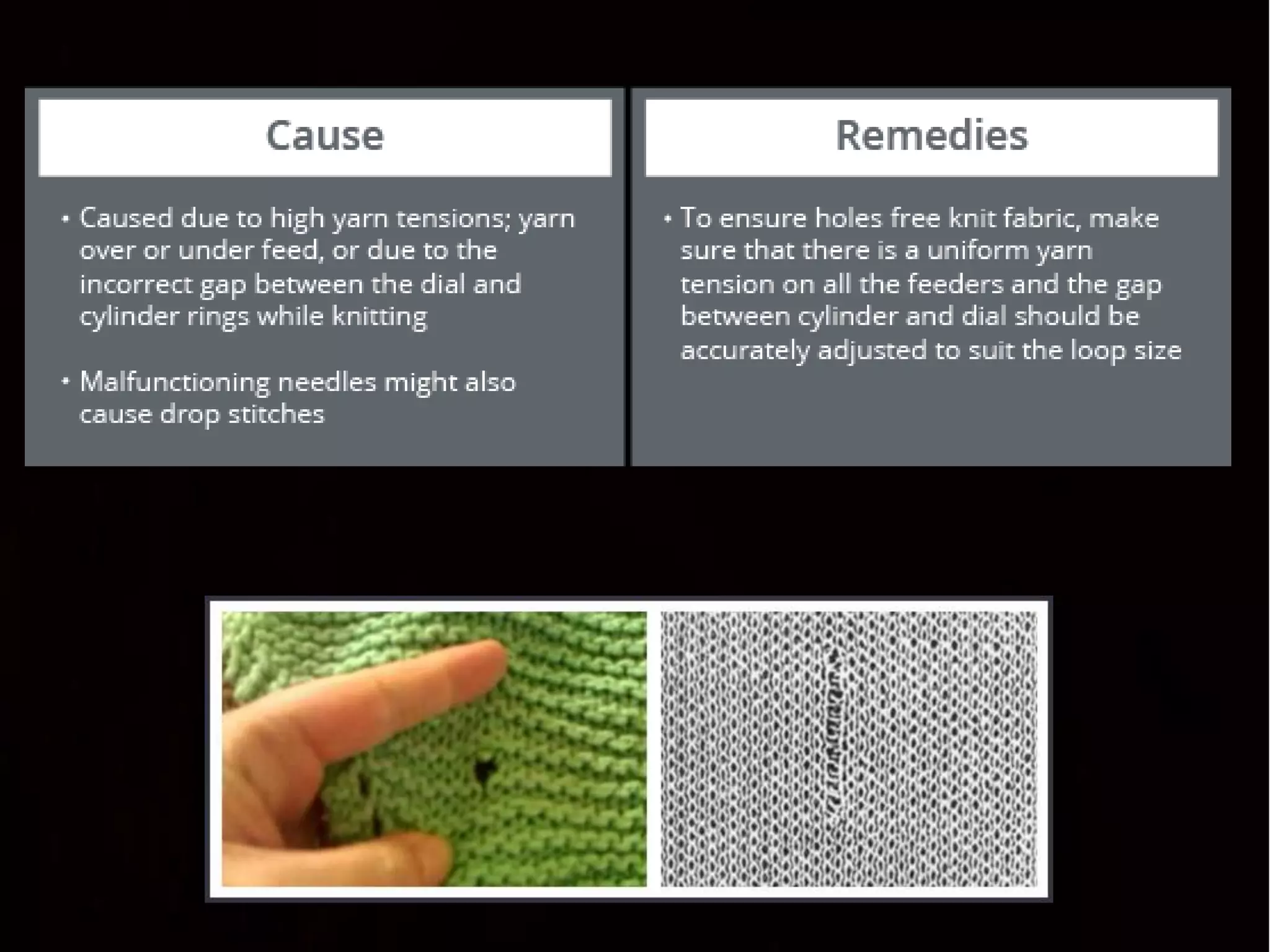

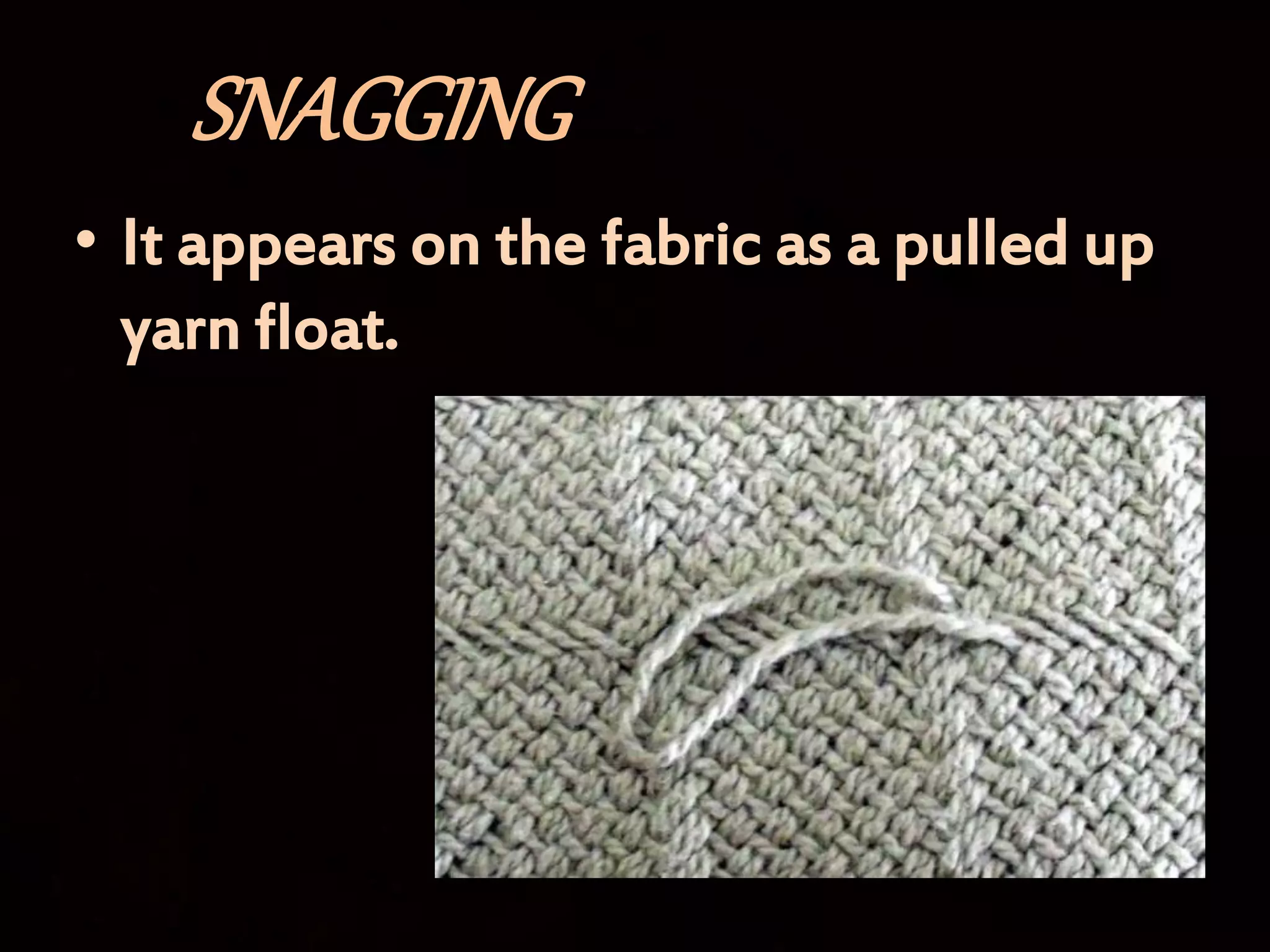

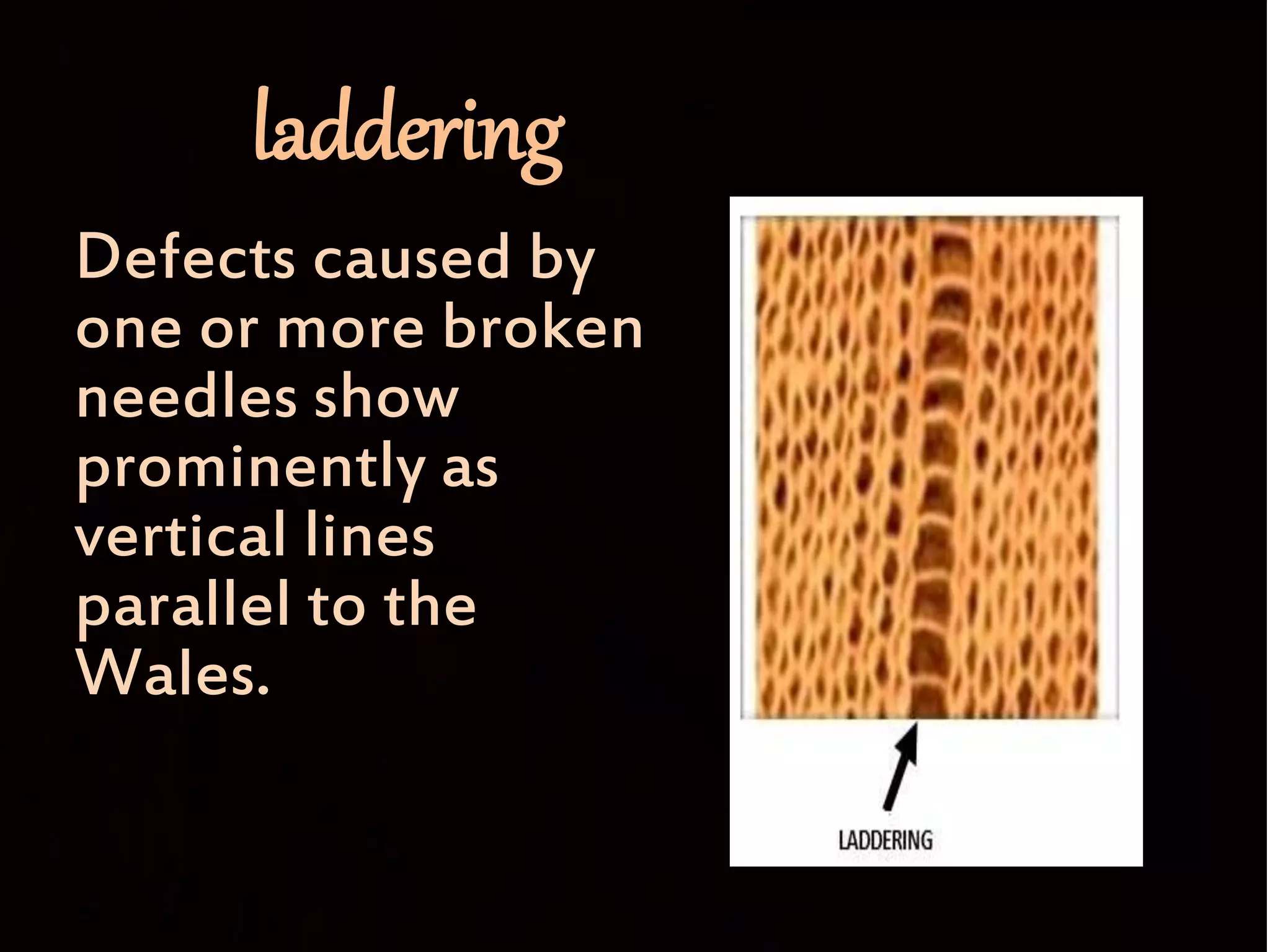

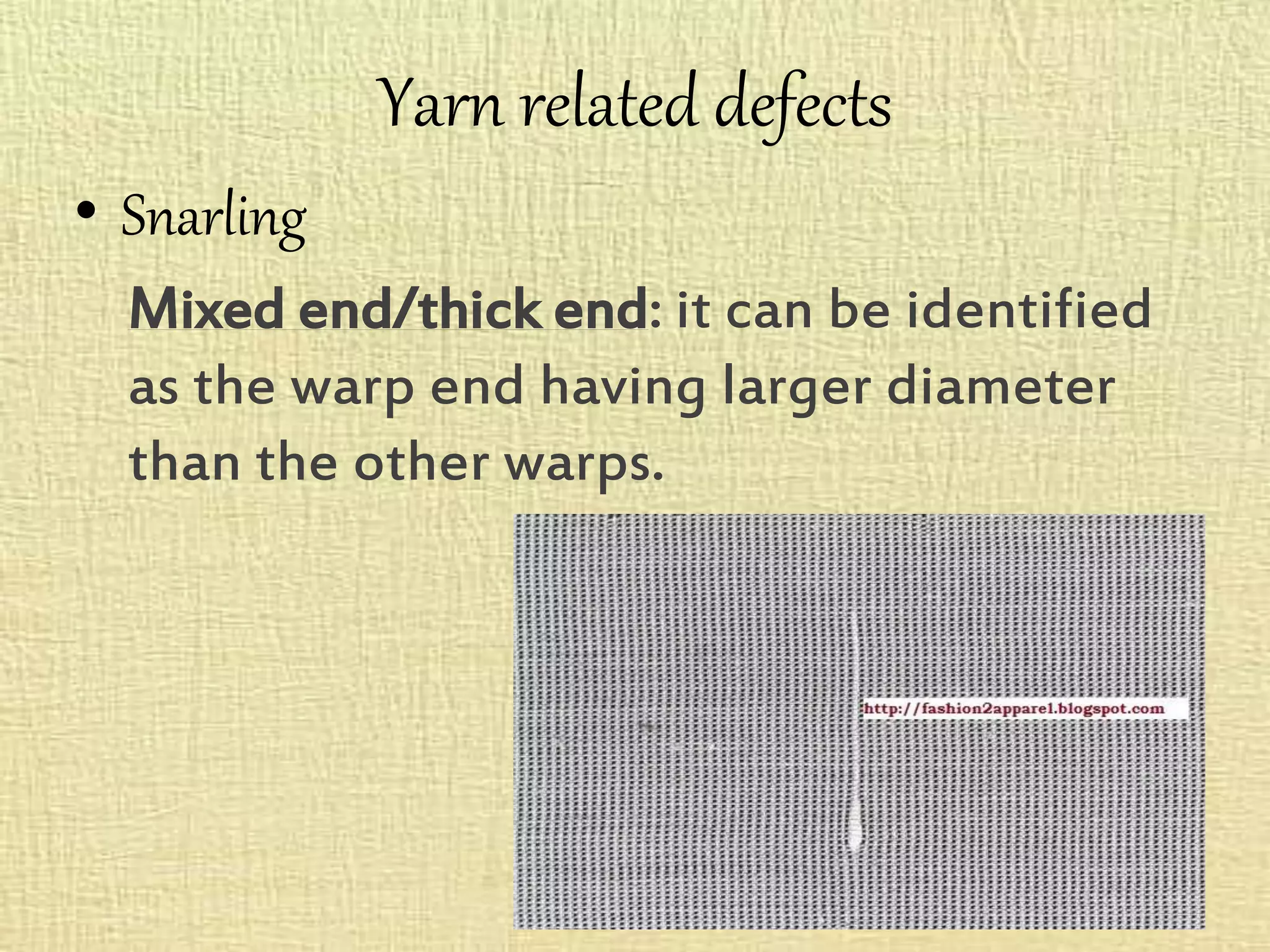

