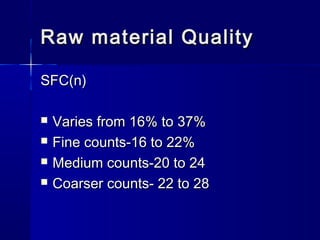

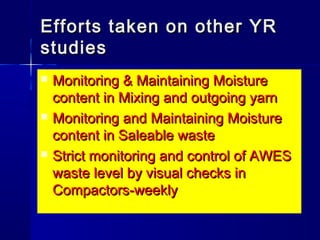

The document presents a critical analysis of yarn realization involving multiple factors such as moisture content, raw material quality, and machine performance that affect yarn imperfections and overall output. It highlights the importance of customer specifications and effective waste management practices in improving yarn quality and reducing waste across various production processes. Additionally, case studies demonstrate successful strategies implemented to achieve significant improvements in yarn realization rates.