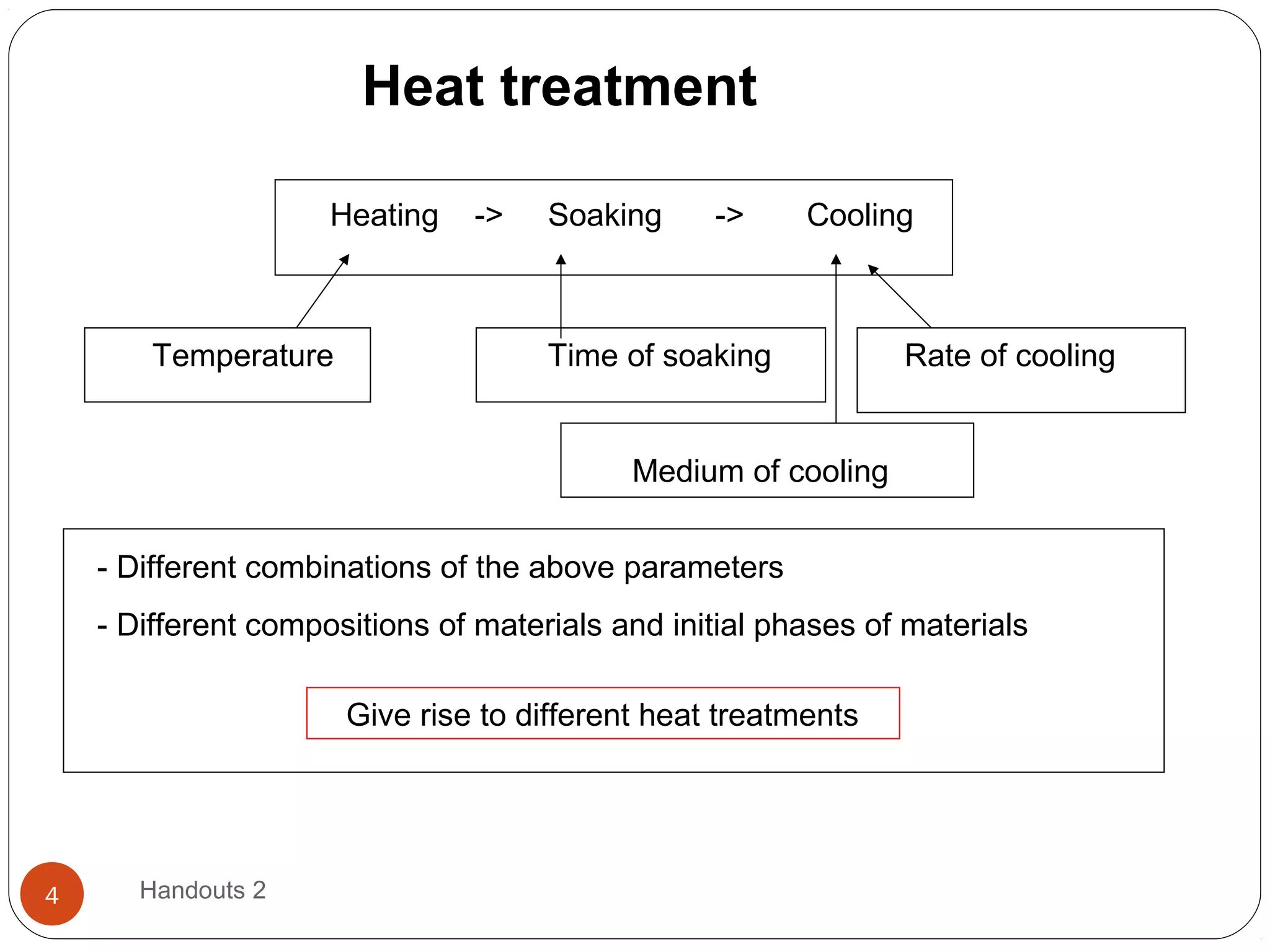

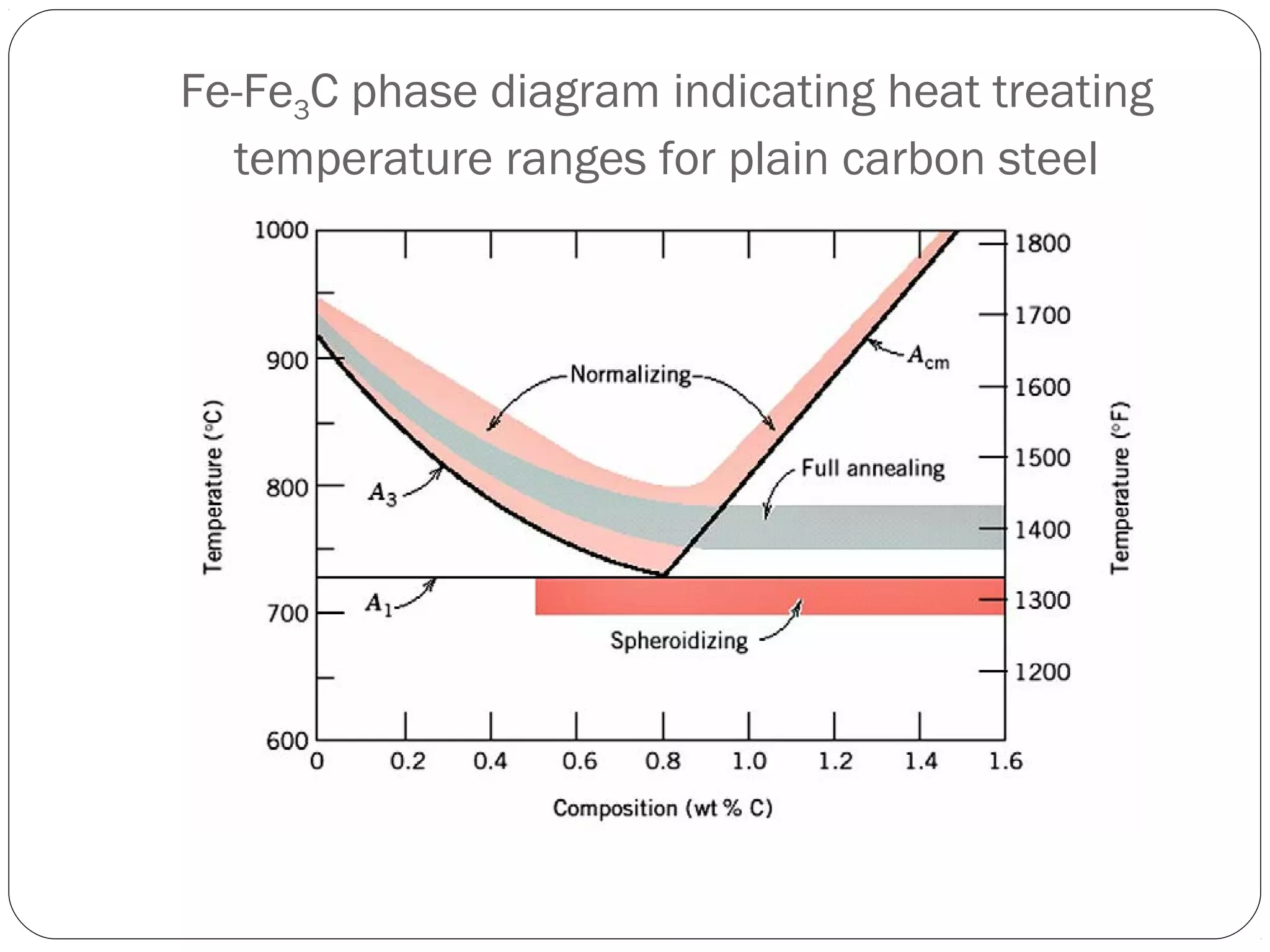

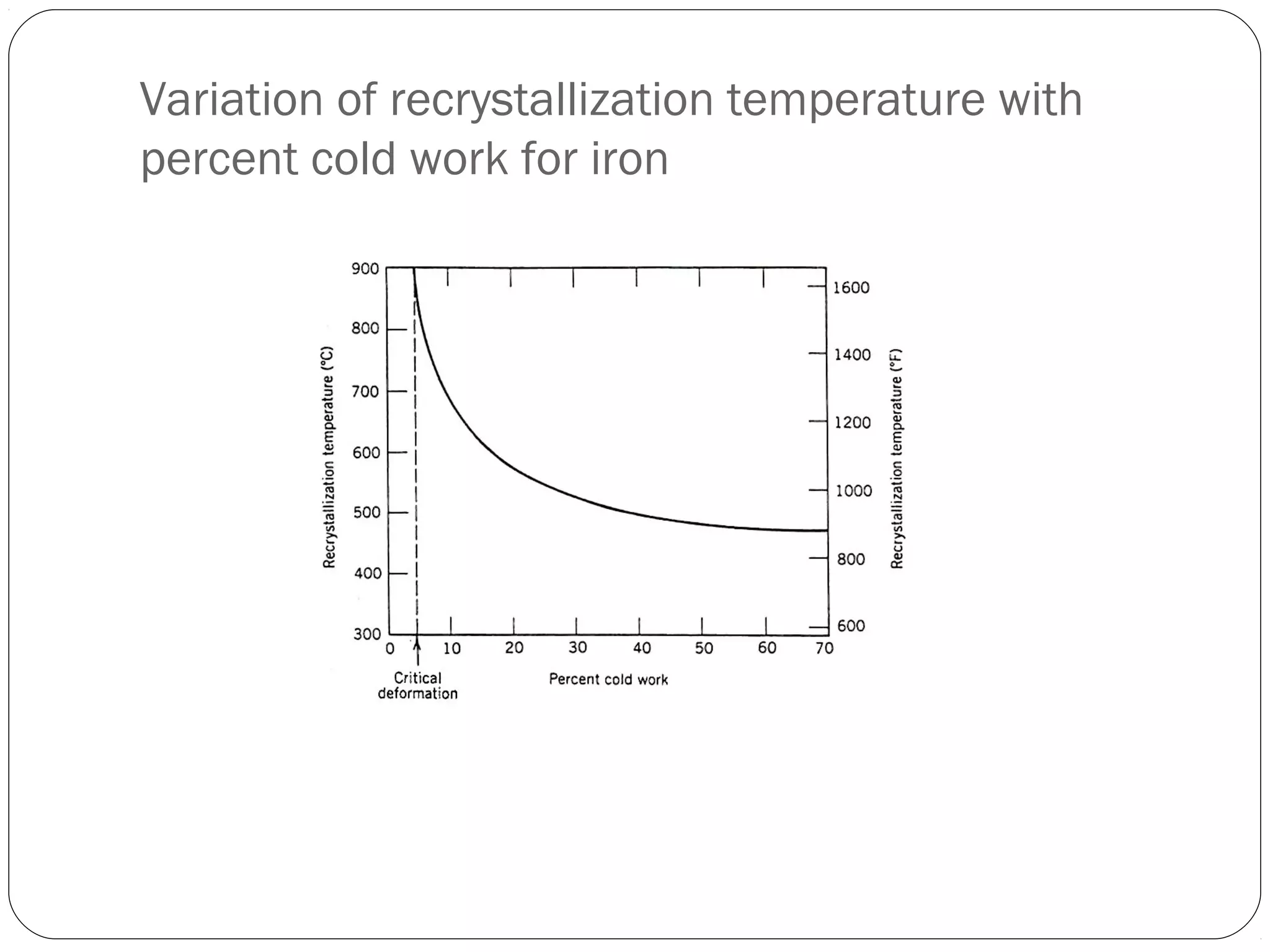

