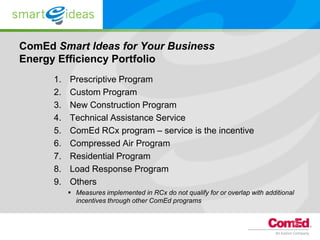

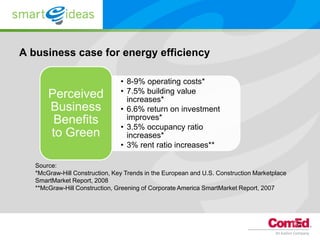

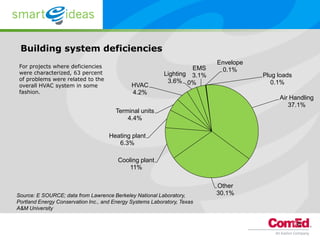

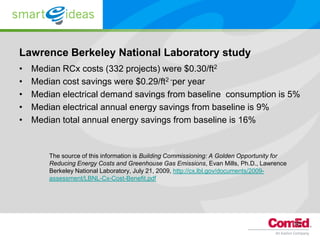

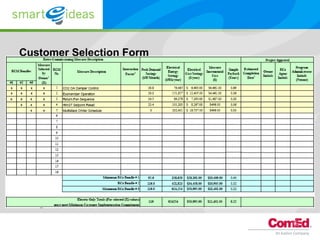

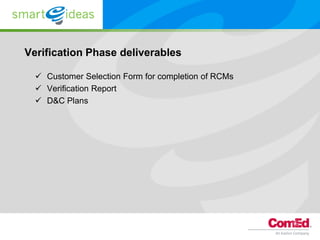

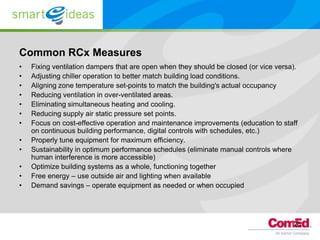

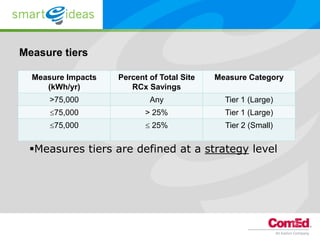

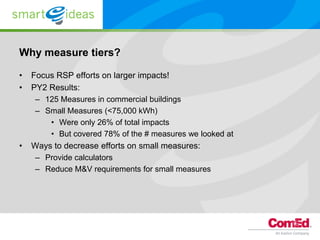

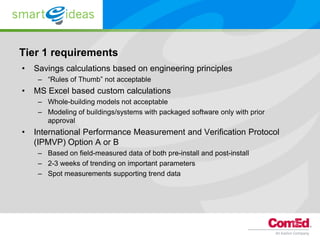

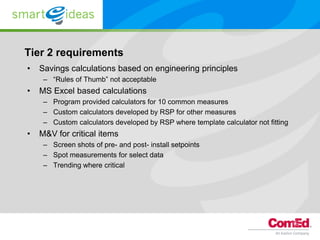

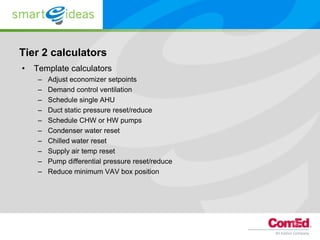

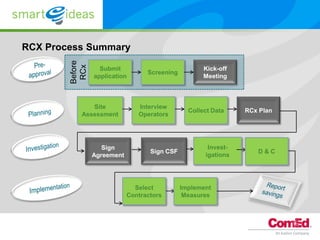

The document provides an overview of a retro-commissioning (rcx) program aimed at improving energy efficiency in buildings through optimized performance of mechanical and electrical systems. It discusses the benefits of energy efficiency such as reduced operational costs, extended equipment lifetimes, and increased asset value, along with common misunderstandings about rcx. The program includes various phases from planning to verification, with specific measures to achieve energy savings and ensure adequate functioning of building systems.