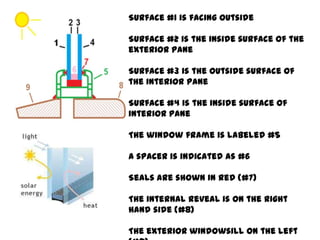

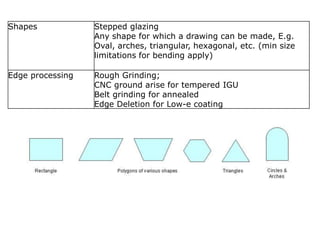

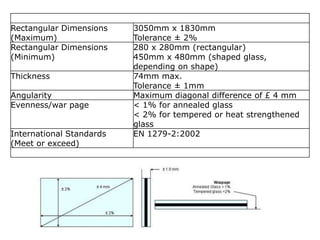

This document provides information about insulated glass units (IGUs). It discusses that IGUs consist of multiple glass panes hermetically sealed with dry air or inert gas between. Key components of IGUs include spacers to separate the glass, desiccants to absorb moisture, and primary and secondary sealants. The document also outlines best practices for IGU production, including using the proper desiccant type and filling method, minimizing spacer joints, and controlling the production environment. Production steps and specifications for IGU properties are defined.