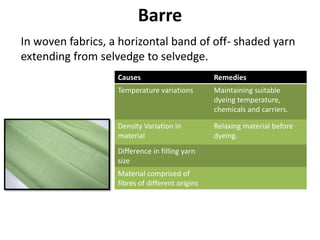

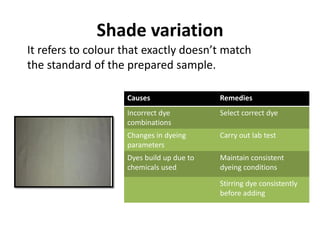

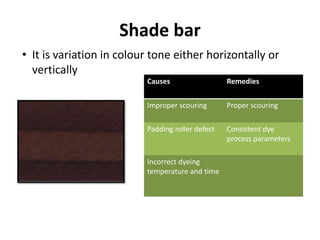

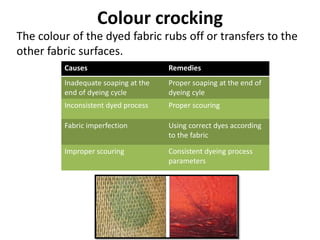

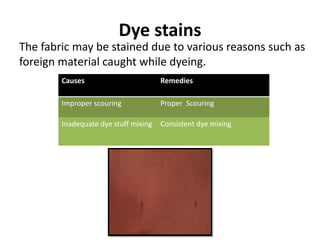

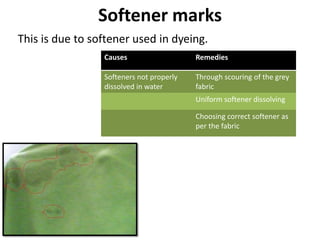

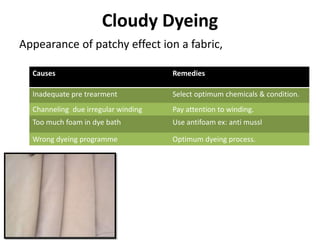

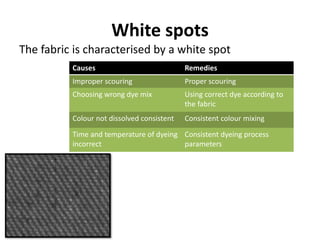

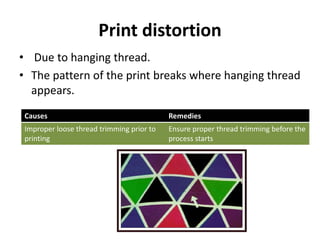

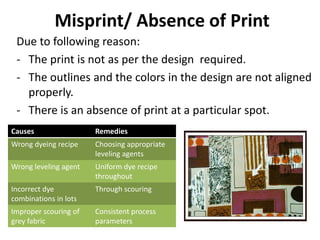

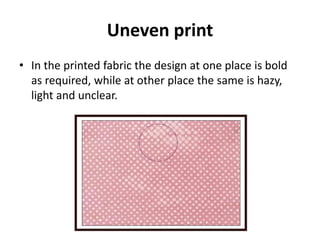

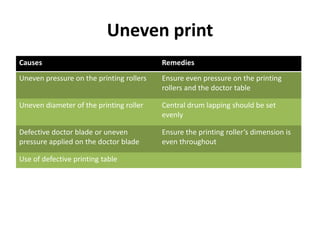

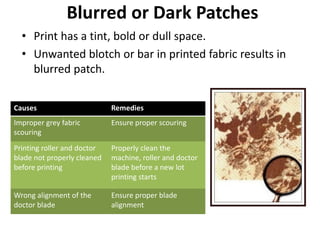

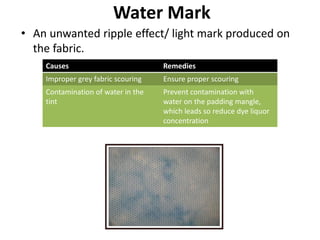

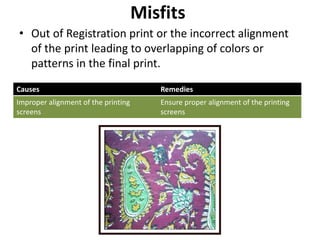

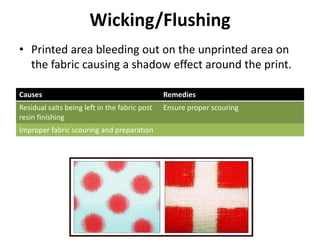

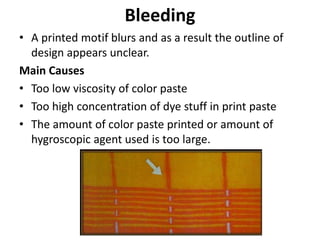

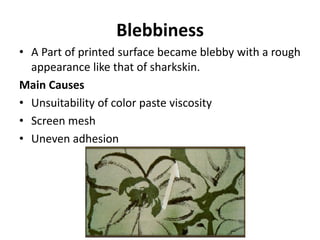

This document discusses common defects that can occur during dyeing and printing of textiles. It describes two main methods for adding color to fabrics - dyeing and printing. Dyeing involves applying color evenly throughout the fabric using dye solutions, while printing uses localized application of dyes or pigments in a paste form to create patterns. Common dyeing defects include uneven color, crocking, stains and softener marks. Printing defects can result from faulty processes or fabric imperfections, and include issues like misprints, uneven color, water marks, misregistration and bleeding of dyes. Potential causes and remedies are provided for many of the typical defects.