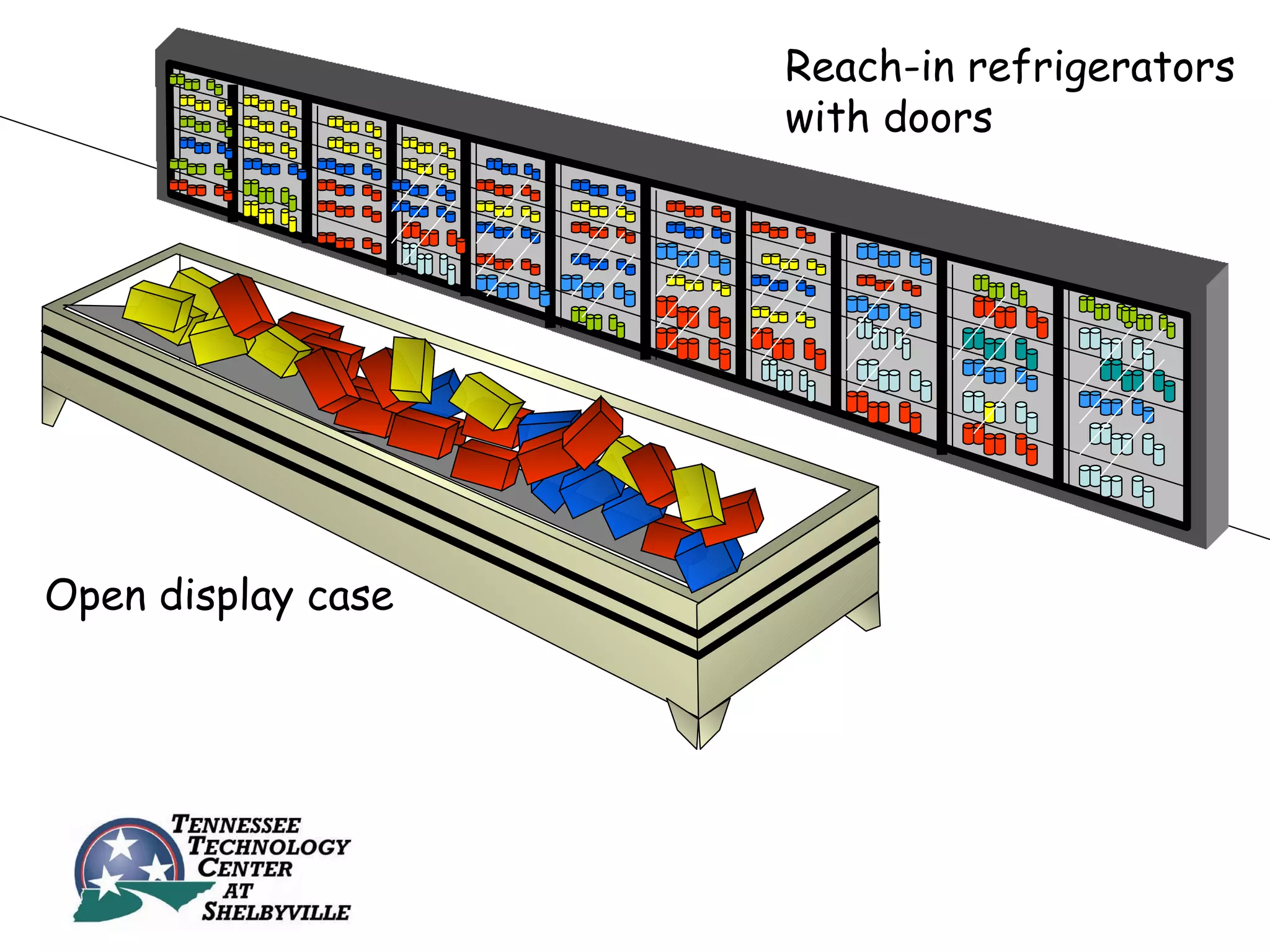

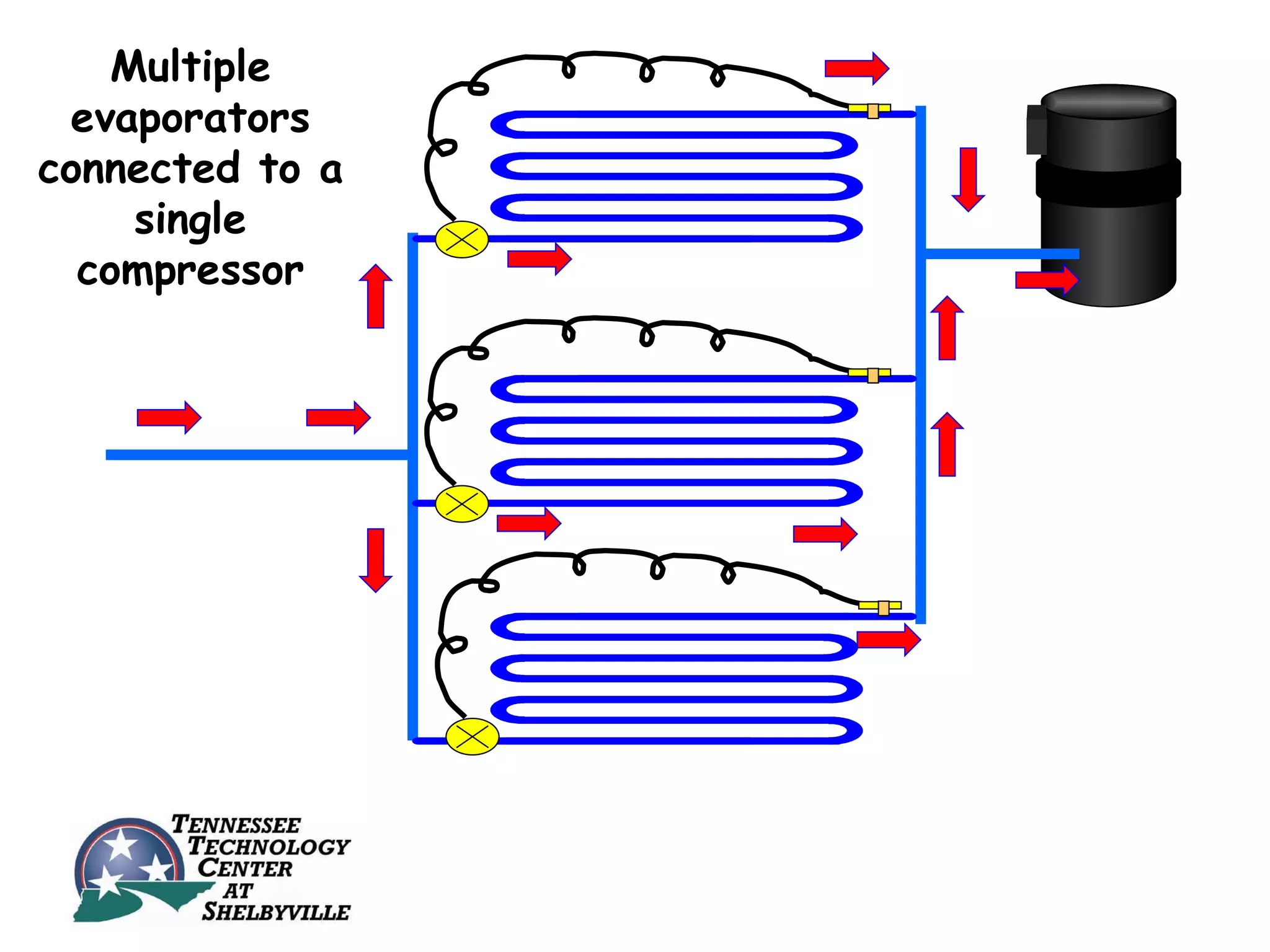

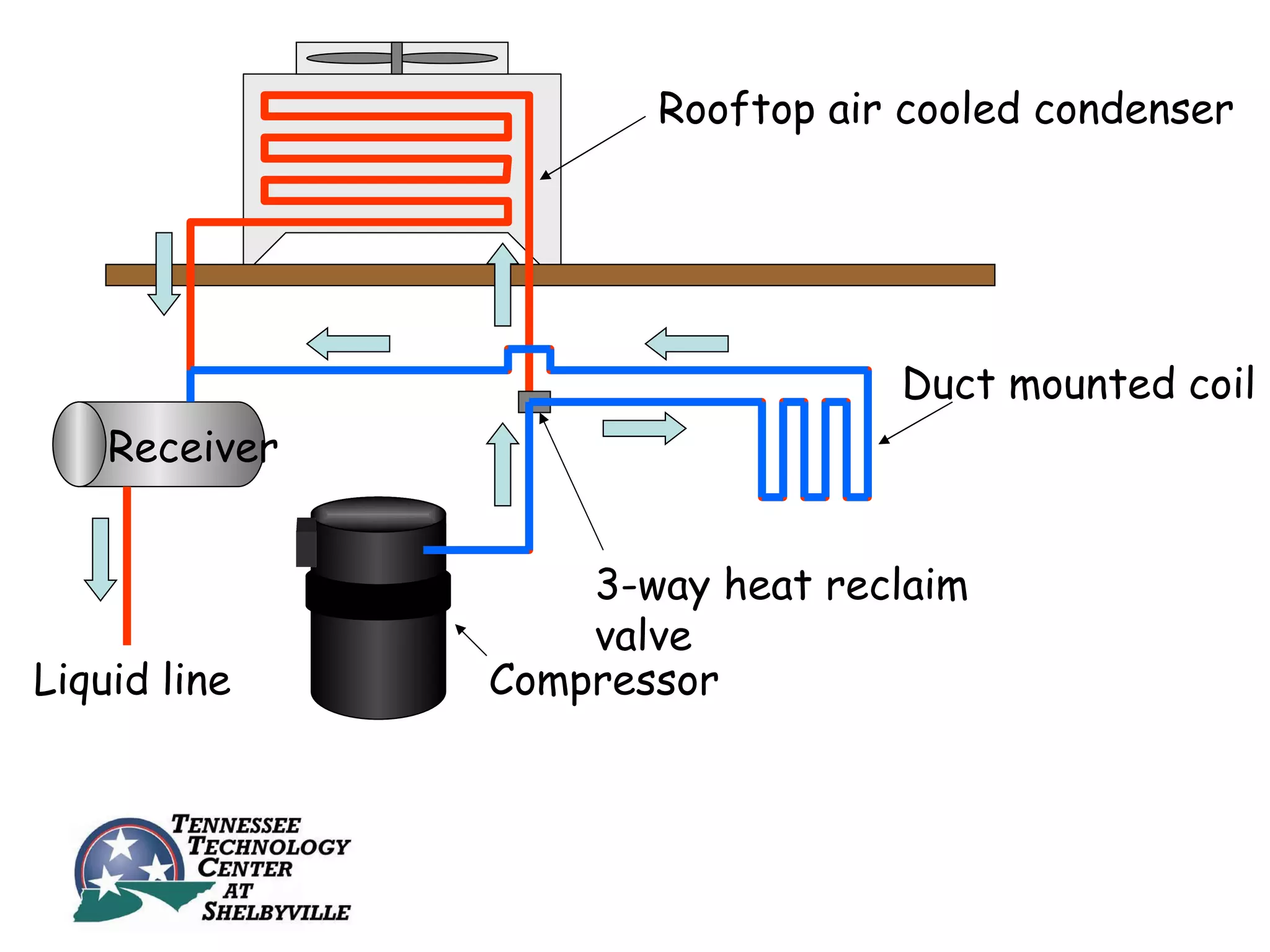