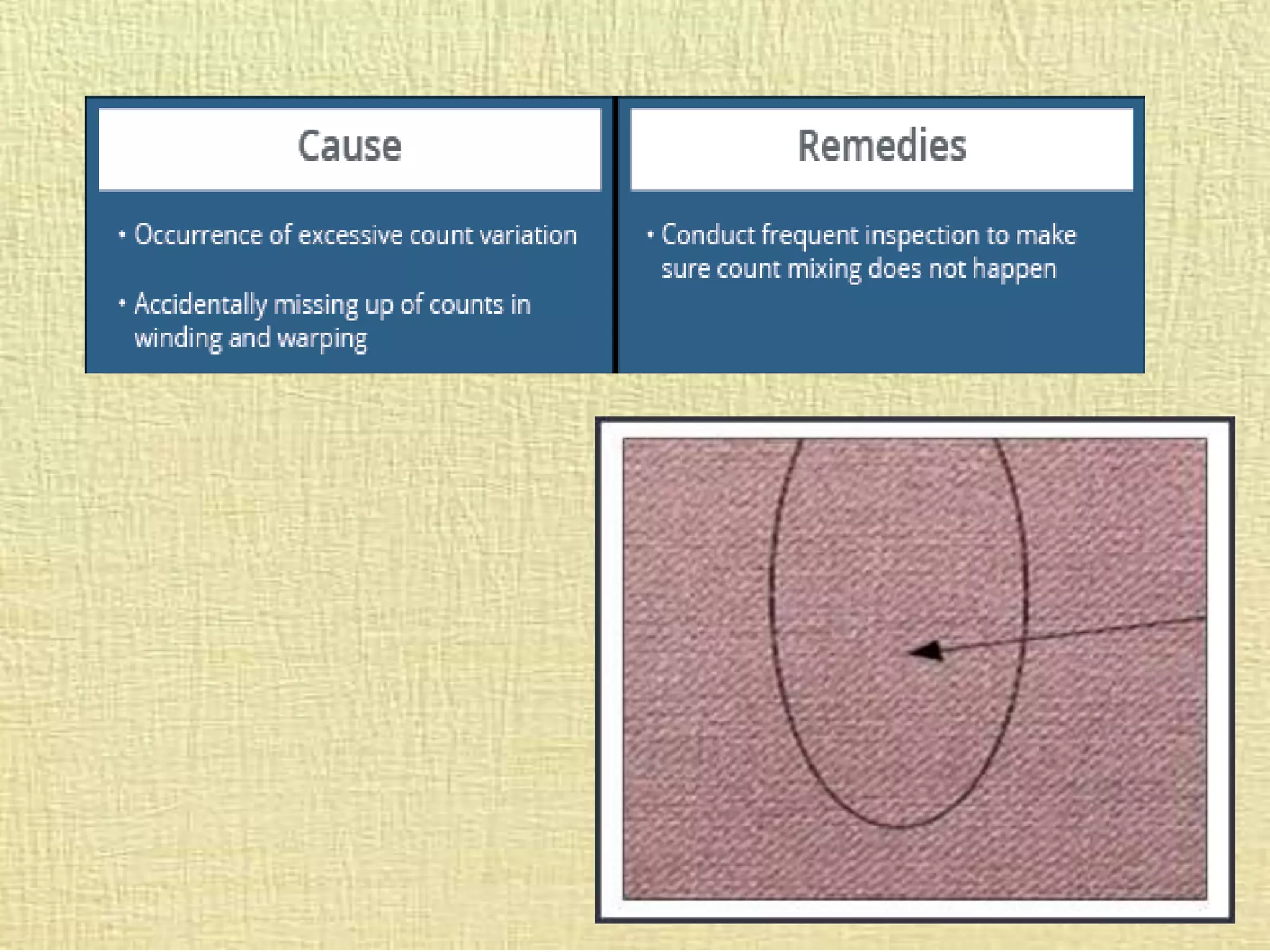

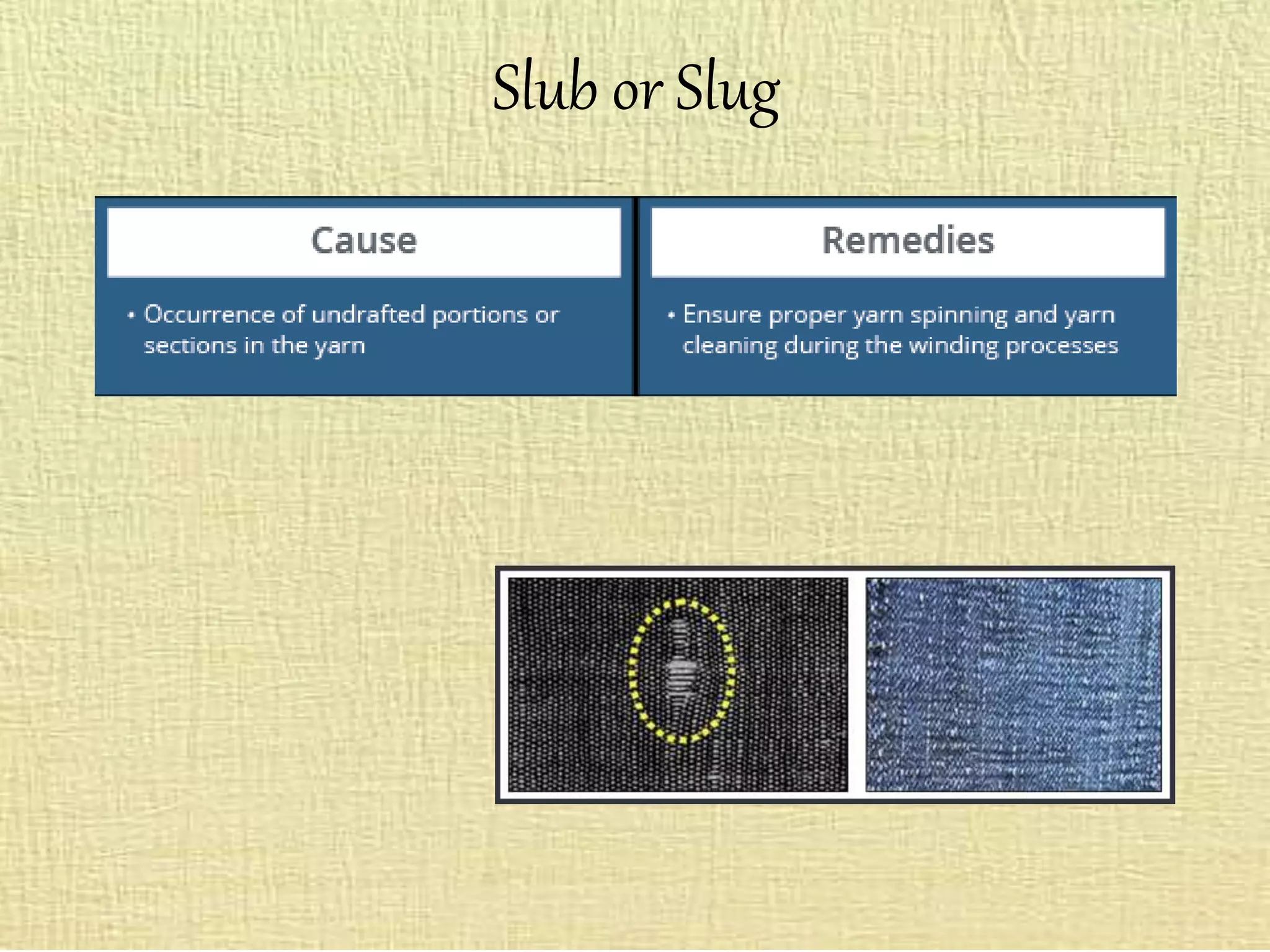

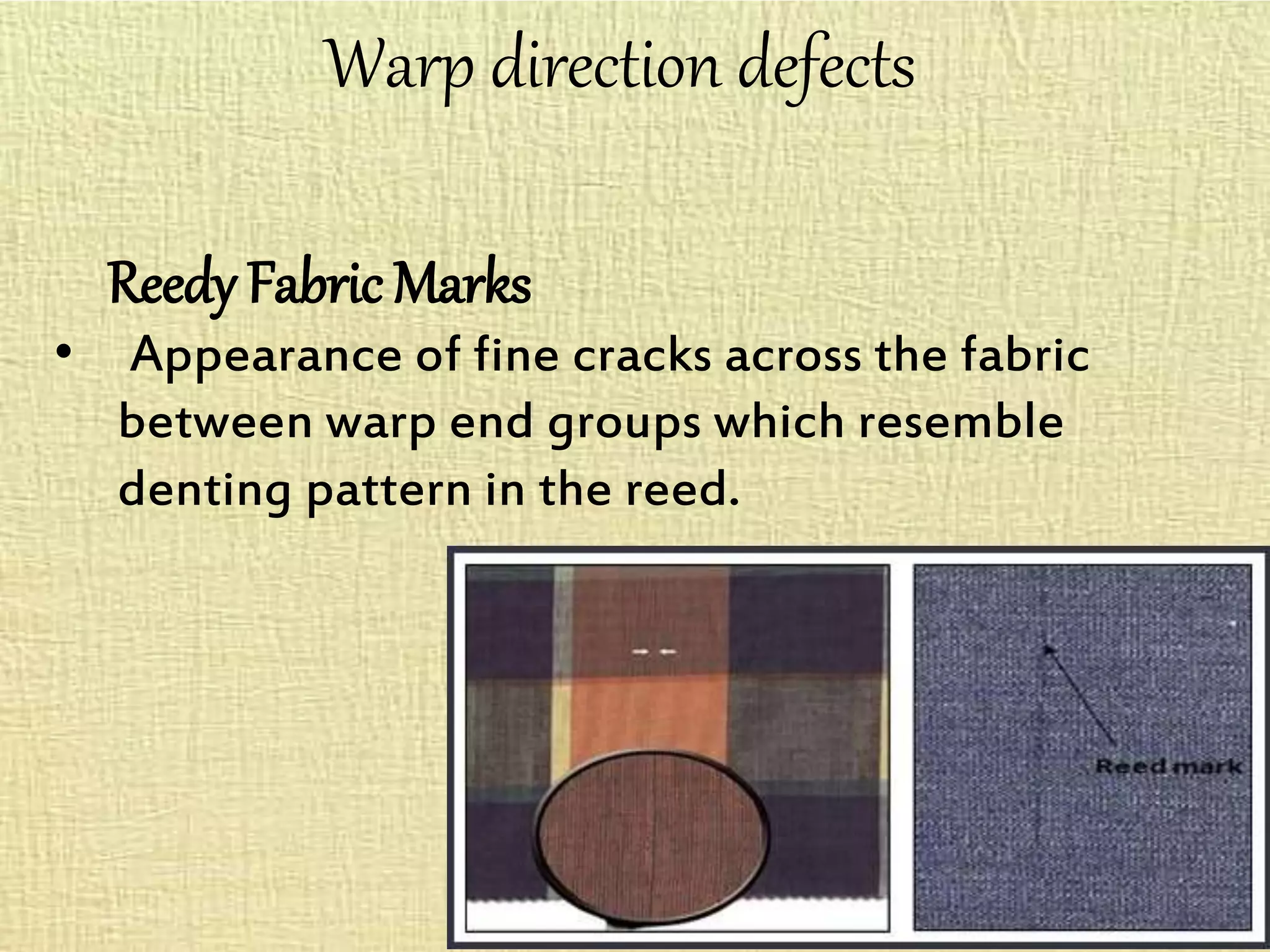

