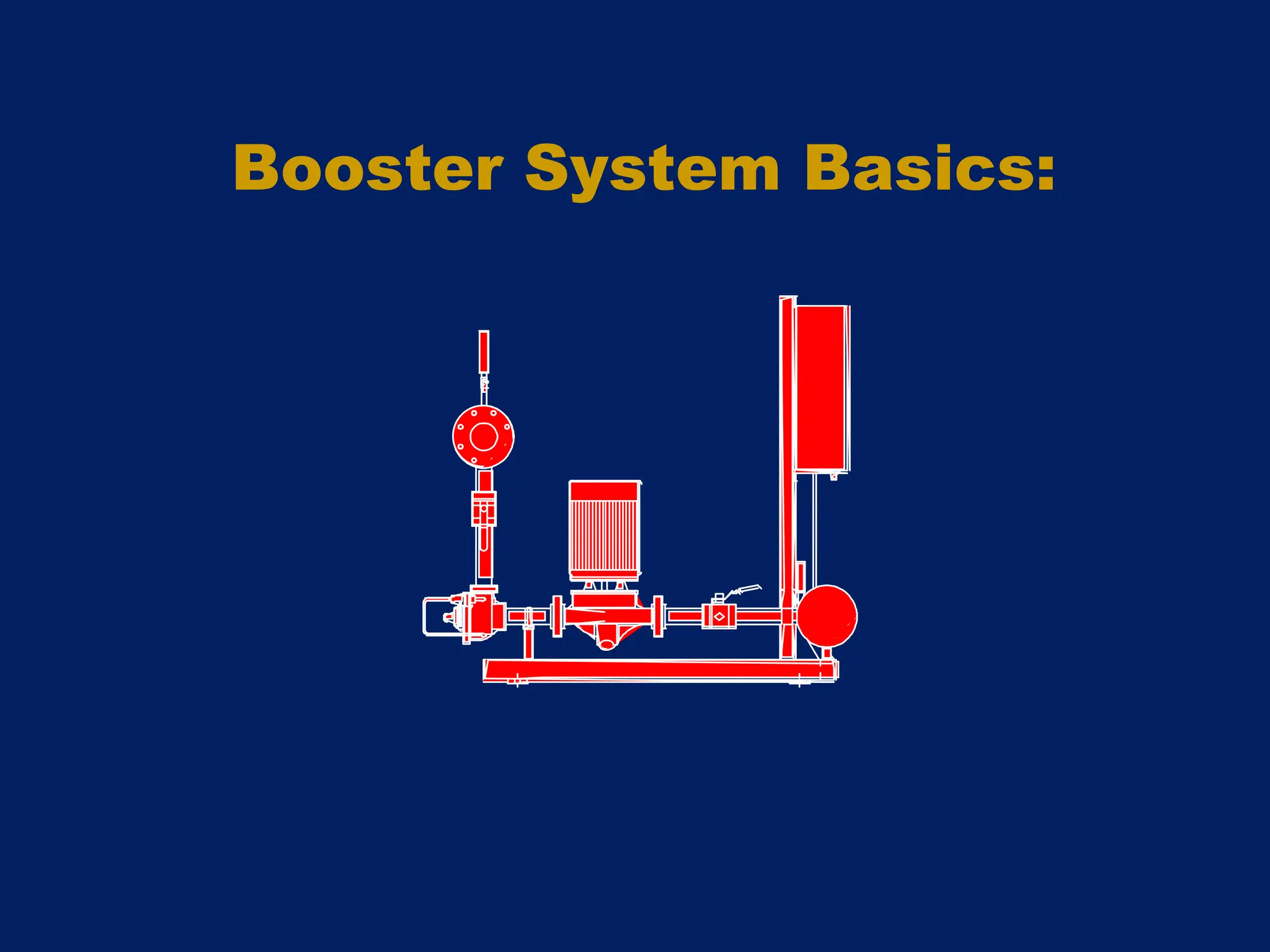

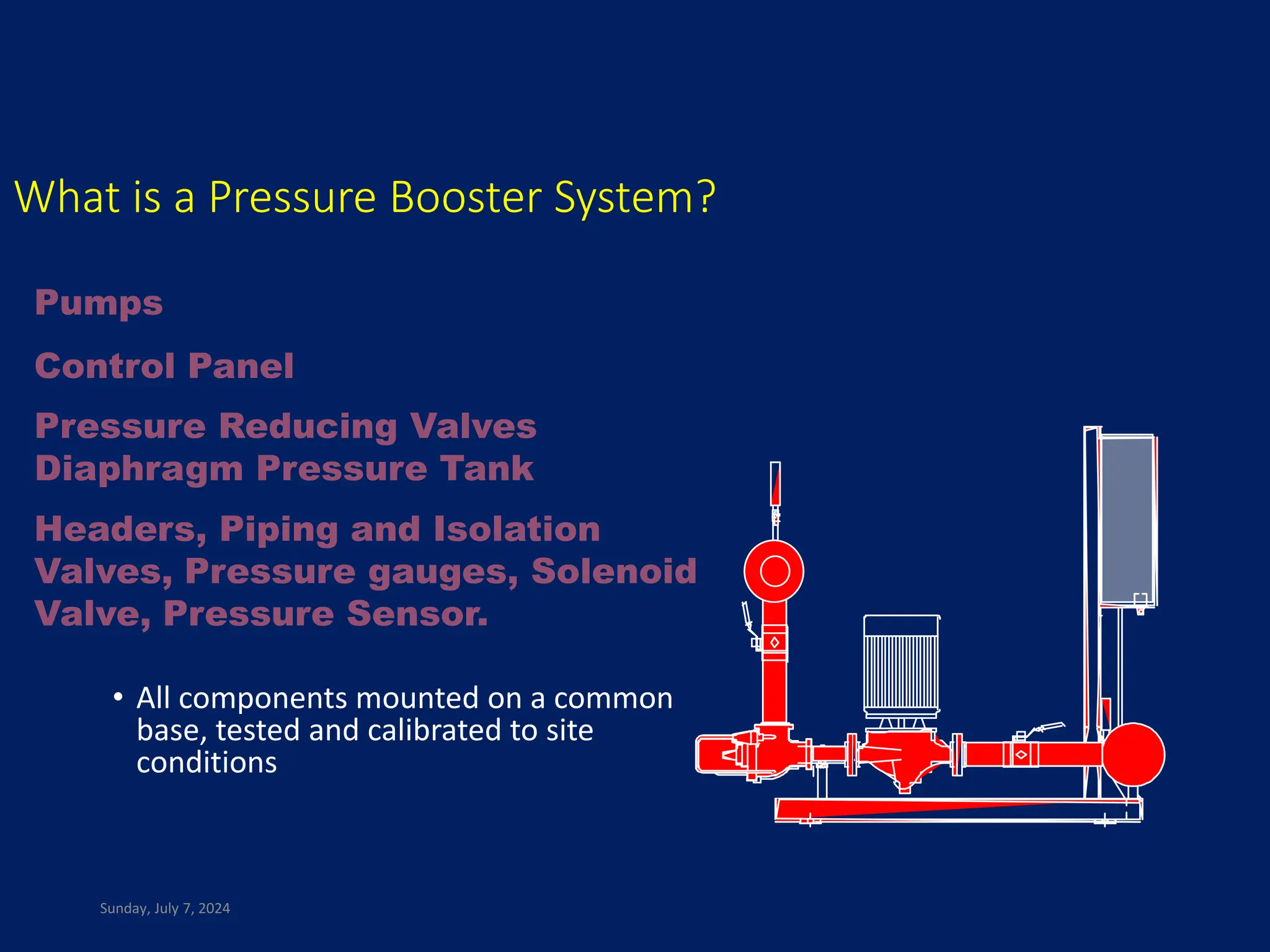

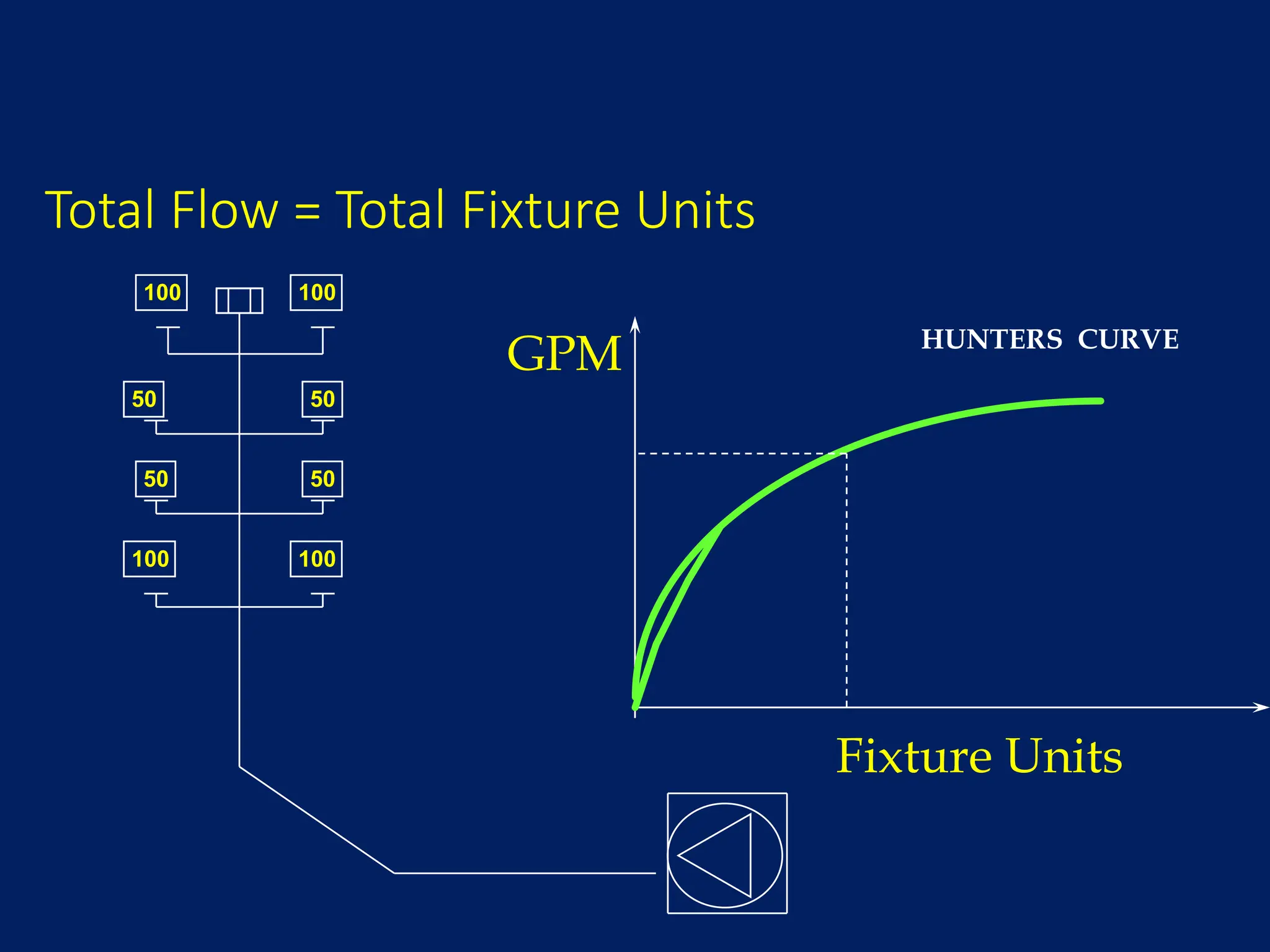

