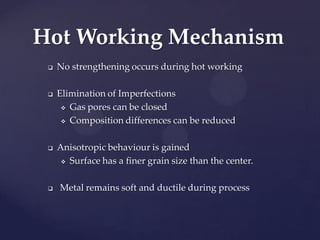

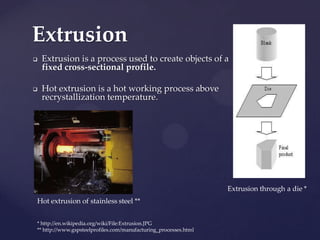

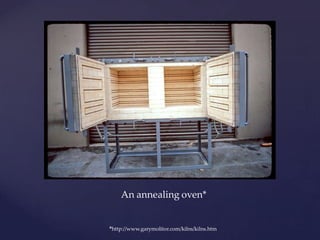

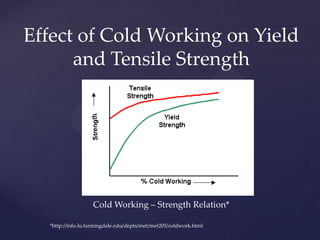

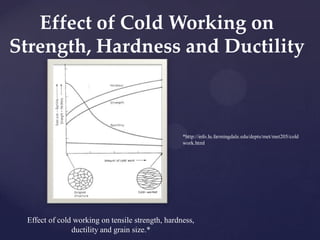

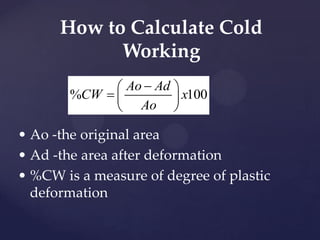

The document discusses cold working, hot working, and annealing processes for metals. Cold working involves plastic deformation at low temperatures to increase strength but reduce ductility through dislocation formation. Hot working above recrystallization temperatures can reduce imperfections through atomic mobility. Annealing heats metals slowly to allow recovery and recrystallization, reducing dislocations and improving properties like ductility. Examples of each process and their advantages/disadvantages are provided.

![The temperature at which atomic mobility can

repair the damage caused by the working process.

Recrystallization Temperature

Metal Recrystallization Temperature [°C]

Lead, tin 10 °C (below room temperature)

Zinc 25

Magnesium, aluminium 150

Gold, copper and silver 200

Iron, low-alloy steels 450

Tungsten 1400

Table: Recrystallization Temperatures of Some Metals *

* http://school.mech.uwa.edu.au/unit/MECH2402/lectures/hot_cold_working/](https://image.slidesharecdn.com/coldhotworkingannealing-151006182437-lva1-app6892/85/Cold-hot-working_annealing-16-320.jpg)