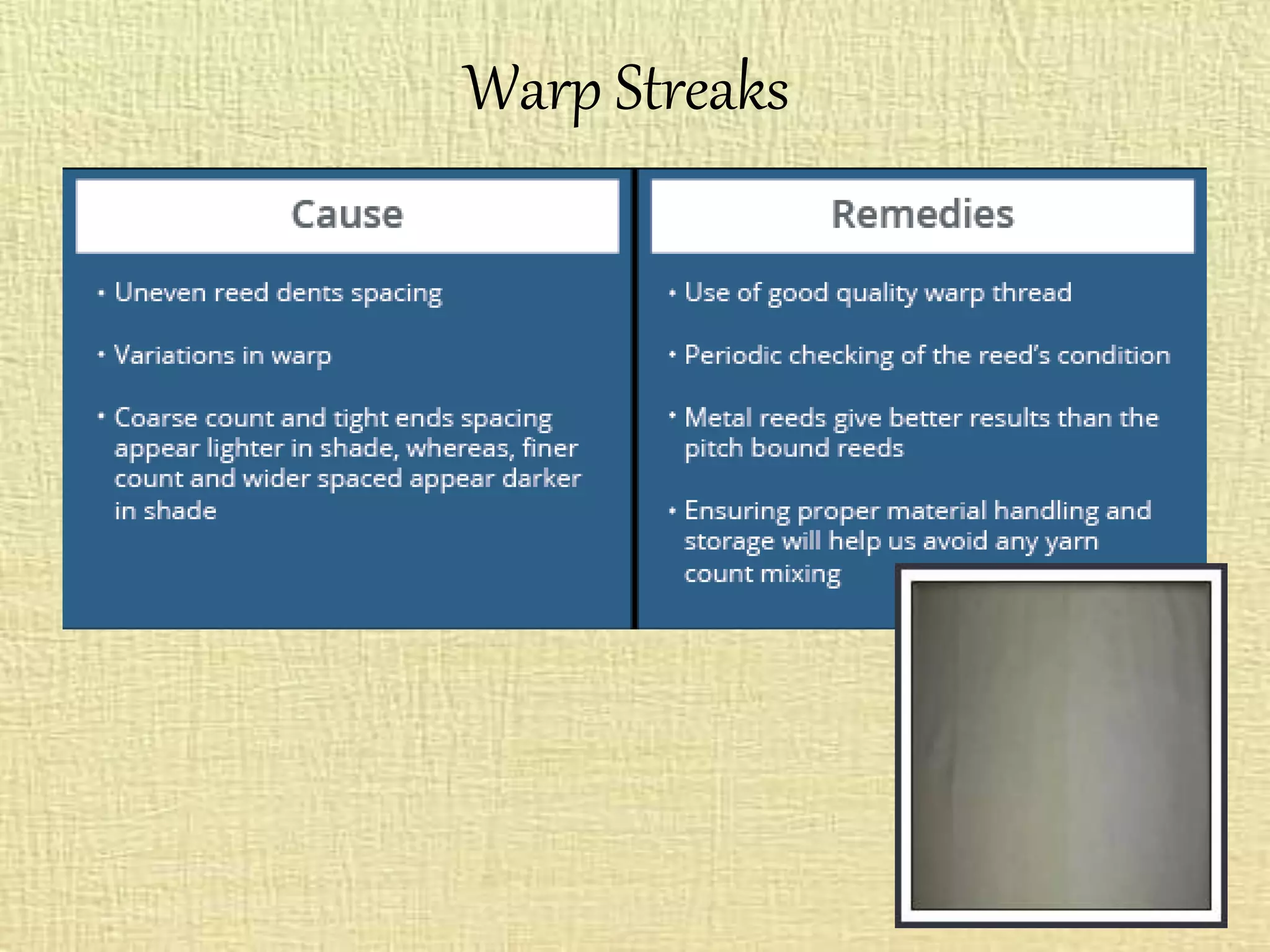

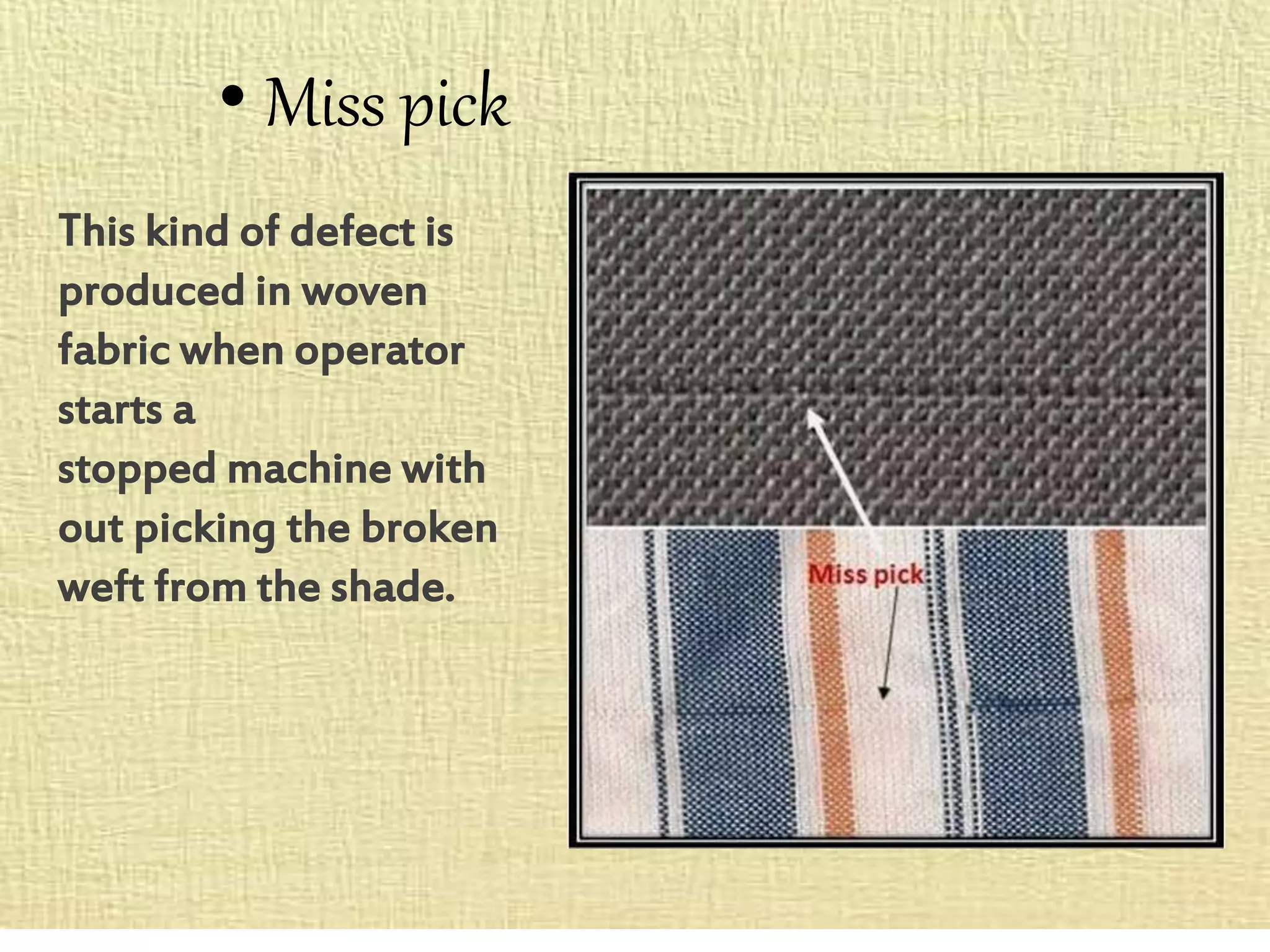

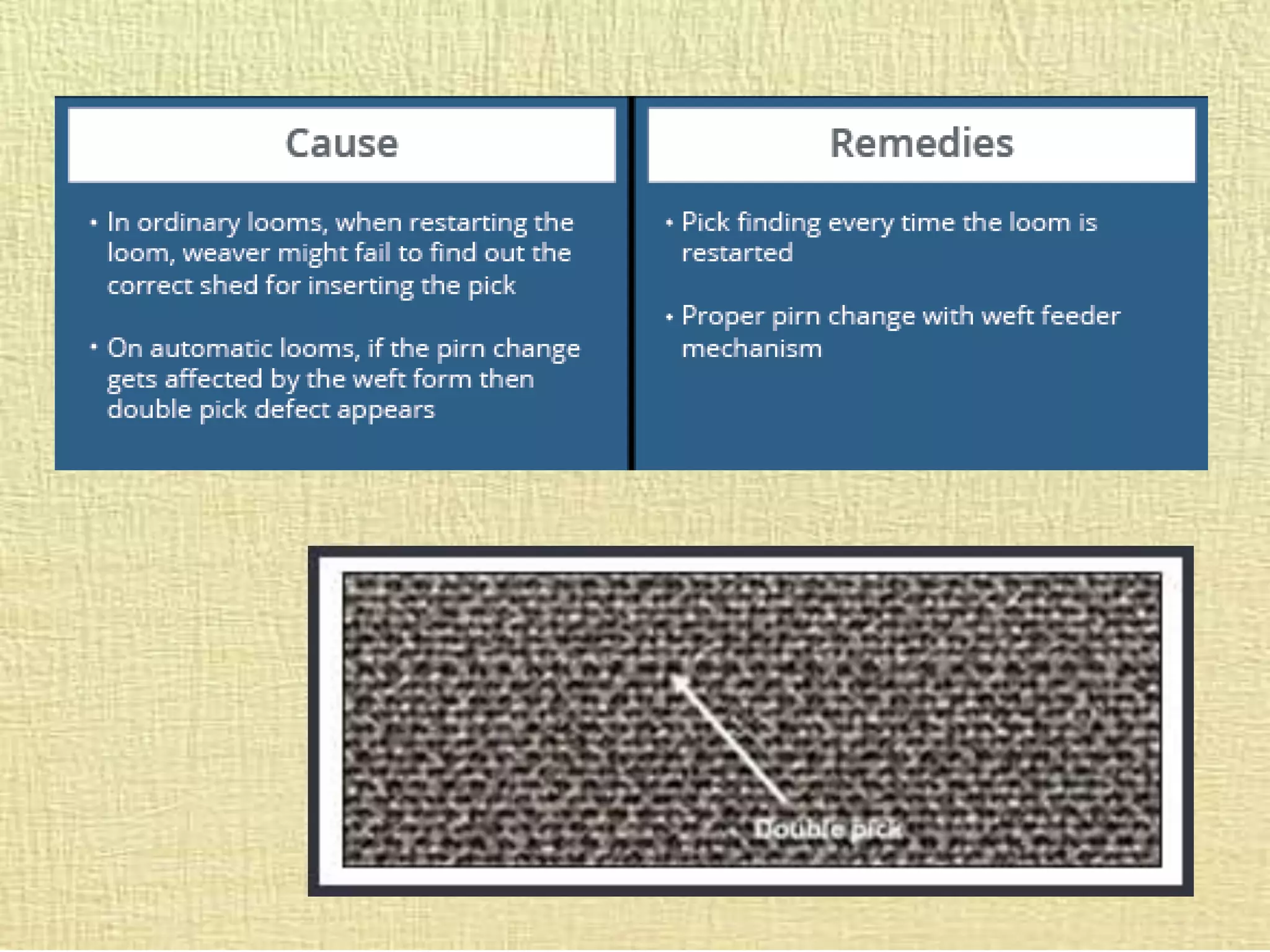

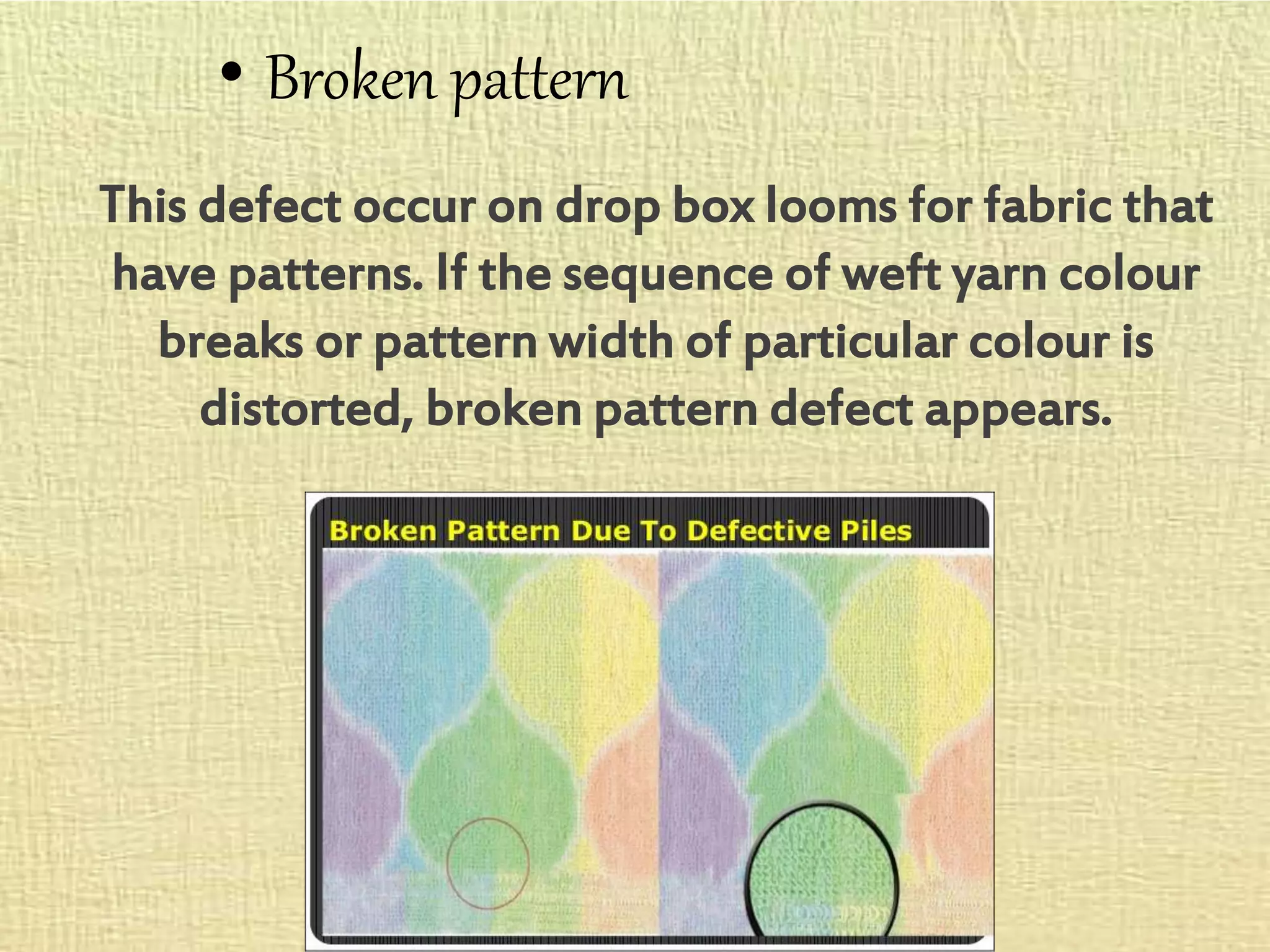

