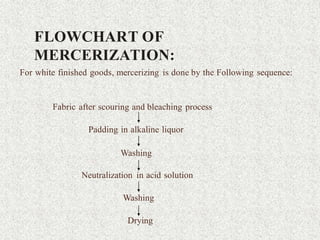

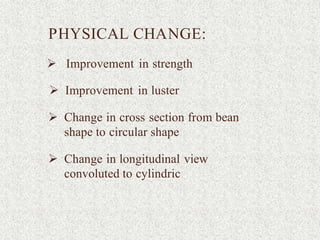

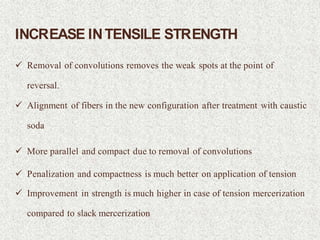

This document discusses mercerizing, which is a process that treats cellulosic materials like cotton with a concentrated alkali solution. Mercerizing improves properties like luster, strength, dye uptake, and dimensional stability. It involves padding fabric with an alkaline liquor, washing, neutralizing with acid, and drying. Physically, it changes the cotton fiber's cross section from bean-shaped to circular and removes convolutions. Mercerizing can be done continuously using a J-Box system that passes fabric through alkali and acid baths over several minutes.