This document provides an overview of the condensate system in a power plant, including:

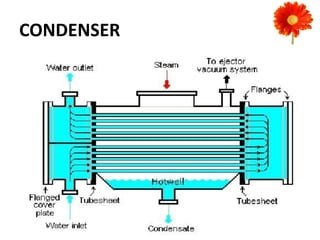

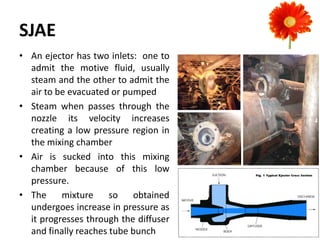

- Key components like the condenser, CEP pumps, SJAE ejectors, LP heaters, and their functions.

- Parameters and specifications of the condenser and LP heaters.

- Importance of maintaining vacuum in the condenser.

- Startup and shutdown procedures for the condensate system, which involve opening/closing valves, maintaining fluid levels, and isolating components as needed.