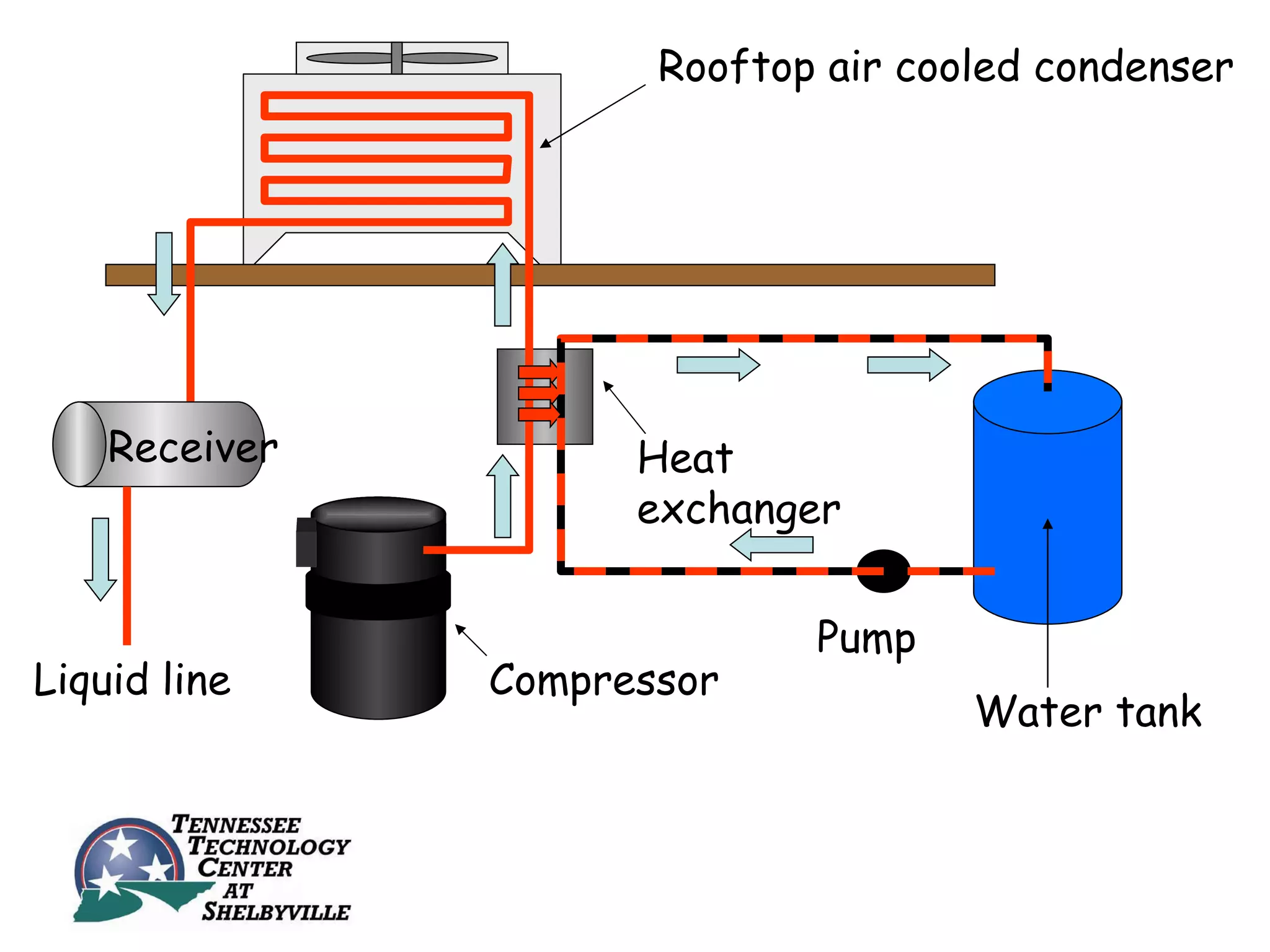

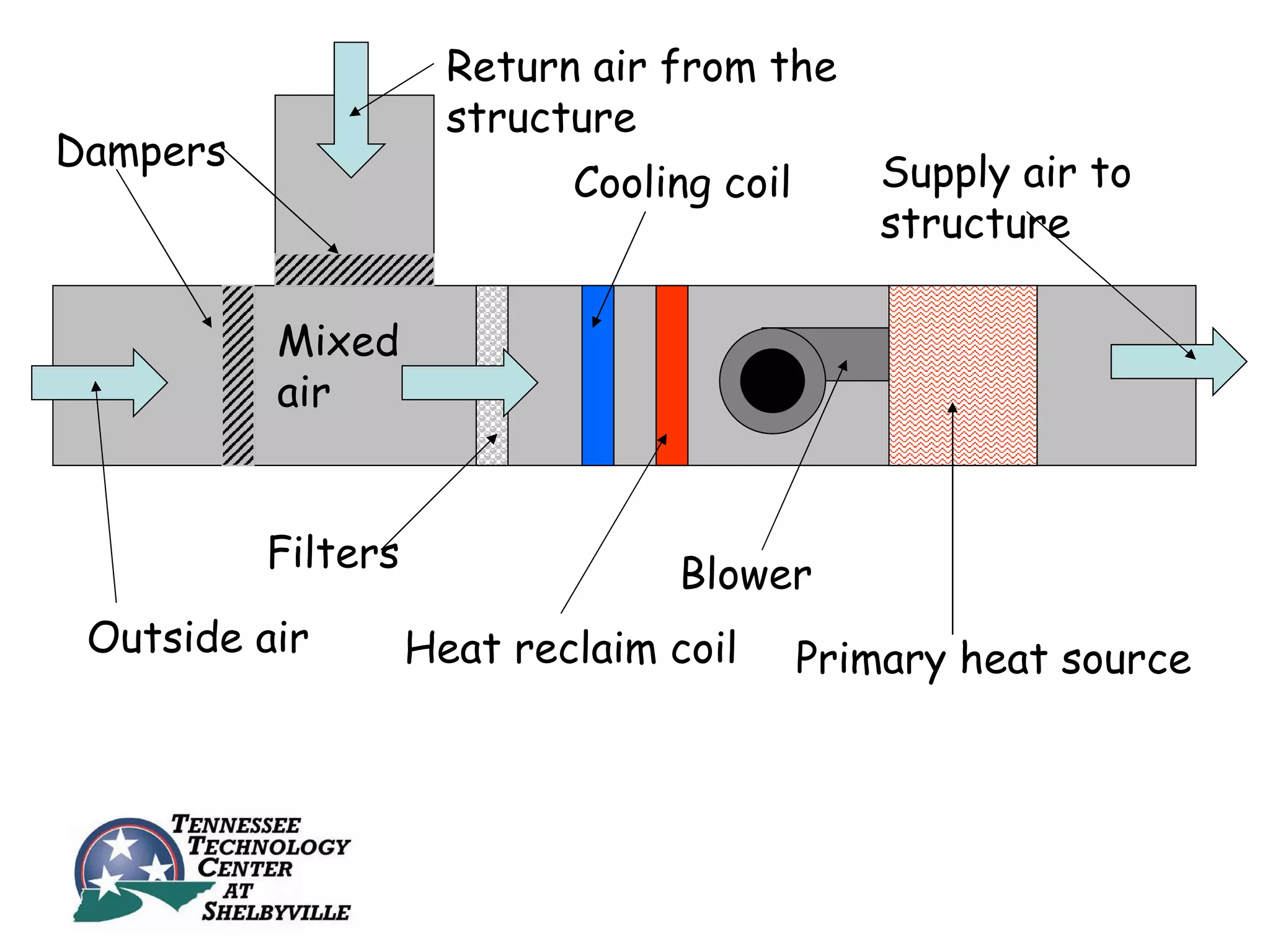

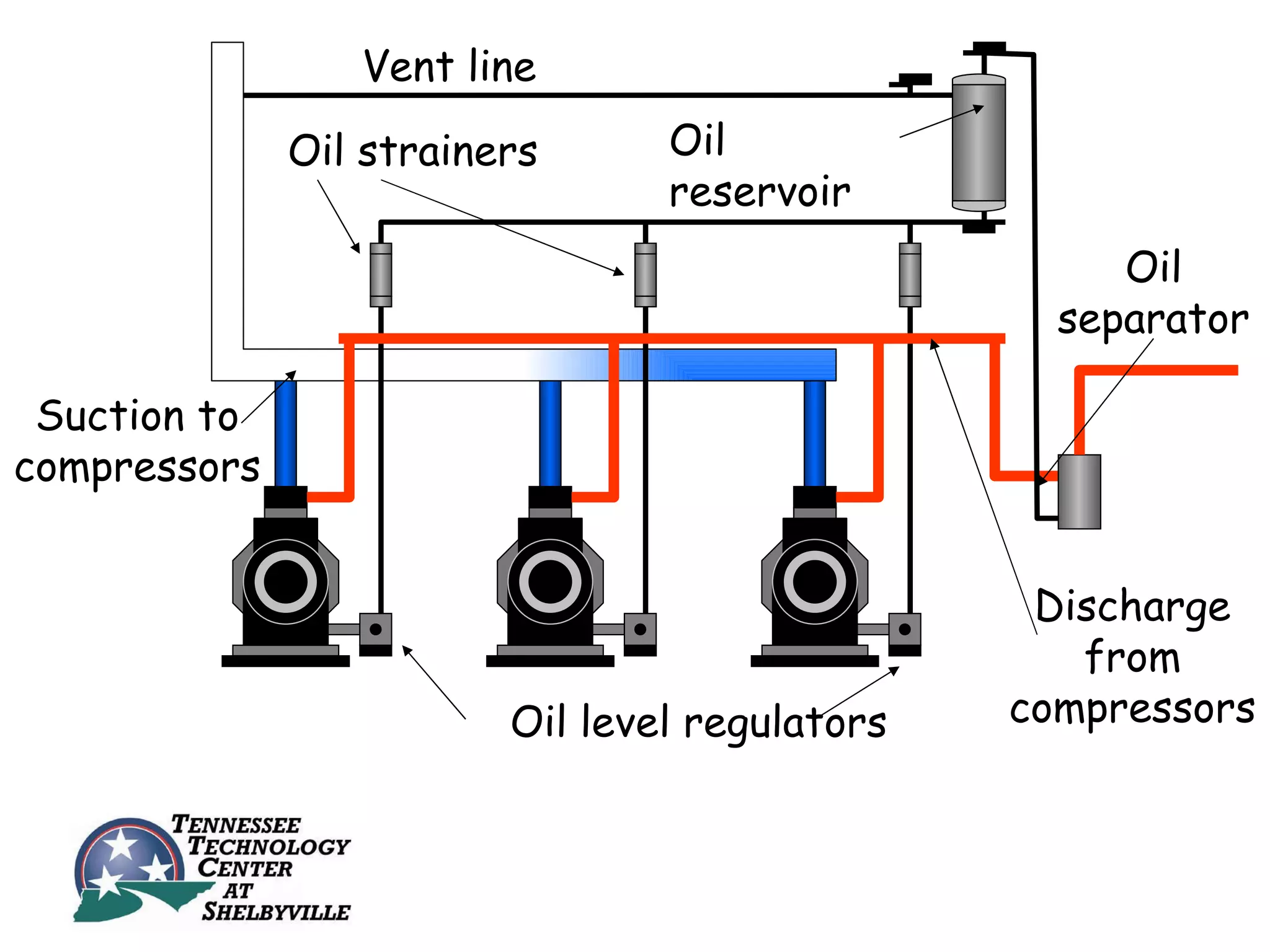

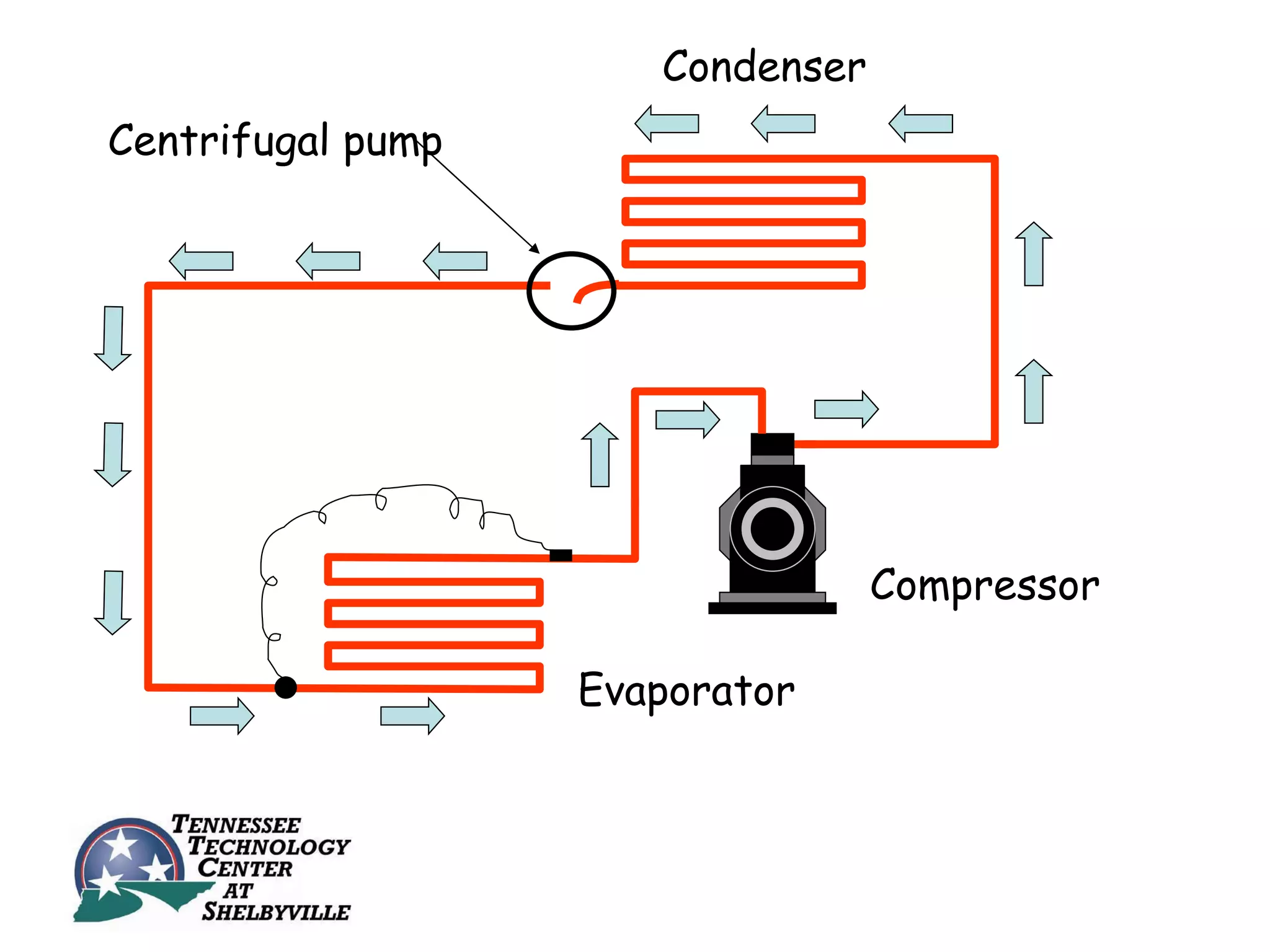

