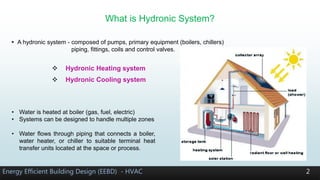

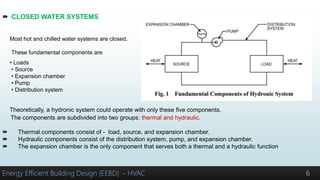

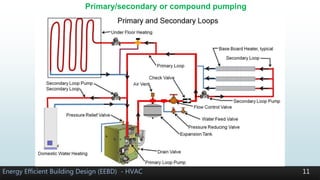

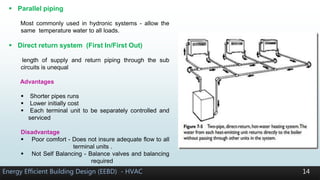

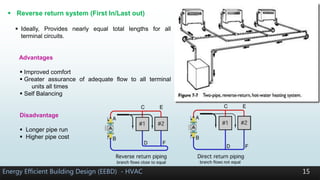

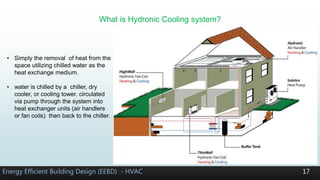

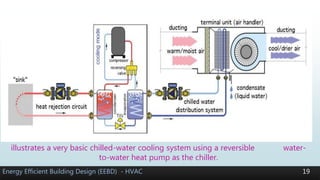

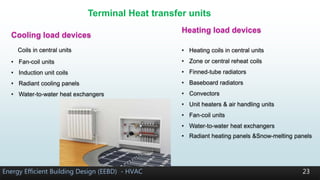

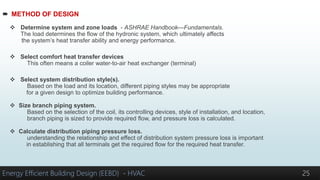

The document discusses the design and components of hydronic heating and cooling systems, which utilize water as a heat transfer medium. It highlights various types of hydronic systems, their advantages and disadvantages, and essential components such as pumps, expansion tanks, and distribution piping. It also covers considerations for effective and economical system design, emphasizing the interrelationship between system components for optimal performance.