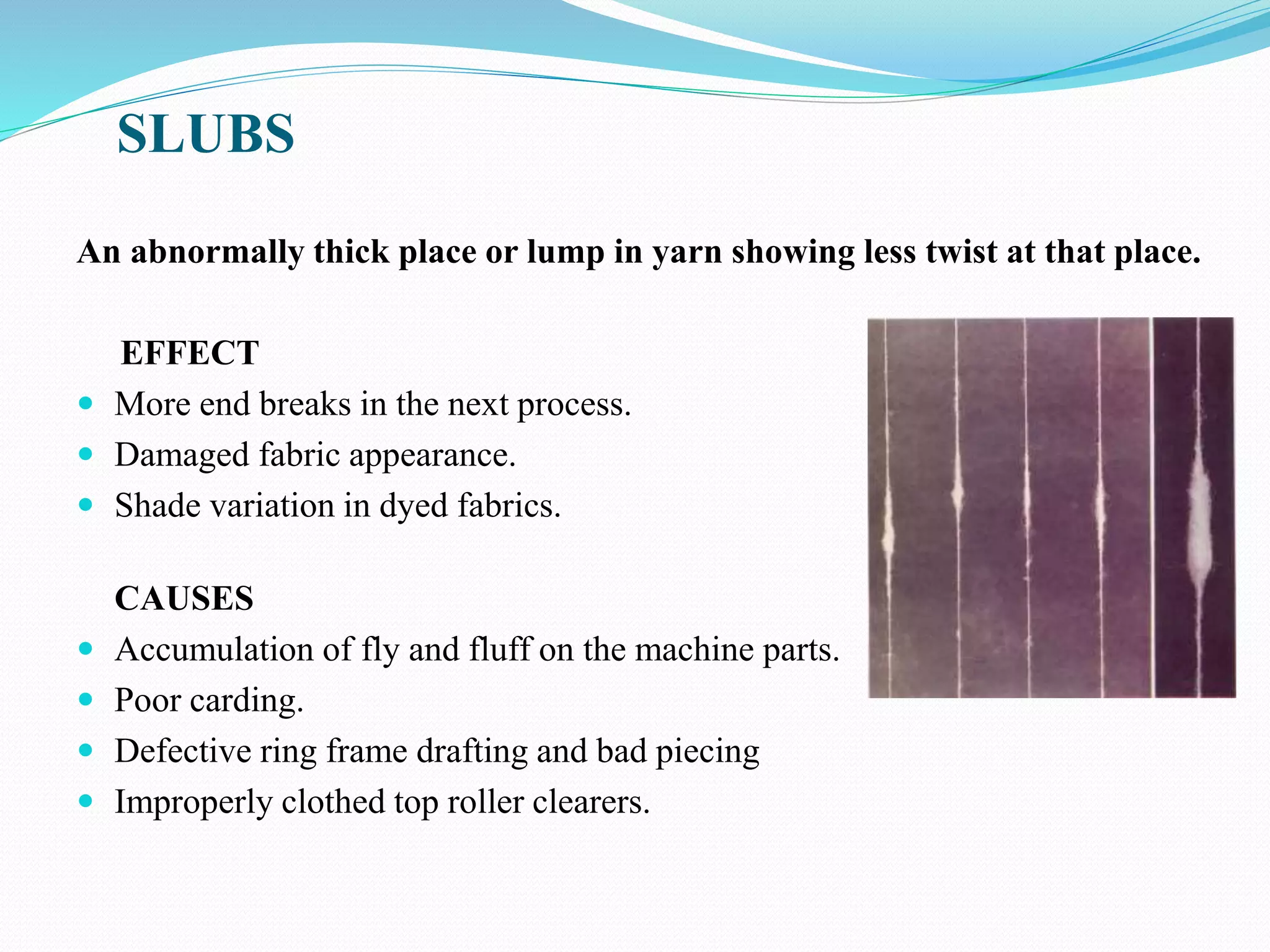

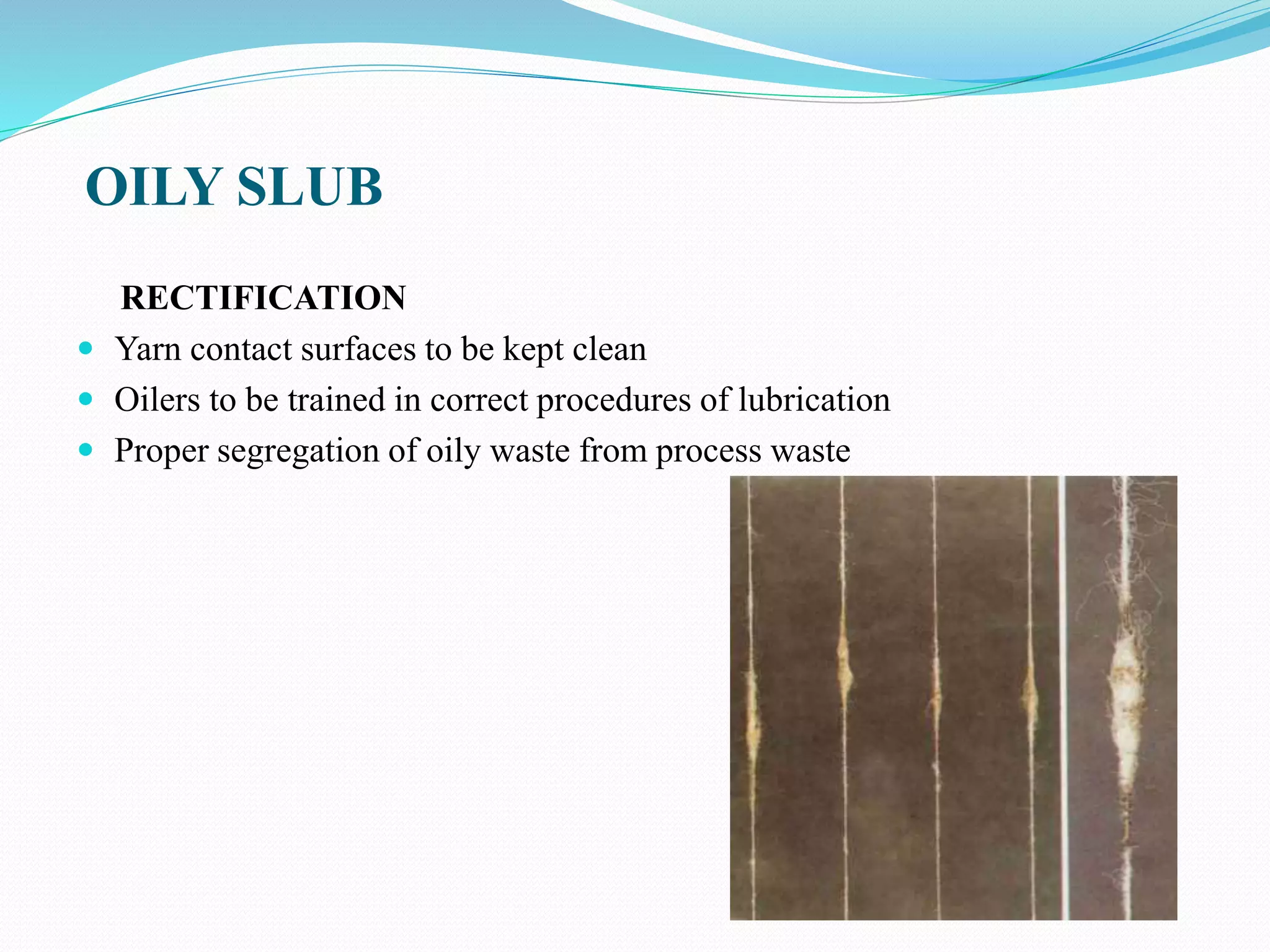

This document discusses common yarn faults like slubs, neps, snarls, thick and thin places, soft yarn, and oil stained yarn. It describes the effects and causes of each fault as well as methods for rectifying the issues. Some ways to prevent yarn faults include maintaining clean machinery, ensuring proper drafting and piecing, and avoiding mixing cotton with widely varying properties. Overall, the document provides information on identifying, understanding, and addressing different types of defects that can occur in yarns during spinning.