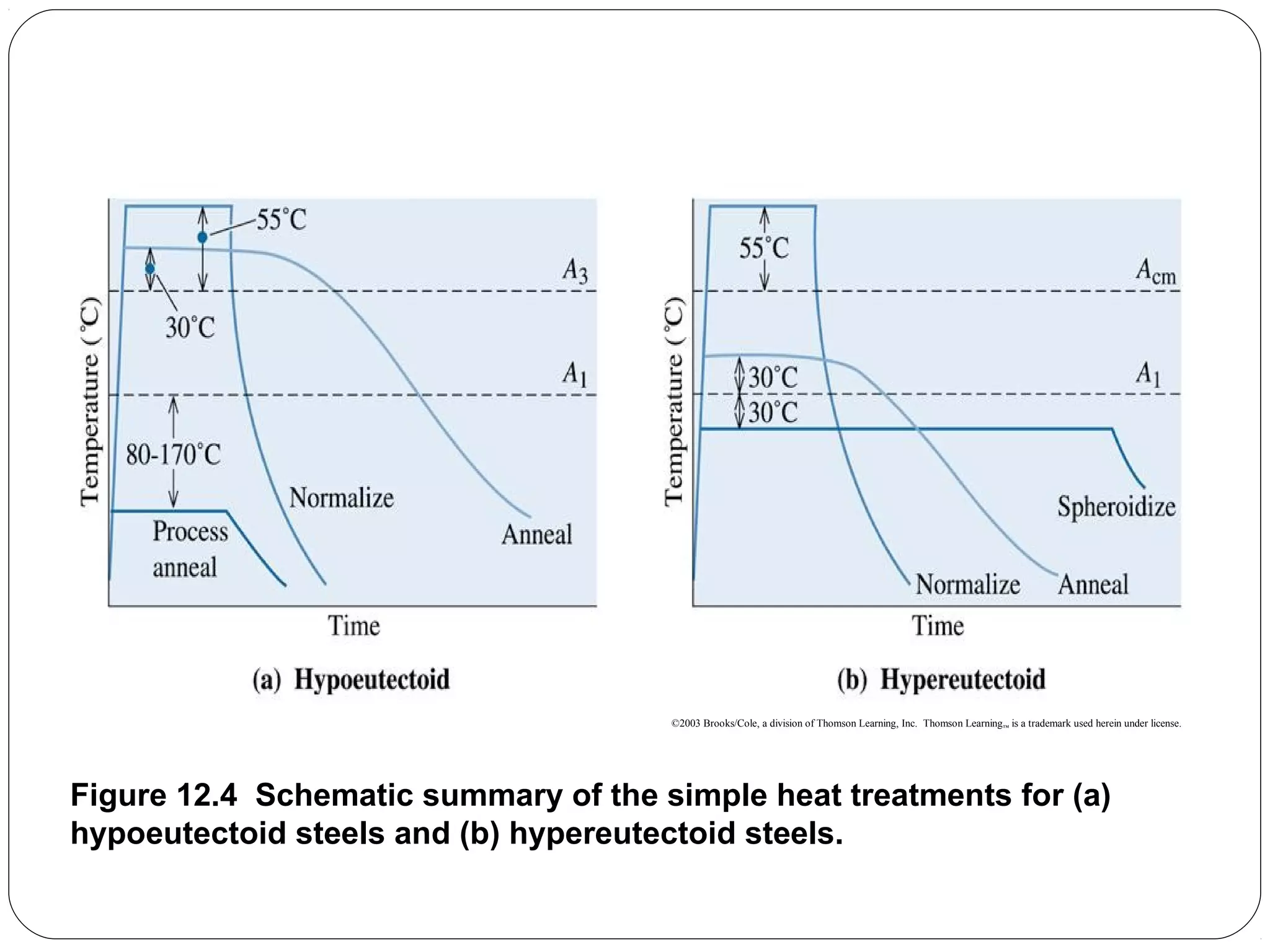

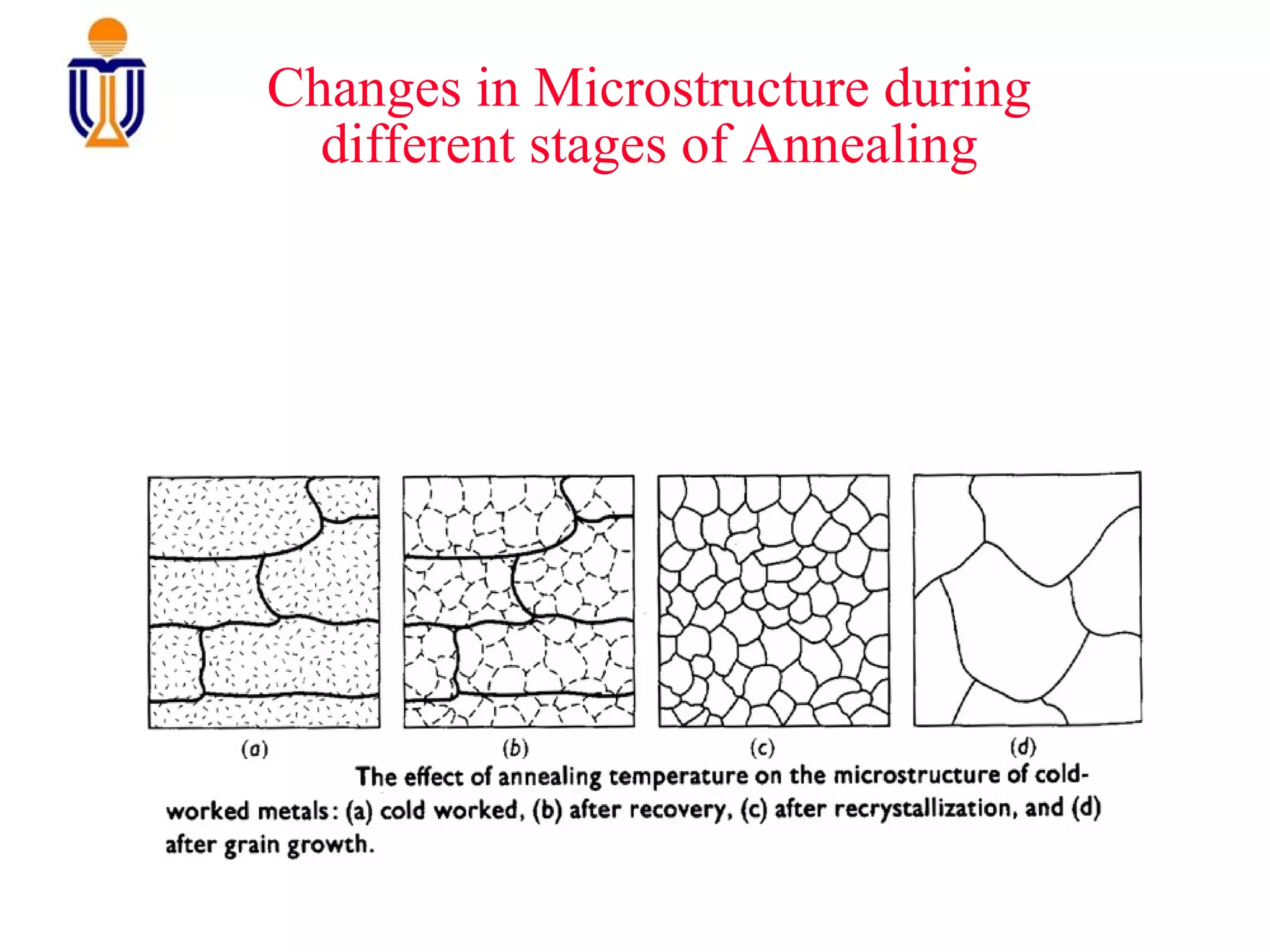

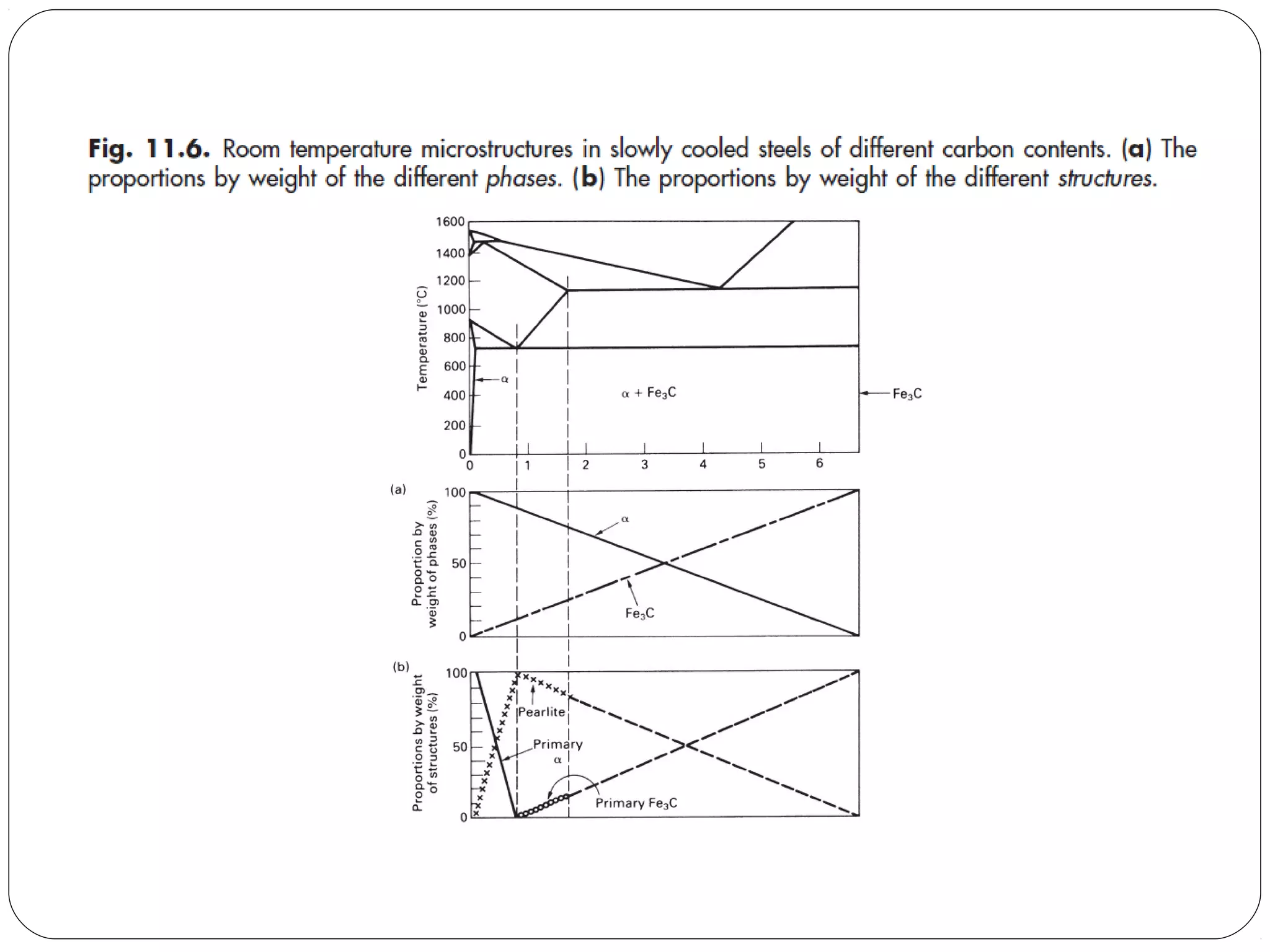

