Rahul vyas annealing process and it's importance

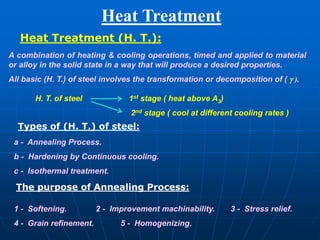

- 1. Heat Treatment Heat Treatment (H. T.): A combination of heating & cooling operations, timed and applied to material or alloy in the solid state in a way that will produce a desired properties. All basic (H. T.) of steel involves the transformation or decomposition of ( g ). H. T. of steel 1st stage ( heat above A3) 2nd stage ( cool at different cooling rates ) Types of (H. T.) of steel: a - Annealing Process. b - Hardening by Continuous cooling. c - Isothermal treatment. 1 - Softening. 2 - Improvement machinability. 3 - Stress relief. 4 - Grain refinement. 5 - Homogenizing. The purpose of Annealing Process:

- 2. Steps of Annealing Process Types of Annealing Process: 1 - Heating above A3. 2 - Hold at a temperature for a definite time. 3 - Cooling to the Room Temperature ( R. T. ) at slow rate. 1 - Full Annealing. 2 - Homogenizing. 3 - Normalizing. 4 - Stress relief anneal. 5 - Process Anneal ( Recrystallization – Anneal). 6 - Spherodizing. Full Annealing: Heating the Steel to the proper temp. and then cooling slowly ( typical cooling rate 1 oC / min) through the transformation range ( in furnace ). The purpose of annealing ( a ) - refine the grain. ( b ) - softness. ( c ) - improve electrical & magnetic properties. ( d ) - improve machinability. Refinement of the grain size of hypoeutectiode steel will occur about 50 of above the lower critical temp. line ( A3,1 ). See fig. 2.

- 3. Spherodizing Stress relief Fig. (2) The Change in microstructure during annealing of: ( a ) - 0.2% C. ( b ) – 1.0% C.

- 4. b - improve machinability. c - modify & refine cast dendritic structure. d - refine the grain & homogenize the structure. less proeutectoid ( a ) in normalized hypoeutectiode steel & less proeutectoid Cementite ( Fe3C ) in hypereutectoid steel as compared with annealed one because of there is less time for the formation of proeutectoid constituent. The faster the cooling rate, the lower the temp. of ( g ) transformation and the finer the Pearlite ( see fig. 3 ). Normalizing: Homogenizing Treatment: It is carried out by heating to ( 100 of ) above ( A3 ) or ( Acem ) followed by cooling in still air (cooling rate 5-10 oC) to Room Temp. ( RT ) to : a - produce harder & stronger steel than annealing. A heat treatment of an alloy intended to make it uniform in composition by eliminating Coring & Concentration gradient. It is achieved by heating to a temp. ( 1100 – 1200 oC ) for ( 10 – 20 hour ) followed by slow cooling in air or furnace. Sometimes needed to refine the coarse grains. Fig. (3) The difference in P structure due to annealing & Normalizing

- 5. Stress relief annealing • Internal stress distortion and warpage • Heat treatment that is used to eliminate internal or residual stresses in metallic components Source of internal stress: - (1) plastic deformation processes such as machining and grinding (2) Non uniform cooling of a piece that was processed or fabricated at an elevated temperature, such as a weld or a casting (3) a phase transformation that is induced upon cooling wherein parent and product phases have different densities • General process: heating to there commended temperature, held there long enough to attain a uniform temperature, and finally cooled to room temperature in air

- 6. Annealing temperature relati'e low, up to 378% effects of cold working and other heat treatments are not affected Stress relief annealing(cont.) It is useful in removing residual stresses due to Cold Work ( C. W. ) process. It is carried out at a Temp. below ( A1 ) ( 1000 – 1200 of ).

- 7. Process Annealing (Recrystallization – Anneal): It is used in the sheet & wire industries after ( C. W. ) see ( fig. 4 ). It is carried out by heating the steel to a Temp. below ( A1 ) ( 1000 – 1250 of ). Fig. (4) The cold – work cycle & Recrystallization diagram

- 8. Heat treatment that is used to negate the effects of cold work -that is, to soften and increase the ductility of a previously strain hardened metal. It is commonly utilized during fabrication procedures that require extensive plastic deformation, to allow a continuation of deformation without fracture or excessive energy consumption Recovery and recrystallization processes are allowed to occur fine grained microstructure heat treatment stop before grain growth Process annealing (cont.)

- 9. Process annealing (cont.) • Surface oxidation or scaling may be prevented or minimized by annealing at a relatively low temperature (but above the recrystallization temperature) or in a nonoxidizing atmosphere • Some people call it recrystallization annealing • Yield strength and tensile strength drasticallyr educed • Commonly used in the production of steel wires,nails, etc

- 10. Spherodizing: This process will produce a Spheroidal or Globular form of carbide in ( a ) matrix ( as shown in fig. 5 ) to improve machinability. One of the following methods may be used for Spherodizing: 1 - prolonged holding at a Temp. just below ( A1 ). 2 - Heating & cooling alternatively between a Temp. that just above and just below ( A1 ). 3 - Heating to a Temp. above ( A1 ) and then either cooling very slowly in furnace or holding at a Temp. just below ( A1 ). Fig. ( 5 ): Stages of Spheroidized Annealing.