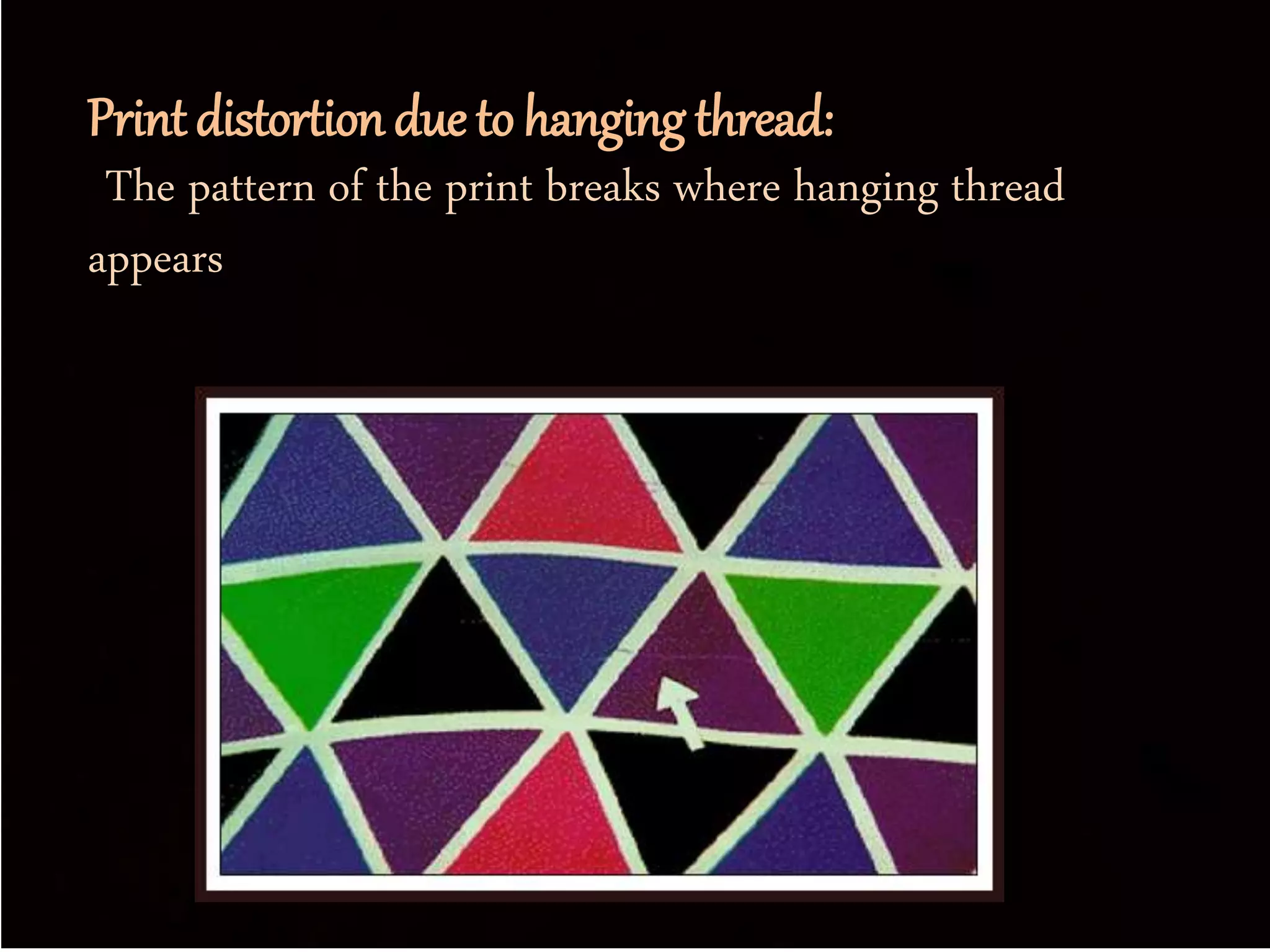

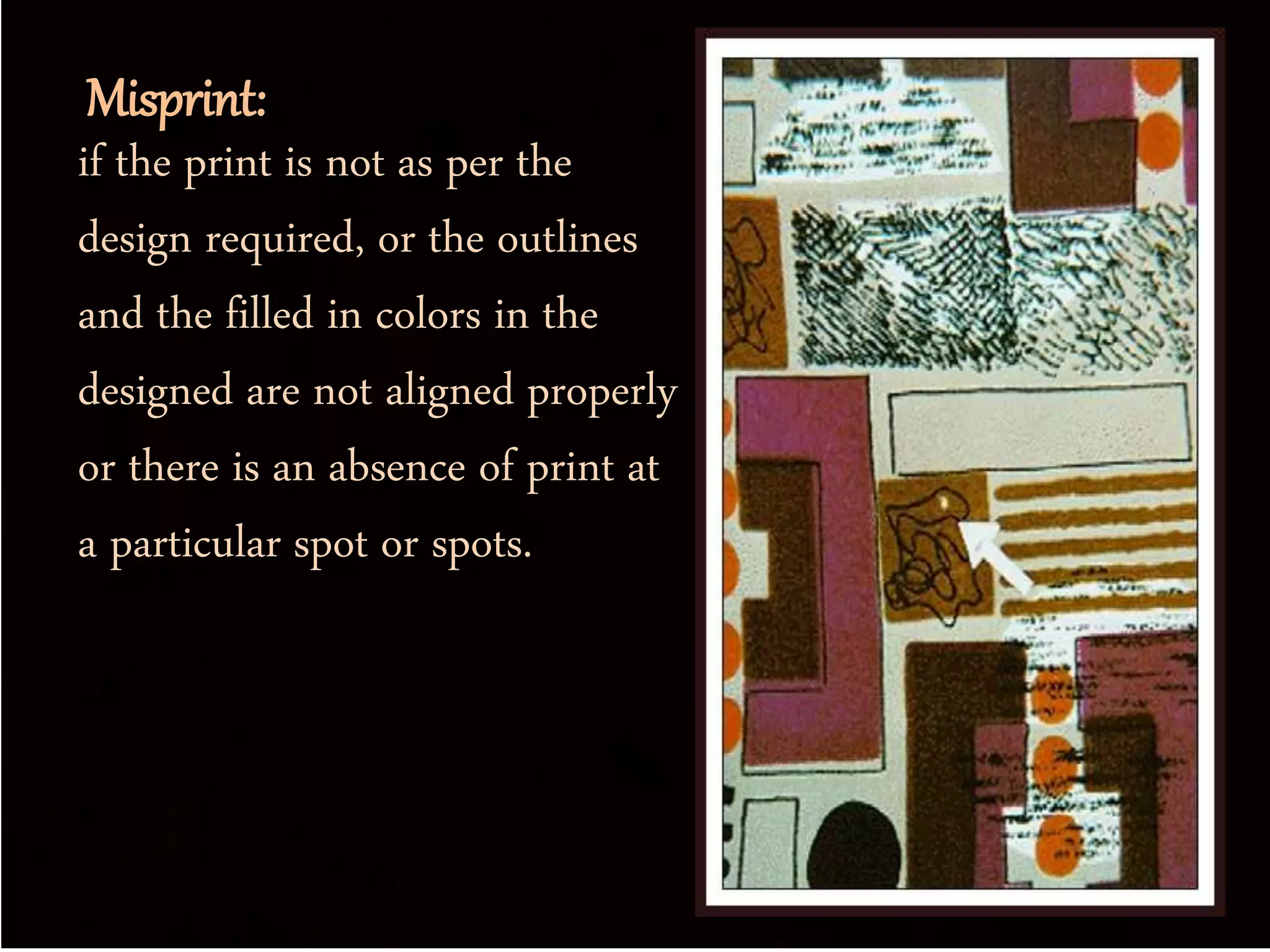

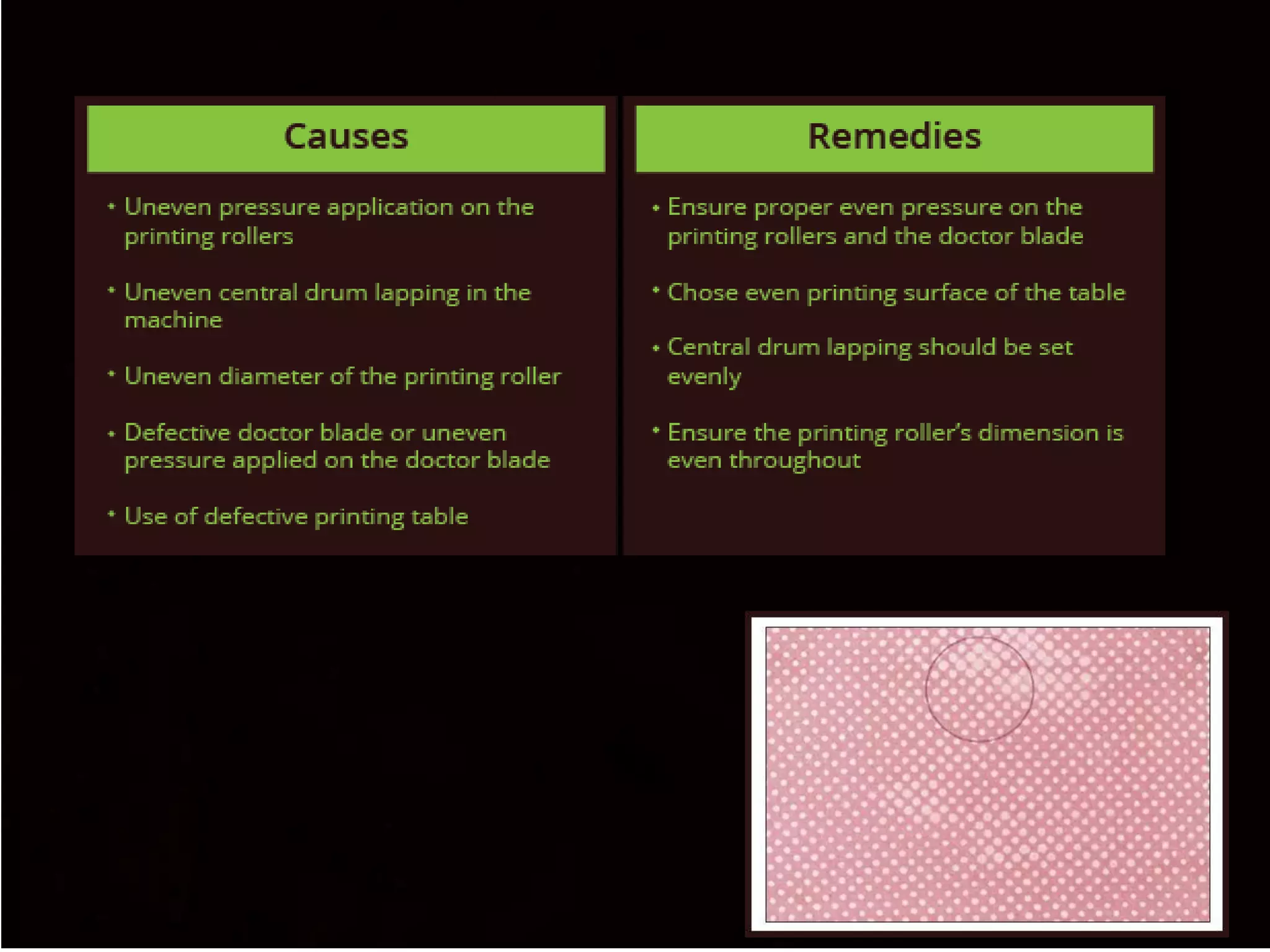

