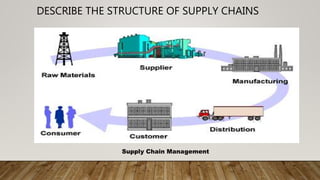

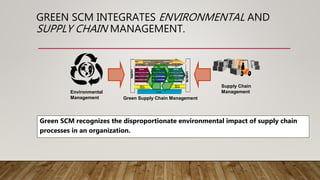

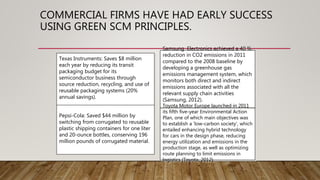

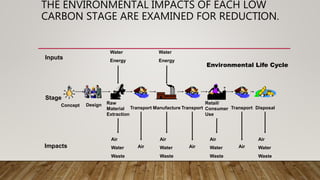

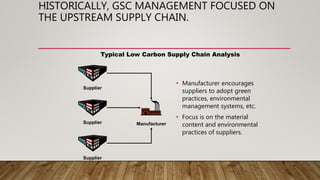

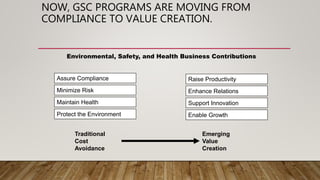

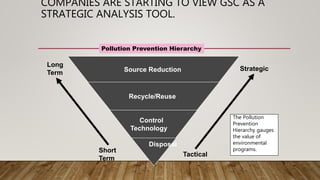

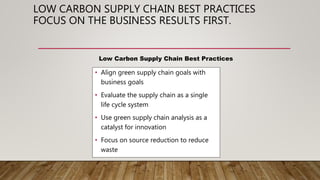

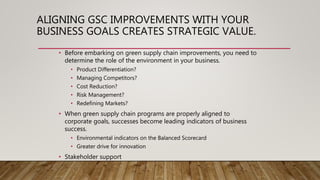

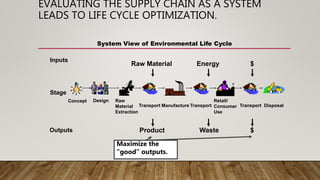

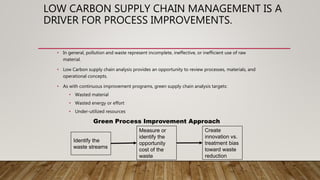

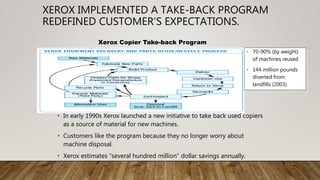

The document presents a low carbon supply chain management project submitted to the Department of Mechanical Engineering at Raj Kumar Goel Institute of Technology, Ghaziabad. It discusses the importance of adopting low carbon practices in supply chain management to improve sustainability and reduce environmental impact. It describes key principles of low carbon supply chain management including examining the environmental impacts at each stage of the product lifecycle and evaluating the supply chain as a single system. The document also outlines best practices such as aligning green goals with business objectives, focusing on waste reduction, and using environmental analysis to drive innovation.