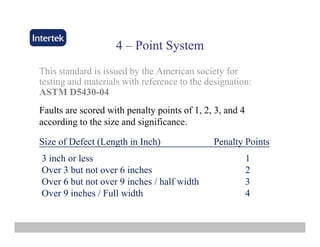

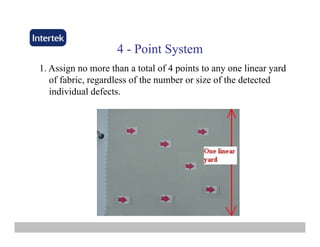

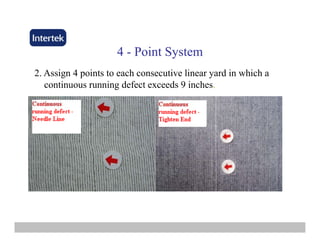

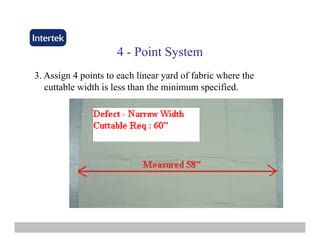

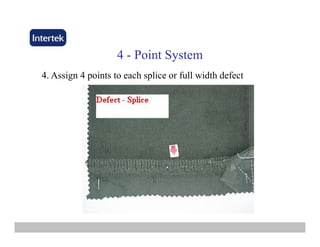

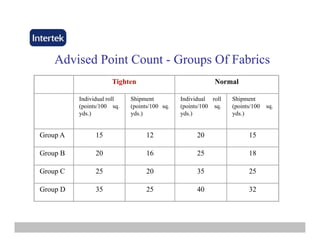

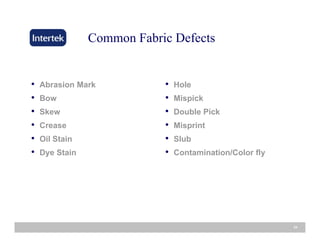

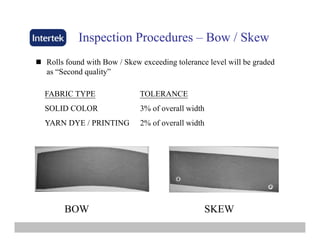

1. The document outlines a 44-point inspection system used to evaluate fabrics based on defect size and significance, with penalties ranging from 1 to 4 points.

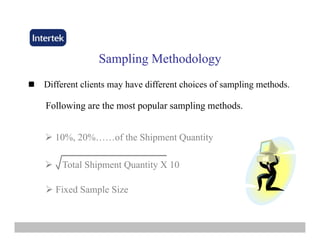

2. It describes random sampling methods for inspections and specifies that 10-20% of shipment quantities should be sampled.

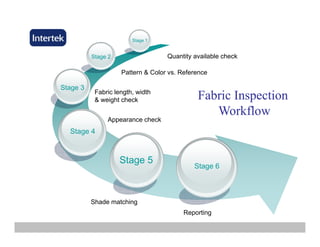

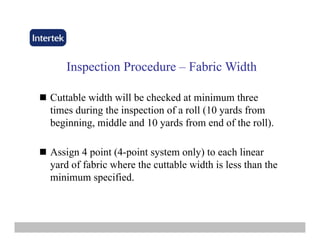

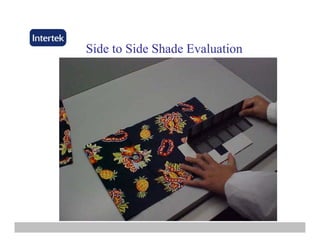

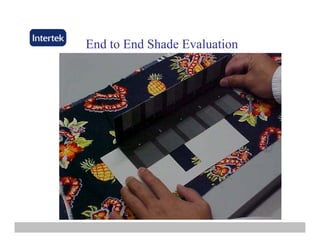

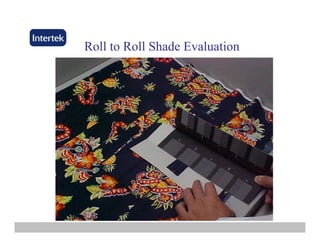

3. A multi-stage inspection process is defined involving quantity checks, pattern/color verification, measurements, appearance evaluation, and shade matching.