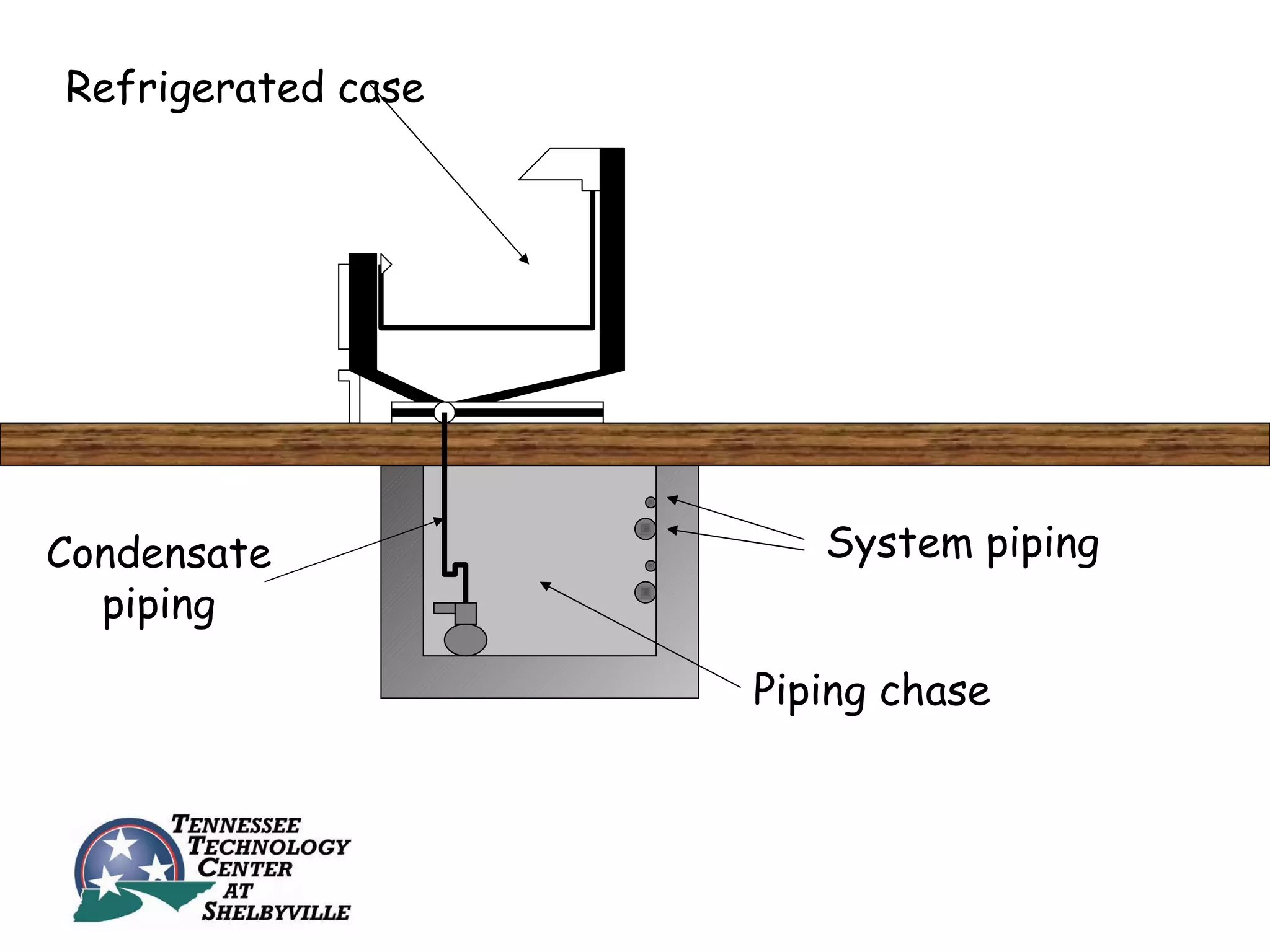

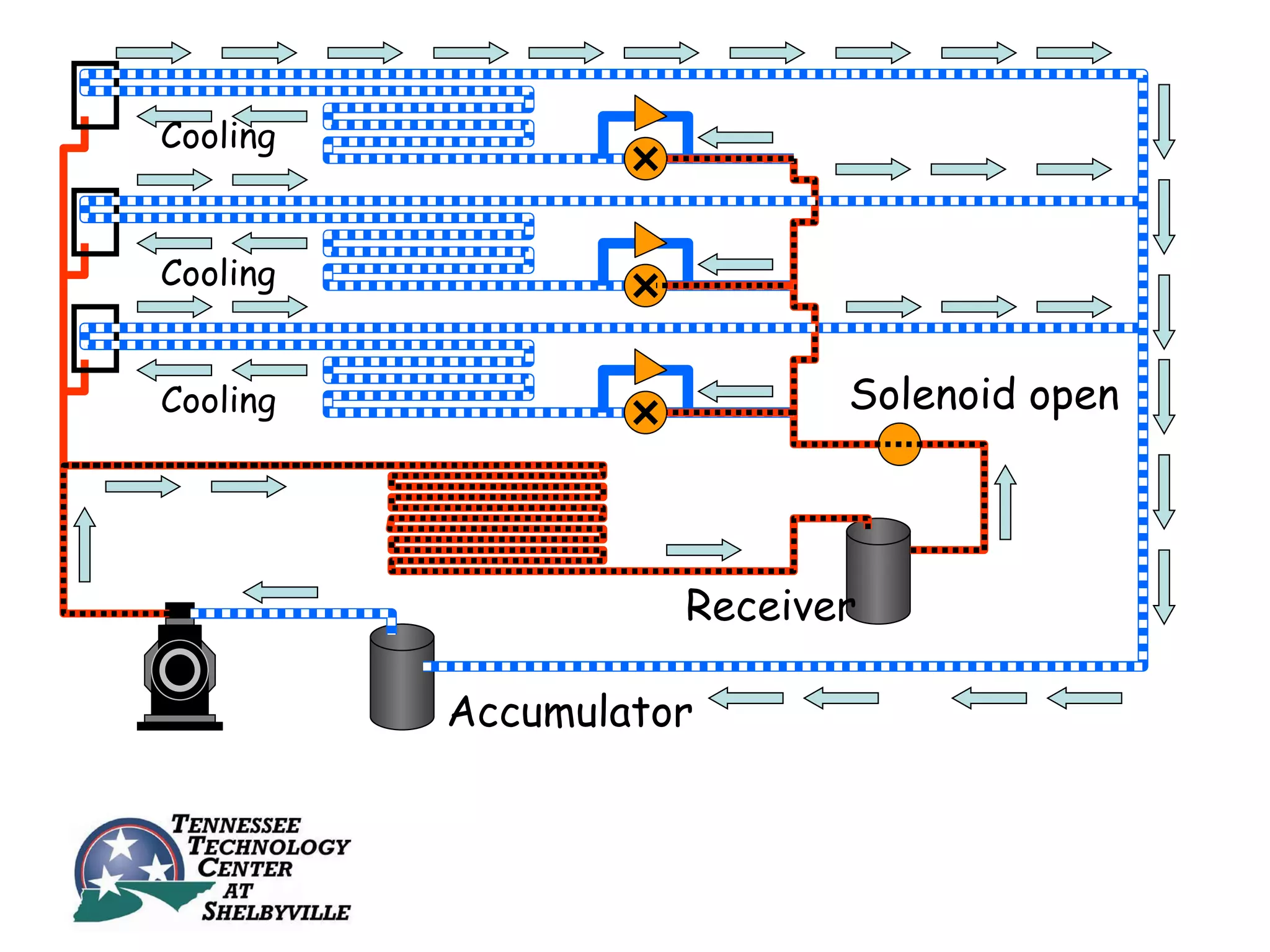

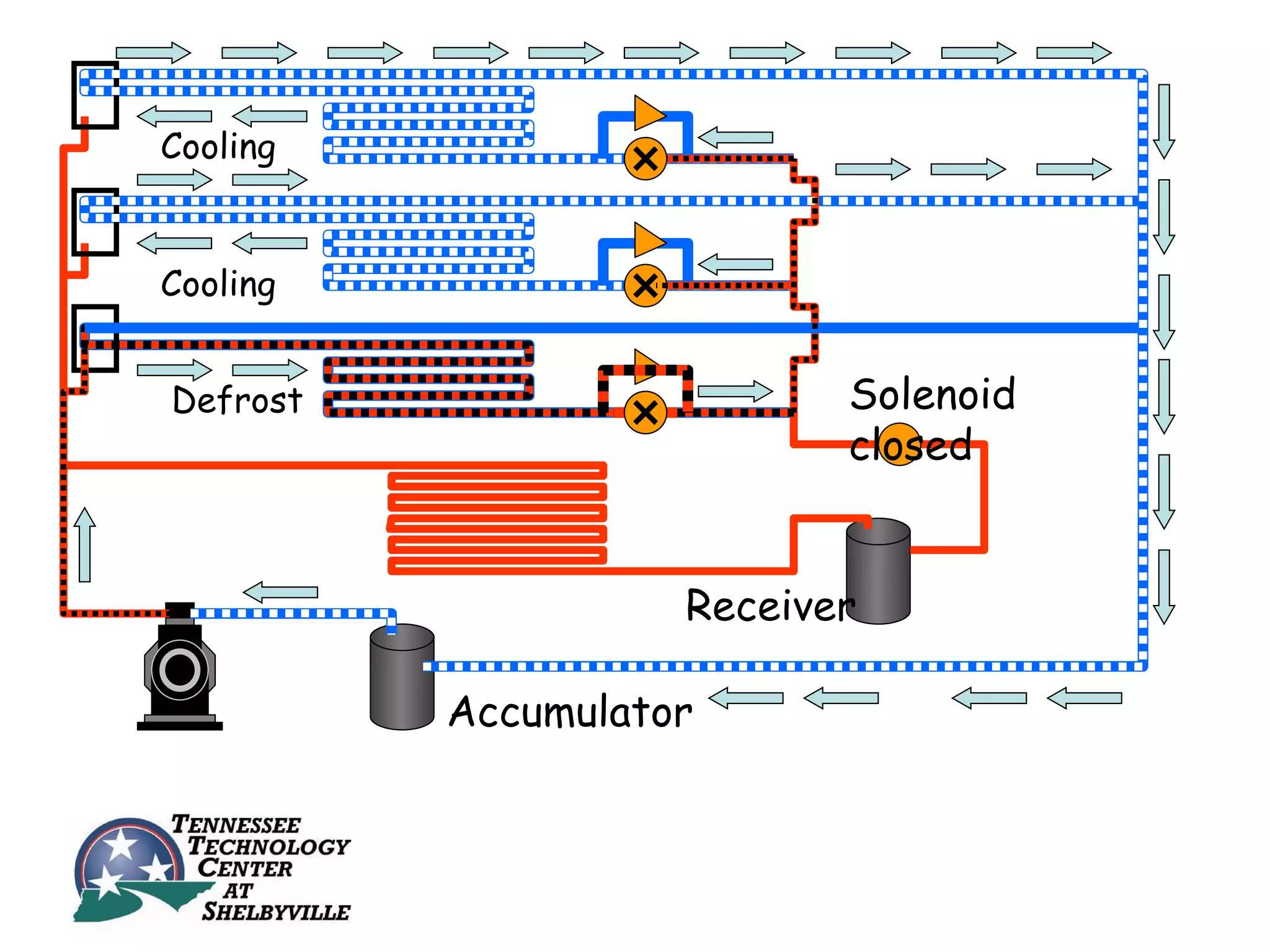