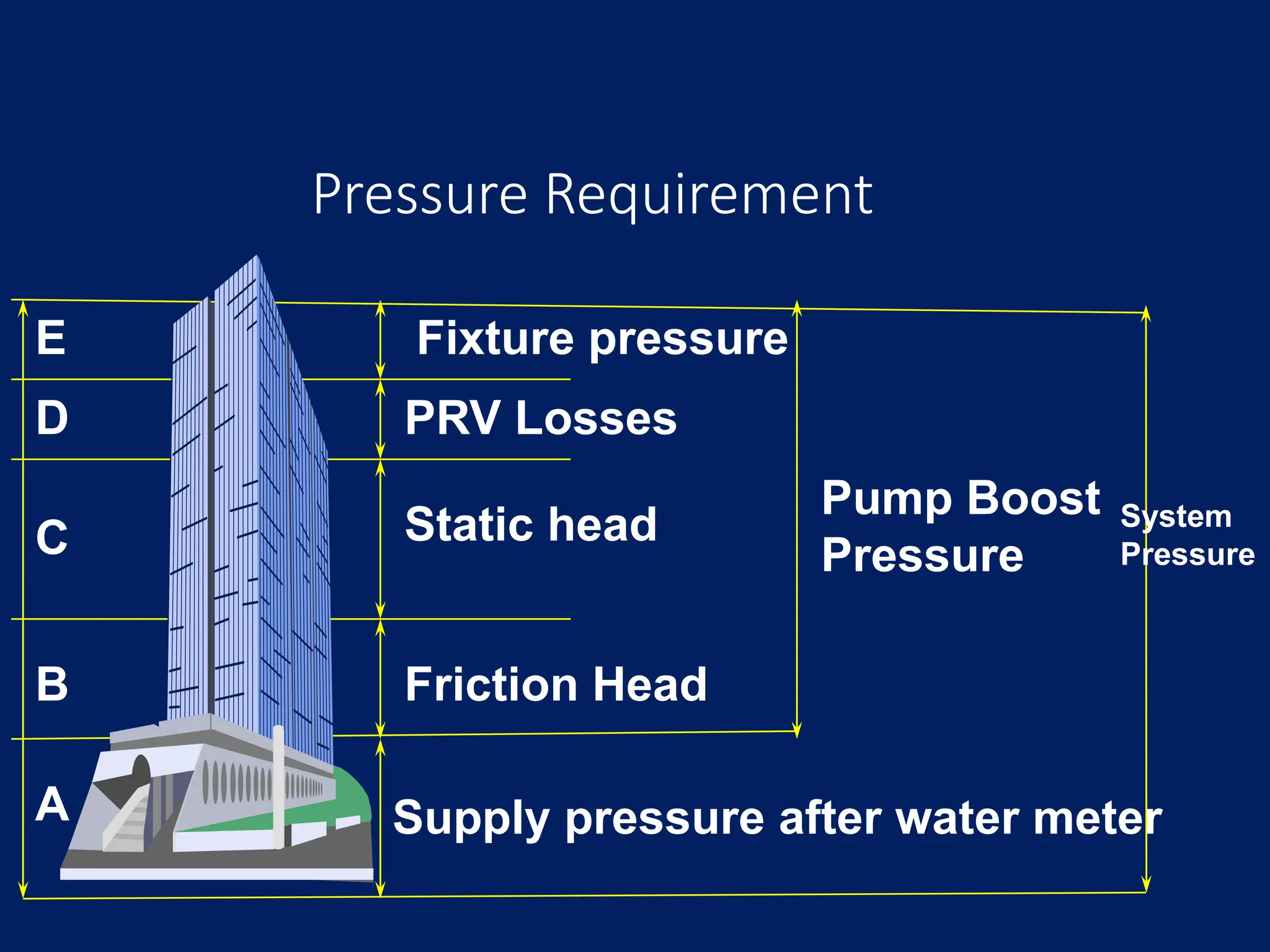

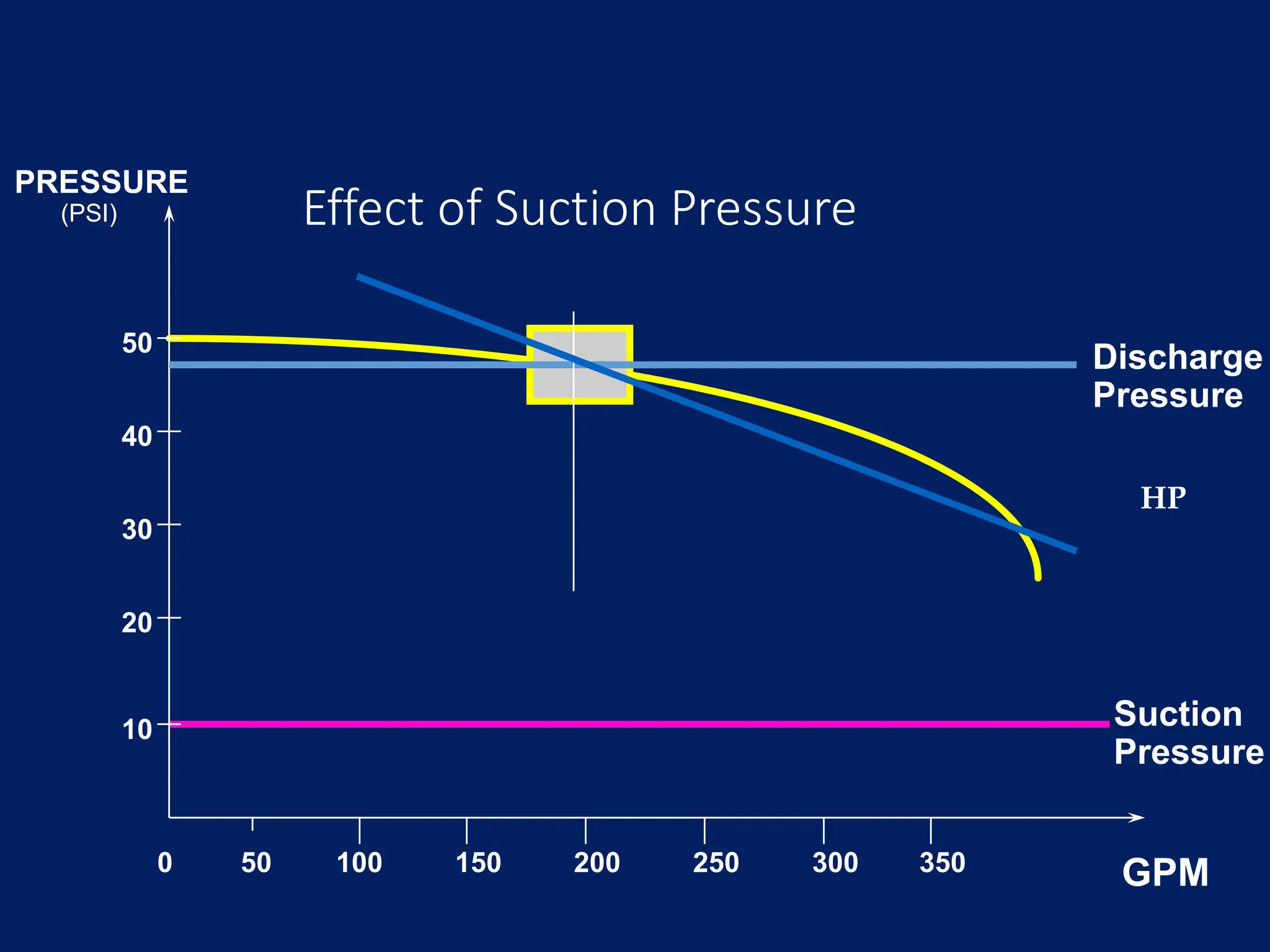

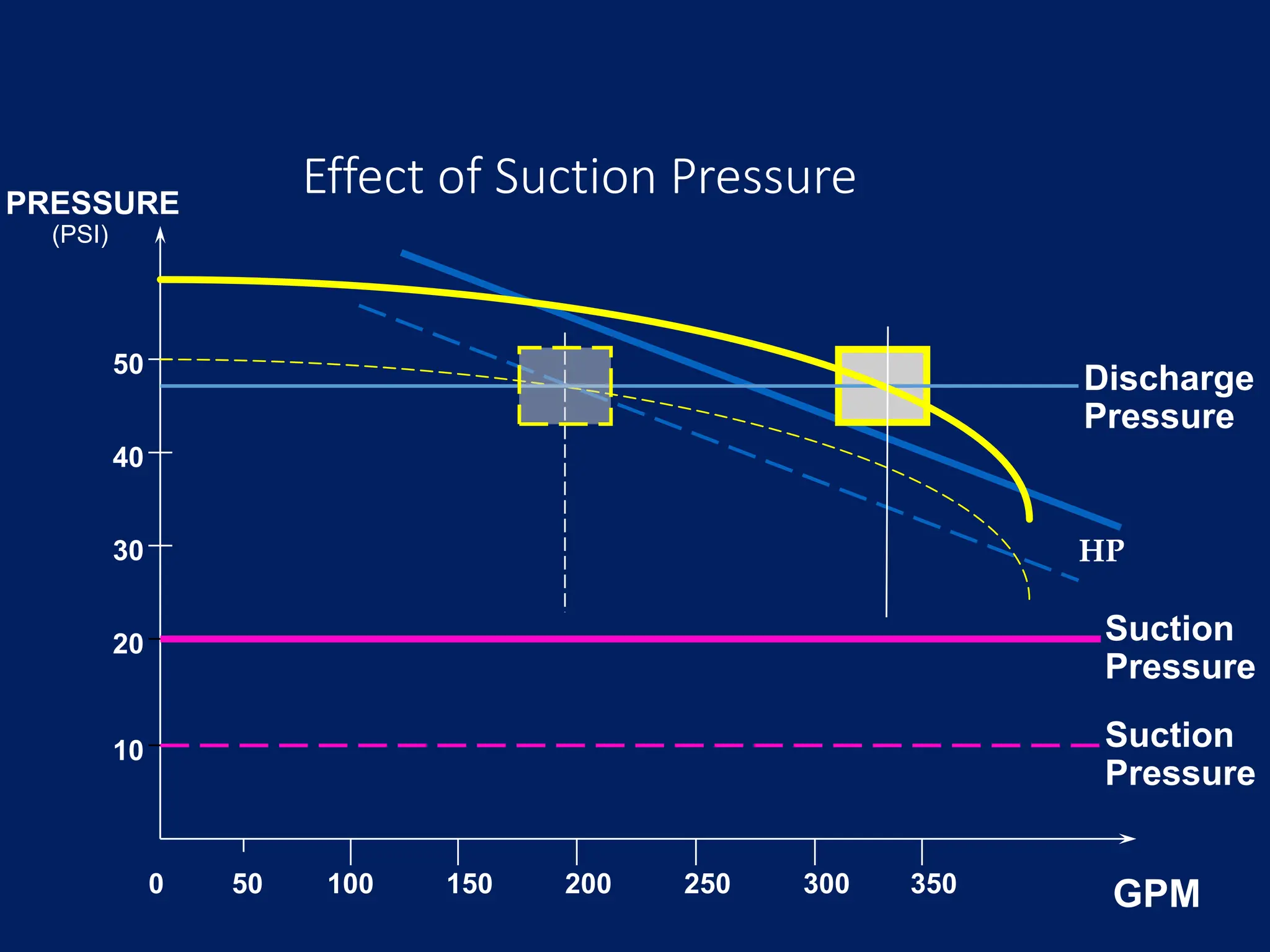