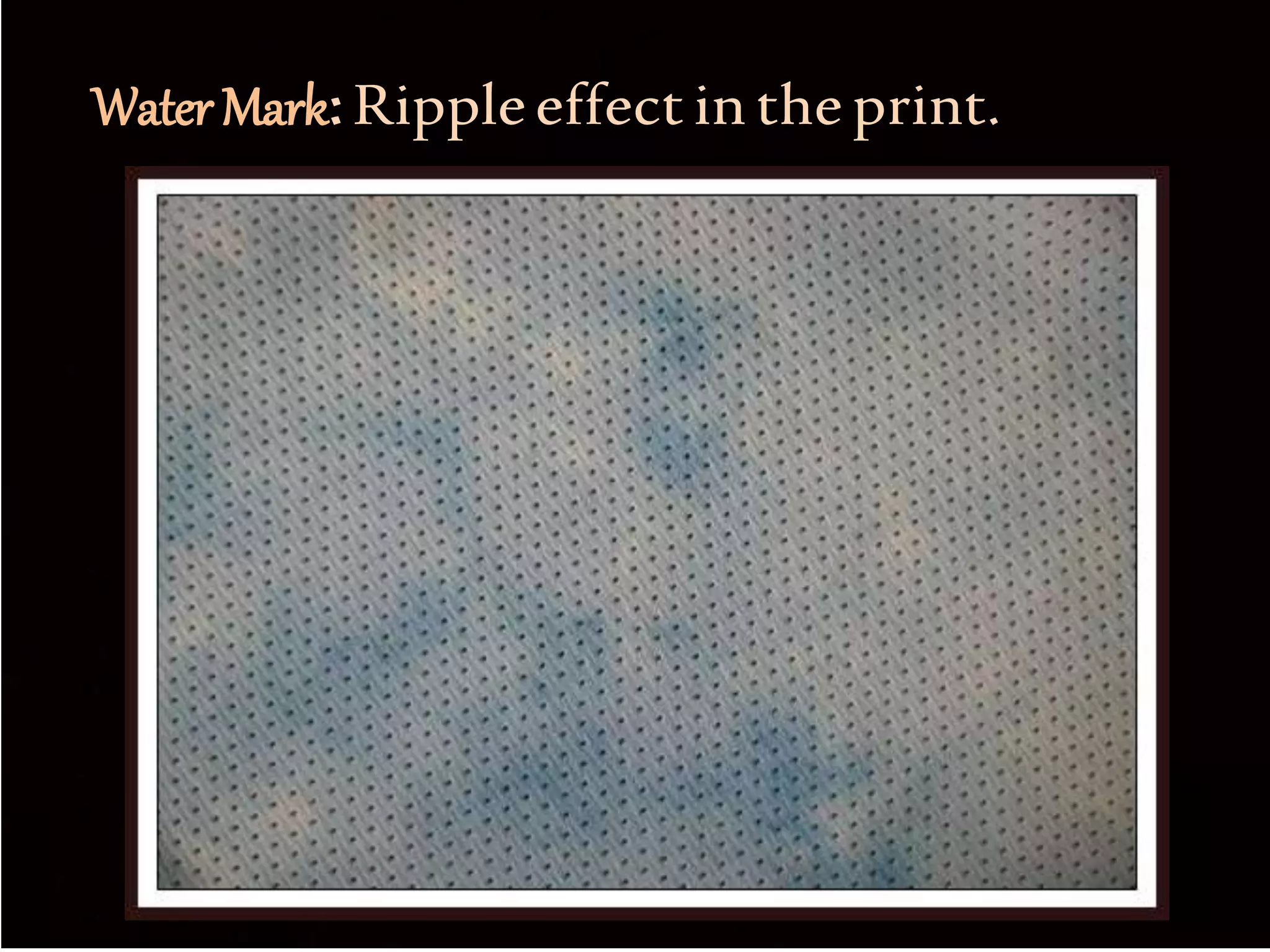

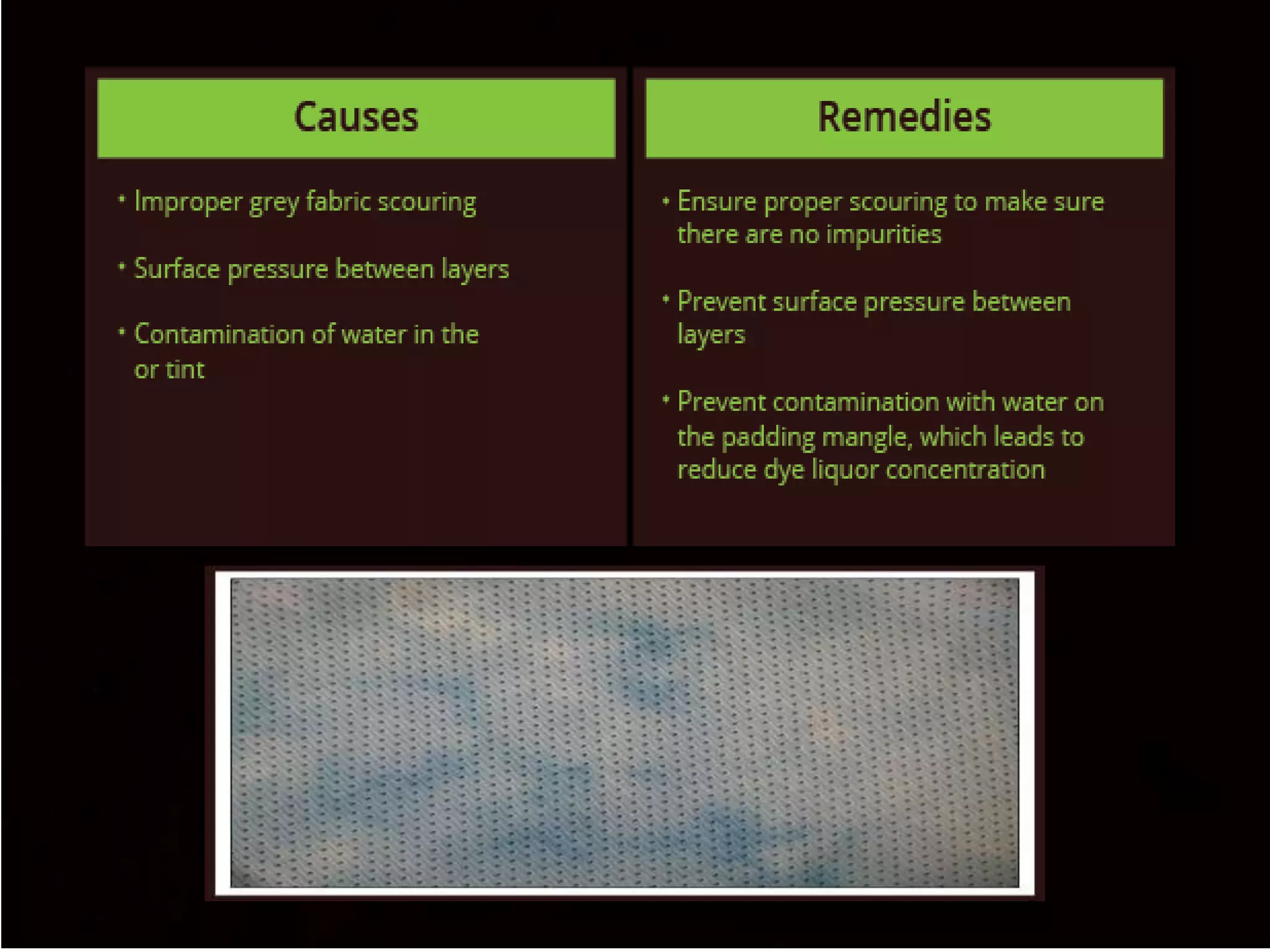

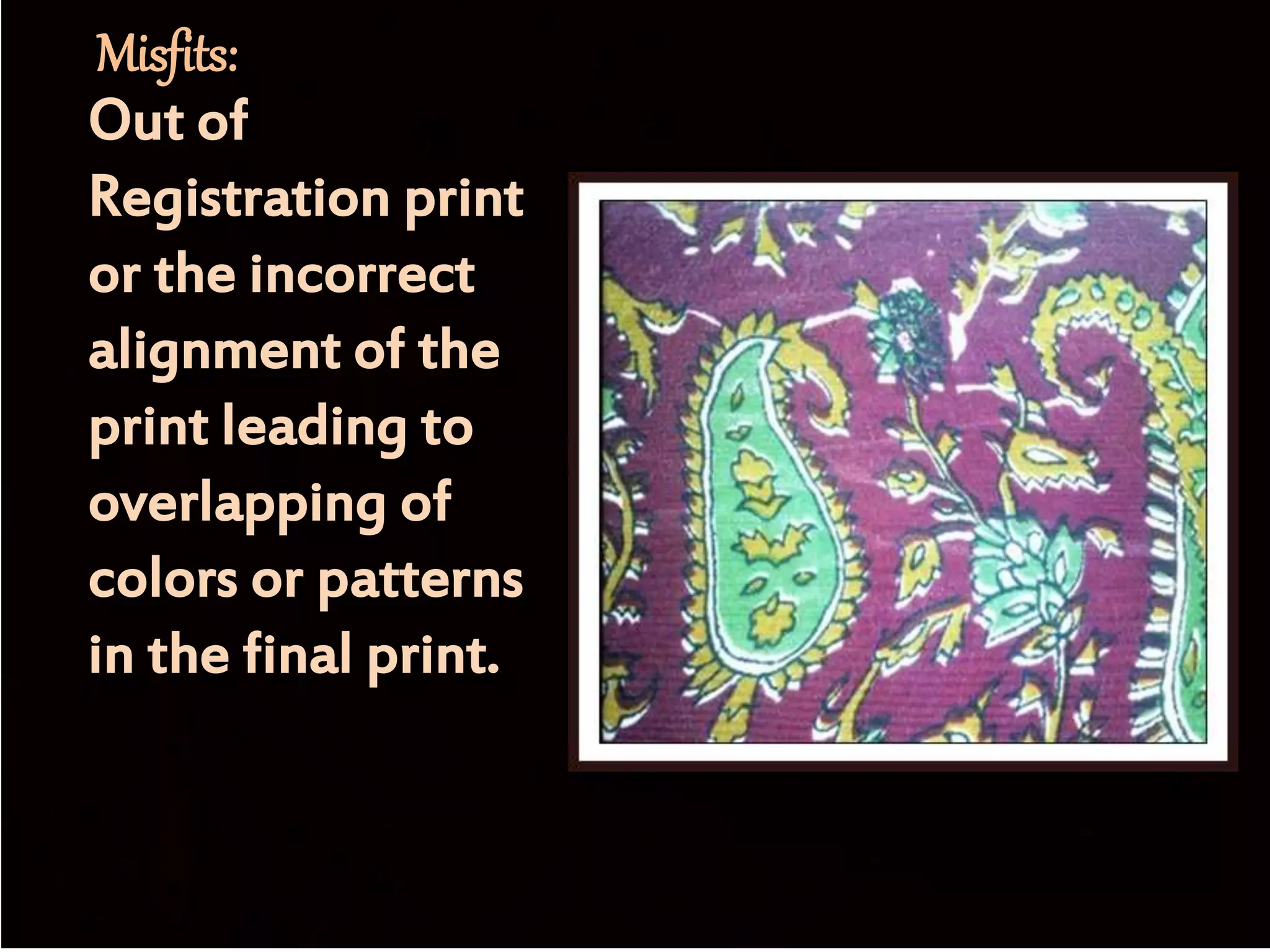

The document outlines various fabric defects, categorizing them into knitted, woven, dyeing, and printing defects, along with their causes and remedies. It explains that fabric defects can result from issues in yarn manufacturing, fabric processing, and mechanical influences during knitting and weaving. Specific defects, such as barriness, drop stitches, and print misalignment, are detailed to highlight their impact on fabric quality and consumer acceptability.