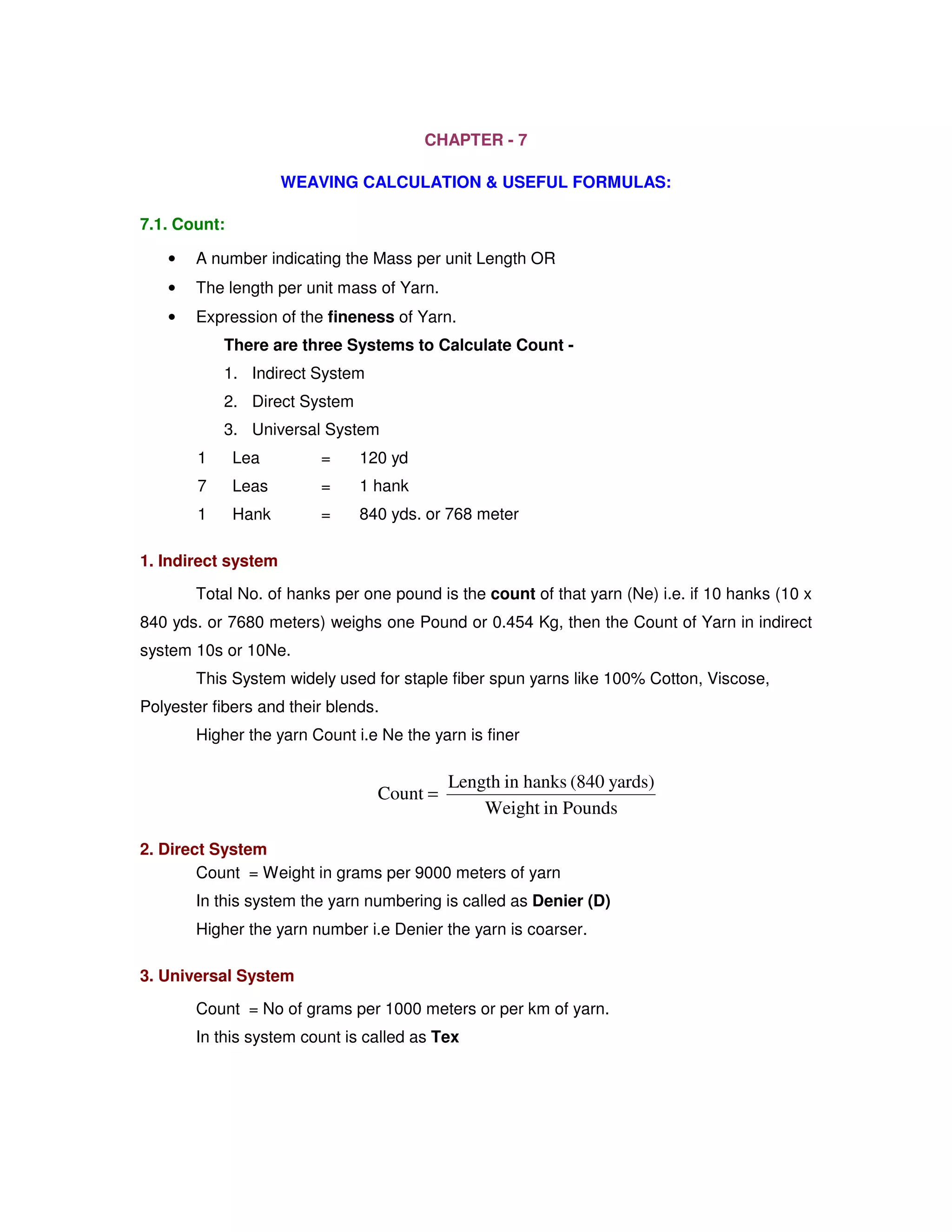

This document provides calculations and formulas related to yarn count, twist, winding, warping, sizing, weaving, and yarn quality parameters. It discusses three systems for calculating yarn count: indirect, direct, and universal. It also covers formulas for twist per inch, multi-filament yarns, winding calculations, warping calculations, sizing calculations, weaving calculations, and parameters for assessing yarn appearance, unevenness, linear density, and single thread strength.