- Testing is important in the textile industry to ensure high quality products. Fiber testing is carried out at various stages - fiber, yarn, fabric and garment.

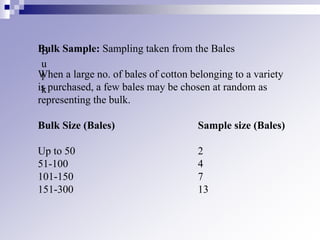

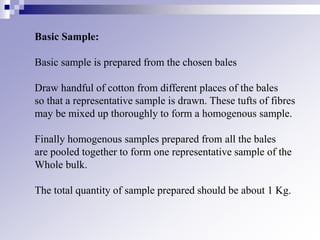

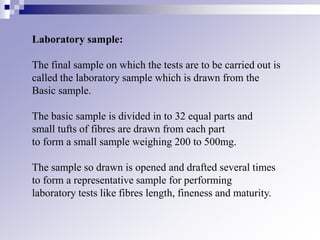

- Proper sampling is required as textile testing is both time consuming and destructive. Samples should be representative of the overall lot. In cotton, sampling is done at the bulk, basic, and laboratory levels.

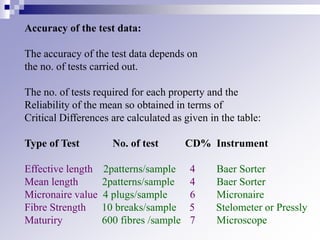

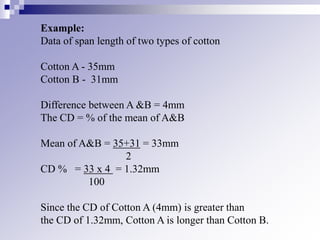

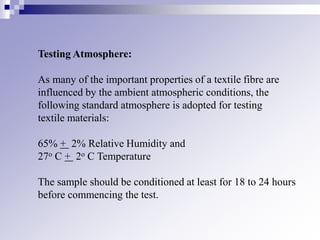

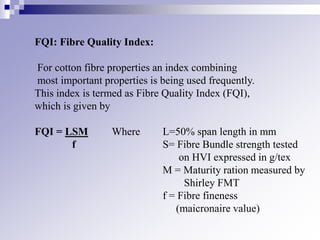

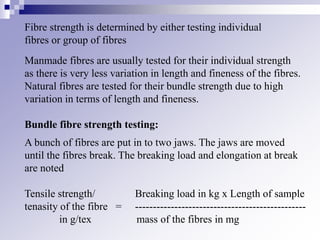

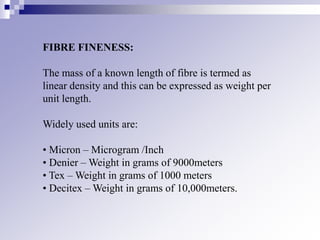

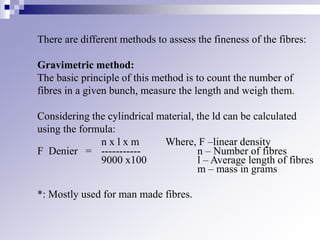

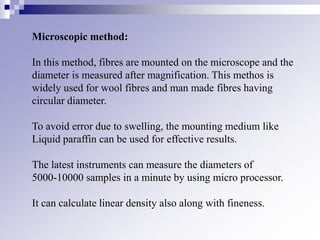

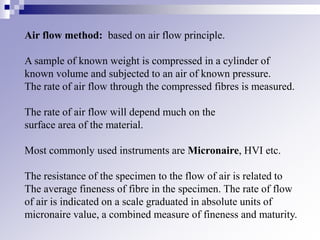

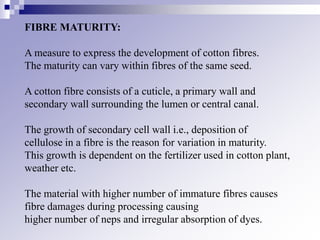

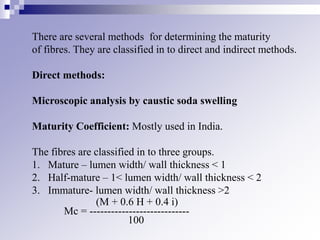

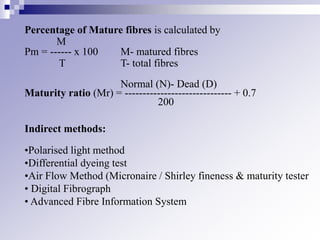

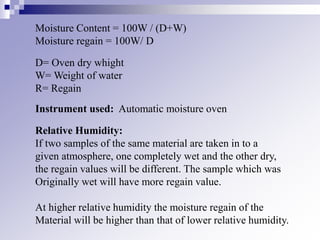

- Key fiber properties that are tested include length, strength, fineness, and maturity. Tests are conducted under standard atmospheric conditions. Test results need to be properly interpreted and applied to fiber selection and process control.