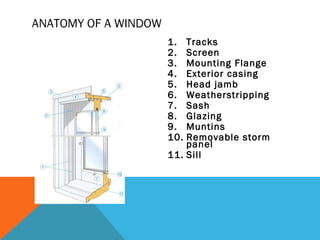

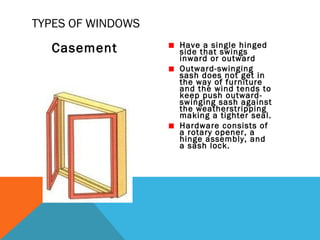

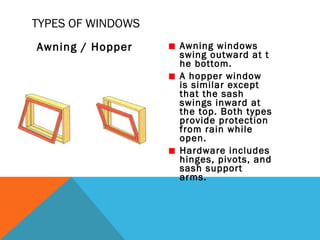

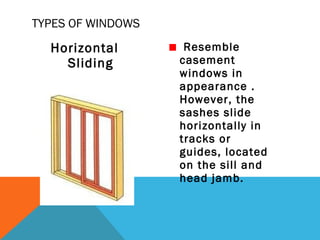

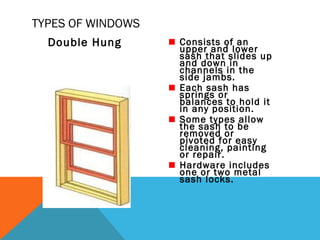

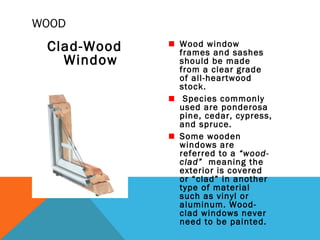

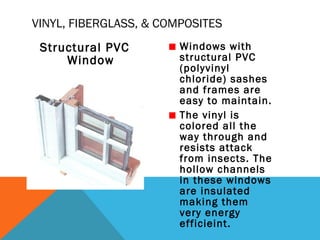

Windows are composed of glazing (glass or plastic), a sash that holds the glazing, and a frame. There are several types of windows including casement, awning/hopper, horizontal sliding, and double hung. Window frames can be made from wood, metal, vinyl, fiberglass, or composites. Energy efficiency and standards depend on factors like glazing, weatherstripping, and materials. All windows in Canada must meet standards for performance, insulation, and durability. Proper weatherstripping around windows helps prevent air leakage.