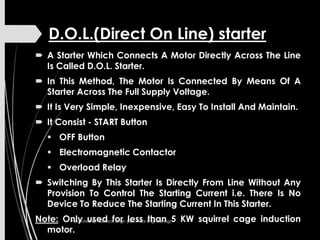

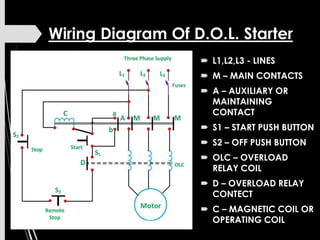

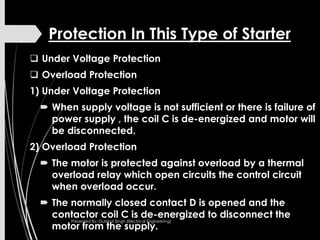

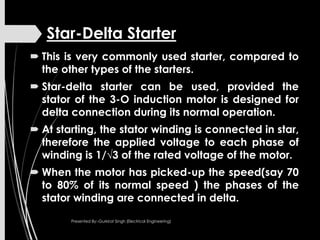

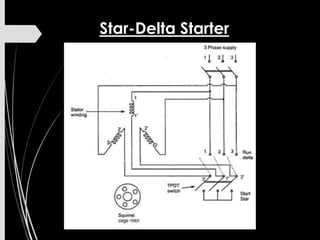

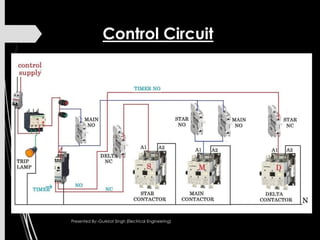

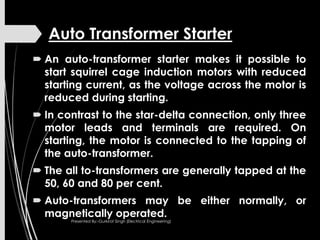

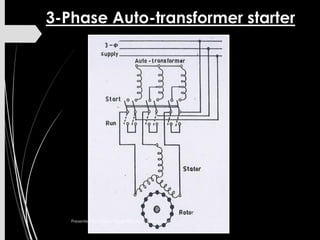

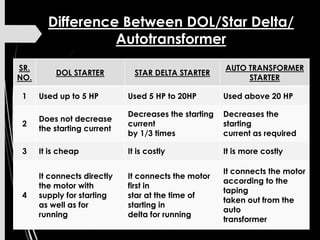

The document discusses various methods for starting 3-phase induction motors, including types of starters such as D.O.L., star-delta, and auto-transformer starters. It highlights the significance of managing starting currents and torque to avoid mechanical and electrical issues during motor start-up, which can lead to extensive wear and unscheduled shutdowns. Each starter type is presented with its advantages, disadvantages, and applications, providing essential information for electrical engineering purposes.