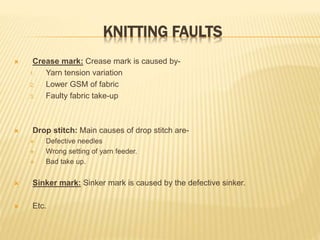

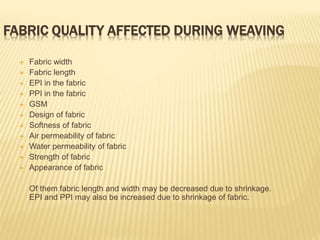

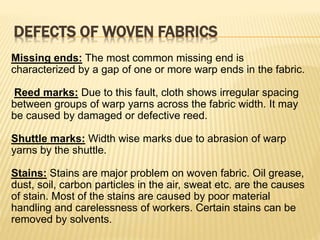

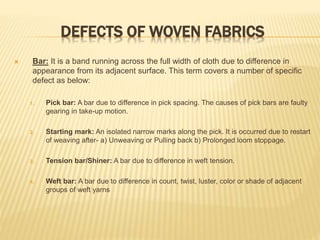

This document discusses quality control in fabric manufacturing. It outlines several factors that affect quality at different stages of production, including winding, warping, sizing, knitting, and weaving. Specifically, it notes that winding tension, knot strength, and machine functioning impact quality. In warping, beam and drum conditions, stop motions, and length measurements are important. For sizing, factors like viscosity, pressure, tension, and speed influence size pickup. Drying is impacted by speed, density, pickup, and temperature. Common fabric defects from knitting and weaving like loops, bars, holes, and stains are also described. Maintaining quality at all stages of production is essential to avoiding defects and customer rejections.