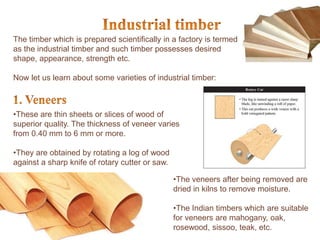

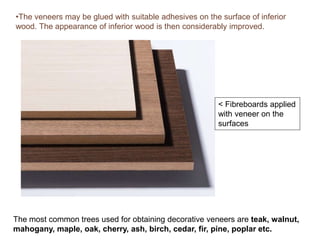

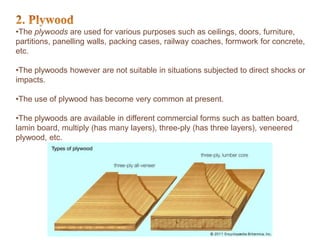

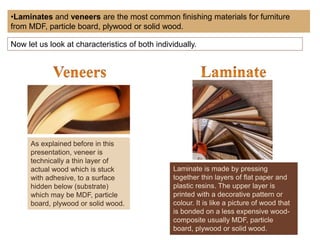

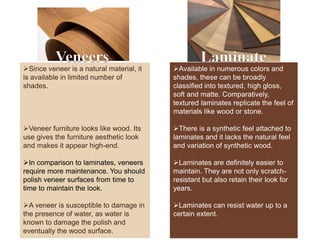

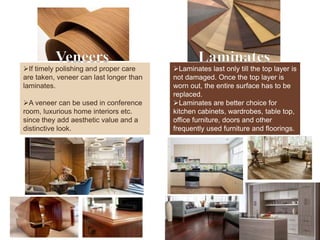

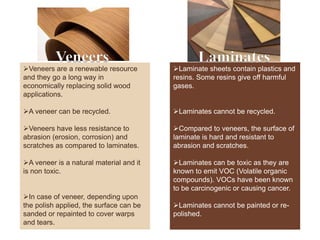

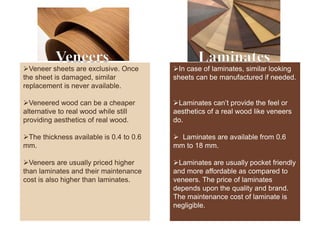

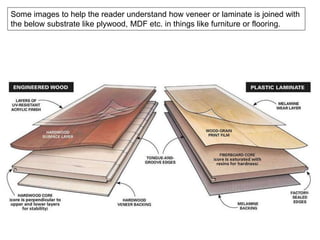

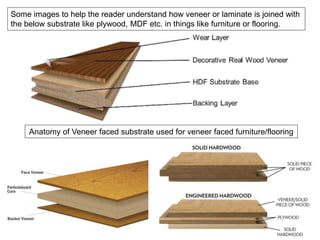

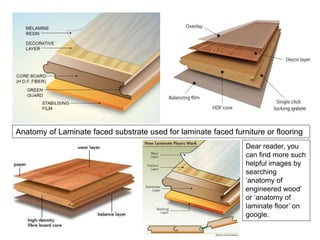

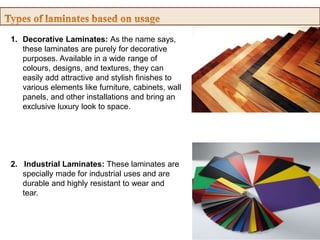

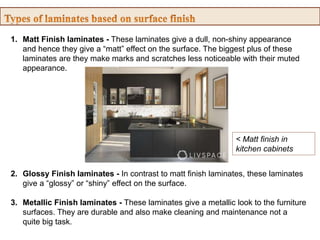

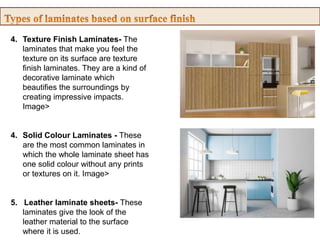

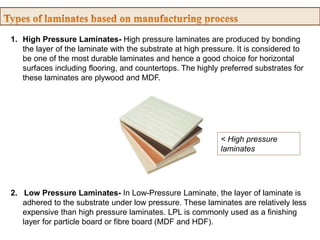

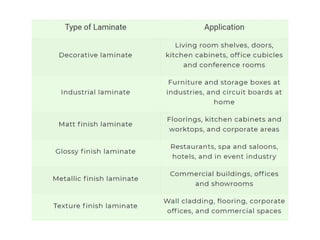

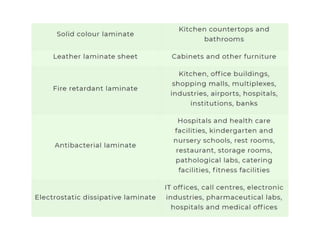

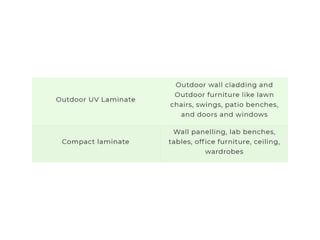

The document discusses industrial timber, specifically focusing on veneers and laminates used in furniture and construction. It highlights the characteristics, applications, advantages, and differences between veneers, which are natural wood layers, and laminates, composed of paper and plastic resins. Additionally, it classifies different types of laminates based on finish, usage, and advanced properties, emphasizing their popularity and versatility in both residential and commercial projects.