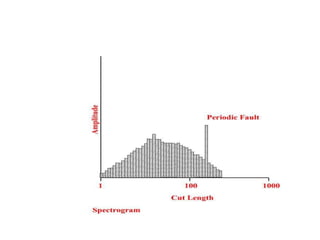

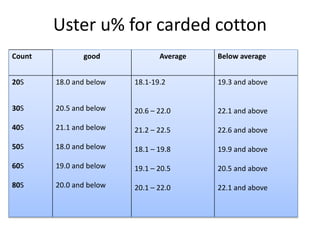

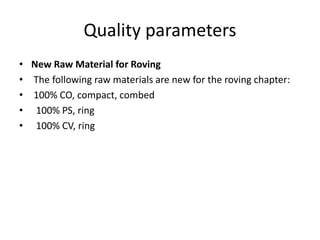

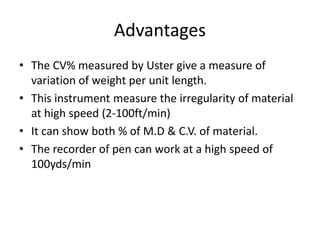

This document provides an overview of yarn evenness testing and the latest developments in yarn evenness testing machines. It discusses what yarn evenness testing is, the different types of variations that can occur, and how the Uster evenness tester works. The Uster tester uses a capacitance principle to measure mass variations as yarn passes through an electric field, and can test yarn, roving, and sliver at speeds from 2-400 meters per minute. It provides measurements of parameters like unevenness percentage, neps, and thickness variations that can help evaluate yarn quality.