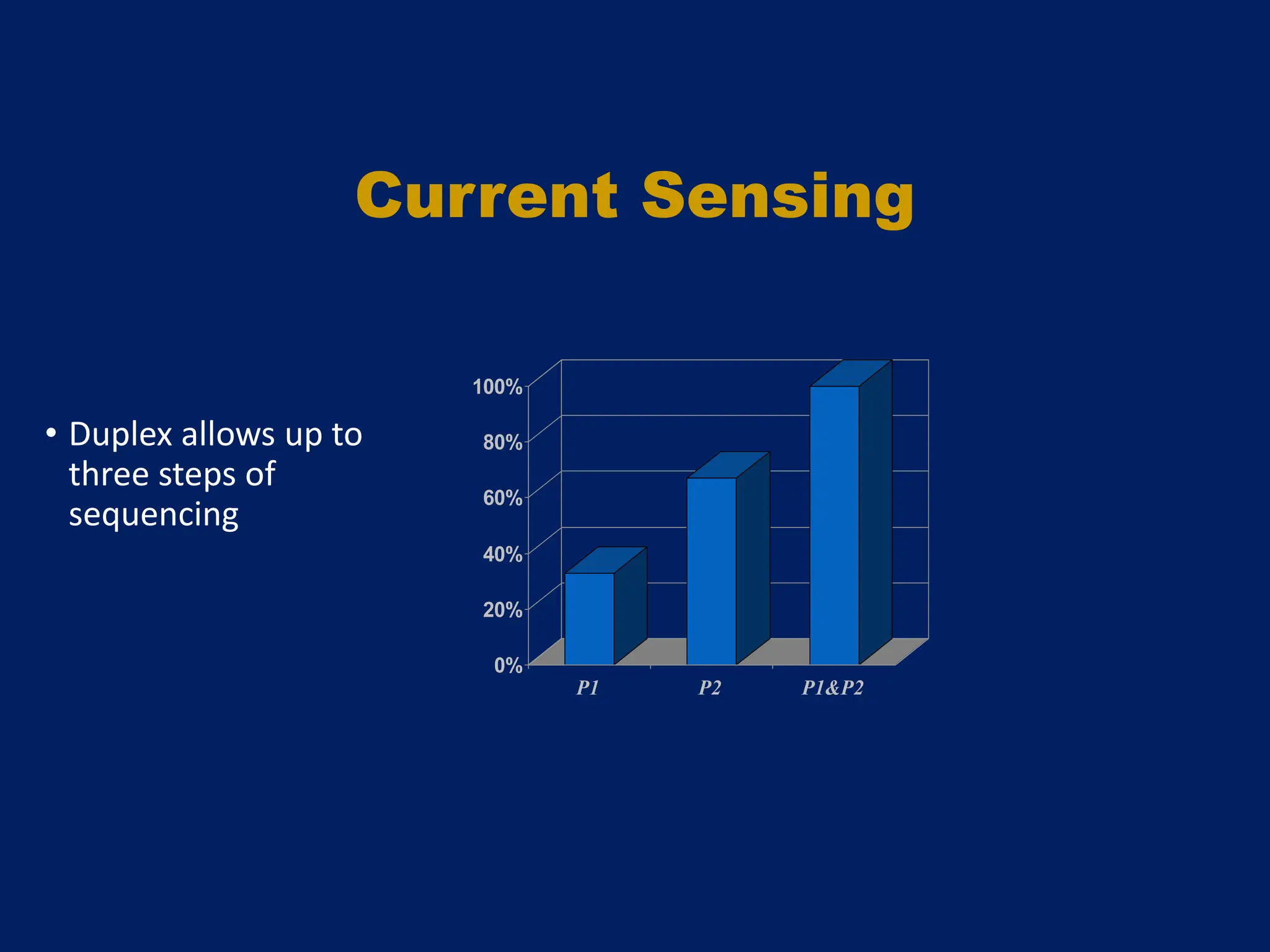

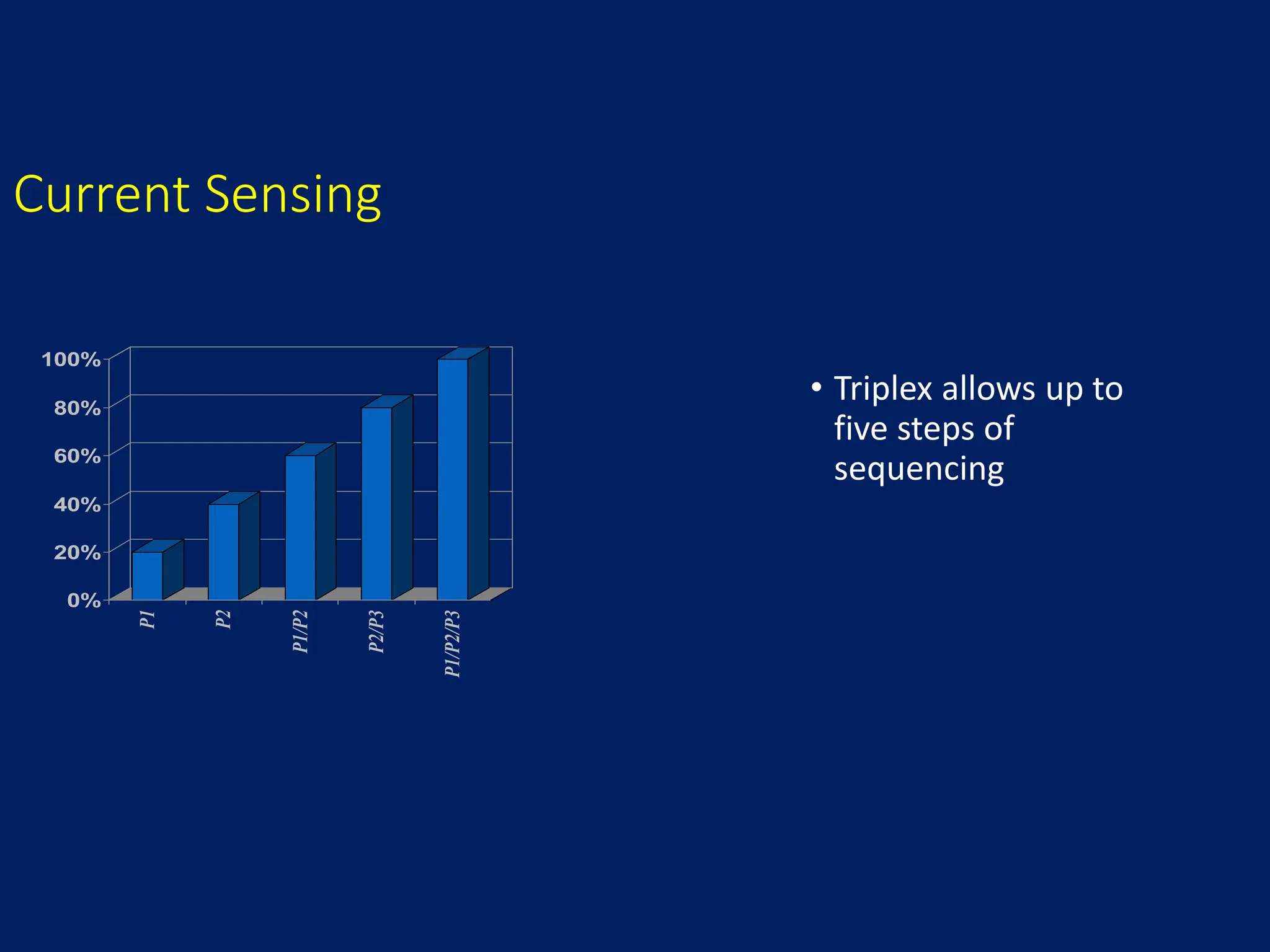

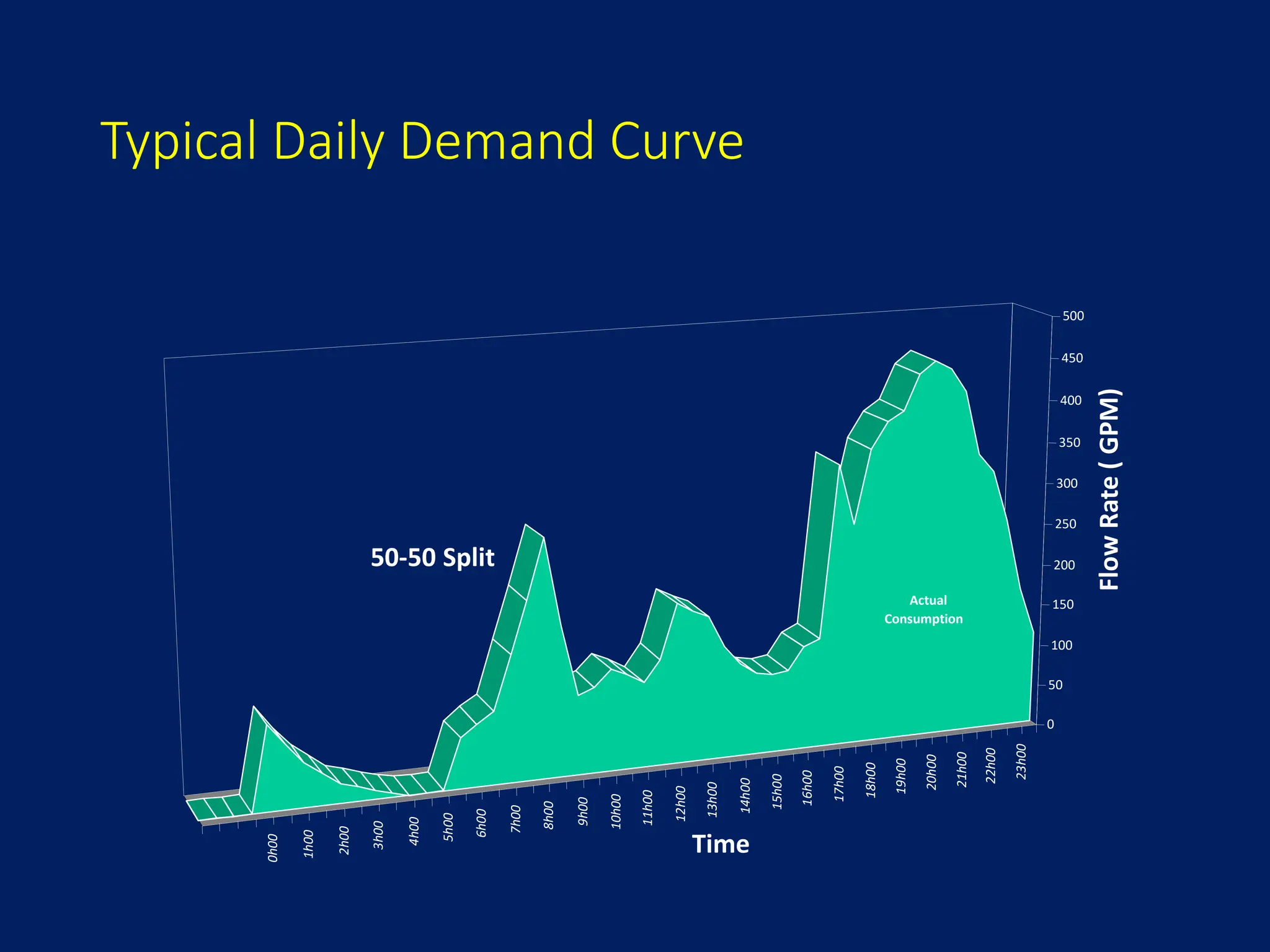

