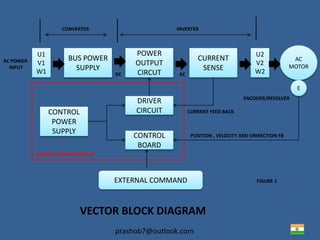

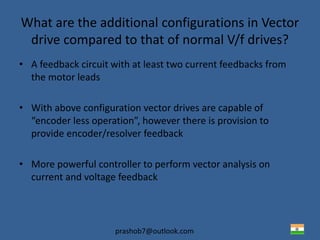

The document discusses the basics of vector control in AC drives, specifically focusing on Variable Frequency Drives (VFDs) used for AC motor speed control. It details the hardware components, control schemes such as v/f control and vector control, and highlights the advantages of vector control including precise speed control and 100% torque delivery. Additionally, it covers features like auto-tuning and the architectural differences between vector drives and standard v/f drives.

![prashob7@outlook.com

Advantages of Vector Control

• Vector control can deliver 100% torque form 0 to rated

speed

• Speed control is more precise than that of V/F

• Since closed loop control is excellent, vector control can

be implemented were PID loops or set point is

continuously coming from a process feed back or other

systems

• This control is suitable for applications involving

1. Torque control

2. Basic position control[advance control require servo drives]

3. Electronic gearing , pulse following

4. Tension control with dance adjustment etc](https://image.slidesharecdn.com/vectorcontrolinacdrives-130611071305-phpapp01/85/Vector-speed-control-8-320.jpg)