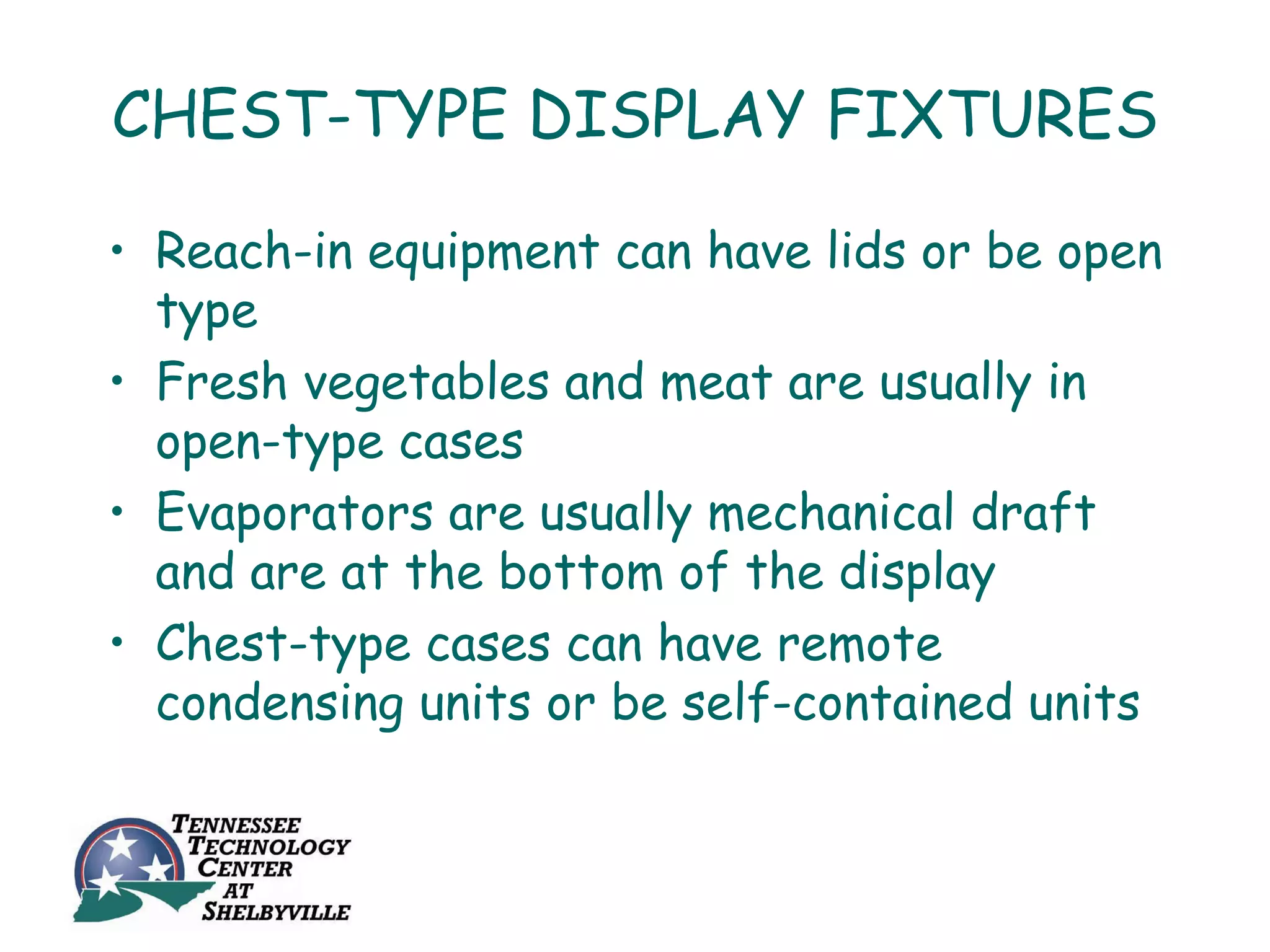

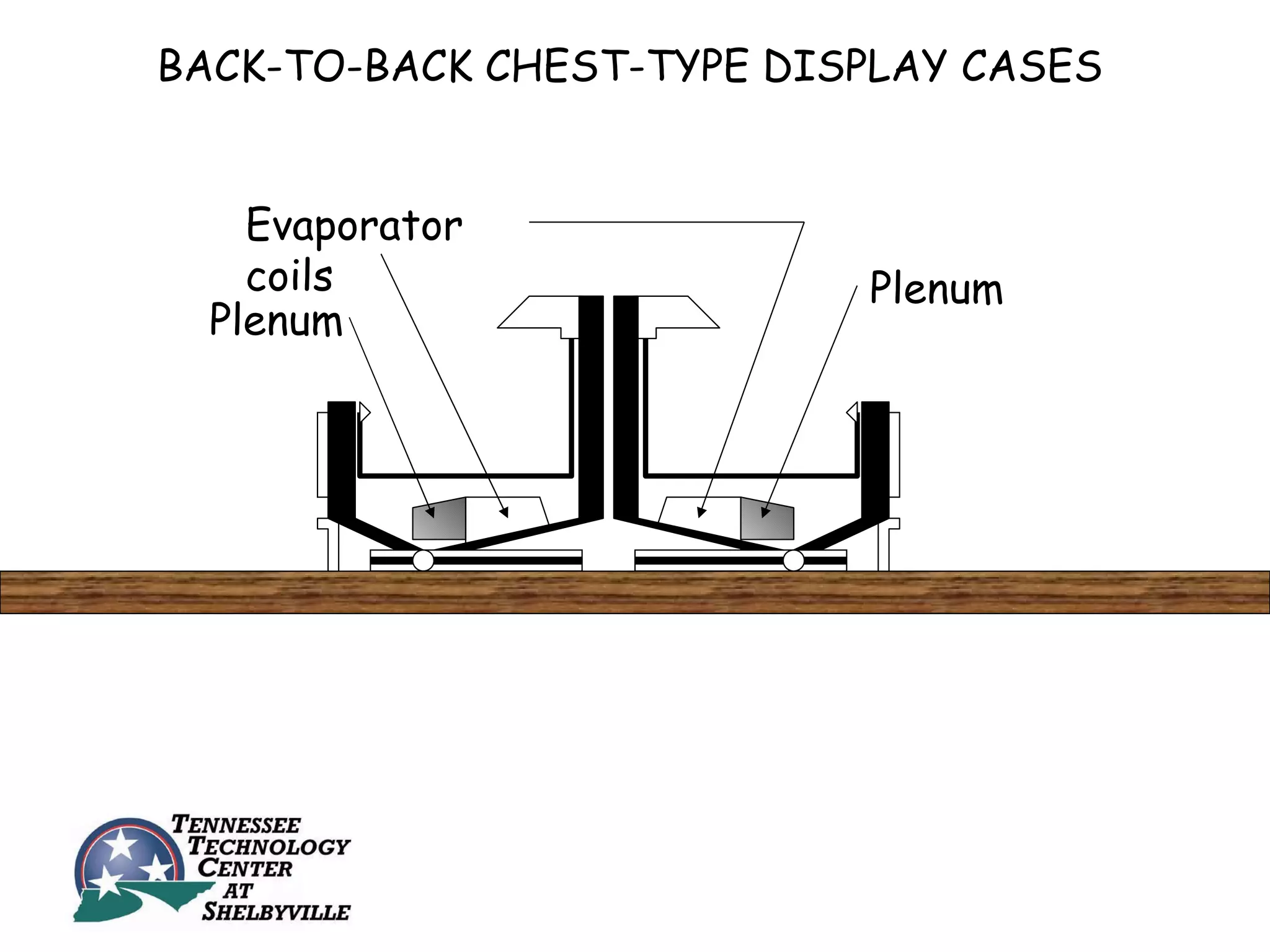

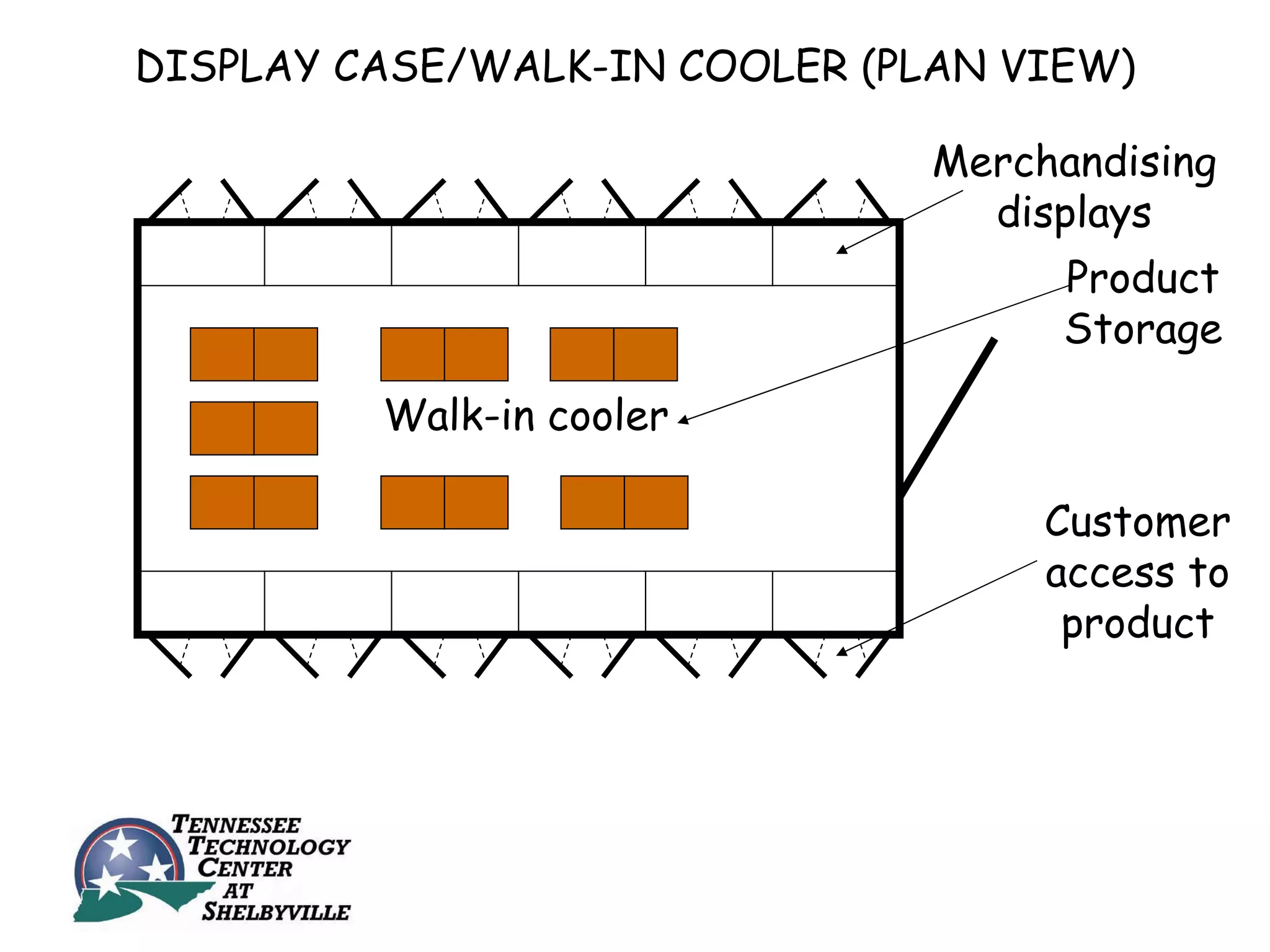

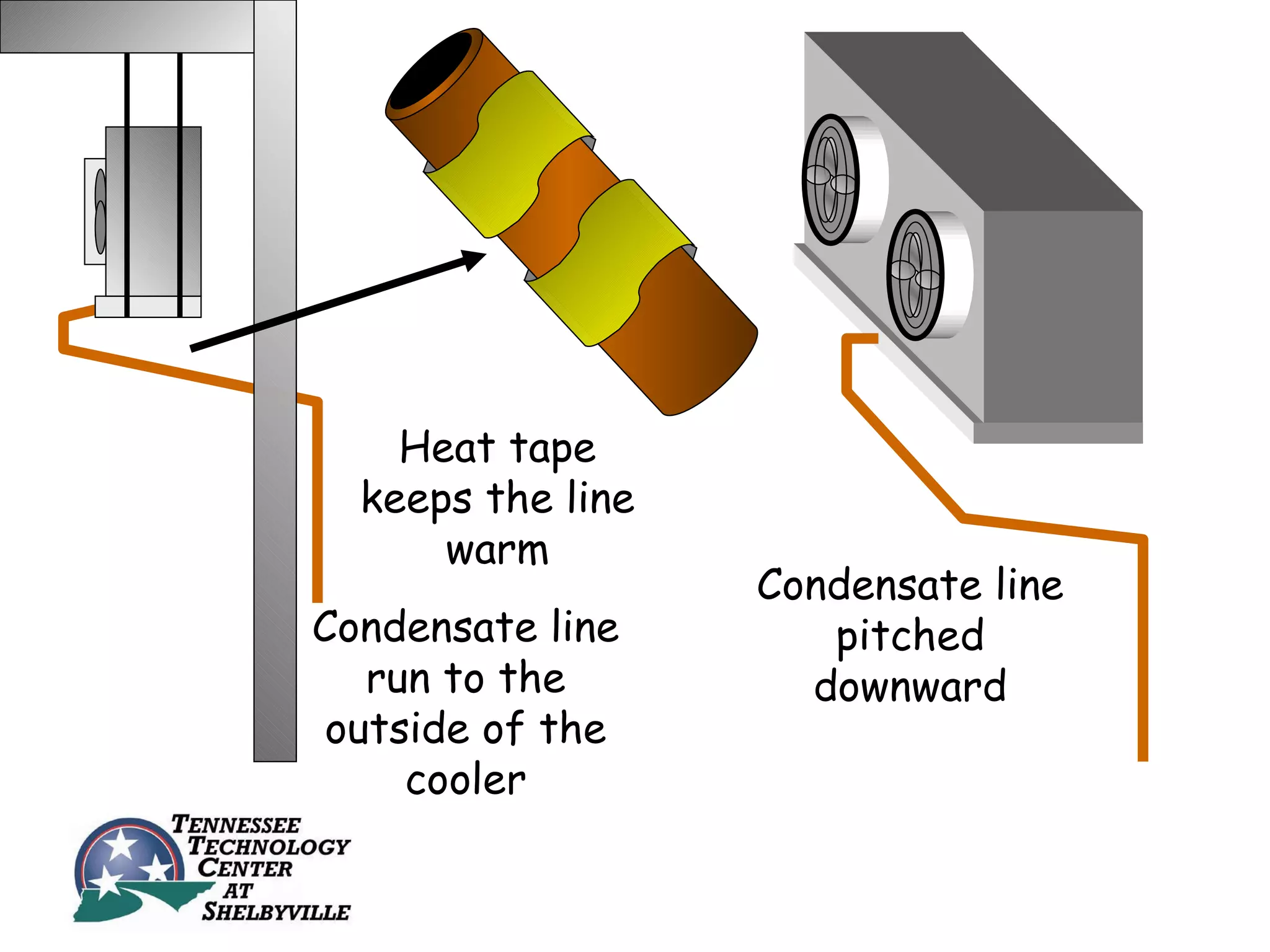