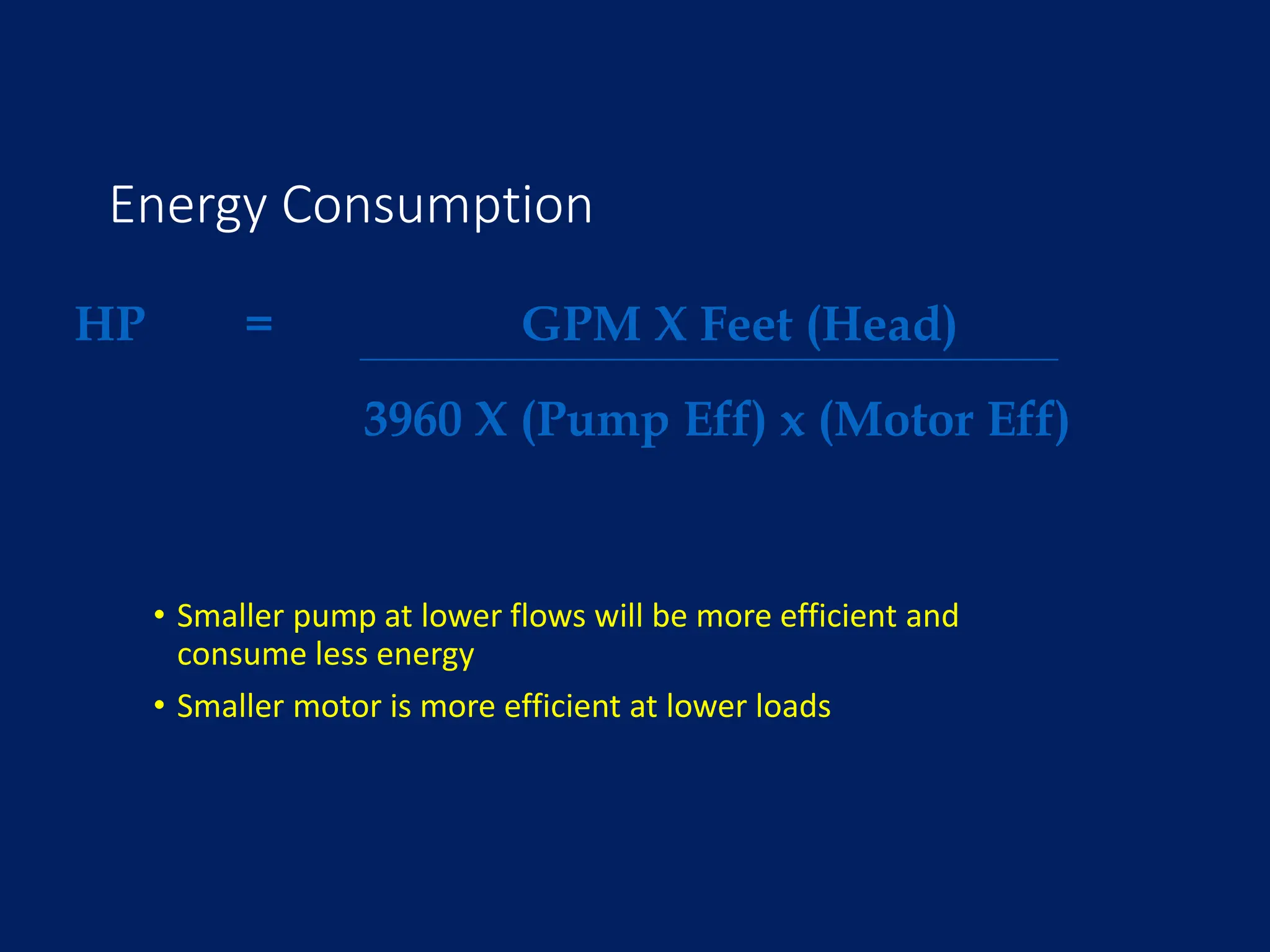

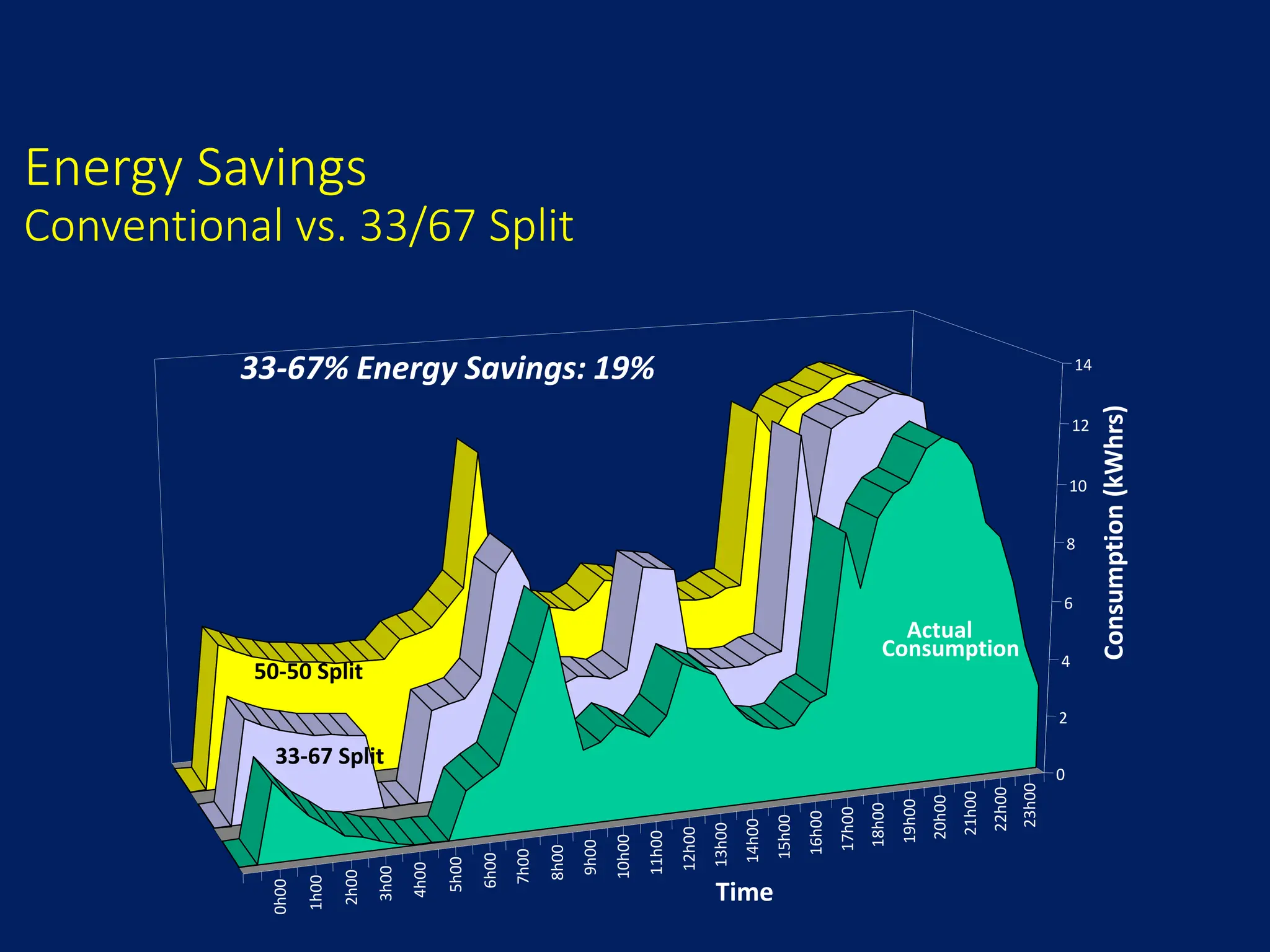

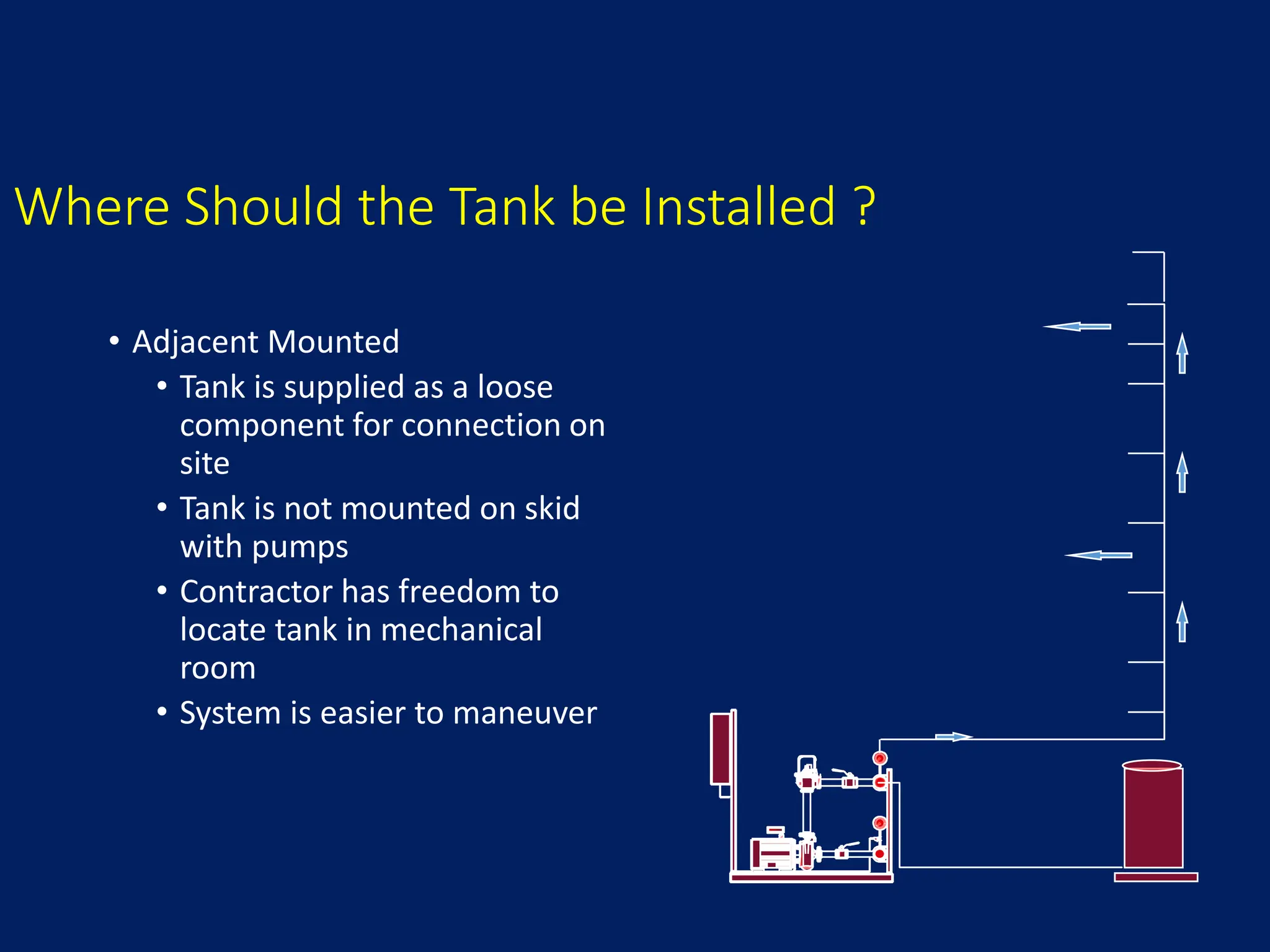