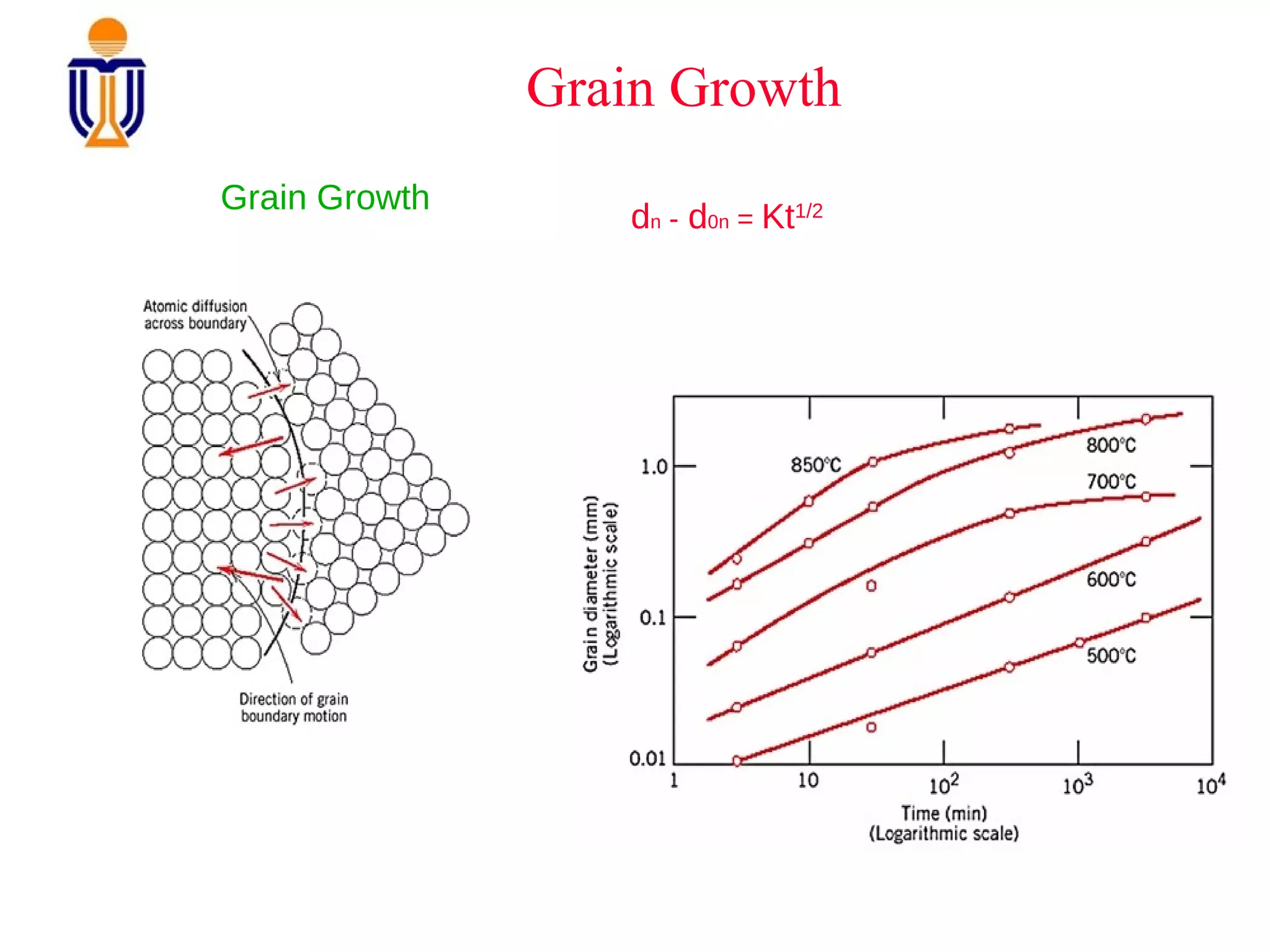

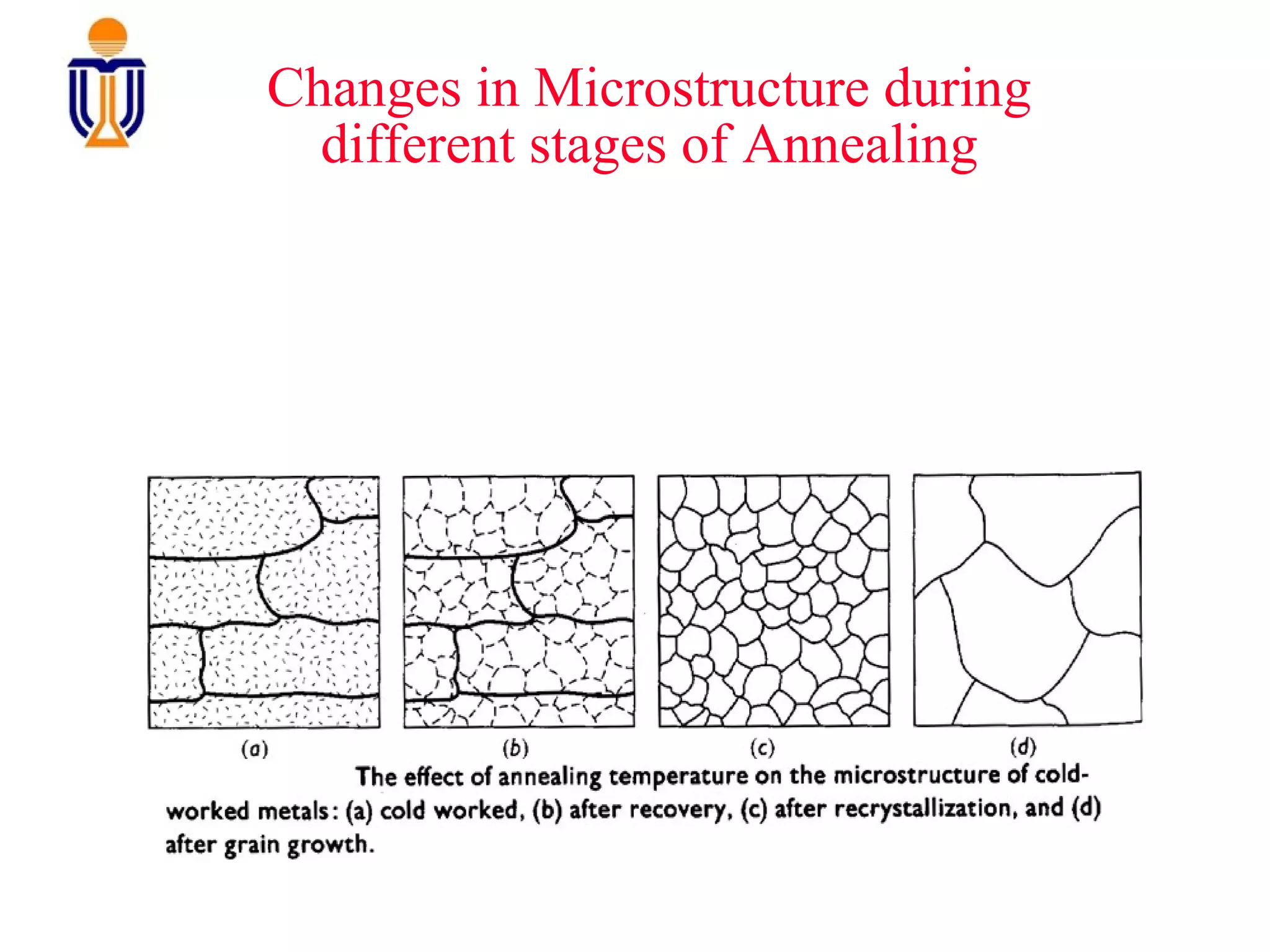