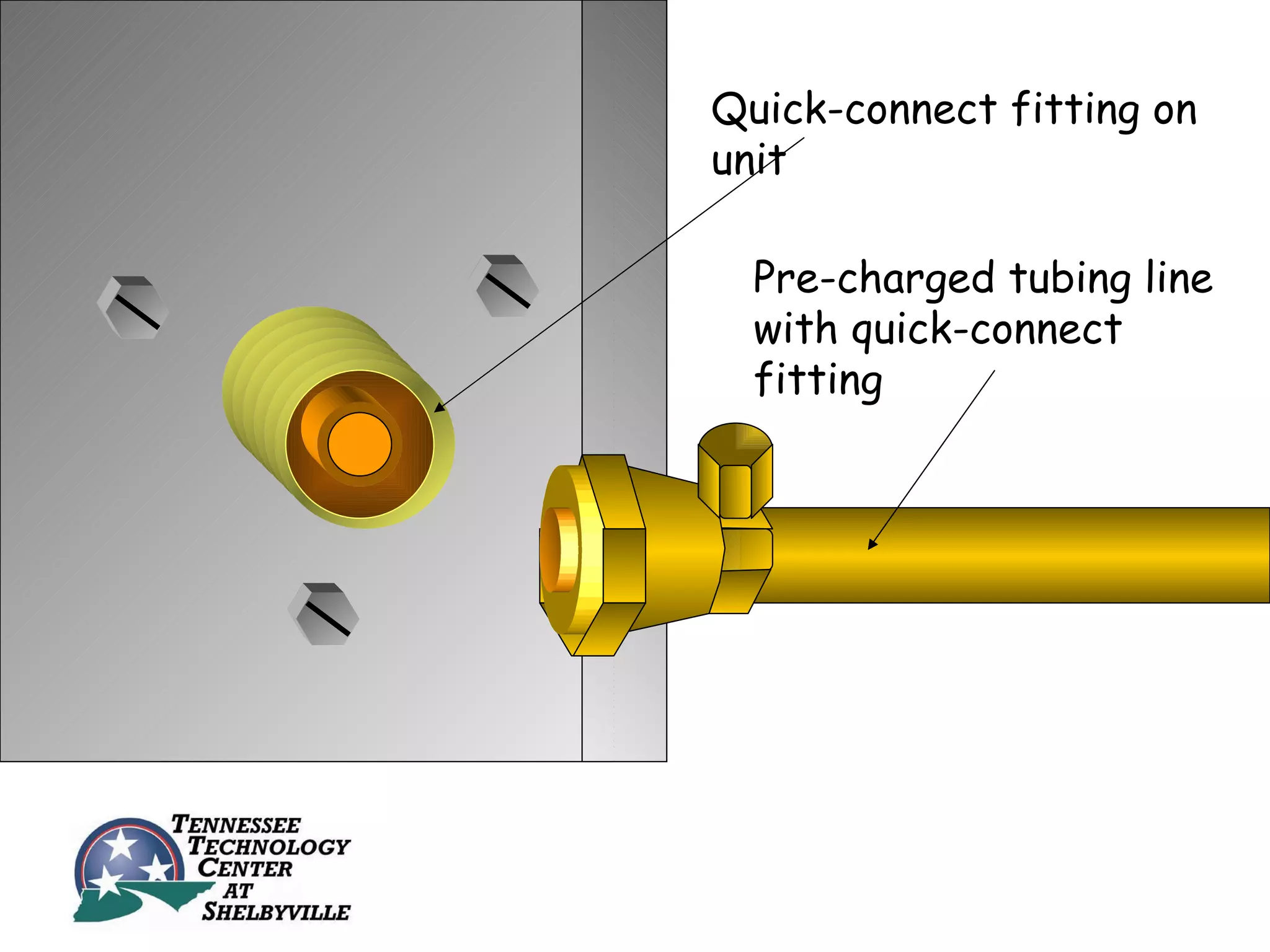

This document discusses various commercial refrigeration systems and applications. It describes reach-in refrigeration cases, self-contained and remote condensing units, multiple evaporator systems, and package versus remote condensing applications. It also covers topics like heat reclaim, mullion heat, walk-in refrigeration, vending machines, and air dryers. The objectives are to describe different display equipment types, discuss heat reclaim concepts, and explain various refrigeration system applications.