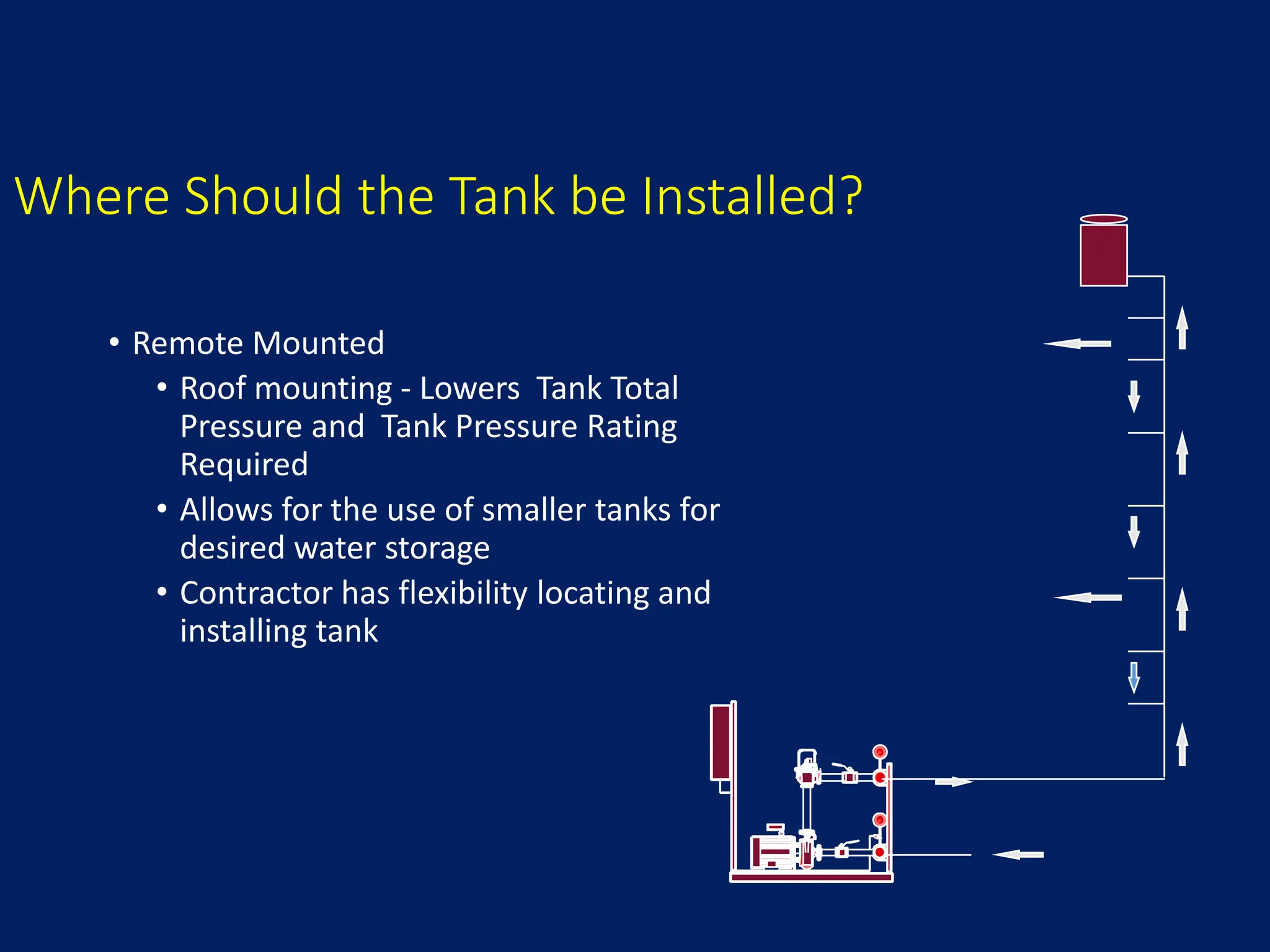

The document outlines the fundamentals of pressure booster systems, detailing their components, sizing requirements, and control methods. Key considerations for sizing include total flow and pressure requirements based on building specifications, fixture types, and system losses. It also emphasizes the importance of energy-saving strategies and the effective use of drawdown tanks to maintain pressure in systems with intermittent demands.