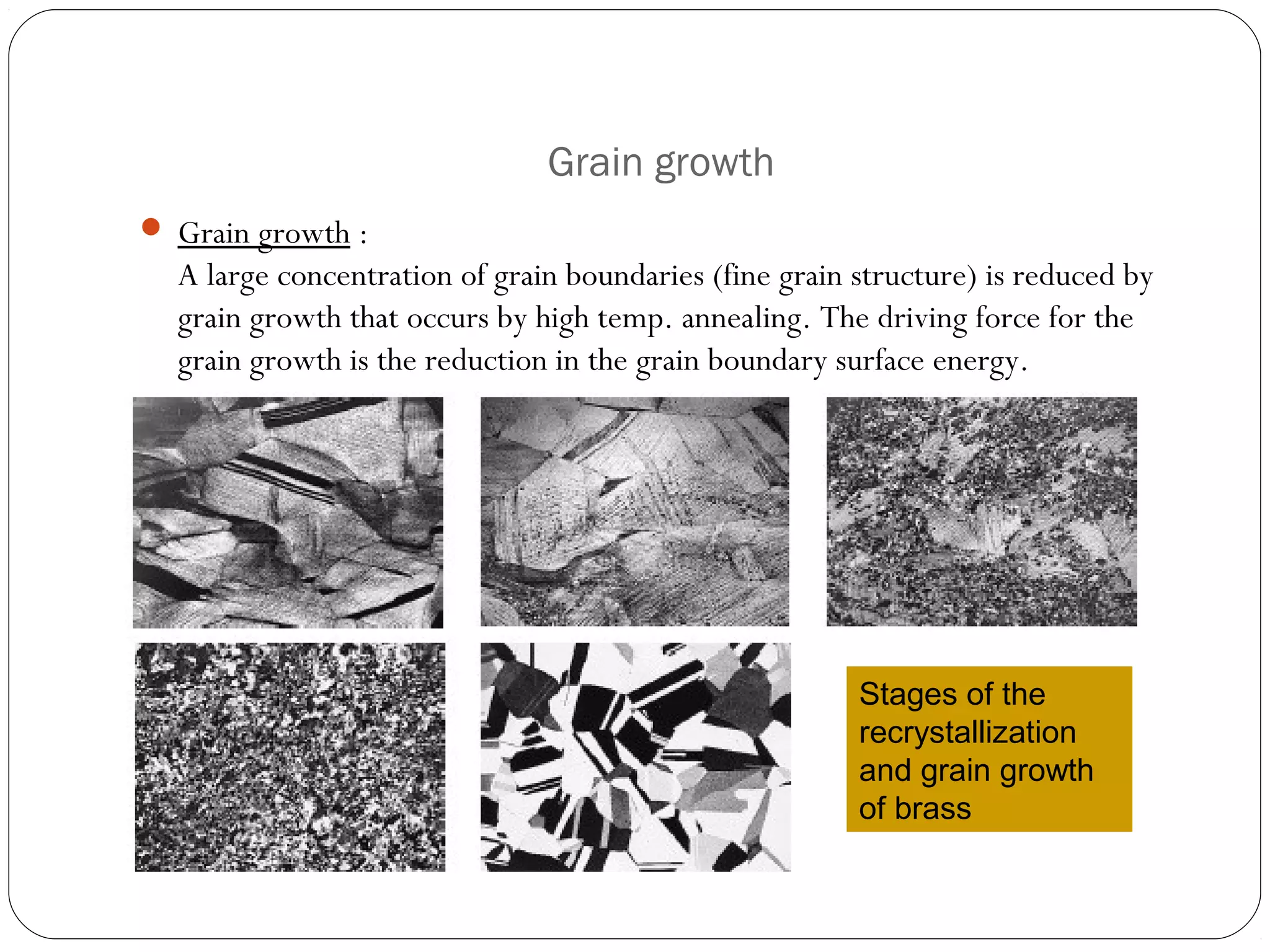

The document discusses the heat treatment process of annealing. It begins by defining heat treatment as heating a metal to a specified temperature, keeping it at that temperature for a period of time, then cooling at a specified rate. Annealing is described as a heat treatment that involves heating metal above its recrystallization temperature, holding for some time, then slowly cooling to develop an equilibrium structure with increased ductility. The document outlines the stages of annealing as recovery, recrystallization, and grain growth.