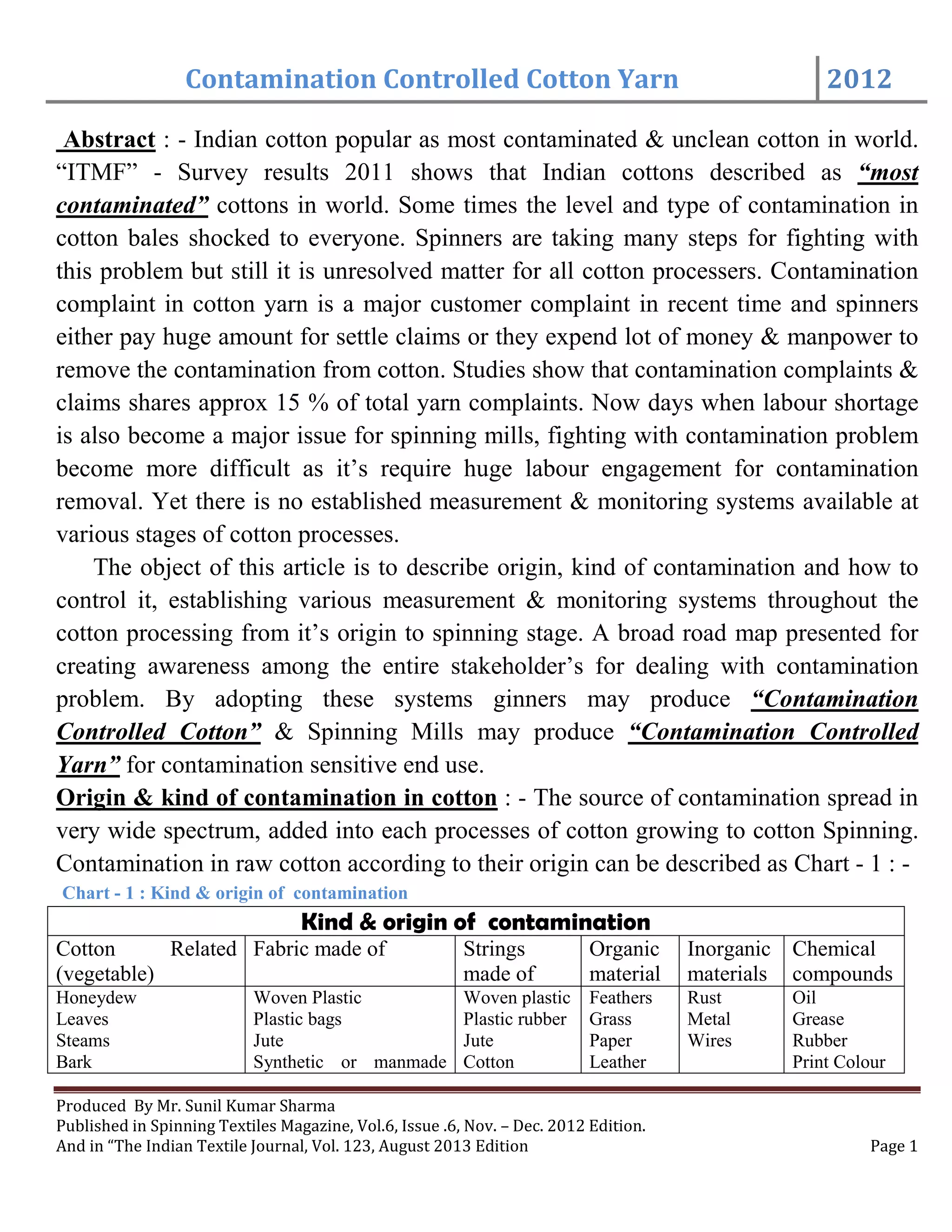

The document discusses significant contamination issues in Indian cotton, recognized globally for its high levels of impurity, impacting the quality of cotton yarn. It outlines sources and types of contamination throughout the cotton supply chain, emphasizing the necessity for effective monitoring and control systems, particularly during ginning and spinning processes. Recommendations for various stakeholders, including stakeholders involved in cotton processing and spinning mills, are provided to mitigate contamination and ensure better quality textile products.